Parahydrogen enrichment device suitable for high-flow and high-pressure conditions

A large-flow, high-pressure technology, applied in the direction of hydrogen separation, etc., can solve the problems of insufficient hydrogen conversion effect, inability to detect hydrogen temperature, good heat exchange effect, etc., to achieve faster temperature conduction speed, small diameter of circular holes, and conversion reaction full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

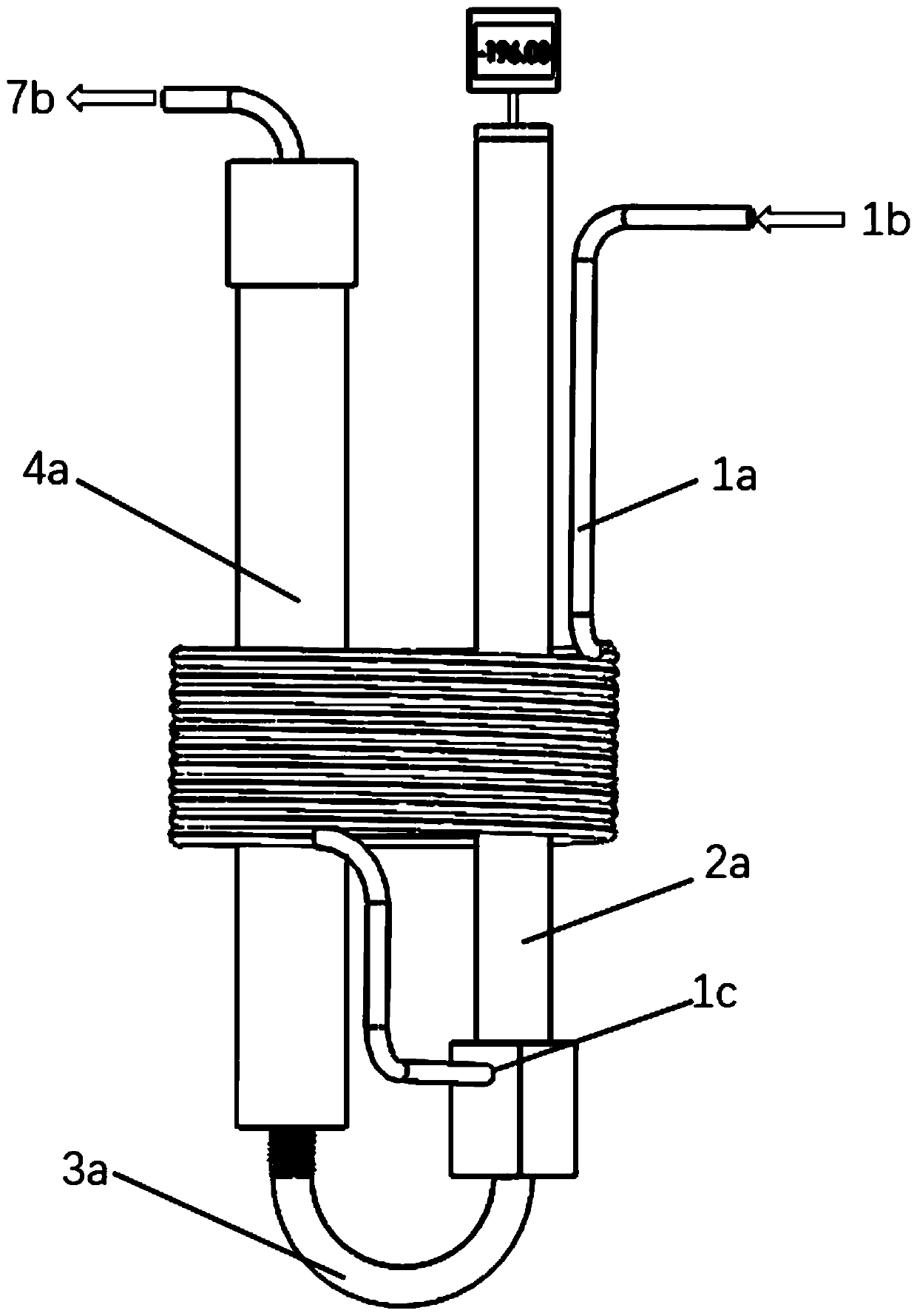

