UV curing device

A technology of curing device and fixing seat, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problem of troublesome adjustment of ultraviolet lamp operation, and achieve the purpose of saving material, saving cost and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

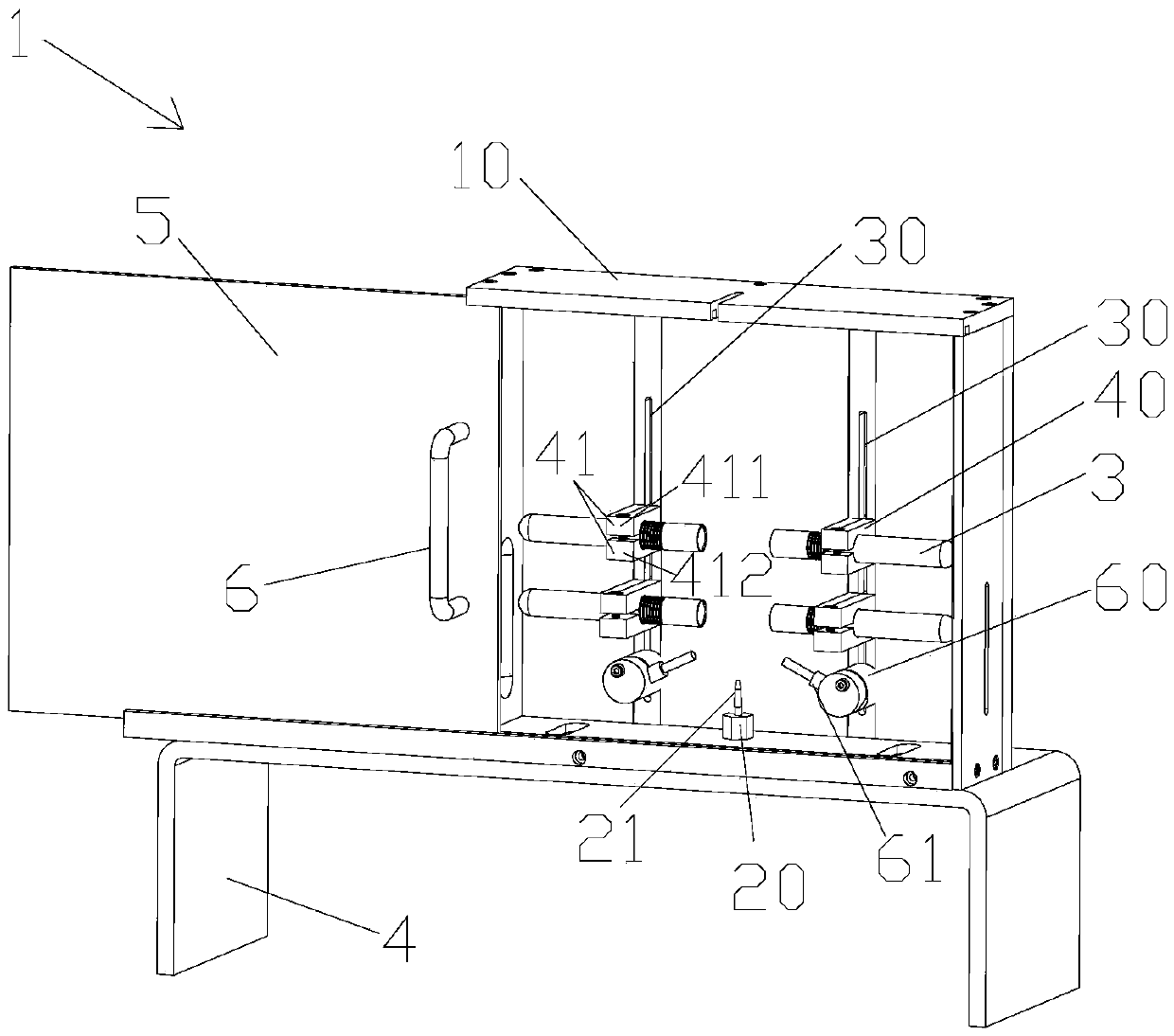

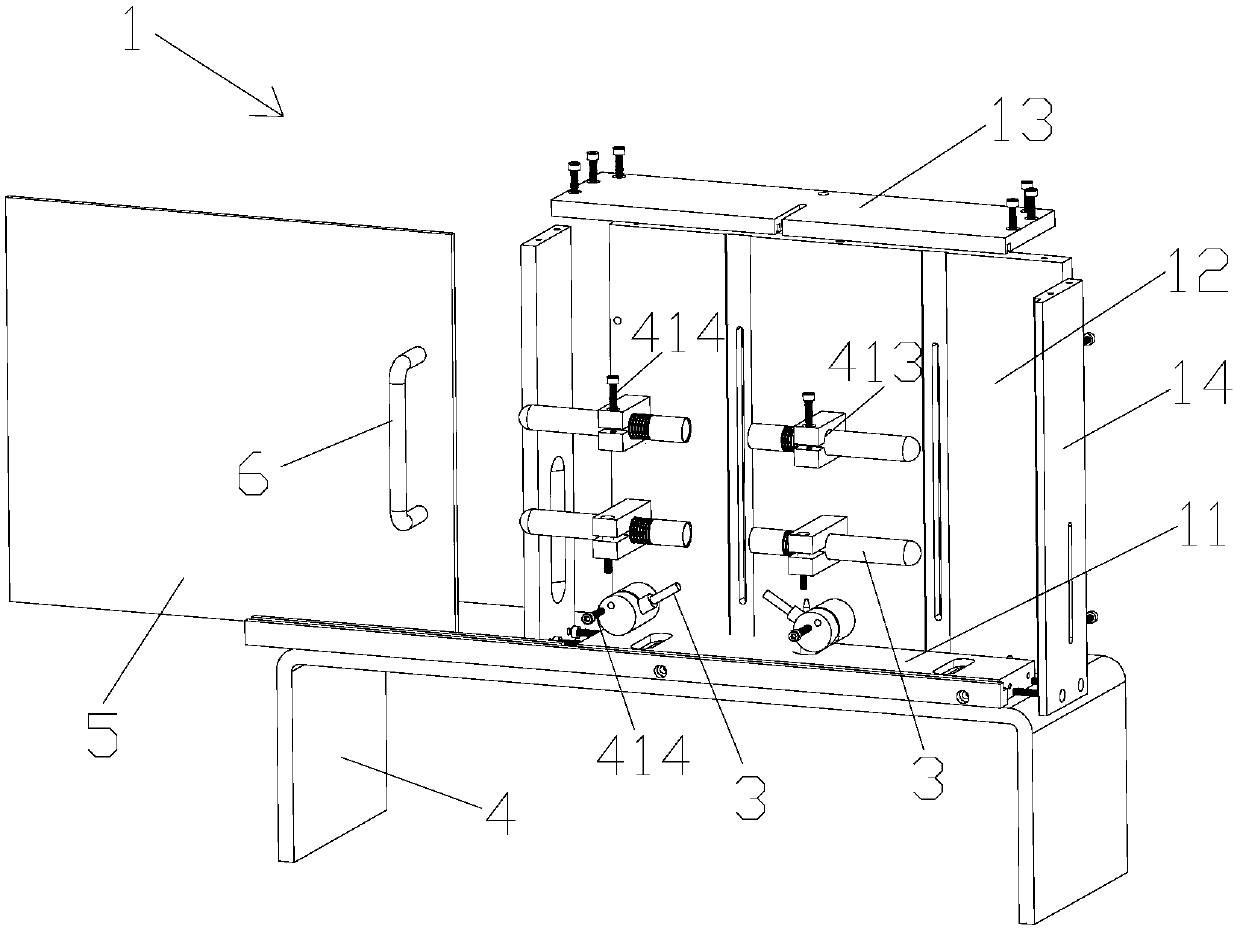

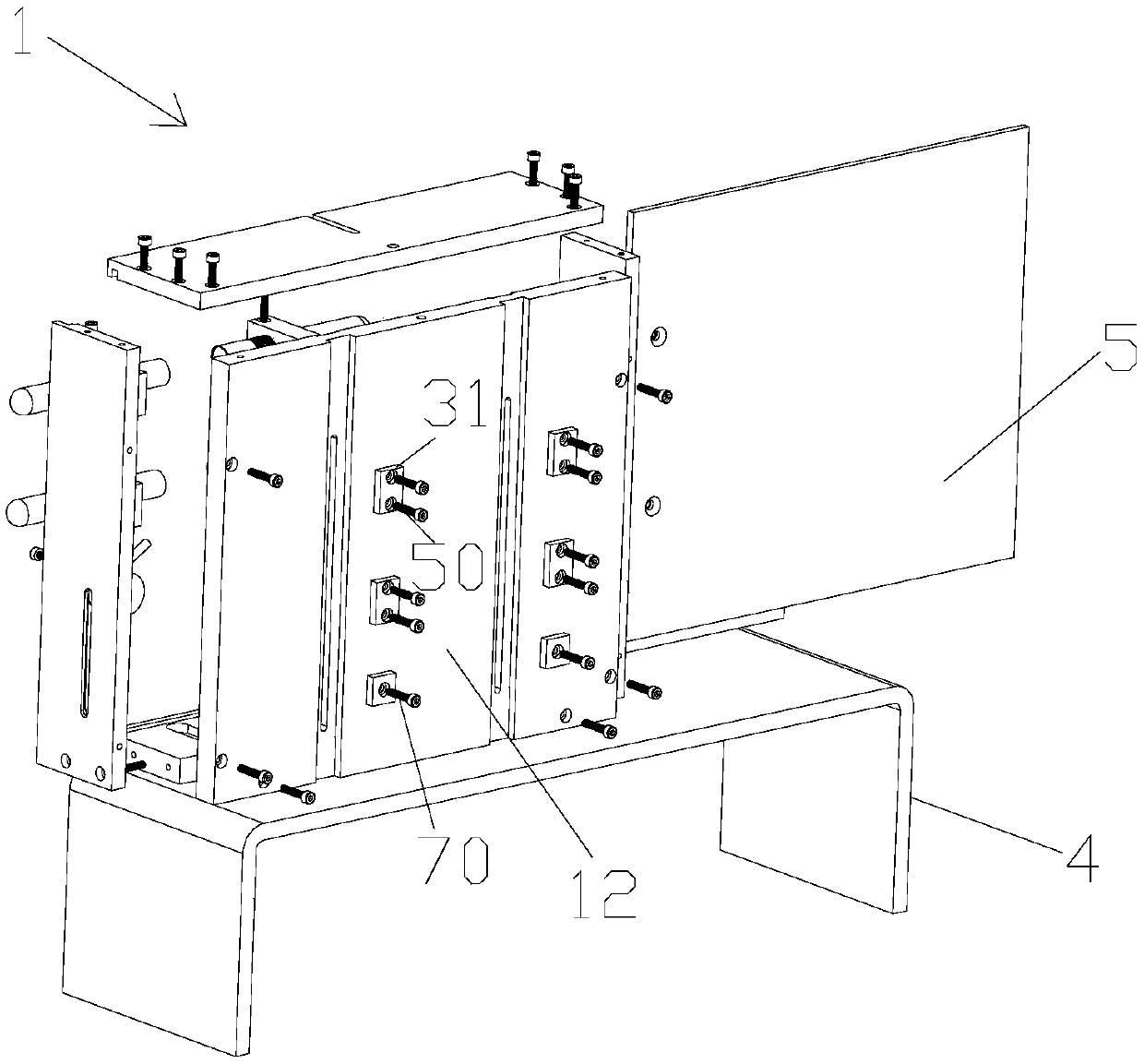

[0072] Such as figure 1 As shown, the embodiment of the present application provides a UV curing device 1, which performs UV curing on the workpiece to be cured. UV is the abbreviation of Ultraviolet Rays. UV curing generally refers to the use of ultraviolet rays to convert coatings, inks, adhesives, resins or The process of converting other potting sealants from liquid to solid is illustrated in the embodiment of the present application by taking the workpiece to be solidified as the handle 2 as an example. The handle 2 is as follows: Figure 5 As shown, the handle 2 may be a resin handle made of a resin material, and the UV curing principle of the handle 2 may be to irradiate the resin with a photoinitiator (or photosensitizer) with ultraviolet rays to absorb high-intensity ultraviolet rays in ultraviolet rays. Afterwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com