Automatic welding equipment for cage top and bottom cover

An automatic welding and bottom cover technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming and laborious, manual welding, etc., and achieve the effect of high welding quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

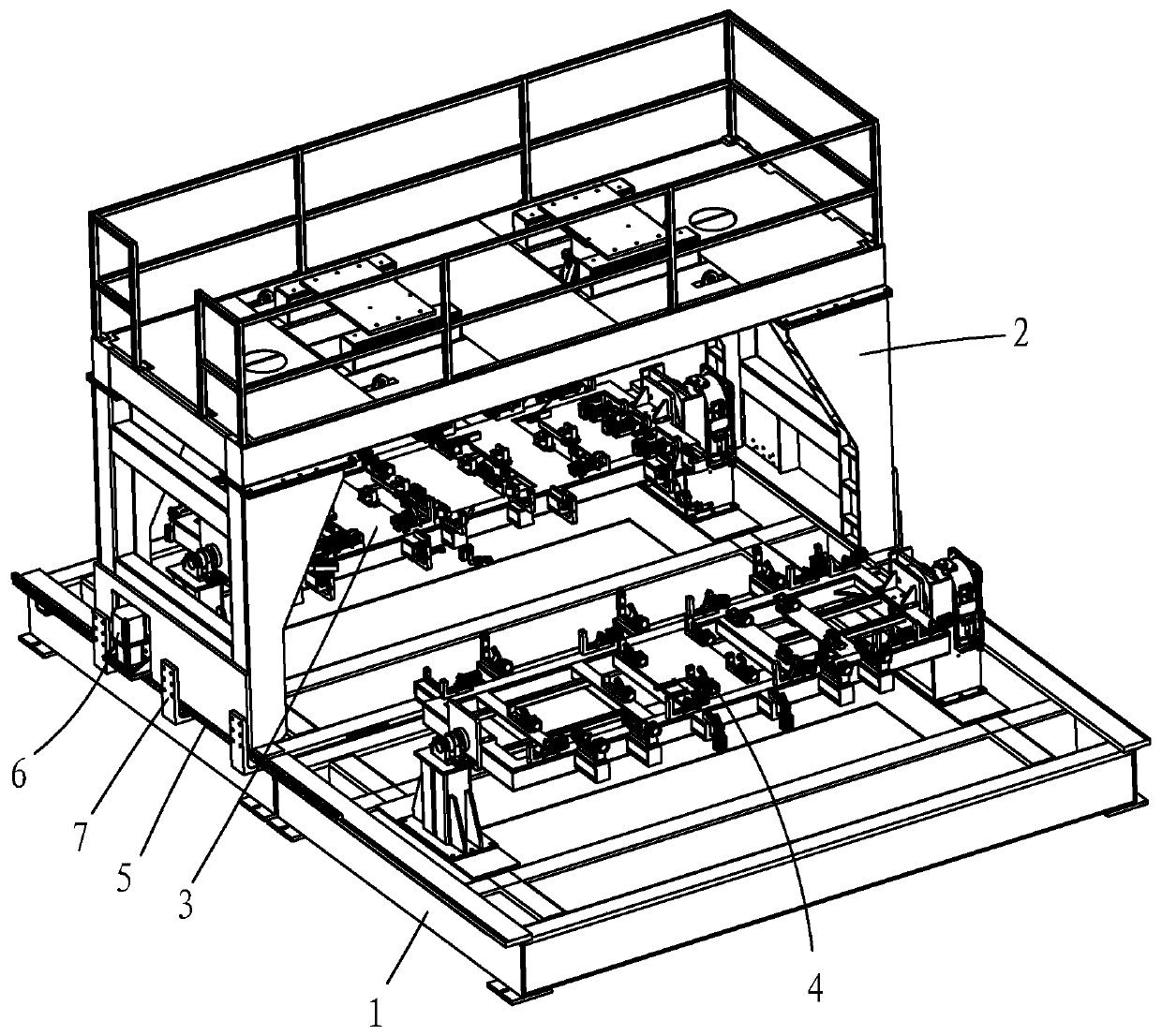

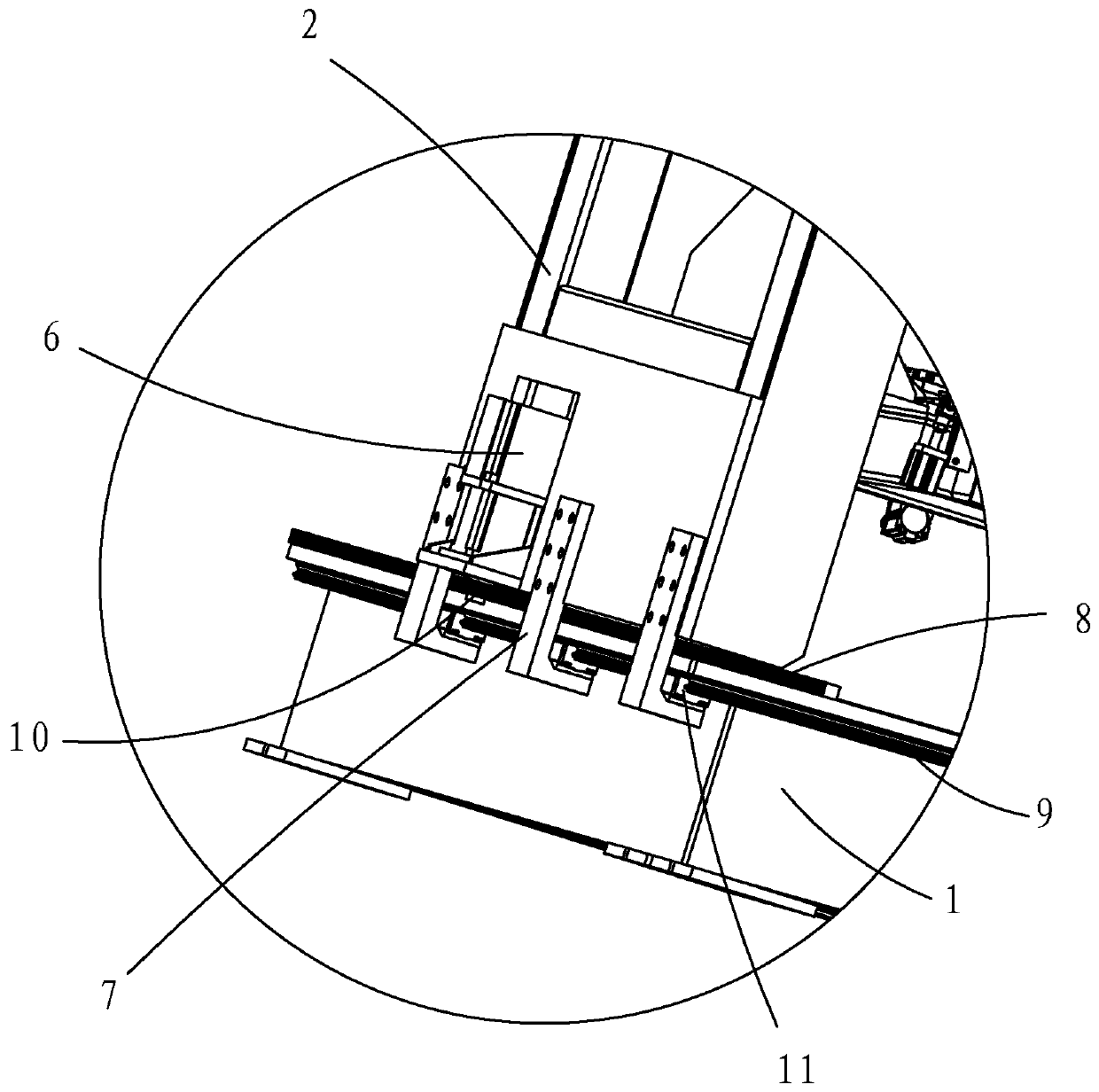

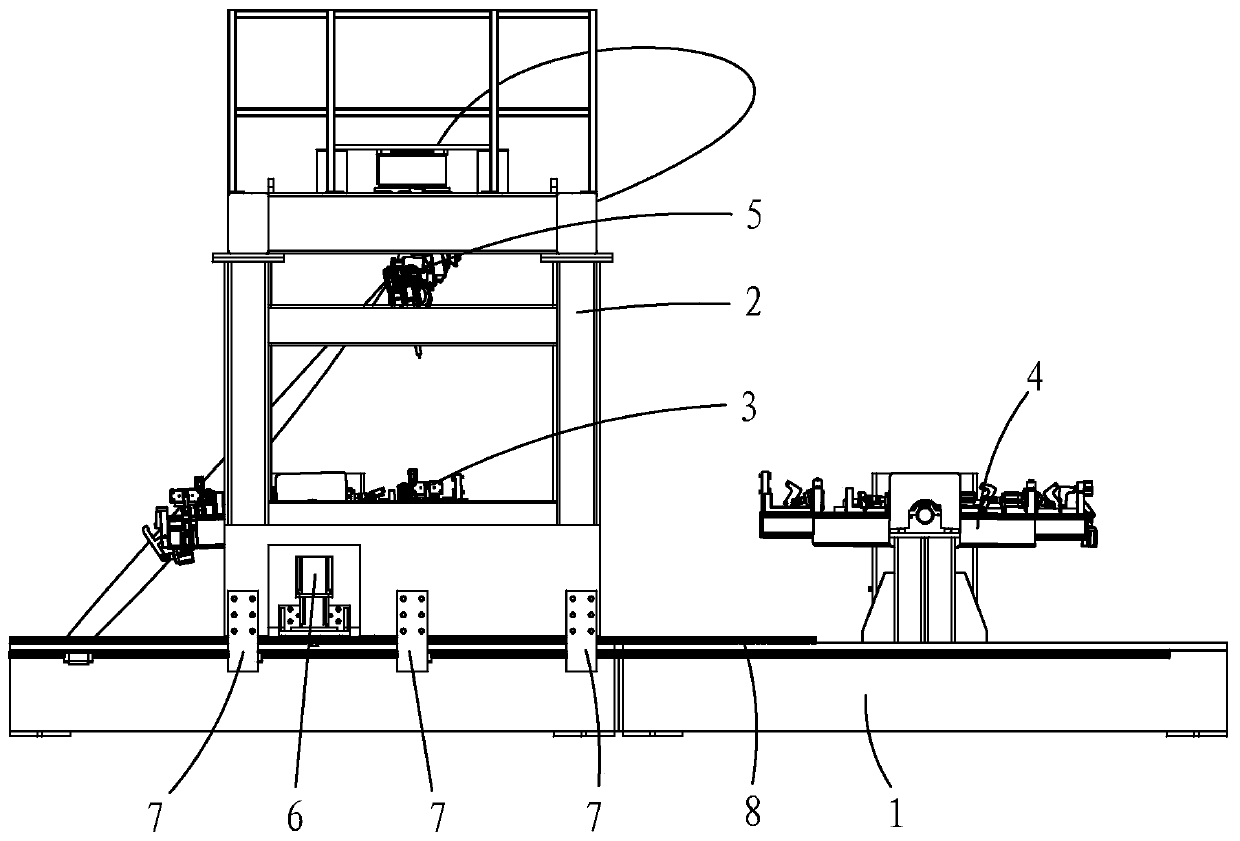

[0039] Such as Figure 1 to Figure 7 Shown, a kind of automatic welding equipment of cage top and bottom cover, comprises: fixed workbench 1, gantry frame 2, cage top bottom plate tooling 3, bottom cover bottom plate tooling 4, welding robot 5, gun cleaning device (not shown in the figure) shown), PLC master controller (not shown).

[0040] The fixed workbench 1 is respectively fixedly provided with the hoisting cage top and bottom plate tooling 3, the bottom cover bottom plate tooling 4, and the gun cleaning device.

[0041] A gantry 2 is also erected on the fixed workbench 1 . The bottom of the gantry 2 is provided with a welding robot 5 ; the control device of the welding robot 5 is arranged on the top of the gantry 2 .

[0042] The gantry 2 moves on the fixed workbench 1 driven by two servo motors 6, and welds the raw materials on the cage top and bottom plate tooling 3 and the bottom cover bottom plate tooling 4 respectively.

[0043] A position sensor (not shown) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com