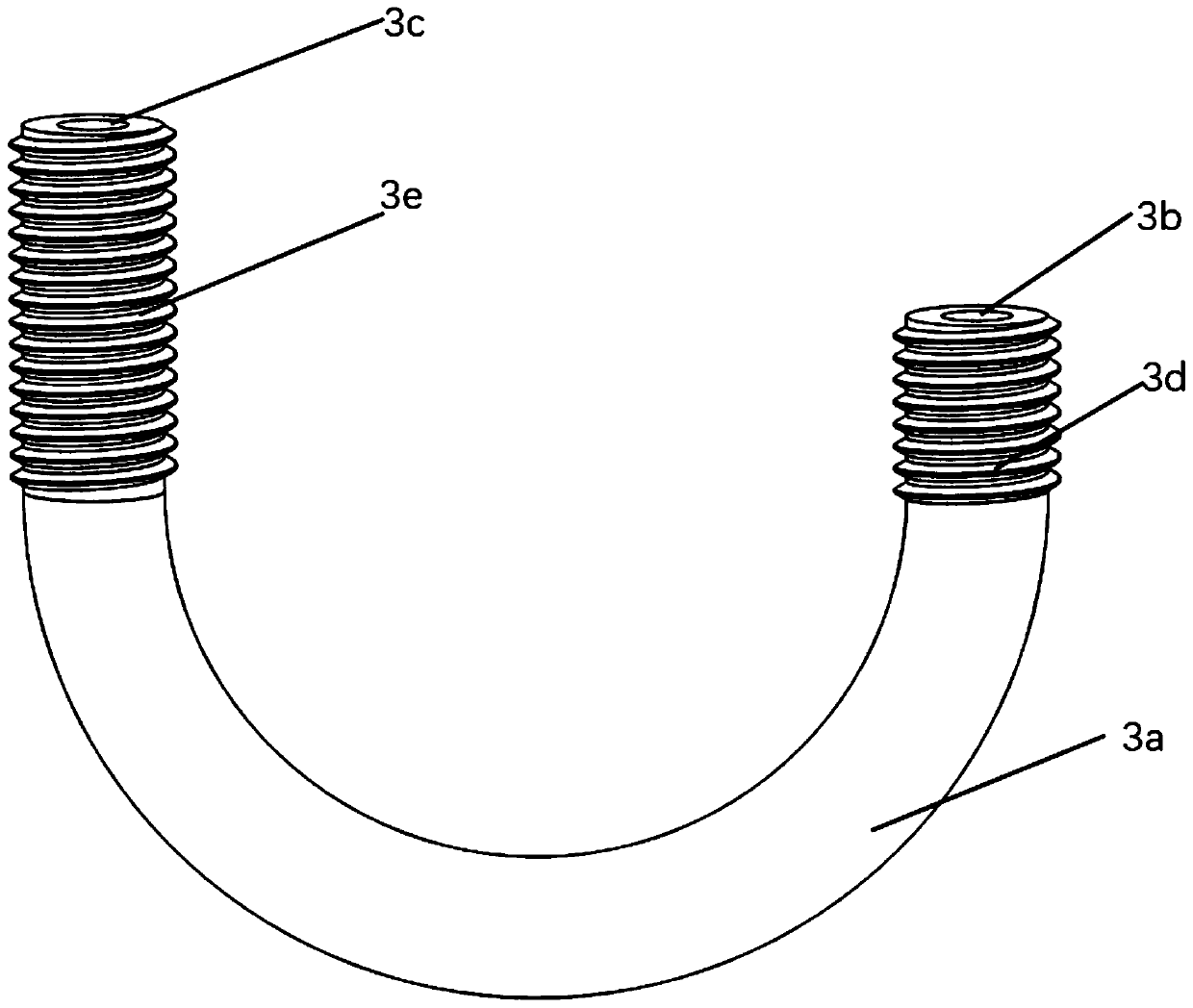

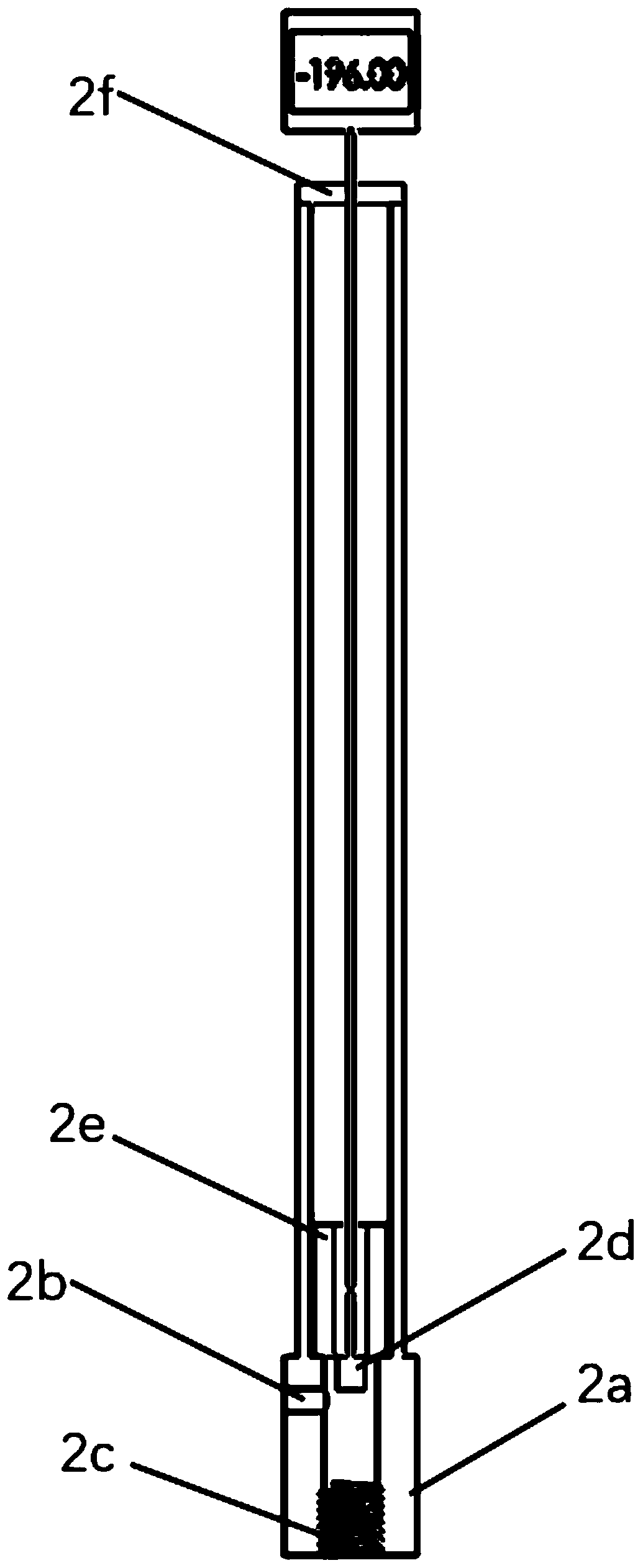

[0034]A parahydrogen enrichment device suitable for large flow and high pressure conditions, comprising a temperature detection chamber 2a, a thermostat line protection pipe 2e, a double chamber connecting pipe 3a, a parahydrogen enrichment chamber 4a, a heat exchange rod 5a, and a pressure maintaining filter cap 6a, cooling pipe 1a, catalyst 9a and temperature display. The double-chamber connecting pipe 3a includes a double-chamber connecting pipe inlet 3b and a double-chamber connecting pipe outlet 3c; the temperature detection chamber 2a is connected with the cooling pipe 1a, the double-chamber connecting pipe 3a and the thermostat line protection pipe 2e; the double-chamber The connecting pipe 3a connects the temperature detection chamber 2a and the parahydrogen enrichment chamber 4a; the parahydrogen enrichment chamber 4a is in the form of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com