Electronic atomization device, atomization assembly thereof and manufacturing method of atomization assembly

A technology for atomizing components and manufacturing methods, applied to tobacco and other directions, can solve the problems of poor wettability, low utilization rate, easy deformation, etc., and achieve the effects of fast heating speed, long service life and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

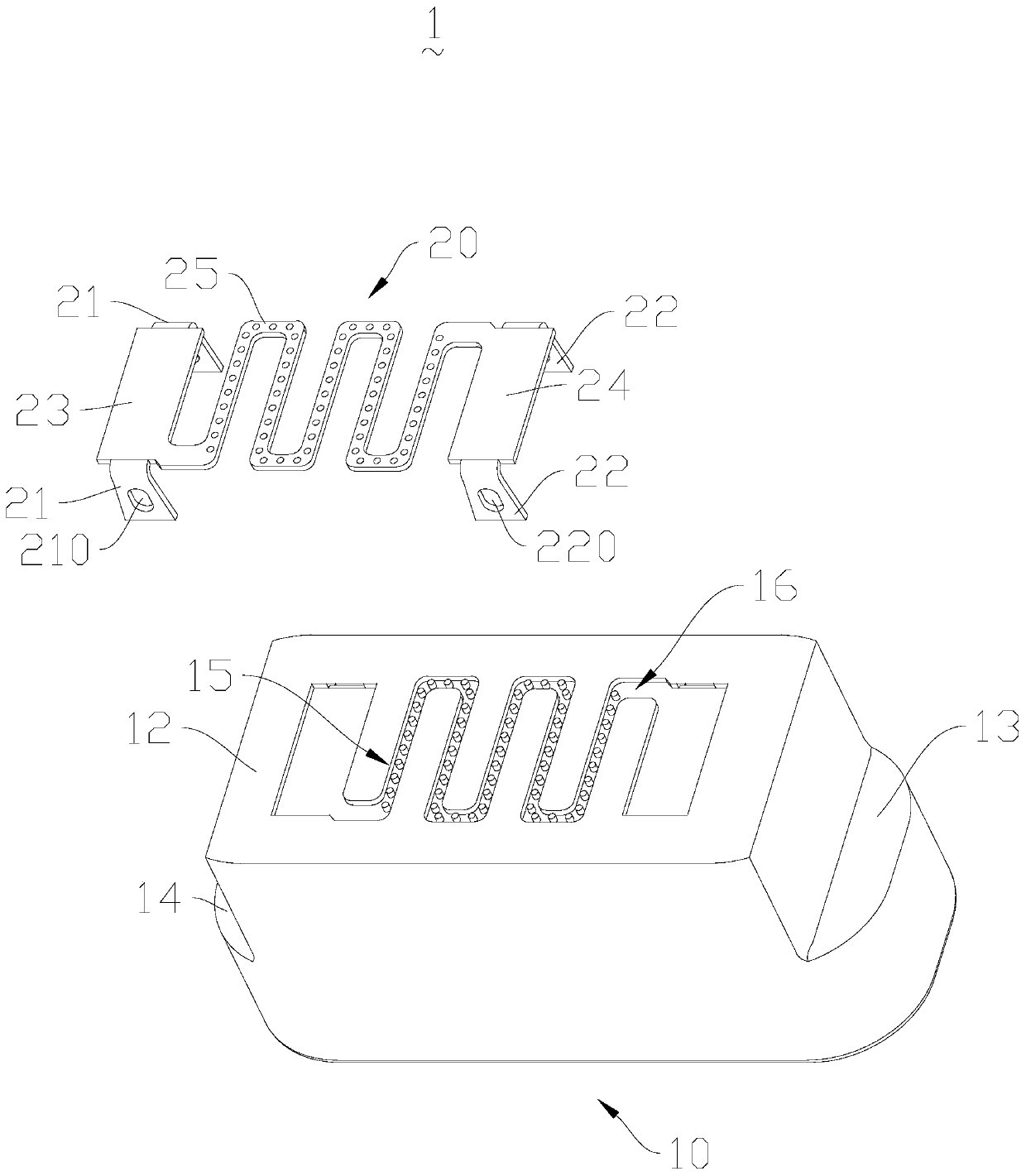

[0038] The specific structure, preparation method and implementation effect of the present invention will be further described in detail and clearly and completely described below in conjunction with this embodiment and the accompanying drawings. Referring now to the drawings, wherein like reference numerals indicate like structural elements or drawing features of the present invention.

