Coal mine hydraulic slag discharge drilling coal slag separation and conveying device

A conveying device and slag-water separation technology, which is applied in the directions of transportation and packaging, earth-moving drilling, underground transportation, etc., can solve the problems of increasing the labor cost of coal mine production, affecting the standardized image of the mine, and the labor intensity of cleaning work, and achieving a simple structure. , the effect of reducing labor intensity and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

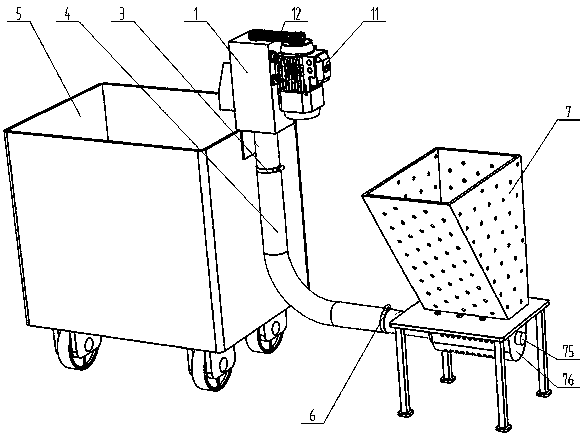

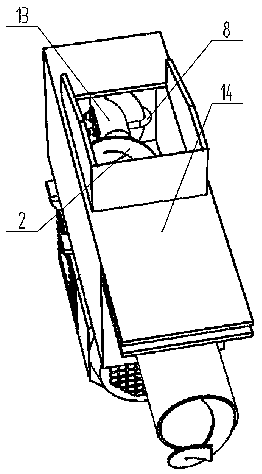

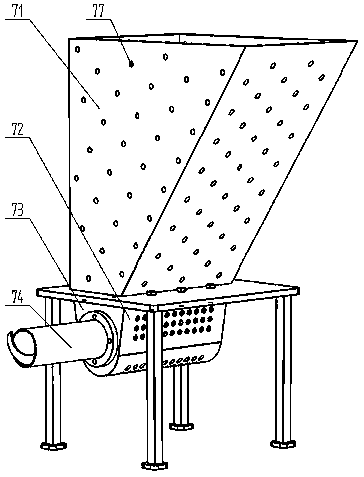

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the coal mine hydraulic slag discharge drilling coal slag separation conveying device includes a driving unloading part 1, a flexible shaftless spiral blade 2, a rubber hose 4 and a slag-water separation collection box 7; wherein, the driving unloading part 1 is composed of Power source 11, belt transmission mechanism 12, drive shaft 13 and discharge chute 14; slag-water separation collection box 7 consists of sieve plate funnel 71, U-shaped collection chute 72, side plate 73, support side plate 76, connecting pipe 74 and end shaft 75 form.

[0015] The discharge chute 14 of the drive discharge part 1 is composed of a rectangular trough 146, a discharge port 142, a transition pipe 144 and a fixed slot 143; the center position of the top plate 141 of the rectangular trough 146 along the length direction has The shaft hole 147, the transition tube 144 runs through the center of the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com