Hydraulic external line-up clamp for steel gas pipeline

A technology for gas pipelines and external counterparts, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy error in axial distance, influence of welding work, and difficulty in precise control of welding seam width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

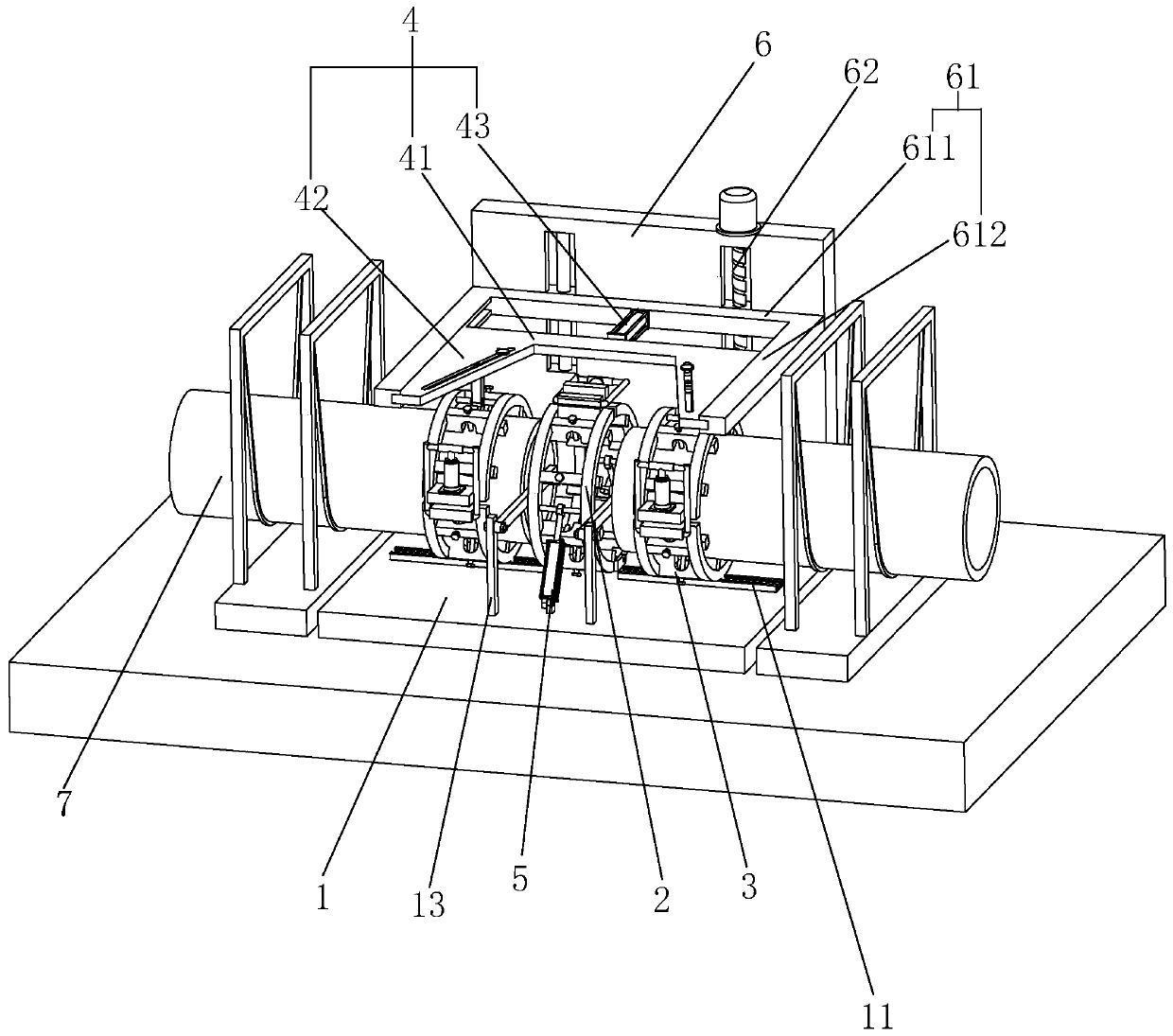

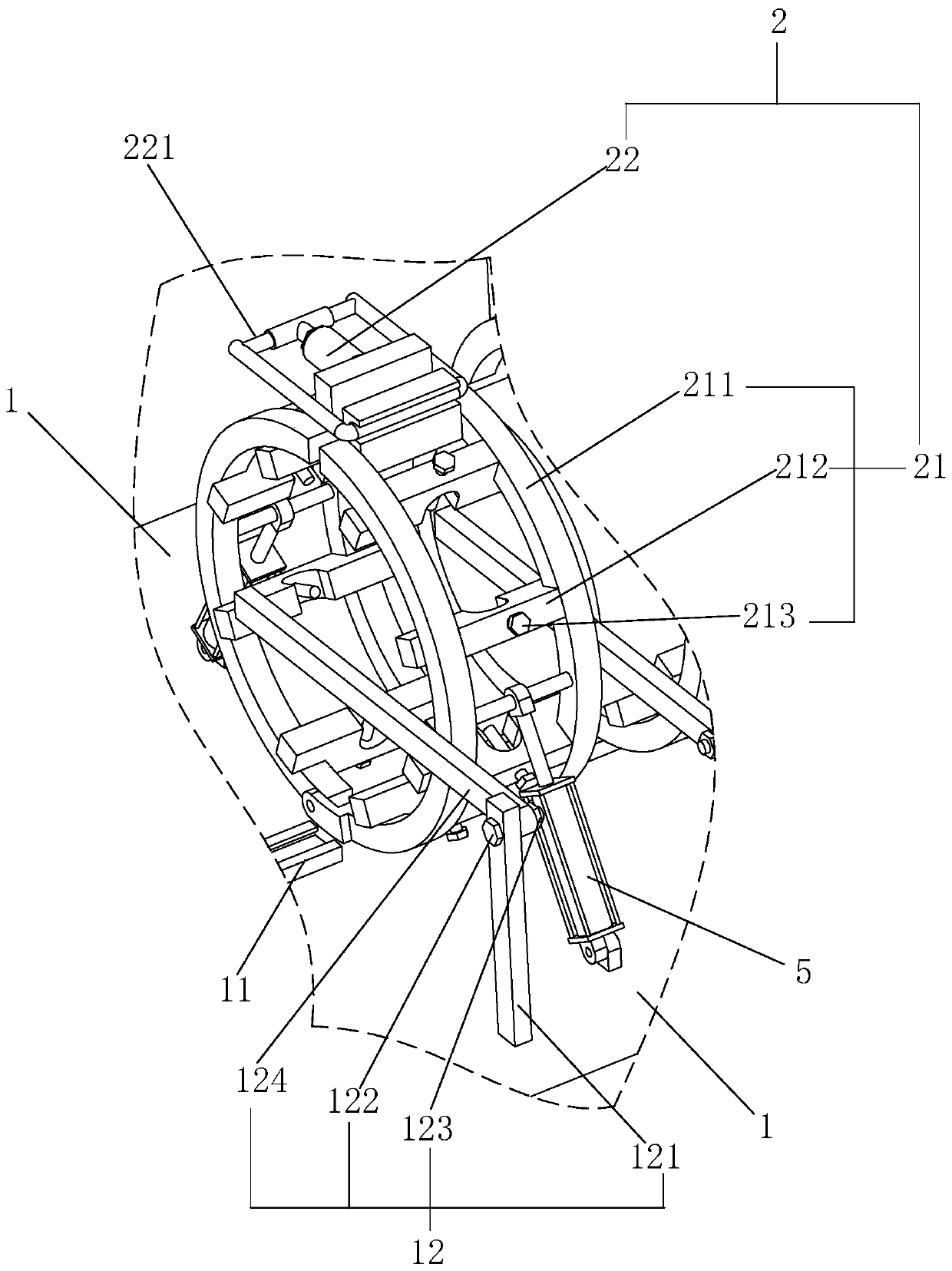

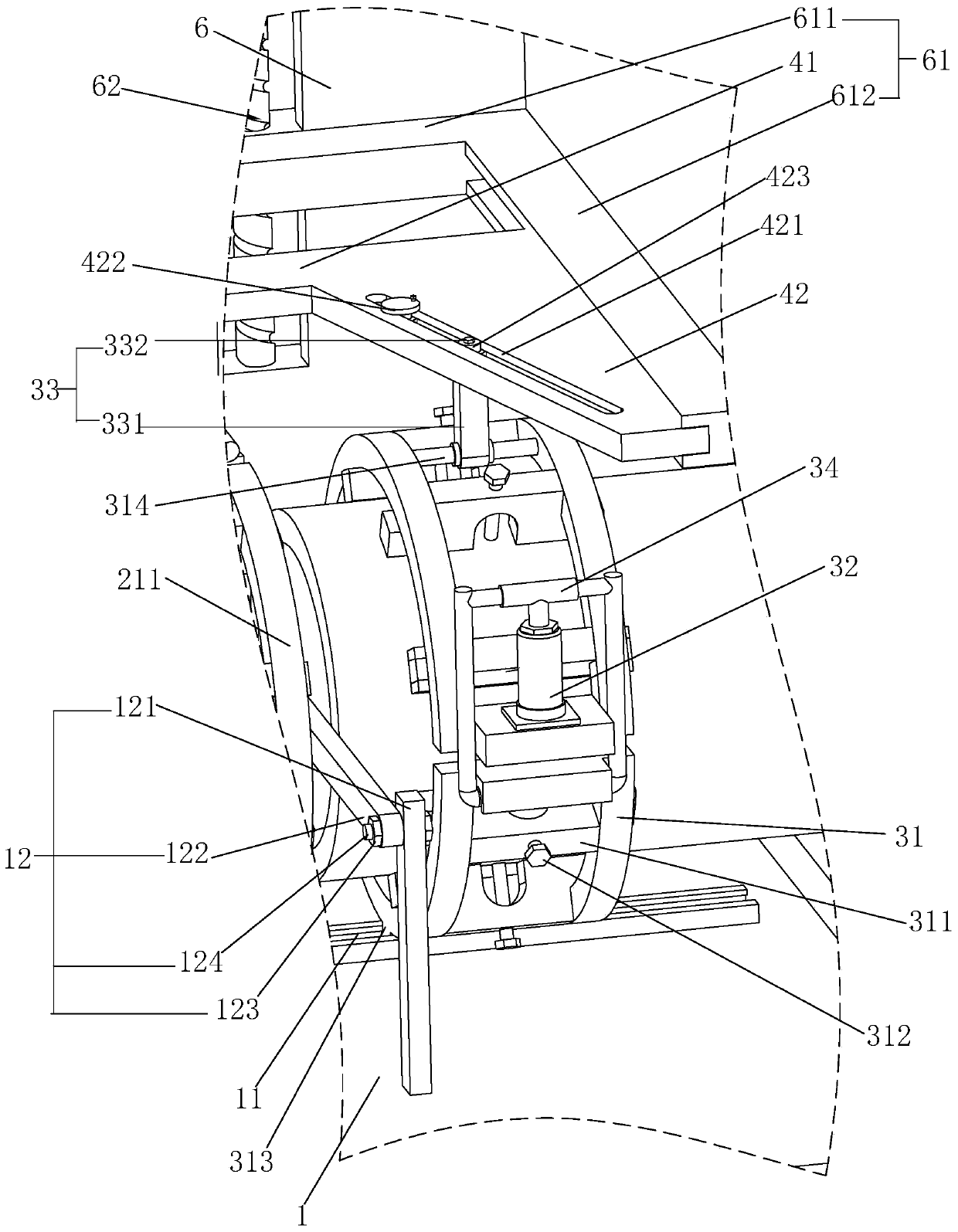

[0035] Such as figure 1 As shown, the present invention introduces a steel gas pipeline hydraulic external counterpart, including a positioning plate 1, a central positioning part 2, a side positioning part 3 and a synchronous feed mechanism 4, and the central positioning part 2 is arranged on the positioning plate 1 On the surface, the central positioning member 2 can press and limit the outer peripheral wall of the pipeline 7, and the side positioning members 3 are symmetrically arranged on both sides of the central positioning member 2, and the side positioning members 3 can press and limit the outer peripheral wall of the pipeline 7, The synchronous feeding mechanism 4 is fixedly arranged on the positioning plate 1 and can drive the two side positioning members 3 to move synchronously toward or away from the central positioning member 2 relative to the positioning plate 1 . Place the positioning plate 1 above the welding table 8 in the horizontal direction, hoist the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com