Plastic steel refractory window

A fire-resistant window and plastic-steel technology, applied to windows/doors, fire-resistant doors, window/door frames, etc., can solve problems such as poor fire resistance of plastic steel, damage to doors and windows, deformation of plastic-steel profiles, etc., to increase fire resistance, maintain integrity, Good fire and smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

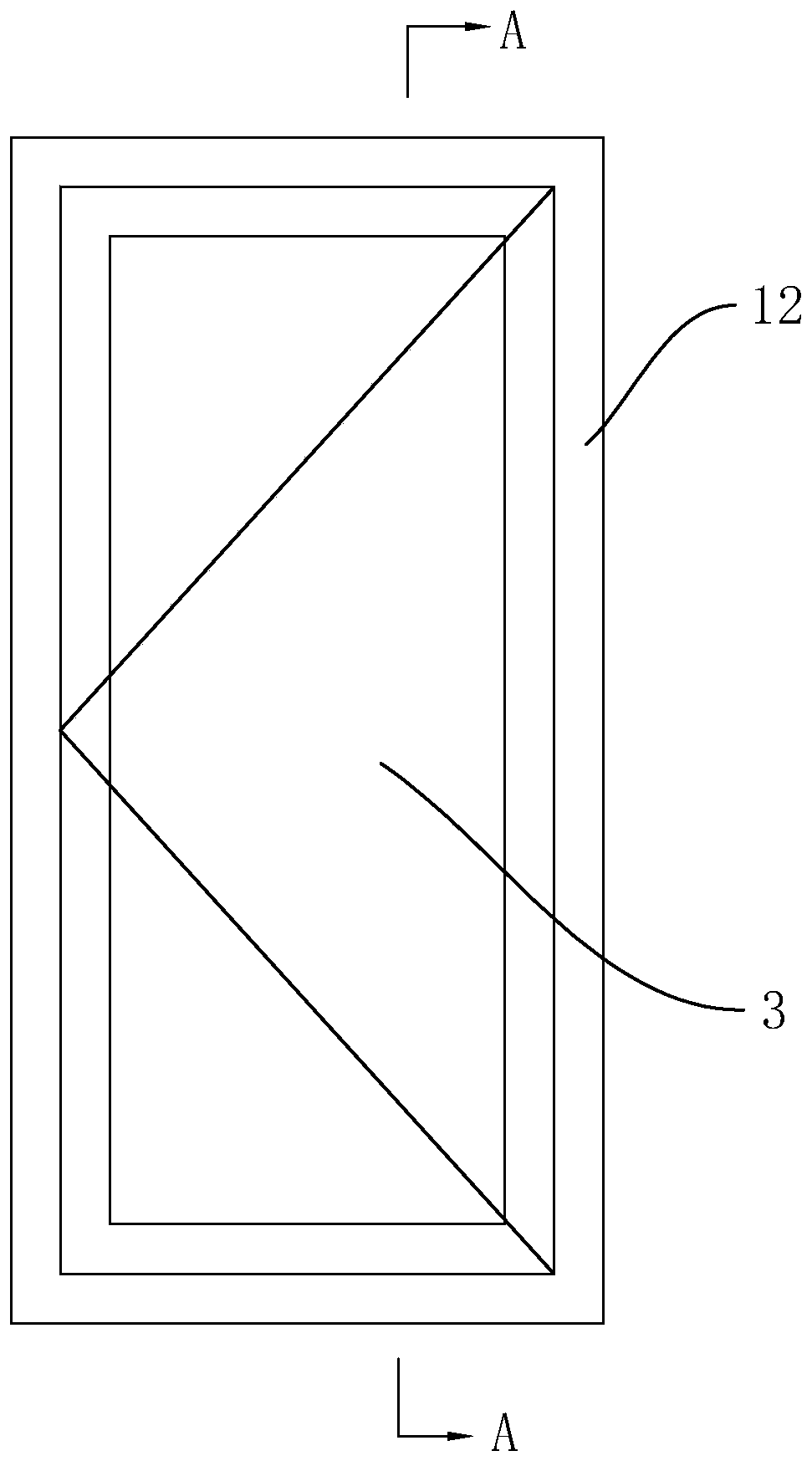

