Carbohydrate humectant, application and method for improving moist feeling of tobacco

A humectant, tobacco technology, applied to a new sugar humectant ingredient, applied and improved in the field of tobacco moisturizing, to achieve the effect of improving sweetness and sweetness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

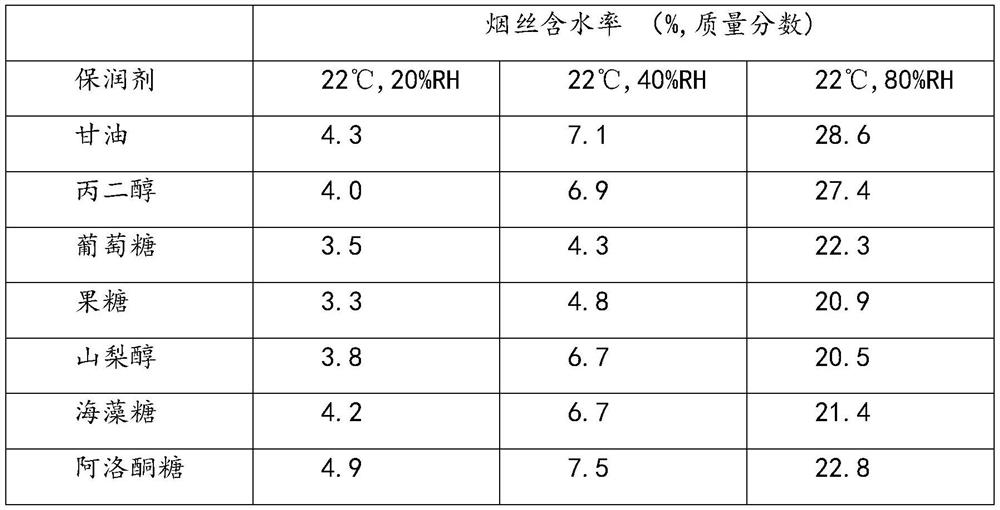

[0024] Example 1: Physical Moisture Retention

[0025] Weigh 10g of allulose, dissolve it in water, and evenly spray it on 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. The shredded tobacco is placed in a constant temperature and humidity box to balance moisture, so that the shredded tobacco has a moisture content of 11.5-13.5%. Simultaneously weigh glycerin, propylene glycol, glucose, fructose, sorbitol, trehalose, erythrose of the same quality respectively, in the same way, after dissolving with water, evenly spray on 1000g shredded tobacco, the consumption of humectant is the quality of tobacco leaf 0.5%. Put the shredded tobacco in a constant temperature and humidity box to balance the moisture, so that the moisture content of the cut tobacco is between 11.5-13.5%, and then put it in a constant temperature and humidity box under specific temperature and humidity conditions to balance for 2 days, and test its moisture content. The ...

Embodiment 2

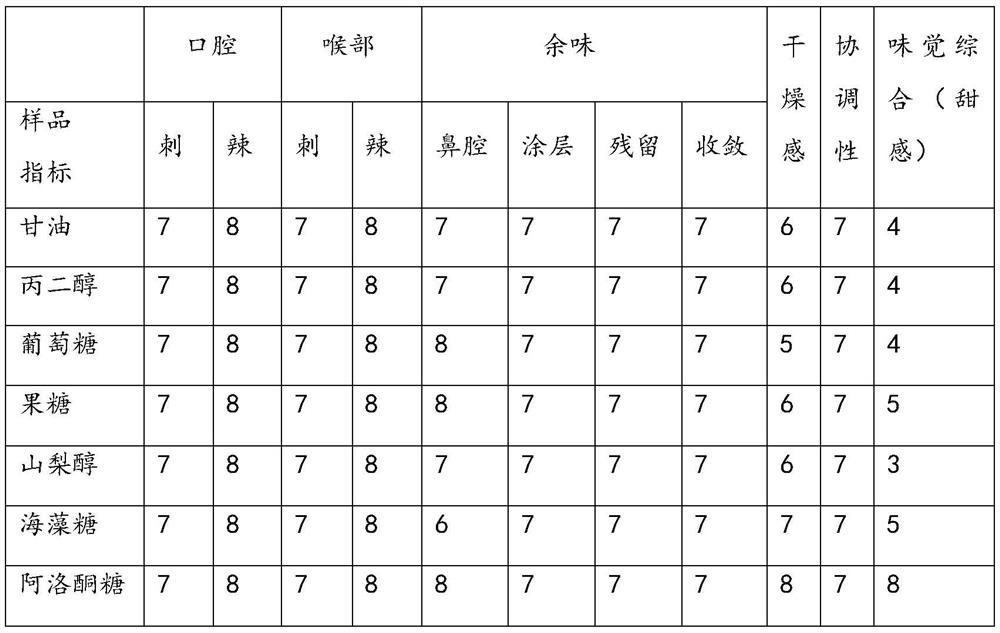

[0028] Example 2: Sensory moisturizing properties

[0029] According to the addition amount of 0.8%, different humectants were evenly sprayed on the shredded tobacco, and then placed in a constant temperature and humidity box with RH60% and 22°C for 48 hours, and then sensory evaluation was carried out. Sensory evaluation The evaluation indicators are designed according to the cigarette sensory quality evaluation method (refer to the technical requirements of YC / T496 cigarette sensory comfort evaluation requirements), and the evaluation indicators are the evaluation results of irritation, aftertaste, dryness, coordination, and comprehensive taste (sweetness) See Table 2.

[0030] In the table, the scores for each indicator range from 0 to 9 points, and the minimum score for a single item is 0.5 points. The irritation is divided into three grades: large, medium, and small, corresponding to 1-3 points, 4-6 points, and 7-9 points respectively. The stronger the irritation, the lo...

Embodiment 3

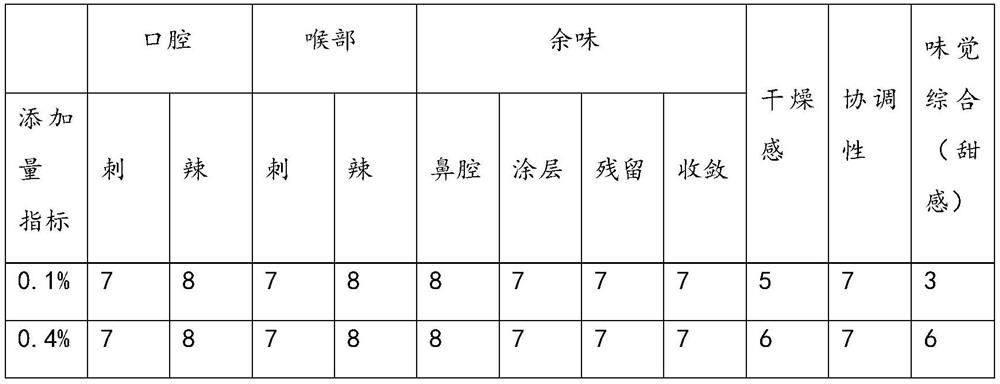

[0034] Embodiment 3: the addition amount of allulose

[0035] Weigh 200g of each shredded tobacco, add allulose according to the mass percentage of 0.1%, 0.4%, 0.7%, 1%, 1.3%, 1.5% and 2.0%, and roll the shredded tobacco into a single cigarette with a weight of 0.9-0.95g RH60%, in a constant temperature and humidity box at 22°C for 48 hours, and then evaluate the sensory tube. The evaluation method is the same as in Example 2, and the evaluation results are shown in Table 3. The results indicated that the added amount of allulose should be higher than 0.4%.

[0036] Table 3: Sensory evaluation of different humectants

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com