Cigarette filter stick added with water-containing material and cigarette

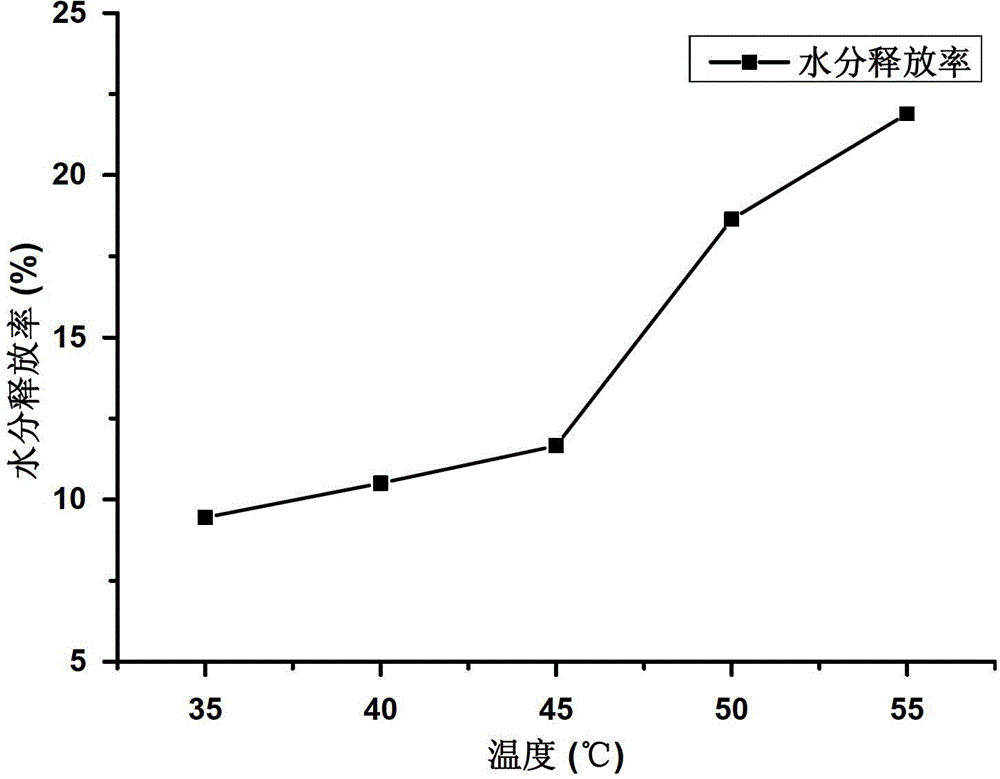

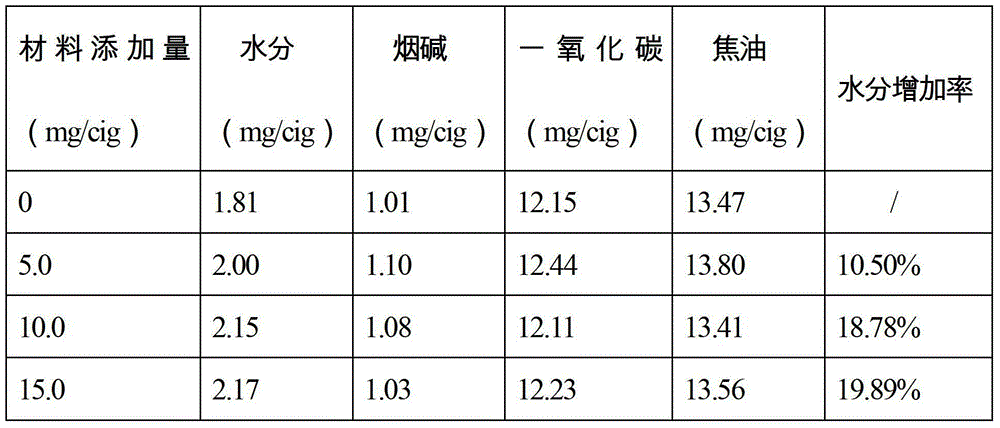

A cigarette filter rod and filter rod technology, which is applied in the fields of e-liquid filter elements, tobacco, and cigar manufacturing, etc., can solve the problems of mildew in shredded tobacco and restrictions on the moisture content of shredded tobacco, and achieve improved smoking quality and reduced smoke irritation , the effect of increasing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