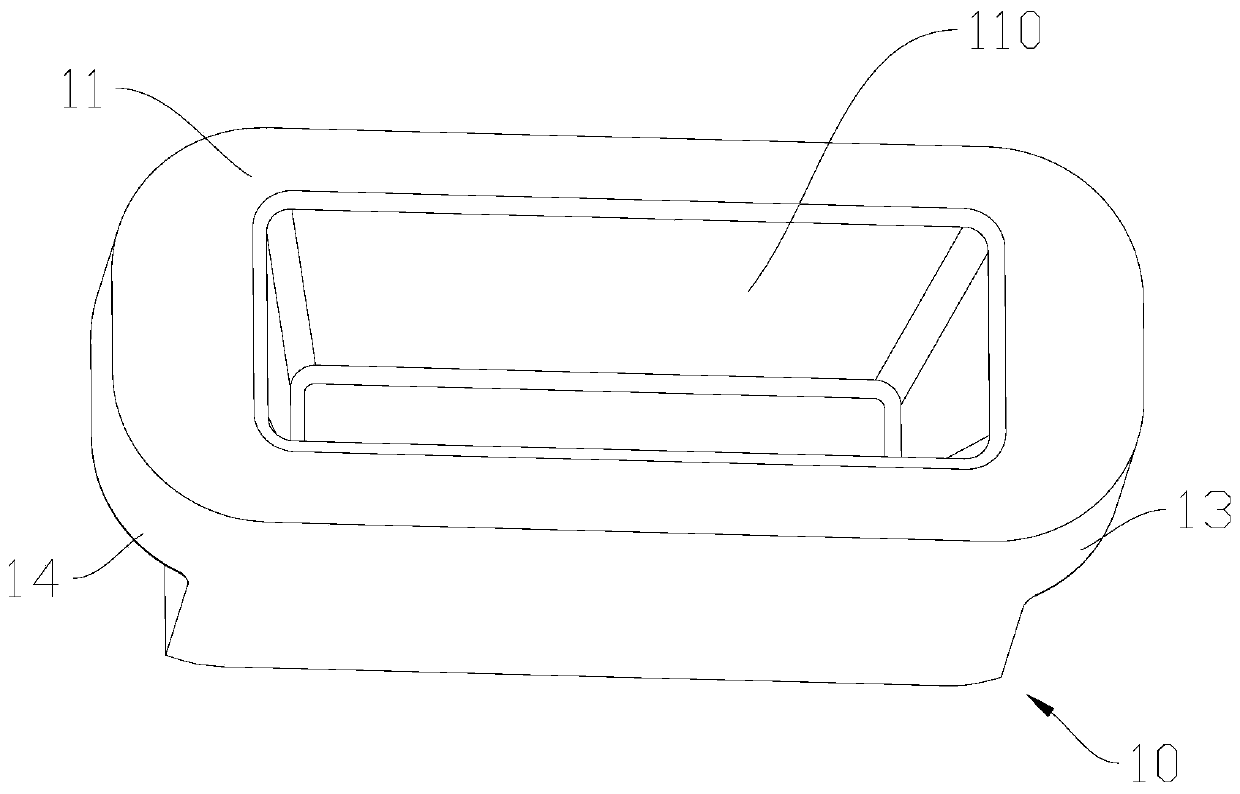

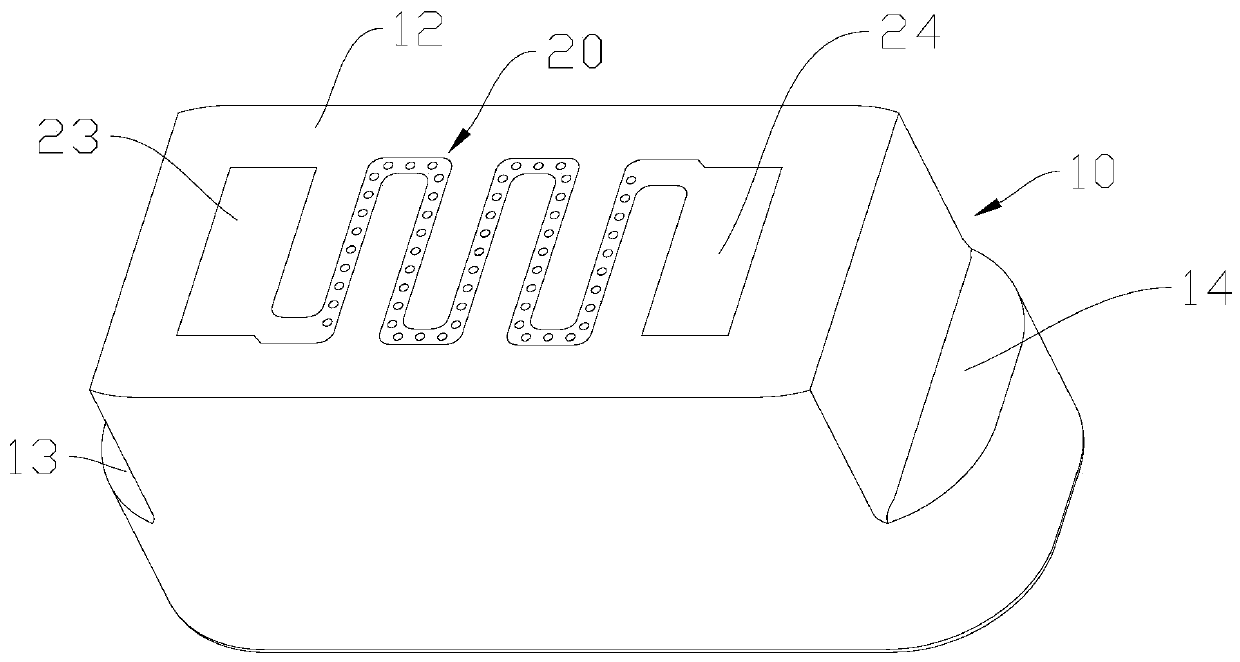

[0039] Figure 1 to Figure 3 The atomization assembly 1 in some embodiments of the present invention is shown, and the atomization assembly 1 can be used in some atomization equipment to heat liquid media such as atomization liquid or atomization oil. The electronic atomization device 1 may include a porous ceramic substrate 10 and a heating element 20. The porous ceramic matrix 10 is used for absorbing and transporting liquid media. The heating element 20 is installed on the porous ceramic base 10 for heating and atomizing the liquid medium absorbed by the porous ceramic base 10 . In some...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap