Automatic visual laser marking system

A laser marking and visual technology, applied in the field of laser marking, can solve the problems of high price, high manufacturing cost and insufficient intelligence, and achieve the effect of improving work efficiency and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

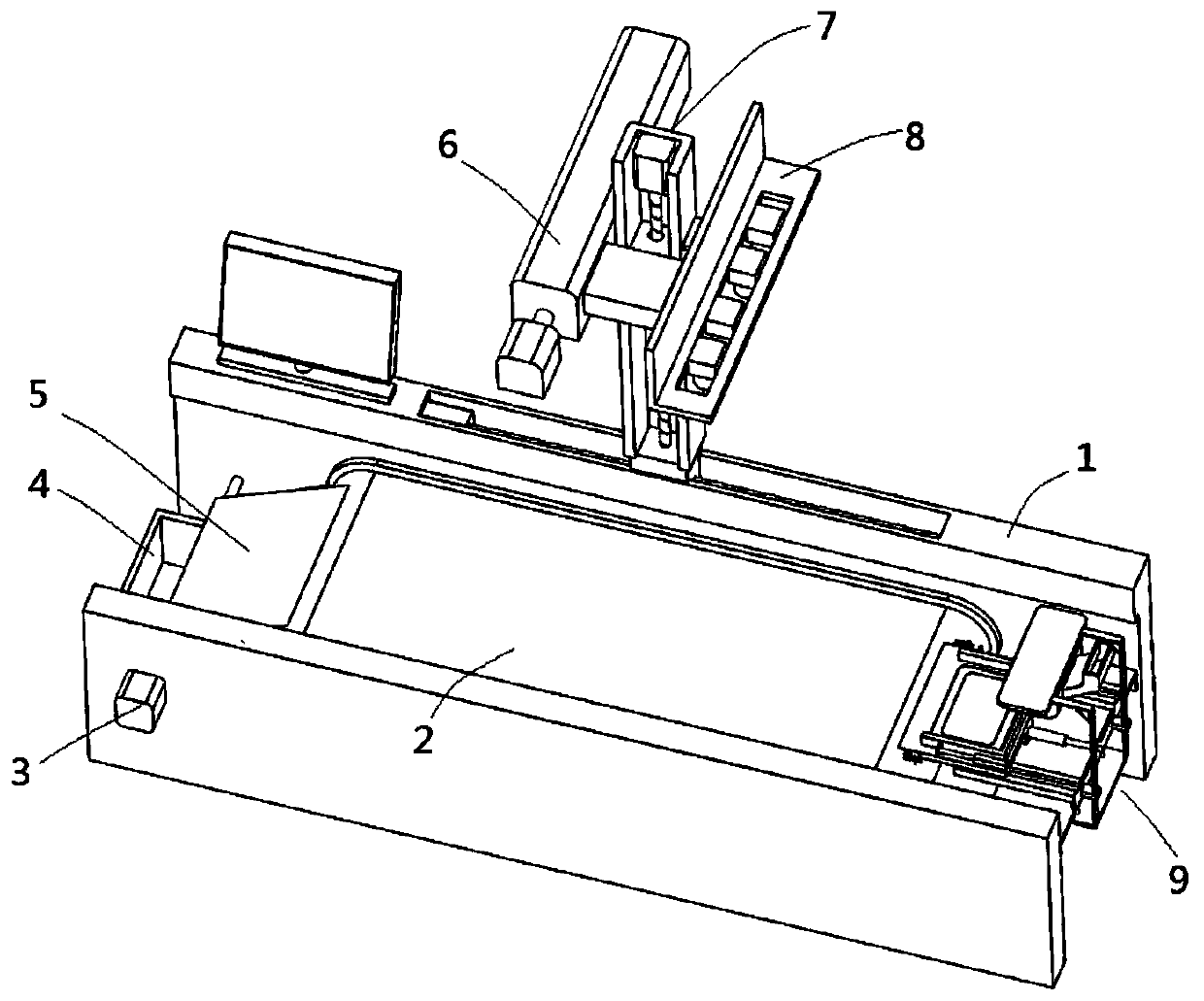

[0045] see Figure 1-4 , an automatic visual laser marking system, including a conveyor belt assembly and a laser marking assembly, one end of the conveyor belt mechanism 2 contained in the conveyor belt assembly is provided with an automatic feeding mechanism 9, and the other end of the conveyor belt mechanism 2 is provided with a receiving mechanism , the laser marking component is arranged on the top side of the conveyor belt component, and is used to automatically identify and mark the workpieces conveyed by the conveyor belt component.

[0046] The automatic feeding mechanism 9 is used to place the workpiece and push the workpiece to the upstream position of the conveyor belt mechanism 2. The workpiece is transferred to the designated position by the conveyor belt mechanism 2 and marked by the laser marking machine 6. The receiving mechanism Used to receive marked workpieces.

[0047] The conveyor belt assembly includes a frame 1 and a conveyor belt mechanism 2. The lase...

Embodiment 2

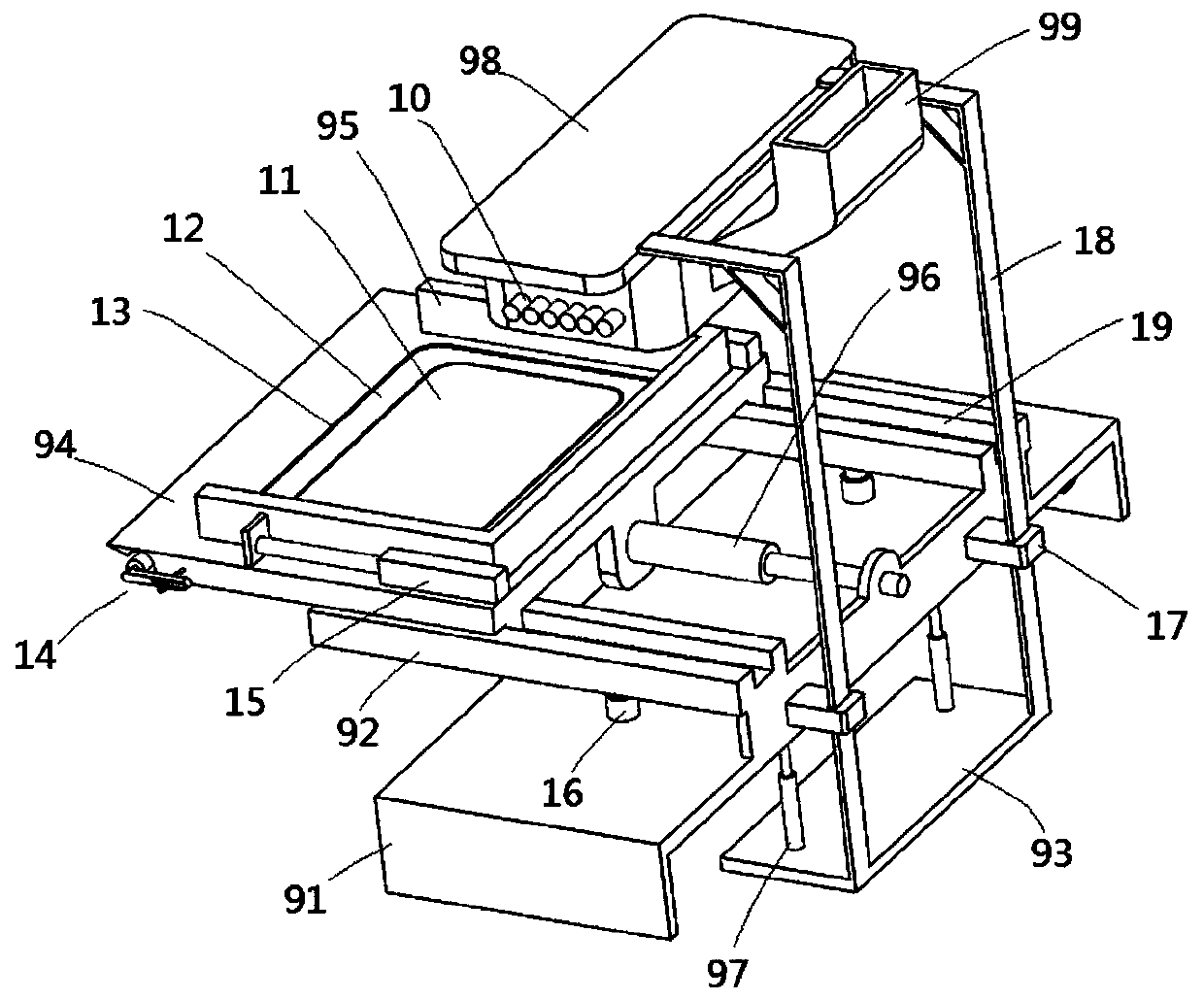

[0062] see Figure 5 , as a further improvement of the present invention, one side end surface of the sliding feeding plate 94 close to the conveyor belt mechanism 2 is in contact with the outer surface of the conveyor belt in the conveyor belt mechanism 2, and the top surface of the sliding feeding plate 94 is in contact with the conveyor belt mechanism 2 The top surface of the inner conveyor belt is on the same plane, and the end surface of the sliding feeding plate 94 close to the conveyor belt mechanism 2 is an arc-shaped surface, and the arc-shaped surface is provided with a groove 26 along its length direction, and the groove 26 is provided with Protection mechanism 14 for conveyor belt rolling contact.

[0063] Wherein, the protection mechanism 14 includes a rolling column 1401 and a side plate 1402, the rolling column 1401 is movably arranged in the groove 26, the two ends of the rolling column 1401 are connected with the side plate 1402 through a pin shaft, the end of...