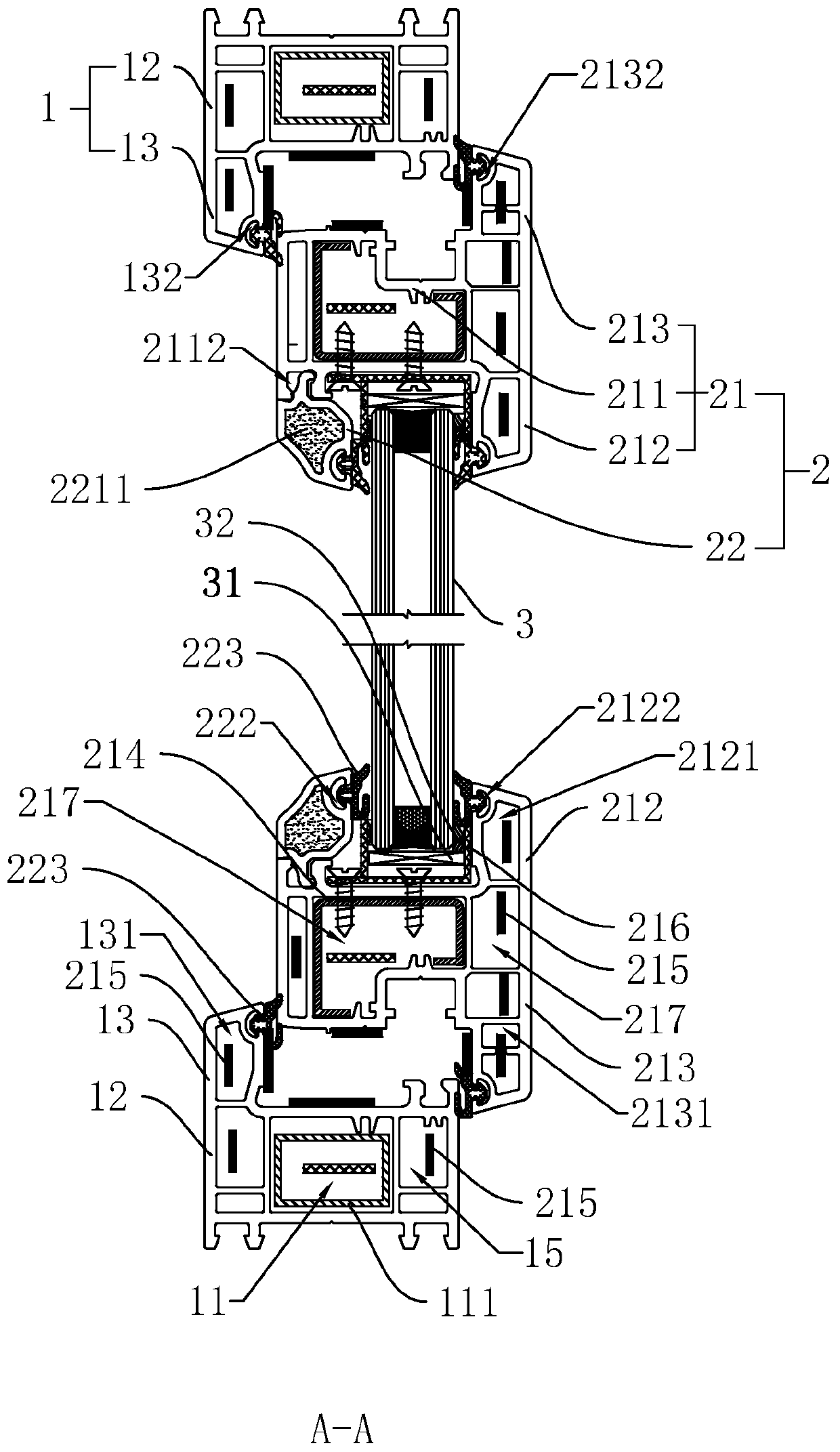

[0036] refer to figure 1 with figure 2 , is a plastic-steel fire-resistant window disclosed by the present invention, comprising a window frame 1, a fan frame 2 and a double-layer fire-resistant glass 3, the double-layer fire-resistant glass 3 is arranged in the fan frame 2, and the fan frame 2 is arranged in the window frame 1. Wherein, the window frame 1 and the fan frame 2 are plastic steel frames.

