Engine expansion section II section groove milling device

A technology of slot milling device and expansion section, which is applied in the field of slot milling device of engine expansion section II, which can solve the problems of increasing the weight of the slot milling device, difficulty in positioning the carcass, and containing hard metal particles, so as to reduce the processing cost and avoid Knife phenomenon, good machinability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with embodiment.

[0027] The invention provides a slot milling device for the second section of the engine expansion section. It provides a small weight, easy to use, and low-cost engine expansion section II section milling device, which is specially used for the tire pressure, size, End removal allowance and milling process.

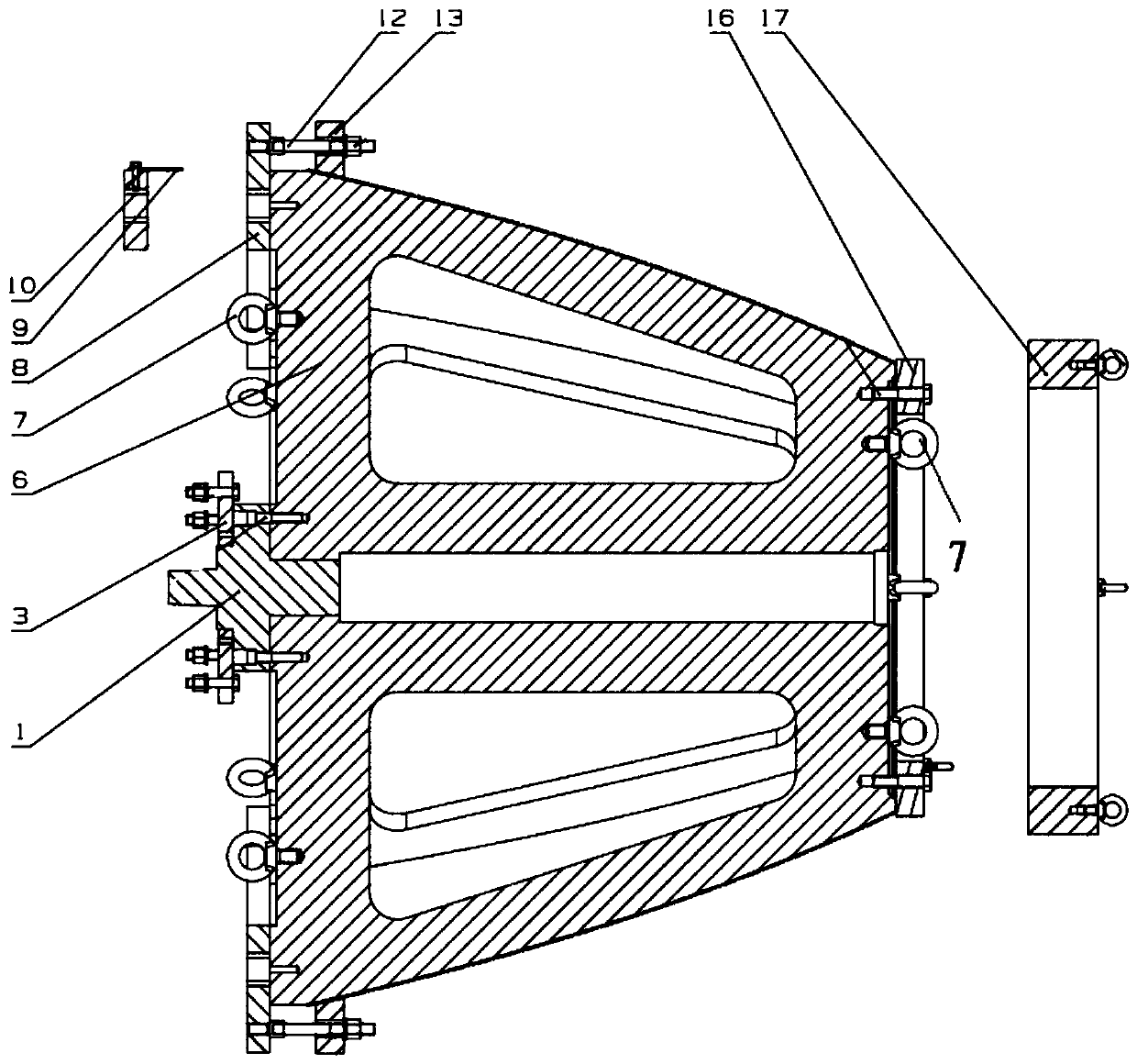

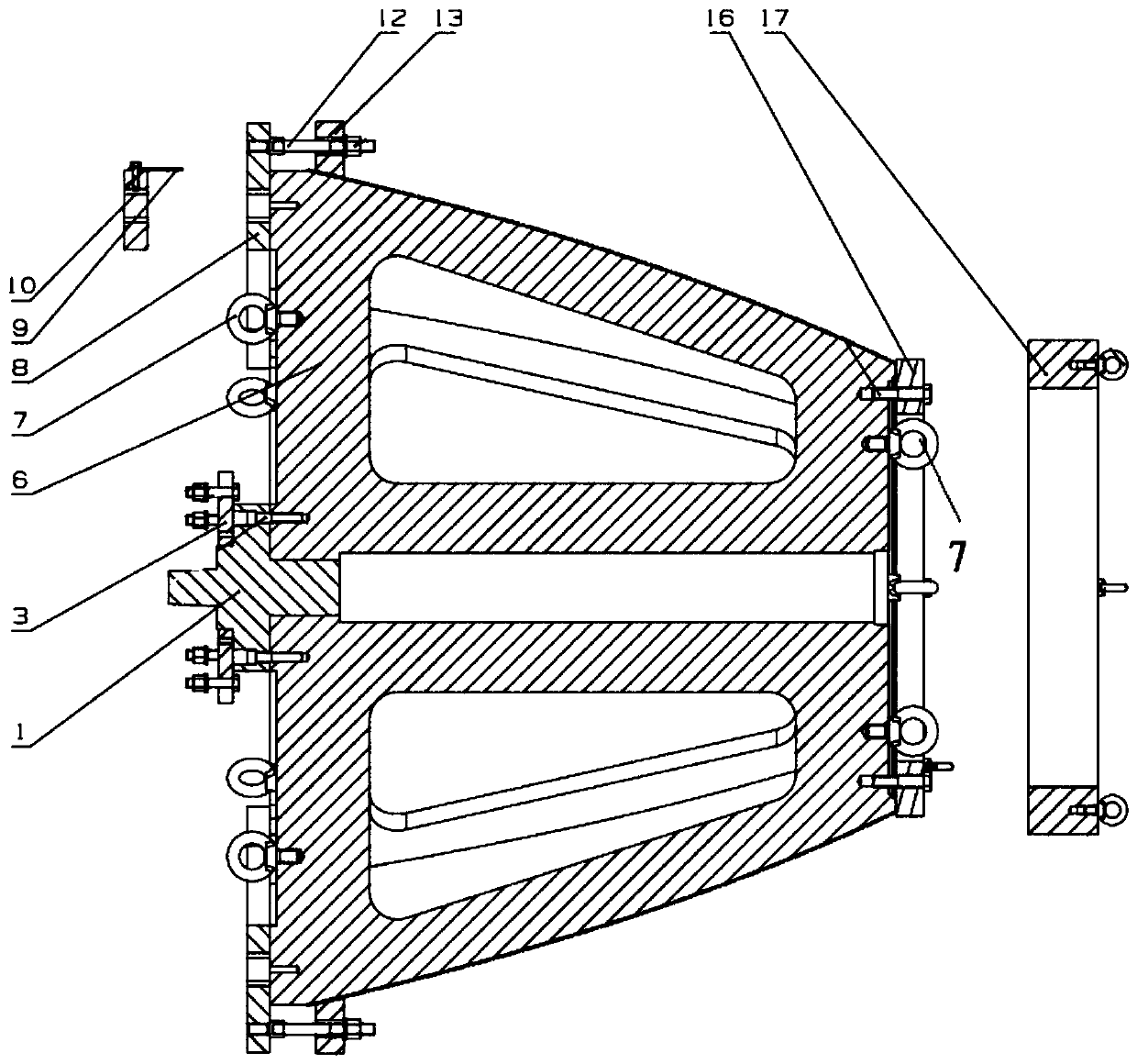

[0028] Such as figure 1 As shown, a milling device for engine expansion section II section mainly includes a tail handle 1, a connecting plate 3, a positioning carcass 6, an eyebolt screw 7, a long support plate 8, an overlapping plate 9, a short support plate 10, a double-head Stud 12, pressure ring 13, pressure plate 16 and large pressure ring 17; wherein, the positioning carcass 6 is a cone column segment structure; the axial large-diameter end and the small-diameter end of the positioning carcass 6 are all provided with eyebolt screws 7; 1 is fixedly installed at the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com