Lithium iron phosphate battery floating charge optimization method

A technology of lithium iron phosphate battery and optimization method, which is applied in the direction of lithium storage battery, secondary battery charging/discharging, secondary battery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

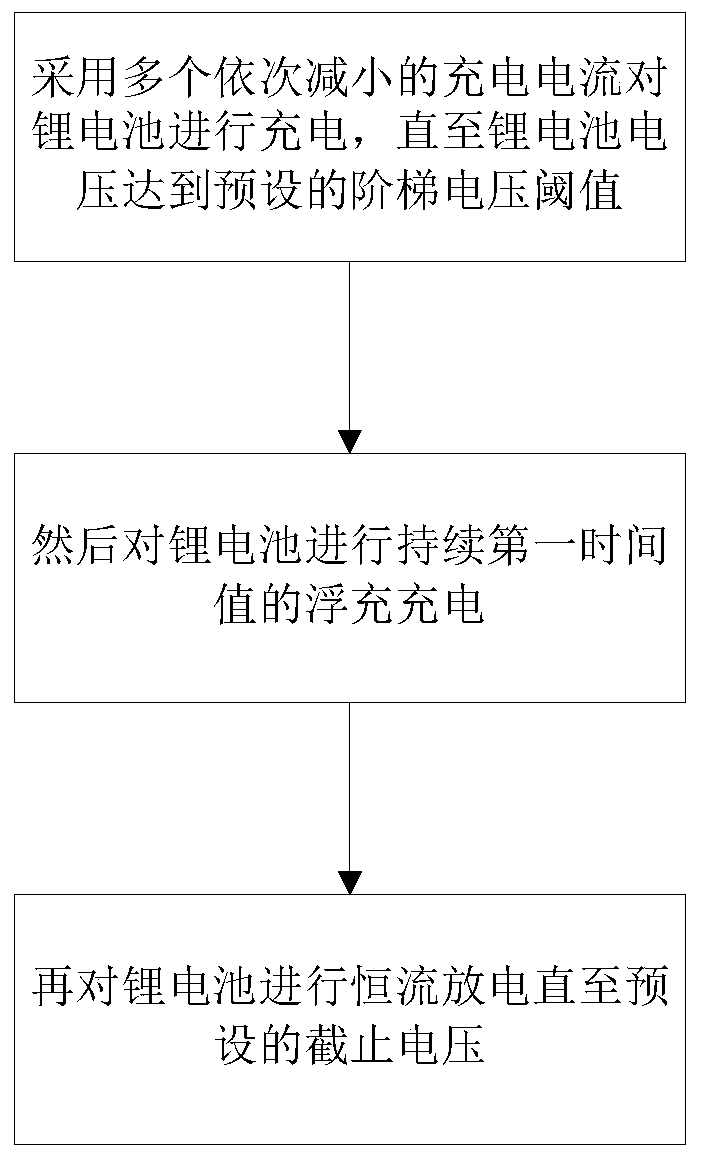

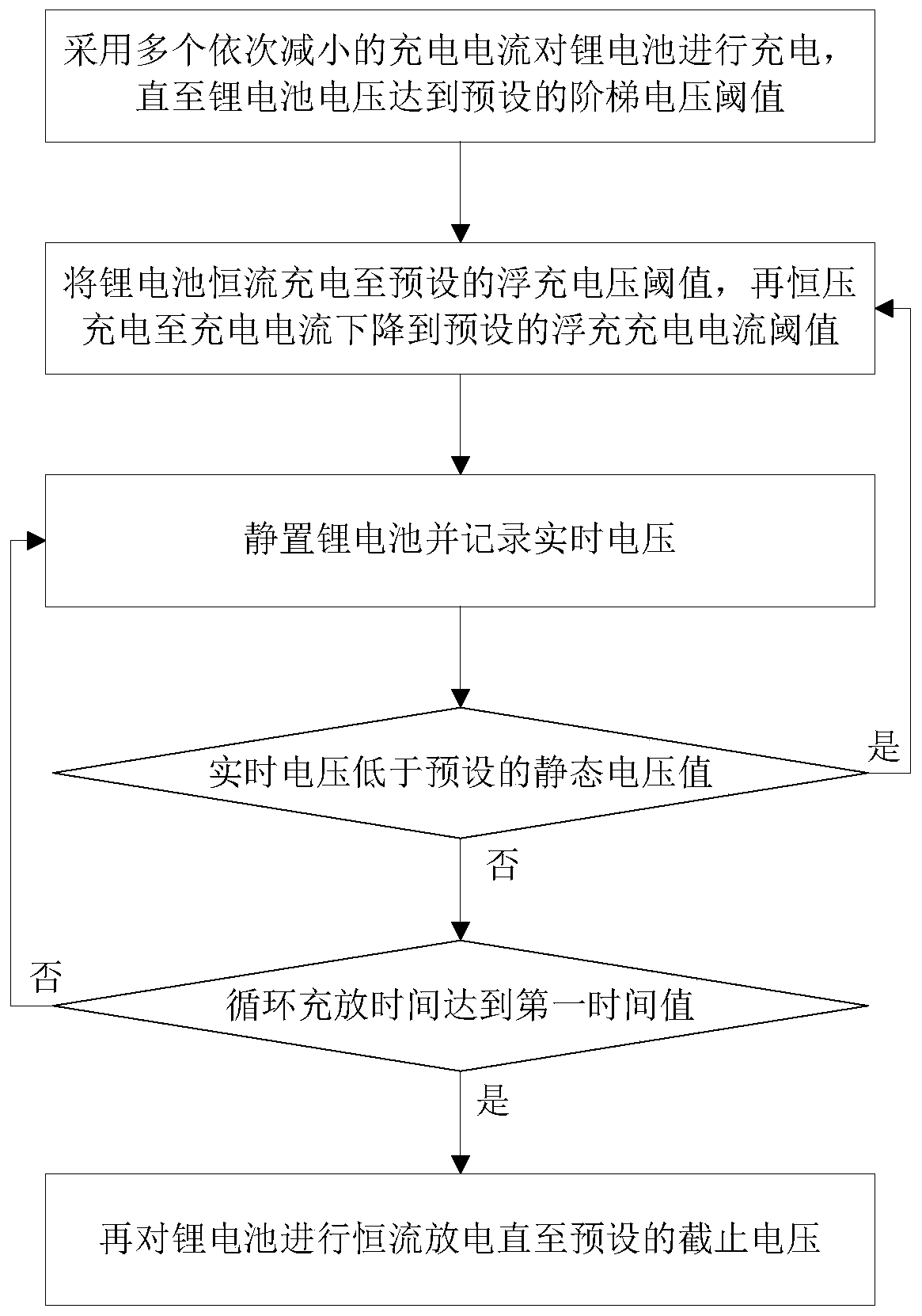

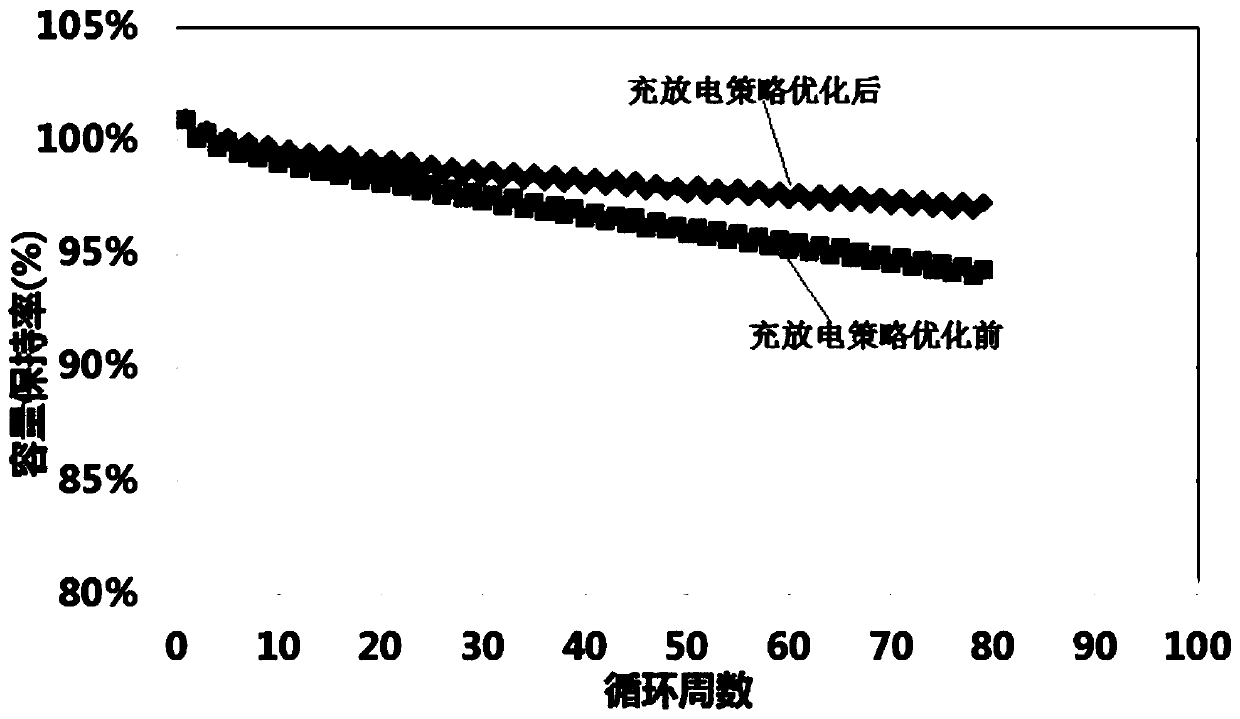

[0021] refer to figure 1 , a floating charge optimization method for a lithium iron phosphate battery proposed by the present invention adopts a three-stage charging and discharging method of "step charge-float charge-constant current discharge" during the float charge cycle process of a lithium iron phosphate battery. After the cycle, a deep discharge and a constant current and constant voltage charge are performed.

[0022] The method for optimizing the float charge of a lithium iron phosphate battery includes the following steps.

[0023] S1. The lithium battery is charged with a plurality of sequentially decreasing charging currents until the voltage of the lithium battery reaches a preset step voltage threshold.

[0024] Specifically, in this step, the first current value is used to charge the lithium battery with a constant current to the first voltage value V 1 , and then use the second current value to charge the lithium battery with a constant current to the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap