Bridge suspender damage and wire breakage detection device based on magnetostriction method

A magnetostrictive and detection device technology, applied in the direction of material magnetic variable, can solve the problem that the sleeve-type induction coil is difficult to meet the actual needs, and achieve the effect of simple assembly, simple and convenient operation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

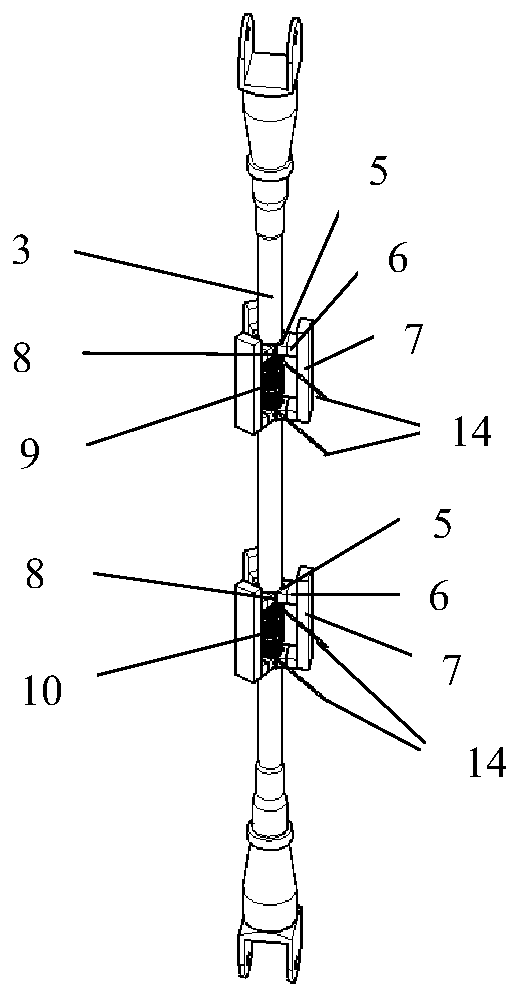

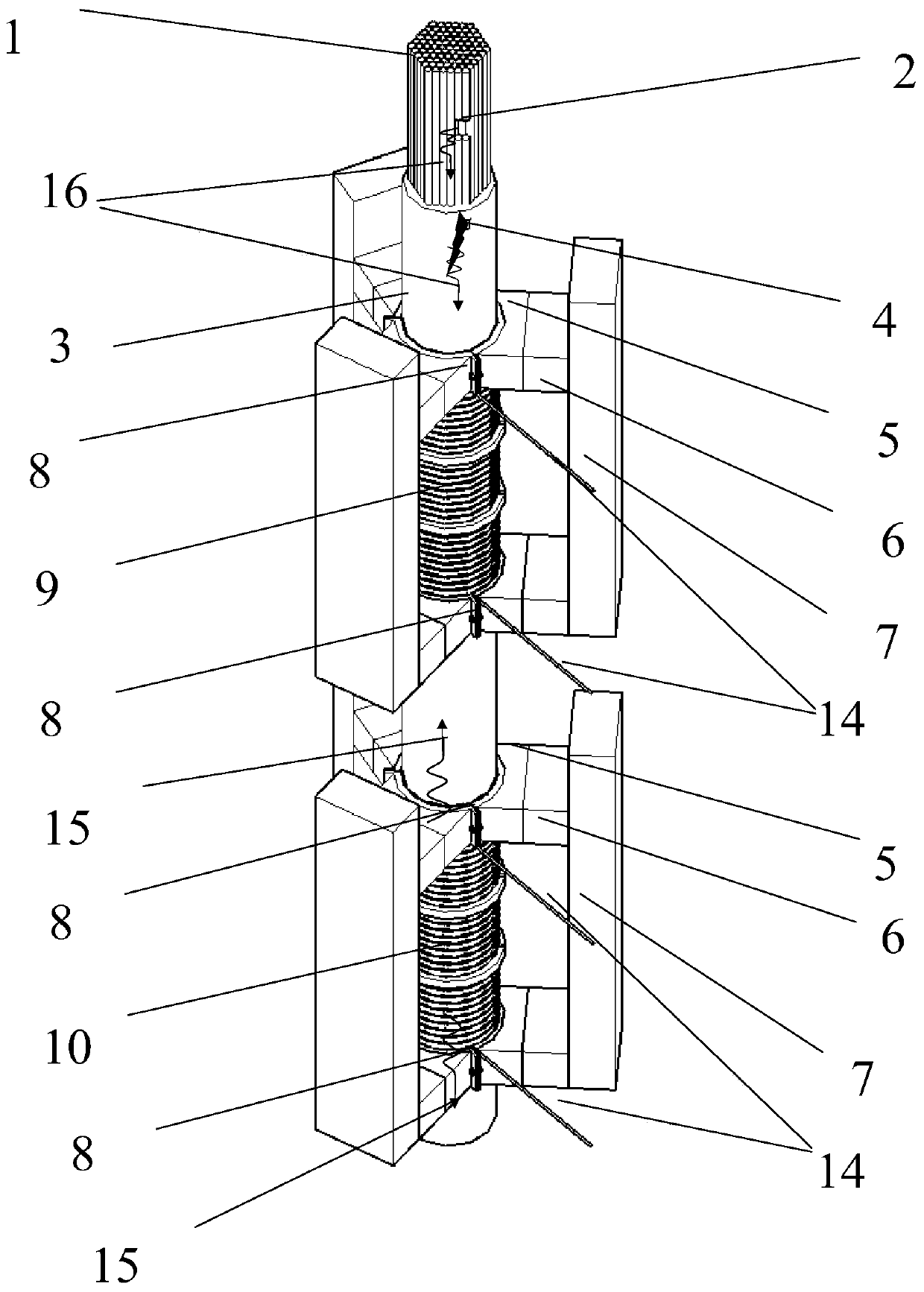

[0031] Such as Figure 1-Figure 4 As shown, the bridge suspender damage and broken wire detection device based on the magnetostrictive method of the present invention includes:

