Manifold device for high pressure mass flow meter and manifold assembly

A mass flow meter and manifold technology, which is applied in mass flow measuring devices, direct mass flow meters, measuring flow/mass flow, etc., can solve the problems of large size of manifold device 1, large consumption of welding materials, and increase of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

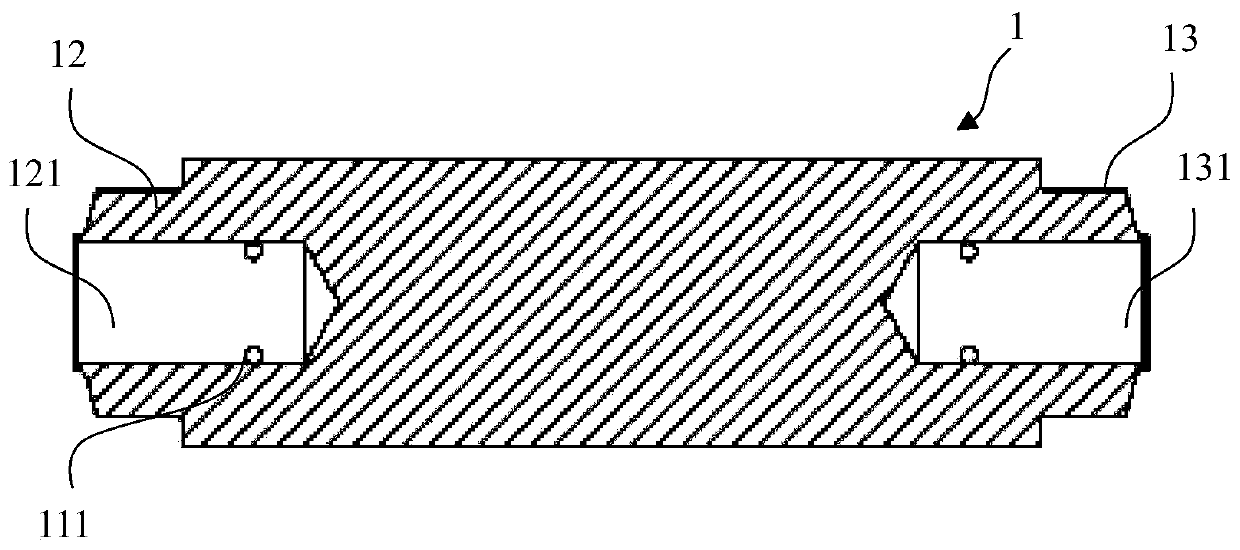

[0029] The foregoing and other features and characteristics of the present application will become more apparent from the following detailed description with reference to the accompanying drawings, which are by way of illustration only and not necessarily drawn to scale. The same reference numerals are used to designate the same parts in the figures. The directions of "front", "left", and "upper" described in the embodiments of the present invention are based on Figure 6 The "X", "Y" and "Z" directions pointed by the arrows in the coordinates shown in , and the directions of "back", "right" and "down" are Figure 6 The direction opposite to the "X", "Y" and "Z" directions pointed by the arrows in the coordinates shown in .