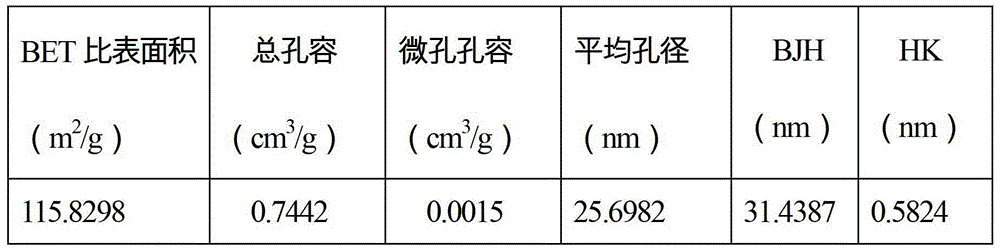

Method used

Image

Examples

Embodiment 1

[0021] Cigarettes in this embodiment include shredded tobacco rods and cigarette filter rods, wherein the cigarette filter rods are cigarette filter rods added with water-containing materials, including filter rod main bodies and water-containing materials added in filter rod main bodies, and the addition of water-containing materials The amount is 5.0 mg / cig, and the water-containing material is a zeolite whose surface is dry and contains water inside.

[0022] Wherein, the preparation process of water-containing material is as follows:

[0023] About 10 g of zeolite was weighed, washed three times with pure water, filtered, and baked at 110° C. for 2 hours to activate the zeolite. After the zeolite was cooled to room temperature, 50ml of pure water was added again, ultrasonicated for 30 minutes, filtered, and dried at 33°C for 10 minutes to obtain a surface-dried aqueous material. Wherein, when drying, the zeolite is flatly spread on the carrier.

Embodiment 2

[0025] Cigarettes in this embodiment include shredded tobacco rods and cigarette filter rods, wherein the cigarette filter rods are cigarette filter rods added with water-containing materials, including filter rod main bodies and water-containing materials added in filter rod main bodies, and the addition of water-containing materials The amount is 6.0 mg / cig, and the water-containing material is a zeolite whose surface is dry and contains water inside.

[0026] Wherein, the preparation process of water-containing material is as follows:

[0027] About 10 g of zeolite was weighed, washed three times with pure water, filtered, and baked at 150° C. for 1.6 hours to activate the zeolite. After the zeolite was cooled to room temperature, 50ml of pure water was added again, ultrasonicated for 35 minutes, filtered, and dried at 30°C for 15 minutes to obtain a surface-dried aqueous material. Wherein, when drying, the zeolite is flatly spread on the carrier.

Embodiment 3

[0029] Cigarettes in this embodiment include shredded tobacco rods and cigarette filter rods, wherein the cigarette filter rods are cigarette filter rods added with water-containing materials, including filter rod main bodies and water-containing materials added in filter rod main bodies, and the addition of water-containing materials The amount is 7.0 mg / cig, and the water-containing material is a zeolite whose surface is dry and contains water inside.

[0030] Wherein, the preparation process of water-containing material is as follows:

[0031] About 10 g of zeolite was weighed, washed three times with pure water, filtered, and baked at 180° C. for 1.5 hours to activate the zeolite. After the zeolite was cooled to room temperature, 50ml of pure water was added again, ultrasonicated for 25 minutes, filtered, and dried at 35°C for 10 minutes to obtain a surface-dried aqueous material. Wherein, when drying, the zeolite is flatly spread on the carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com