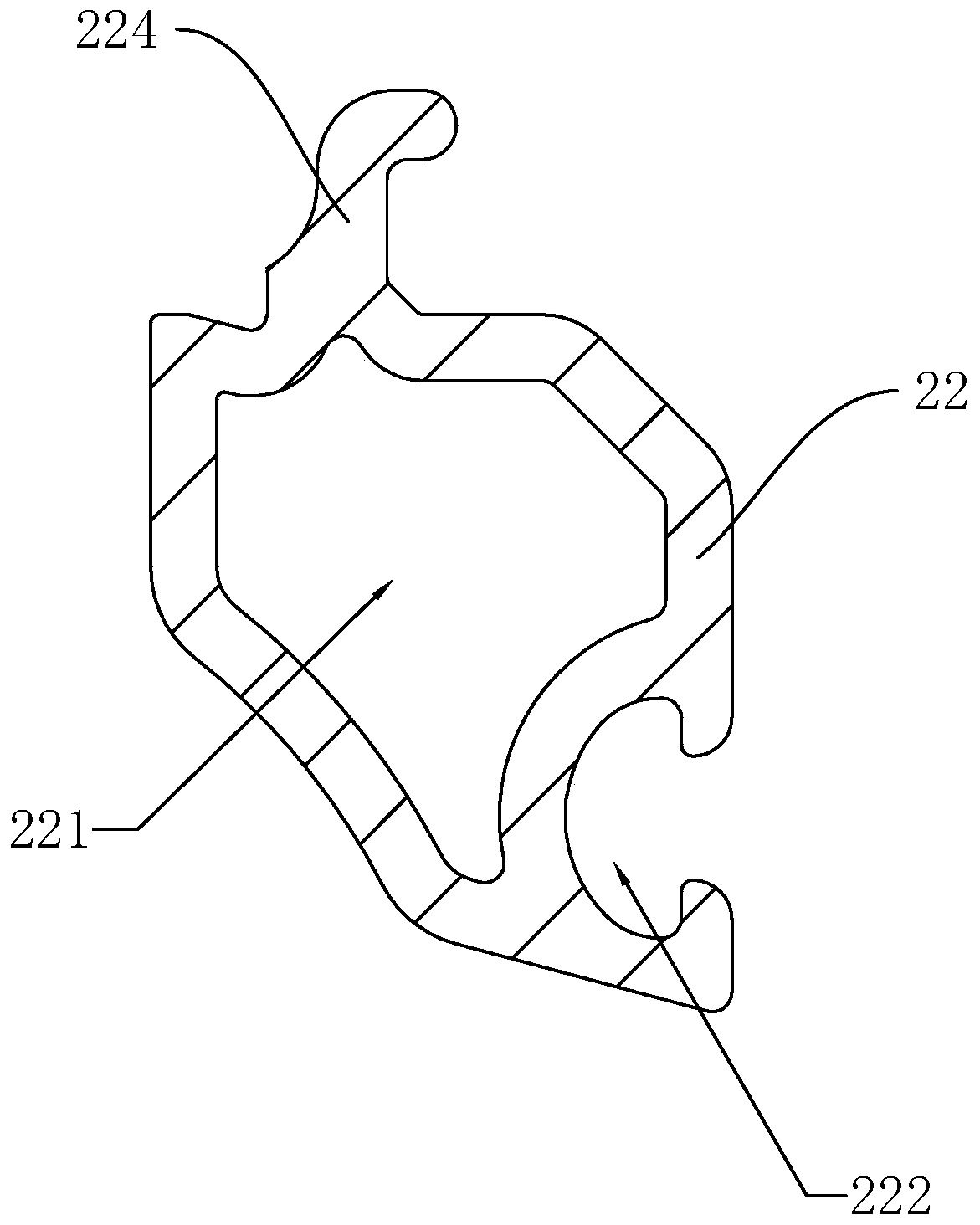

[0037] The fan frame 2 includes a fixed frame one 21 and a clamping frame 22 for clamping the double-layer fire-resistant glass 3, the fixed frame one 21 includes a middle frame one 211, a connecting frame one 212 and a connecting frame two 213, and the connecting frame one 212 and the connecting frame two Frame 2 213 is integrally formed on the edge of the middle frame 1 211 facing the outdoor side, and the connection frame 1 212 and the connection frame 2 213 are respectively located on the side of the middle frame 1 211 facing the center and away from the center. The clam...

Embodiment 2

[0059] refer to Figure 4 The difference from the first embodiment is that the frame 12 and the middle frame one 211 are respectively formed with bayonet five 121 and bayonet six 2111 with a C-shaped cross-section on the opposite side, and a refractory alloy is arranged between the frame 12 and the middle frame one 211 Strip 14, the refractory alloy strip 14 extends along the length direction of the frame 12, the refractory alloy strip 14 has an I-shaped cross section perpendicular to its length direction, and the two ends of the I-shaped refractory alloy strip 14 are respectively snapped into bayonet five 121 and bayonet six 2111; the two ends of the refractory alloy strip 14 I are fixedly connected with a plurality of metal column buckles 141 made of refractory metal, and the plurality of metal column buckles 141 are distributed along the length direction of the refractory alloy strip 14 , the clamping ends of the plurality of metal column buckles 141 are respectively pierce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com