Husking and sieving robot for sesamum indicum production use as well as husking and sieving method thereof

A robot and screening technology, applied in chemical instruments and methods, grain shelling, sieving, etc., can solve the problems of artificial arm soreness, difficult to clean, general use effect, etc., to speed up screening and blanking efficiency, installation and unloading Convenient and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

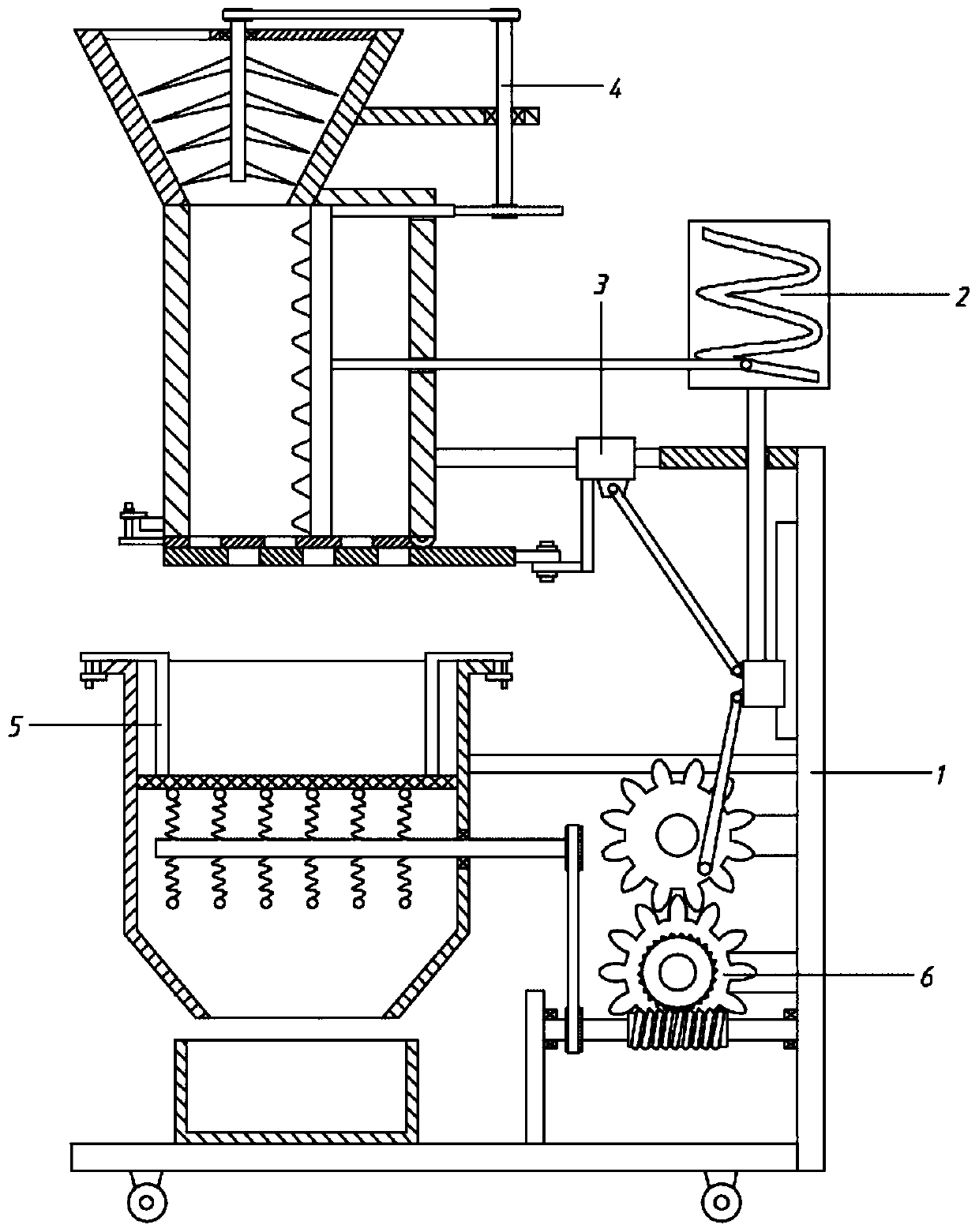

[0065] A shelling and screening robot for sesame production, comprising a skeleton assembly 1, a crushing assembly 2, a blanking assembly 3 and a screening assembly 5;

[0066] The skeleton assembly 1 includes a base 101, a vertical plate 103, a support plate 104, a slide bar 105, a crushing chamber 106, a screening chamber 109 and a receiving box 110; the bottom of the base 101 is equipped with a roller 102, and a vertical Straight vertical plate 103; the top of the vertical plate 103 is connected to a No. 1 support plate 104 to the left, and the left end of the No. 1 support plate 104 is connected to the crushing chamber 106 through a slide bar 105; the crushing chamber 106 is provided with a crushing assembly 2; the crushing chamber 106 A blanking assembly 3 is provided at the bottom; a screening chamber 109 is provided below the crushing chamber 106, and the right side of the screening chamber 109 is connected to the vertical plate through the No. 1 pole 108; the screening ...