Embodiment 3

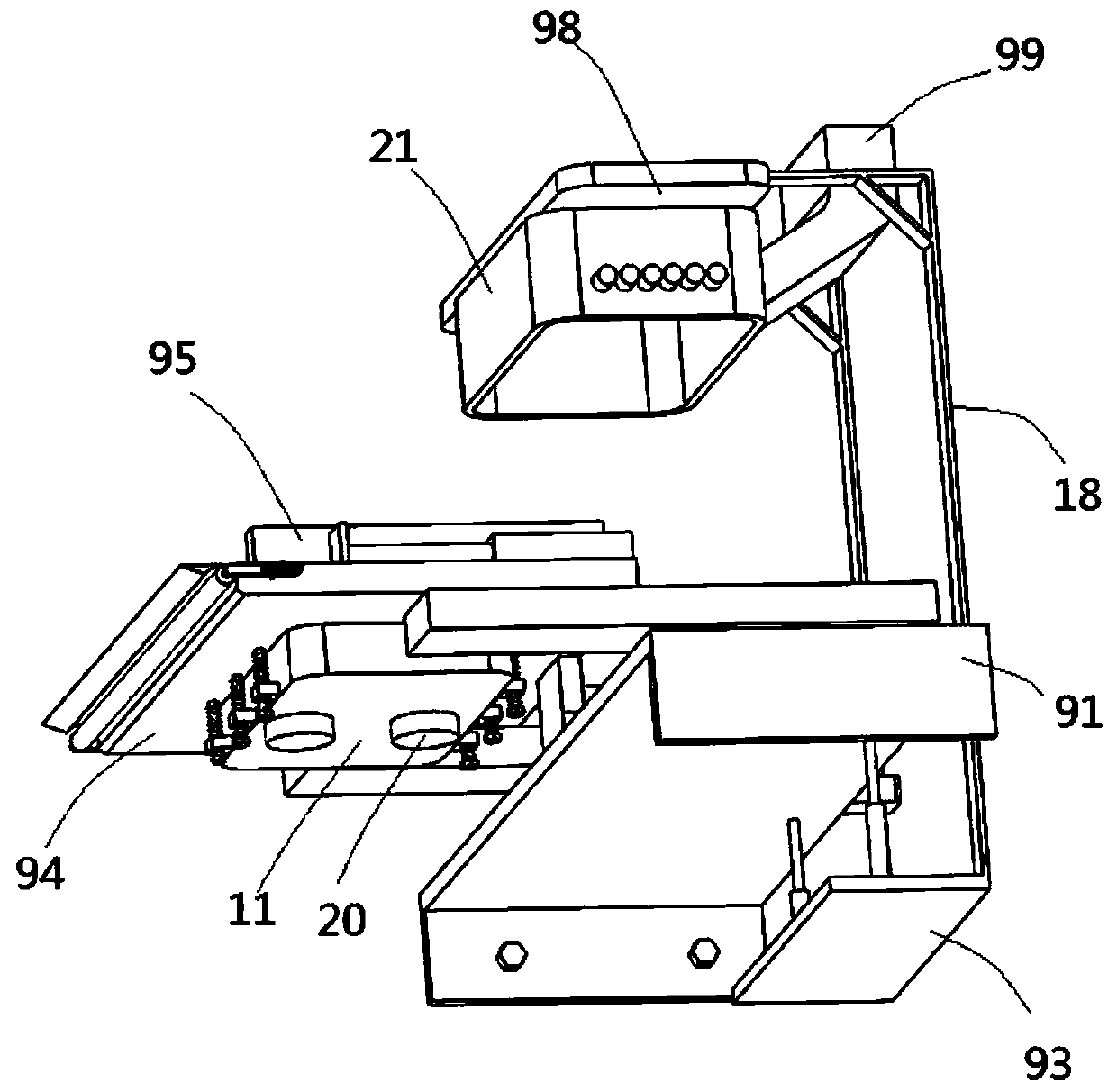

[0067] see Figure 6 , Figure 7 In this embodiment, as a further improvement based on Embodiment 2, in the present invention, a mechanism for assisting in moving the workpiece can be provided in the protective cover 21 to prevent the workpiece from being completely evenly distributed on the vibrating plate 11 under vibration.

[0068]An annular mounting frame 43 is movable in the protective cover 21, and an installation cavity 38 is provided in the protective cover 21 housing, and a movable block 31 is arranged in each installation cavity 38, and threaded holes are arranged in the movable block 31. Screw mandrel 32 is provided with along protective cover 21 depth direction in installation chamber 38, and screw mandrel 32 is threadedly engaged with movable block 31, and drive motor 30 that drives screw mandrel 32 rotations is installed on top plate 98, and installation chamber 38 and protective cover 21 pass through The through hole 35 communicates, and the mounting frame 43 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com