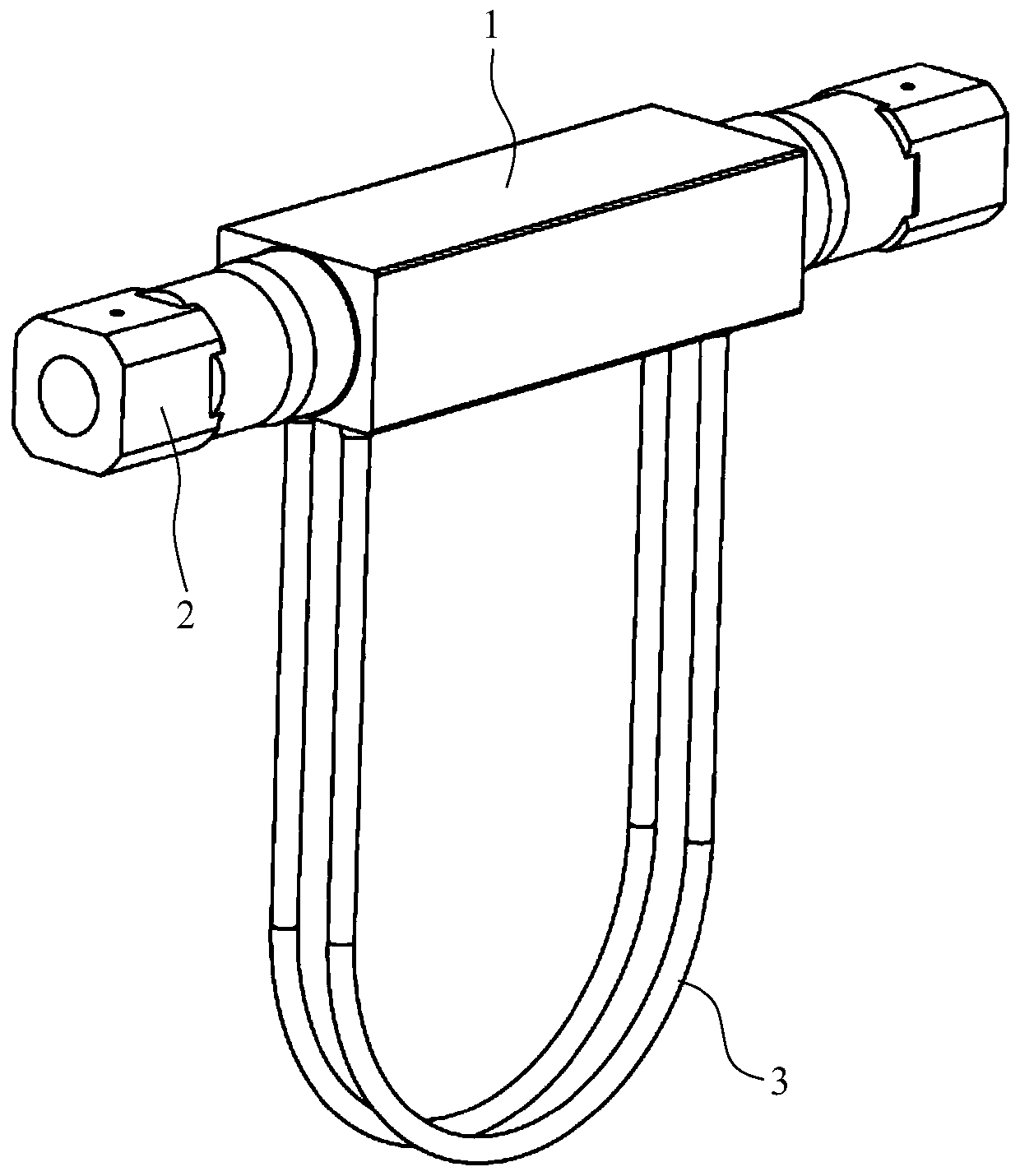

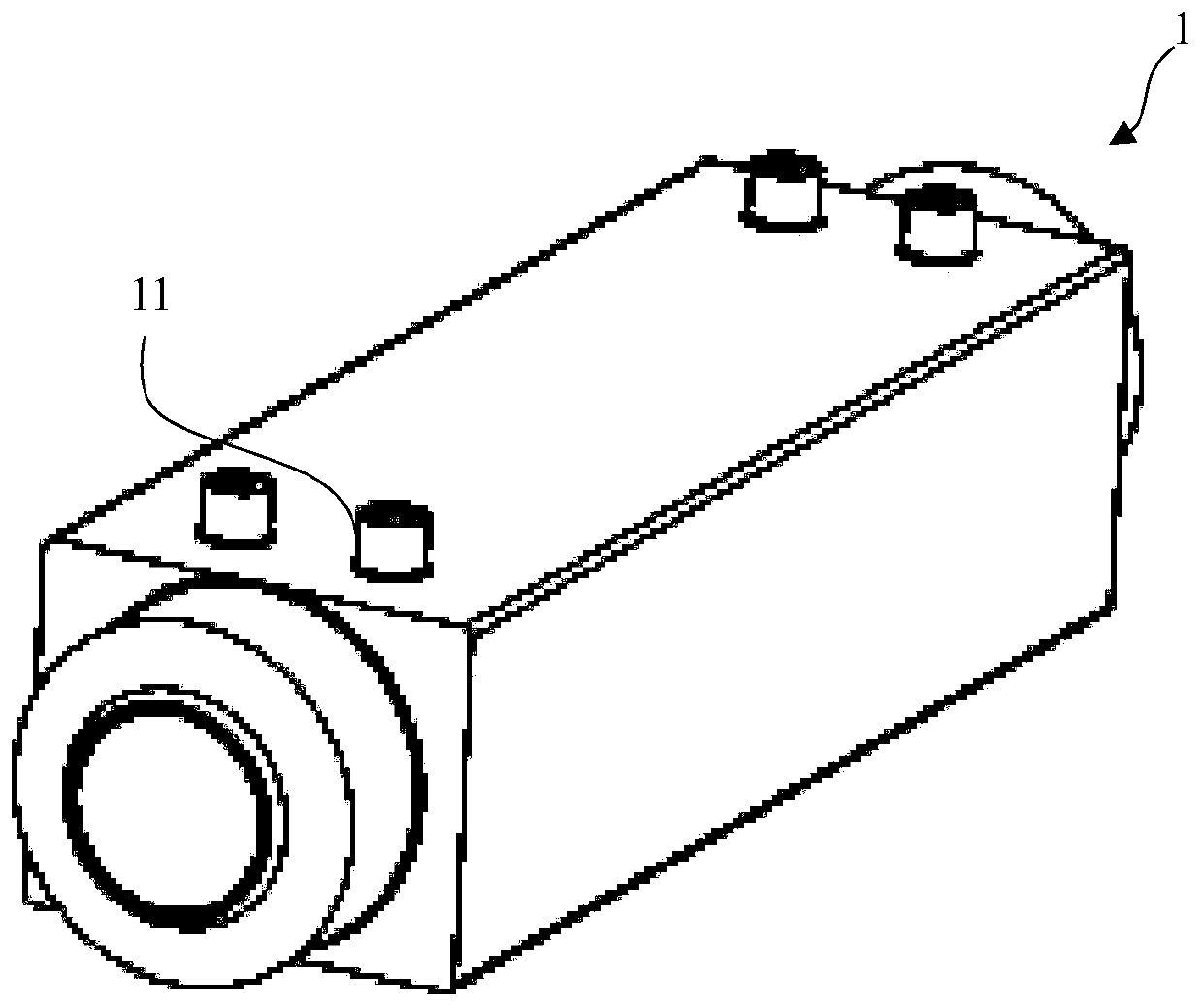

[0030] Figure 6 is a perspective view of a manifold device 100 for a high pressure mass flow meter according to an embodiment of the present invention. Depend on Figure 6 It can be seen that the manifold device 100 includes a rectangular body 110, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com