Processing technology of green tea

A processing technology, green tea technology, applied in the field of green tea processing technology, can solve problems such as unsuitable for drinking, and achieve the effect of improving the cooling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

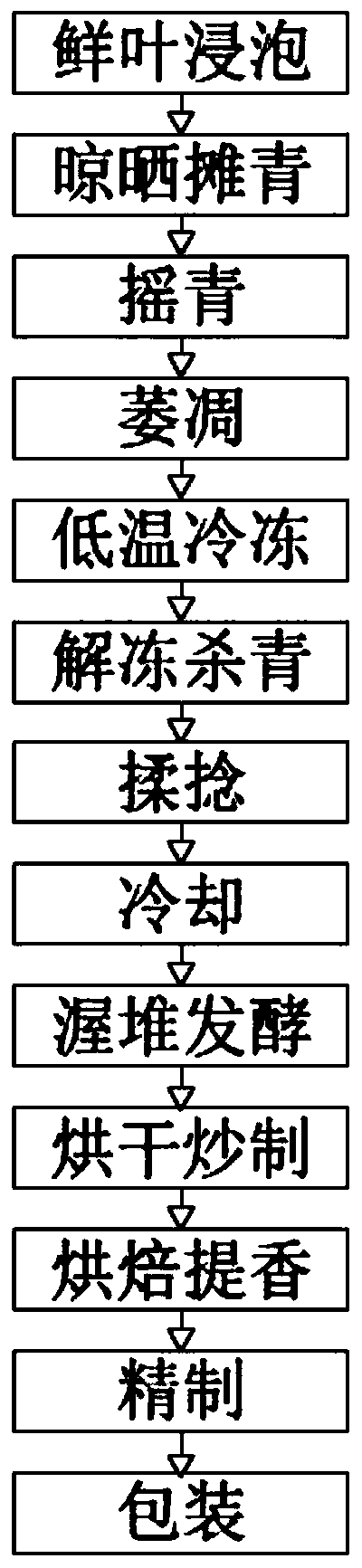

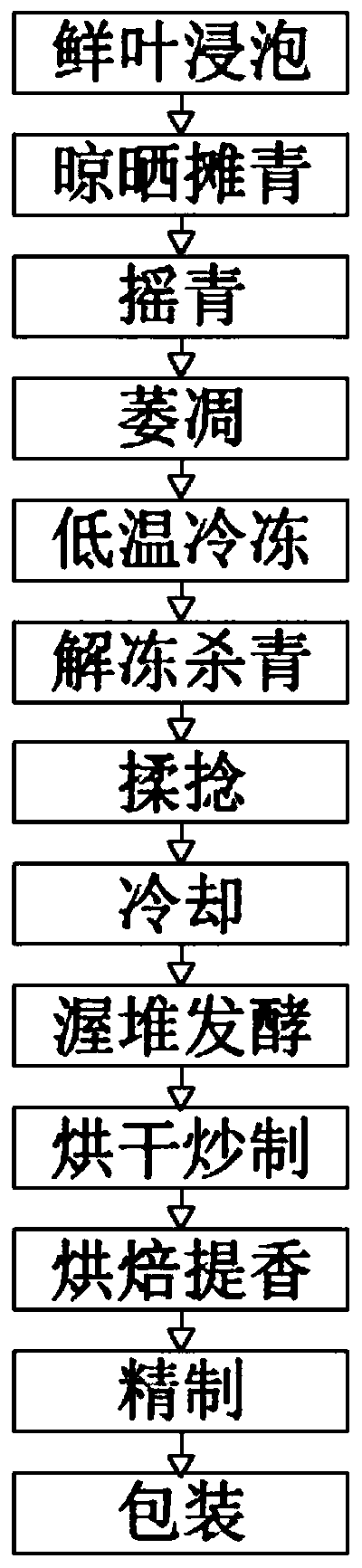

Image

Examples

Embodiment 1

[0032] S1 Soaking of fresh leaves: picking fresh tea leaves with one bud and two leaves or one bud and three leaves, and then soaking in warm water at 37°C for 4 hours;

[0033] S2 drying green leaves in the air: pull out the soaked fresh leaves of tea trees, spread them to a thickness of 3 cm in an environment with a temperature of 20° C. and a relative humidity of 50%, so that the water content of the fresh leaves of tea trees is 70%, and make green leaves;

[0034] S3 shaking green: Shake green leaves 6 times within 8 hours, and let stand for 15 minutes after shaking each time, until the veins are transparent, the leaf color is yellow-green, and the green gas disappears, and the leaf margins roll outwards to form a turtle-back shape, and the leaf quality Soft, with a rustling sound when flipped, and shake green leaves;

[0035] S4 Withering: Spread the shake green leaves in an environment with a temperature of 20° C. and a relative humidity of 60% to a thickness of 5 cm unt...

Embodiment 2

[0046] S1 Soaking of fresh leaves: pick fresh tea leaves with one bud and two leaves or one bud and three leaves, and soak in warm water at 40°C for 5 hours;

[0047] S2 drying green leaves in the air: pull out the soaked fresh leaves of tea trees, spread them to a thickness of 4 cm in an environment with a temperature of 22° C. and a relative humidity of 55%, so that the water content of the fresh leaves of tea trees is 72%, and make green leaves;

[0048] S3 shaking green: Shake green leaves 7 times within 10 hours, and let stand for 20 minutes after each shaking, until the veins are transparent, the leaf color is yellow-green, and the green gas disappears. Soft, with a rustling sound when flipped, and shake green leaves;

[0049] S4 Withering: spread the shake green leaves in an environment with a temperature of 22°C and a relative humidity of 65% to a thickness of 6 cm until the shake green leaves reveal a clear fragrance to obtain withered leaves, and turn the shake green...

Embodiment 3

[0060] S1 Soaking of fresh leaves: pick fresh tea leaves with one bud and two leaves or one bud and three leaves, and soak in warm water at 42°C for 6 hours;

[0061] S2 drying green leaves in the air: pull out the soaked fresh leaves of tea trees, spread them to a thickness of 5 cm in an environment with a temperature of 24° C. and a relative humidity of 60%, so that the water content of the fresh leaves of tea trees is 74%, and make green leaves;

[0062] S3 shake green: Shake green leaves 8 times within 12 hours, and let stand for 30 minutes after shaking each time, until the veins are transparent, the leaf color is yellow-green, and the green gas disappears, and the leaf margins roll outwards in a turtle-back shape, and the leaf quality Soft, with a rustling sound when flipped, and shake green leaves;

[0063] S4 Withering: spread the shake green leaves in an environment with a temperature of 24°C and a relative humidity of 70% to a thickness of 7 cm until the shake green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com