[0032] The coil assembly mechanism includes more than two arc-shaped bases, and all the arc-shaped bases are enclosed to form a fixed base structure outside the suspender.

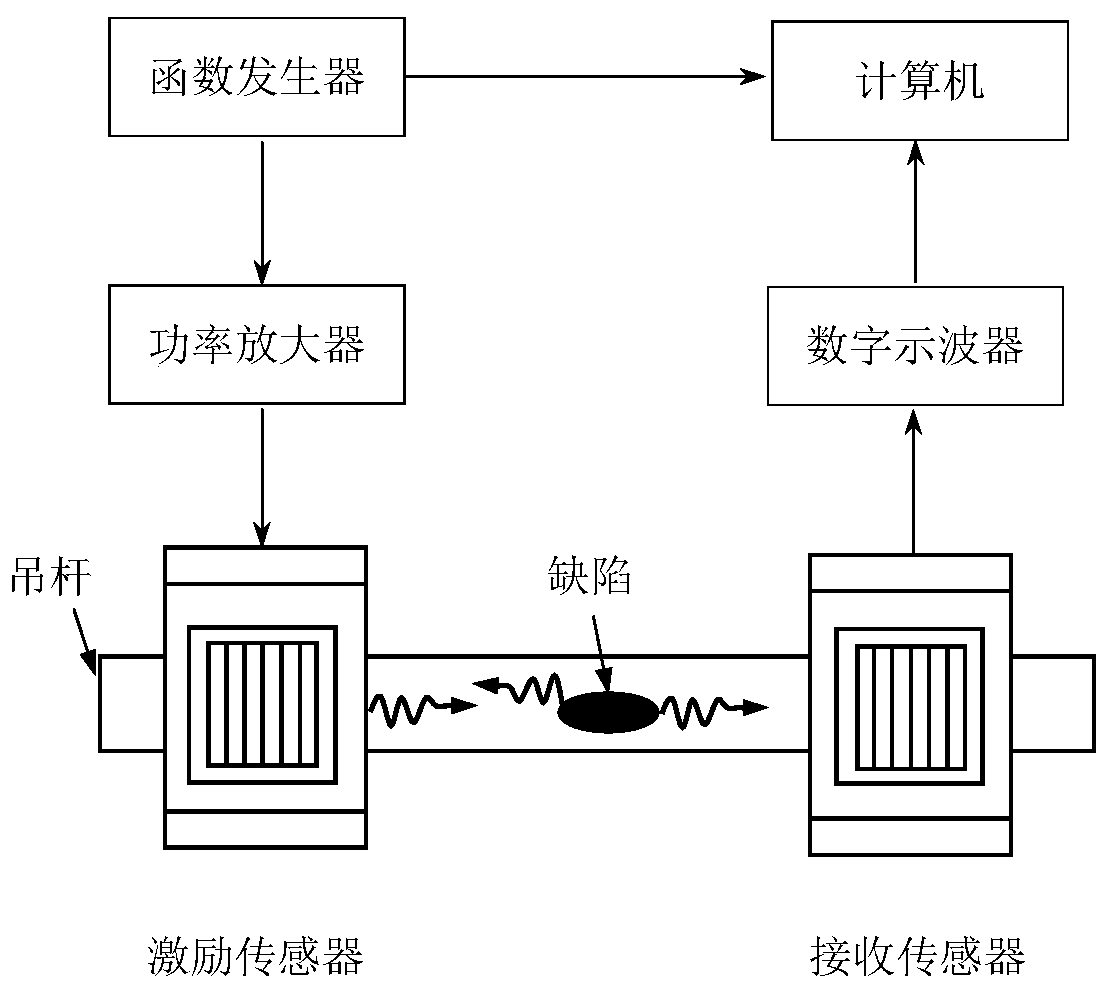

[0033] The coil unit includes an excitation coil 9 and a receiving coil 10, and the excitation coil 9 and the receiving coil 10 are wound on the outside of the base structure; when the excitation coil 9 is fed with alternating current, an alternating magnetic field can be formed inside the boom, and the magnetic domains are subjected to The action of the alternating magnetic field deflects back and forth, resulting in a change in the appearance size of the material, generating magnetostr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com