A vertical round bottle detection device

A detection device, round bottle technology, applied in the direction of measurement device, transportation and packaging, instruments, etc., can solve the problems of high labor intensity of operators, low production efficiency, incomplete testing, etc., to reduce machine costs, reduce labor intensity, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

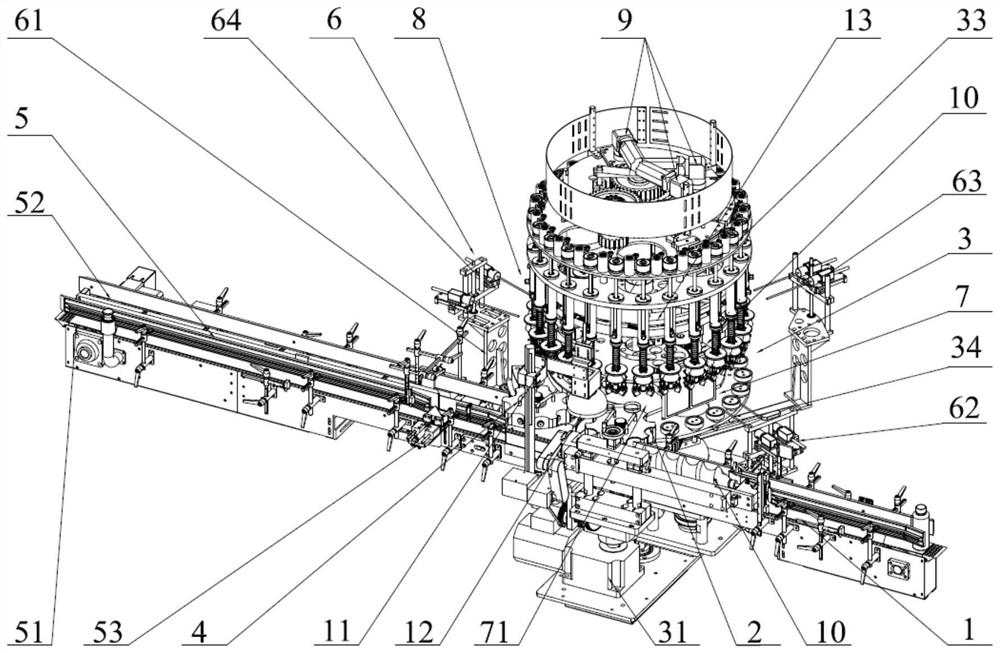

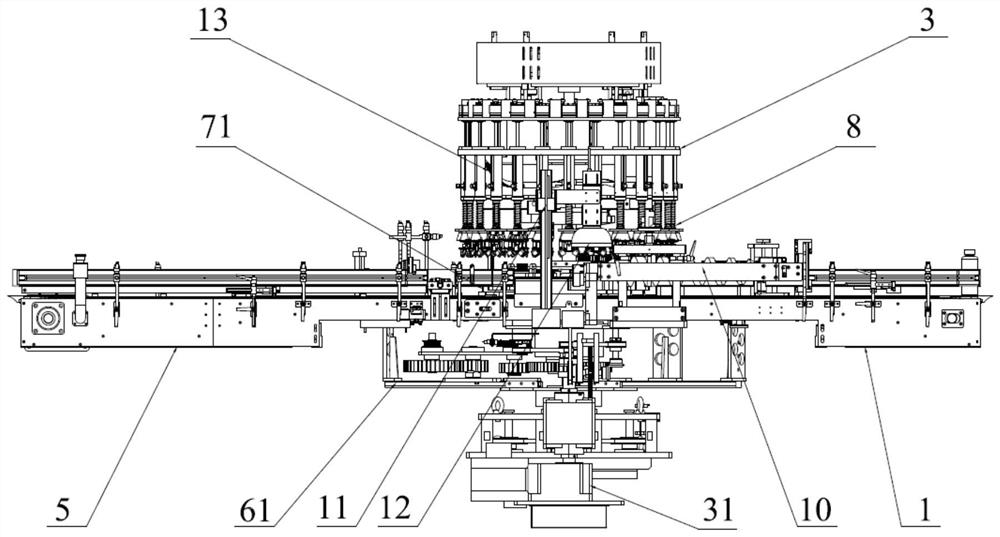

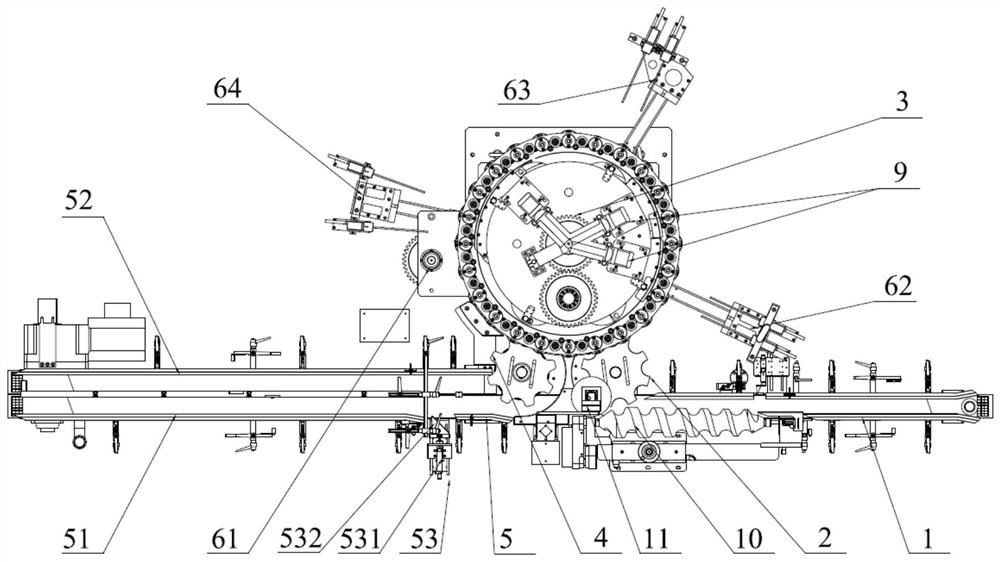

[0037] like Figure 1 to Figure 9 Shown is an embodiment of the vertical round bottle detection device of the present invention, including a feeding and conveying assembly 1, a feeding turntable assembly 2, a station turntable assembly 3, a blanking turntable assembly 4, a blanking and conveying assembly 5, a first shooting Component 6, the first light source component 7, the grasping and rotating component 8 for changing the photographing and detection state of the round bottle, and the rotating component 9 for driving the grasping and rotating component 8 to rotate:

[0038] The feeding carousel assembly 2 is arranged between the feeding and conveying assembly 1 and the station carousel assembly 3, and transports the round bottles located in the feeding and conveying assembly 1 to the station carousel assembly 3;

[0039] Between the feeding conveying assembly 1 and the feeding turntable, there is a bottle dividing assembly 10 for opening the distance between the round bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com