Impeller mould for pump

A technology for impellers and pumps, applied in the field of impeller molds for pumps, can solve the problems of small pump flow and low efficiency, and achieve the effects of ensuring flow and efficiency, convenient manufacturing and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

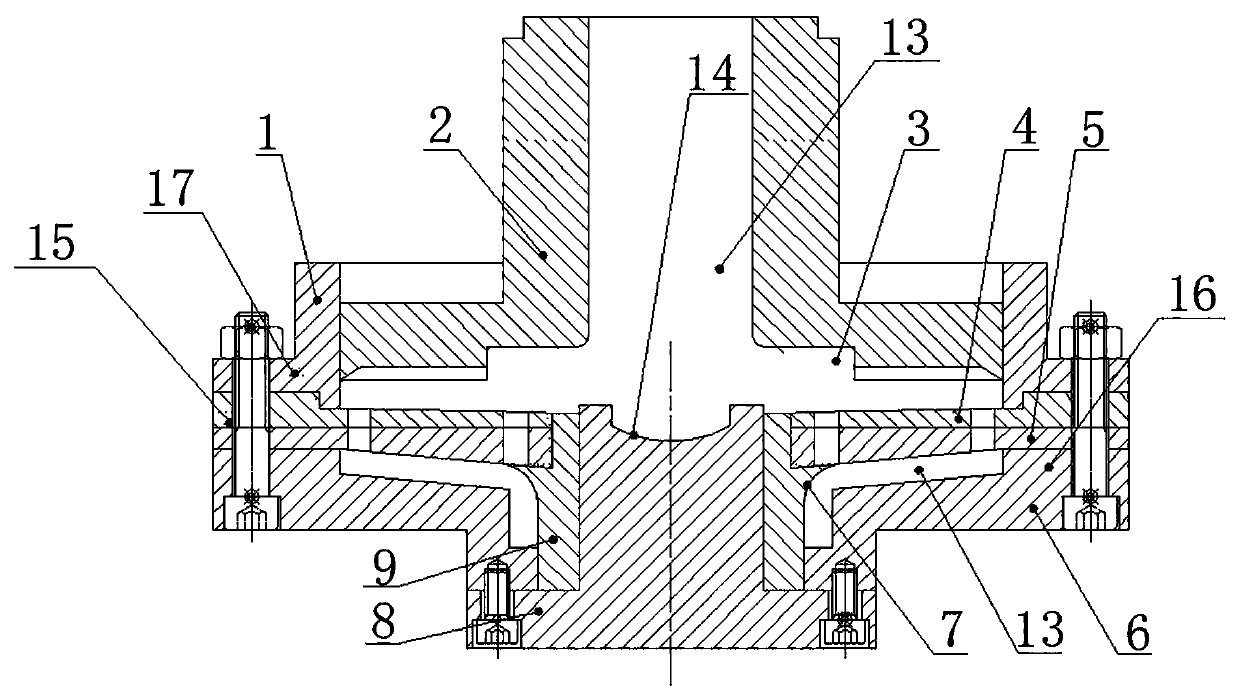

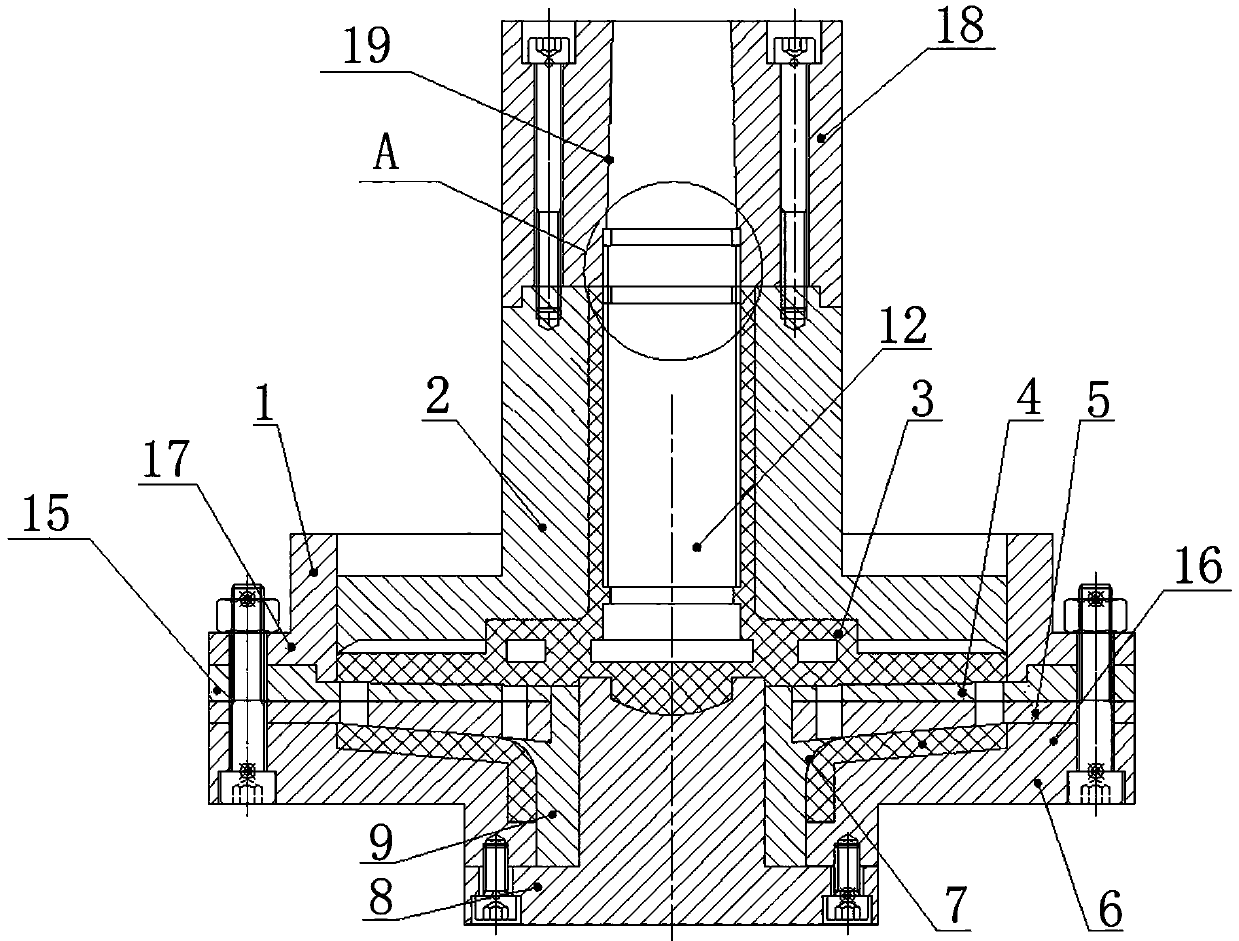

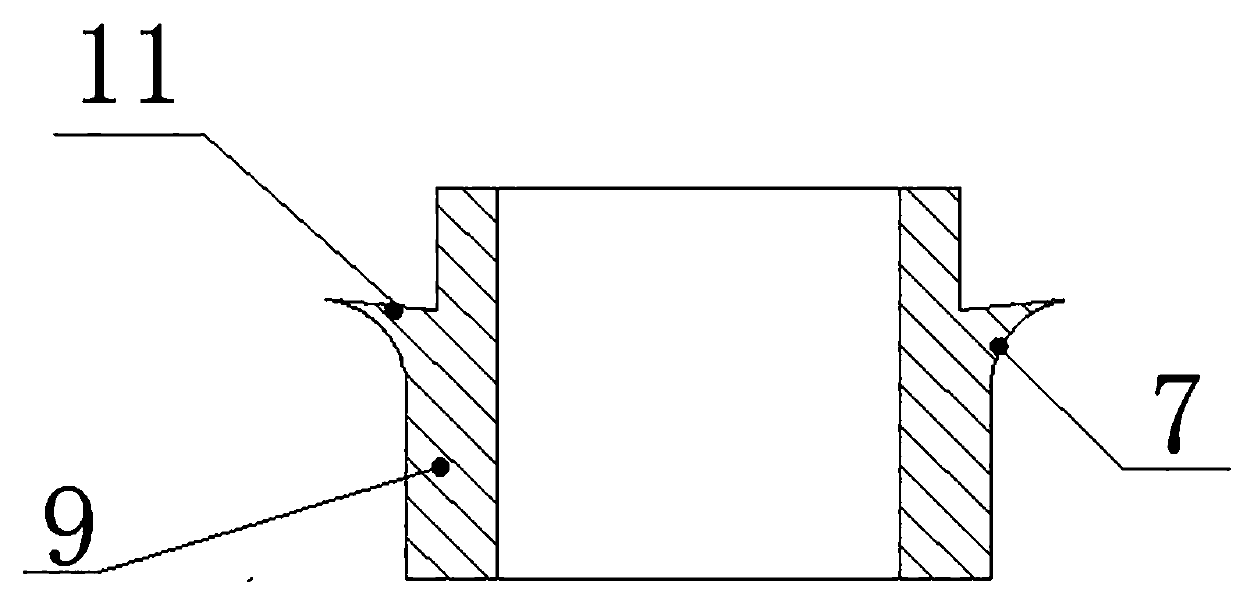

[0028] Such as Figure 1-7 As shown, an impeller mold for a pump includes an upper mold 2, a plurality of plugs, and a bottom mold 6. The top of the upper mold 2 is equipped with an upper die 18 through a hexagon socket screw, and the outer lower part of the upper mold 2 is covered with a barrel 1 , The inner side of the bottom mold 6 is equipped with a mandrel sleeve 9 which is a separate structure, and the mandrel sleeve 9 is divided into five pieces according to the position of the cutting line 10. The inner side of the core rod sleeve 9 is equipped with a core rod 8, and the lower part of the core rod 8 is provided with a core rod round table. The core rod round table is clamped at the bottom of the bottom mold 6 and the core rod sleeve 9, and the bottom of the bottom mold 6 passes through the core rod round table. Bolted.

[0029] The top of the mandrel 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com