Preparation method of tomato extract and application of tomato extract in cigarette production

A technology of tomato extract and tomato, applied in the field of cigarette additives, can solve the problems such as the inability to apply the tomato extract for cigarettes well, the single component of the tomato extract, and the inability to meet the needs of consumers, etc., so as to improve the comfort of cigarettes, improve the The effect of fragrance and improvement of smoke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

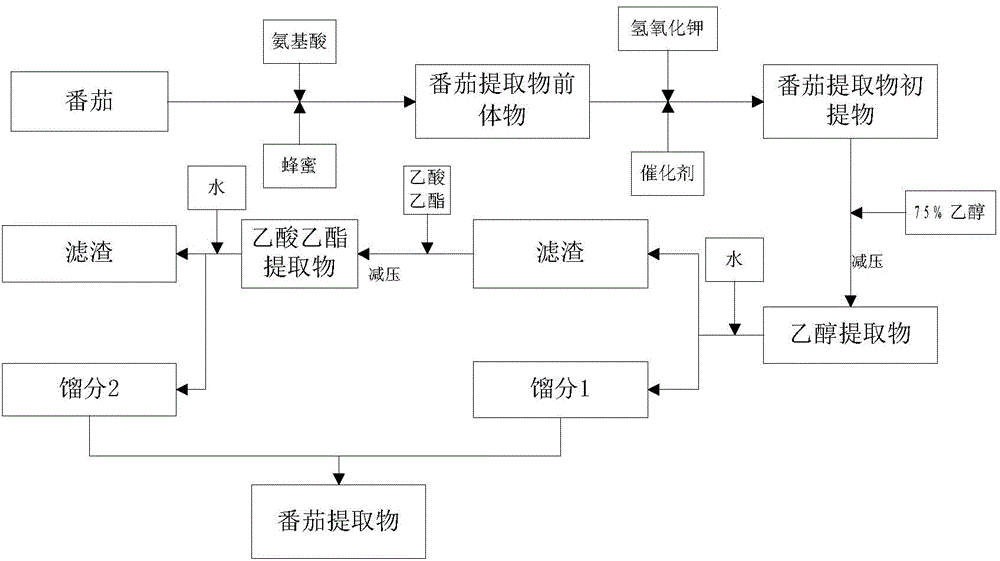

Method used

Image

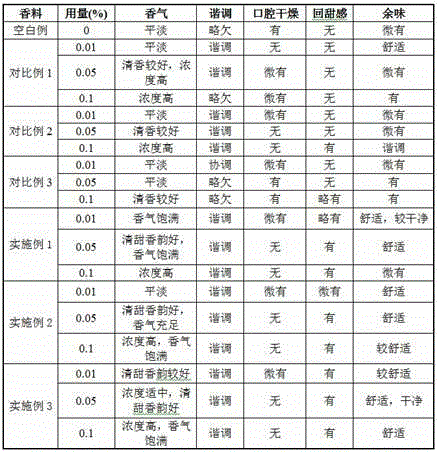

Examples

Embodiment 1

[0028] (1) Cut the fresh tomato into pieces, wash, stir and extract the juice, then add 4% of the tomato weight of honey with a viscosity of 4000cP and 0.1% of the tomato weight of proline, stir well, and react at 50°C for 6 hours to obtain tomato extract precursors;

[0029] (2) Add potassium hydroxide of 1% by weight of tomato and FeCl of 0.01% by weight of tomato to the tomato extract precursor obtained in step (1) 3 , heated to 100°C and reacted for 1 hour to obtain the initial tomato extract;

[0030] (3) Add 3 times the weight of 75% ethanol of tomato extract to the primary tomato extract obtained in step (2), extract for 0.5h, filter the extract, and concentrate the filtrate under reduced pressure to remove ethanol. Obtain the ethanol concentrate, then add deionized water to the ethanol concentrate according to the feed ratio g / mL as 1:1, carry out distillation and collect fractions, stop collecting until 30% of the weight of the ethanol concentrate is obtained, and ob...

Embodiment 2

[0035] (1) Cut the fresh tomato into pieces, wash, stir and extract the juice, then add honey with a viscosity of 3500cP of 8% by weight of the tomato and phenylalanine of 0.2% by weight of the tomato, stir evenly, and react at 70°C for 12 hours to obtain tomato extract precursors;

[0036] (2) Add potassium hydroxide of 3% by weight of tomato and catalyst CuCl of 0.01% by weight of tomato to the tomato extract precursor obtained in step (1) 2 , heated to 120°C for 3 hours to obtain the initial tomato extract;

[0037] (3) Add 5 times the weight of 75% ethanol of tomato extract to the primary tomato extract obtained in step (2), extract for 2 hours, filter the extract, and concentrate the filtrate under reduced pressure to remove ethanol to obtain Ethanol concentrate, and then add deionized water to the ethanol concentrate according to the feed ratio g / mL as 1:3, carry out distillation and collect fractions, stop collecting until 45% of the weight of the ethanol concentrate i...

Embodiment 3

[0042] (1) Cut the fresh tomato into pieces, wash, stir and extract the juice, then add 6% of the tomato weight of honey with a viscosity of 3000cP and 0.4% of the tomato weight of leucine, stir well, and react at 60°C for 8 hours to obtain tomato extract precursors;

[0043] (2) Add potassium hydroxide of 2% by weight of tomato and catalyst CuCl of 0.01% by weight of tomato to the tomato extract precursor obtained in step (1) 2 , heated to 110°C for 2 hours to obtain the initial tomato extract;

[0044] (3) Adding 4 times the weight of 75% ethanol of tomato extract to the initial tomato extract obtained in step (2), extracting for 1 hour, filtering the extract, and concentrating the filtrate under reduced pressure to remove ethanol to obtain Ethanol concentrate, then add deionized water to the ethanol concentrate according to the feed ratio g / mL as 1:2, carry out distillation and collect fractions, stop collecting until 40% of the weight of the ethanol concentrate is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com