Aerosol cooling element, application thereof and filter rod capable of being used for heating cigarette

A cooling element and aerosol technology, applied in the field of tobacco, can solve problems such as safety to be verified, and achieve the effects of improving the sense of satisfaction, strong resistance to thermal deformation at high temperature, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

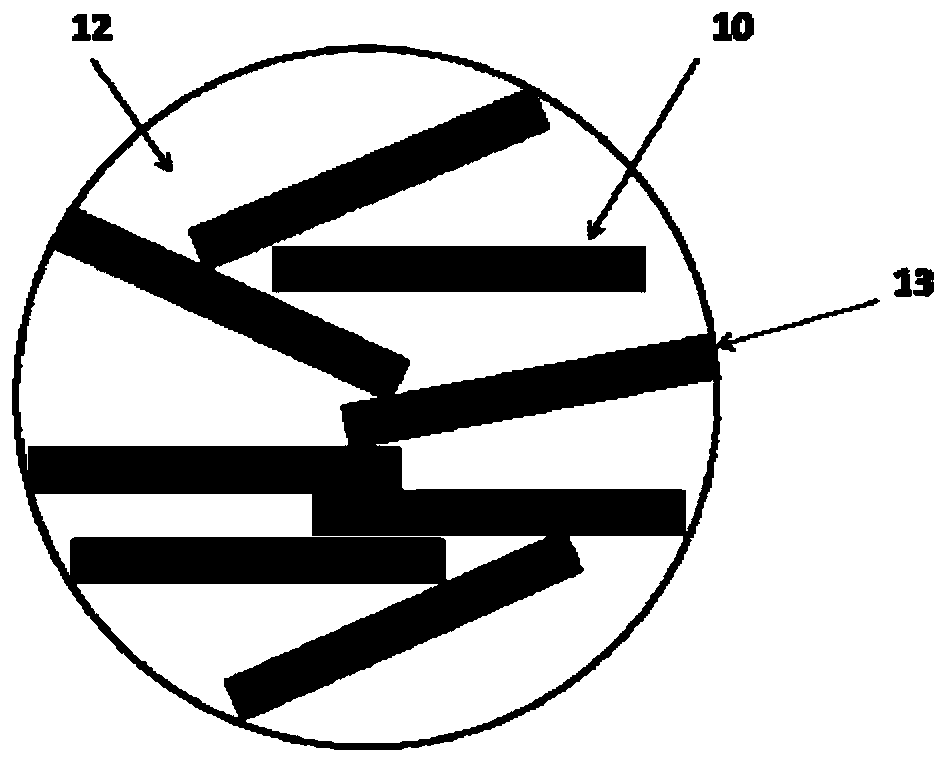

[0056] figure 1 It is a schematic cross-sectional view of the aerosol cooling element 2 of the present invention.

[0057]As mentioned above, the aerosol cooling element 12 of the present invention is composed of several cellulose acetate sheets 10 that are freely stacked and wrapped with molded paper 13 on the outside, and the cellulose acetate sheets 10 are separated from each other. The cellulose acetate sheets 10 of the present invention are allowed to overlap at a certain inclination angle; the aerosol cooling element 12 can be formed by free stacking of cellulose acetate sheets 10 with different lengths, widths and thicknesses, as long as the size It is sufficient to be within the aforementioned numerical range.

[0058] Further, the length of the cellulose acetate sheet: width=(1-10):1, in an optional embodiment, may be a 4mm*18mm sheet, or a 4mm*4mm sheet, or other sizes. For example, in a cylindrical cavity with a diameter of 7mm and a length of 18mm, sheets of diff...

Embodiment 2

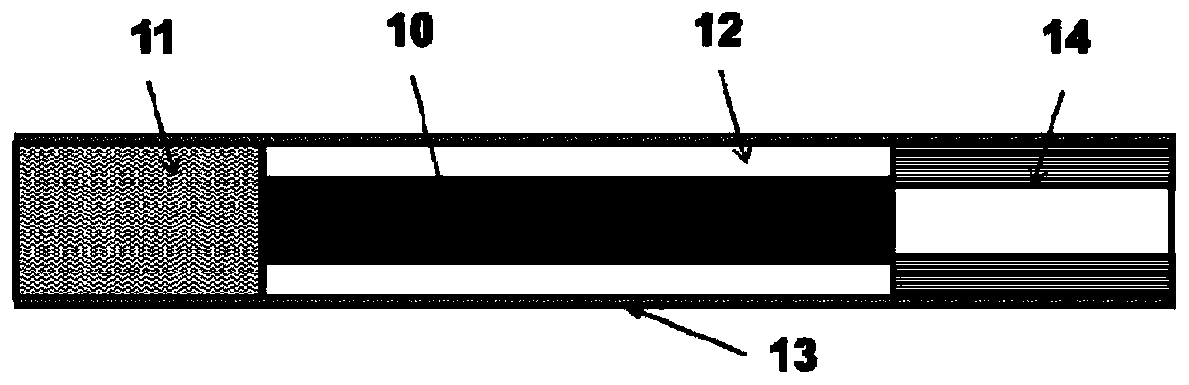

[0083] Figure 4 The axial schematic diagram of the mouth stick embodiment 2 made for the aerosol cooling element shown in embodiment sample 8 and sample 9, as Figure 4 As shown, the cellulose acetate nozzle stick includes a cellulose acetate mouthpiece 11, an aerosol cooling element 12, a molding paper 13, and a hollow cellulose acetate tube 14; the cellulose acetate mouthpiece 11, the cooling section 12, the The hollow cellulose acetate tubes 14 are connected in sequence to obtain the mouthpiece of the present invention, and a heated cigarette product can be obtained by combining the front end of the hollow cellulose acetate mouthpiece 14 with a 13mm tobacco segment.

[0084] The diameter of the composite nozzle rod is 7.2 mm, the inner diameter of the hollow acetate tube 14 is 3.0 mm, and the length is 7 mm; the cellulose acetate mouthpiece 11 is single denier 20 / total denier 27000, and the suction resistance is 9.1 Pa / mm of cellulose acetate tow tip, 8mm long.

[0085]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com