Embodiment 2

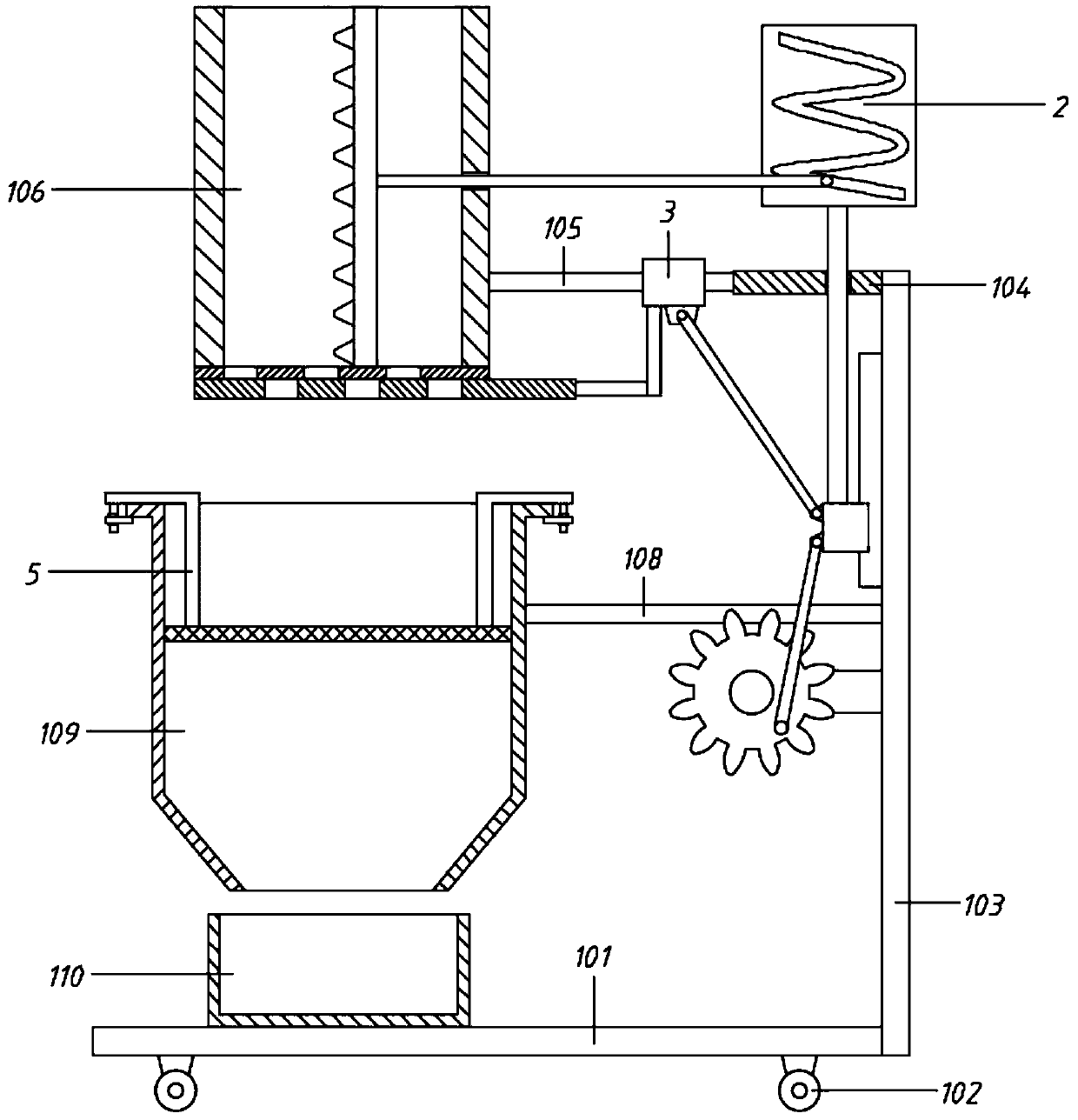

[0068] A shelling and screening robot for sesame production, comprising a skeleton assembly 1, a crushing assembly 2, a blanking assembly 3 and a screening assembly 5;

[0069] The skeleton assembly 1 includes a base 101, a vertical plate 103, a support plate 104, a slide bar 105, a crushing chamber 106, a screening chamber 109 and a receiving box 110; the bottom of the base 101 is equipped with a roller 102, and a vertical Straight vertical plate 103; the top of the vertical plate 103 is connected to a No. 1 support plate 104 to the left, and the left end of the No. 1 support plate 104 is connected to the crushing chamber 106 through a slide bar 105; the crushing chamber 106 is provided with a crushing assembly 2; the crushing chamber 106 A blanking assembly 3 is provided at the bottom; a screening chamber 109 is provided below the crushing chamber 106, and the right side of the screening chamber 109 is connected to the vertical plate through the No. 1 pole 108; the screening ...

Embodiment 3

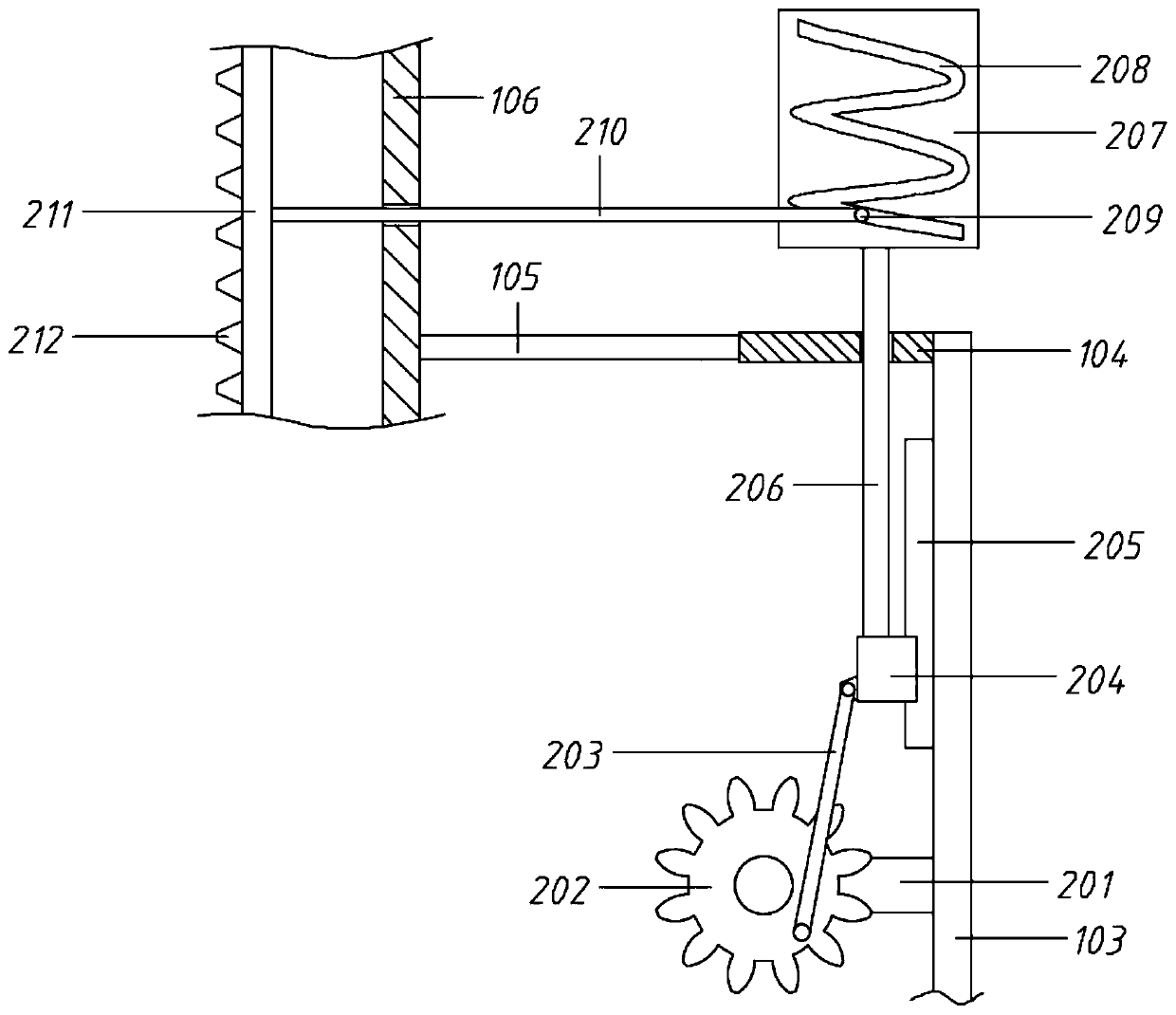

[0080] On the basis of embodiment 2,

[0081]The right end of the blocking plate 305 is hinged to the side plate of the crushing chamber 106, and the left end is detachably connected to the crushing chamber 106 through the fixing assembly 8; the left end of the blocking plate 305 is fixedly connected with the fifth rod 308, the right end of the fifth rod 308 and the bending rod The left end of 303 is damped and connected by connecting bolt 307, so that the blocking plate 305 can rotate, realize direction adjustment, and adapt to blanking and subsequent cleaning of residues.

[0082] The fixing assembly 8 includes a No. 4 support plate 801, a No. 1 installation shaft 802, a No. 1 clamping block 803, a bump 804 and a type of stop ring 805;

[0083] The left end of the bottom plate 111 is connected with the fourth support plate 801, and the fourth support plate 801 is fixedly connected with a No. 1 installation shaft 802; the No. 1 installation shaft 802 is fitted with the No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com