Rotary compressor with pump body lubricating structure and air conditioner

A technology of rotary compressor and lubricating structure, applied in the field of compressors, can solve the problems of insufficient lubrication of friction pairs, increased wear, and reduced performance of the compressor, so as to improve performance and reliability, reduce wear, and improve assembly clearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present application is further described in conjunction with the following examples.

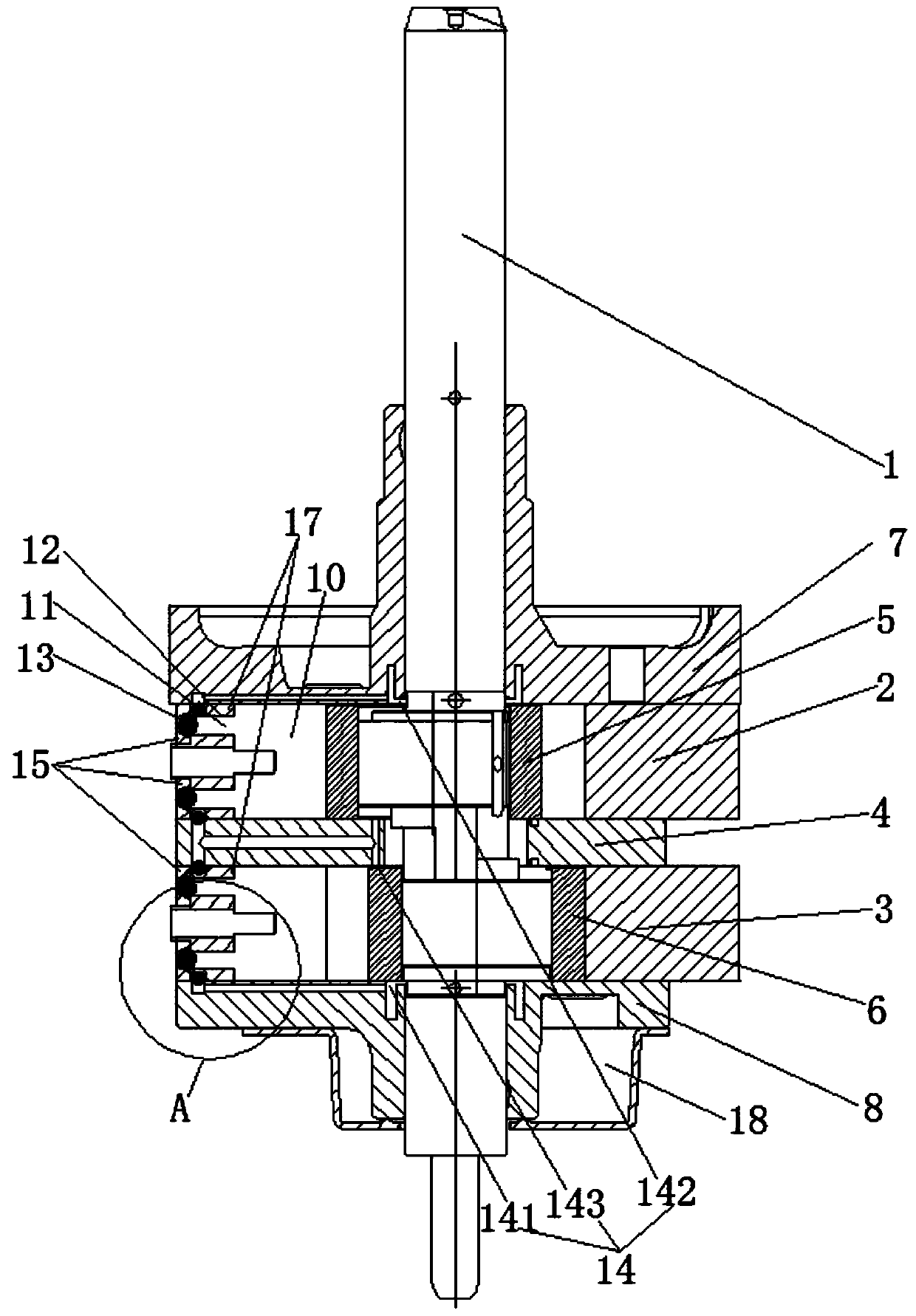

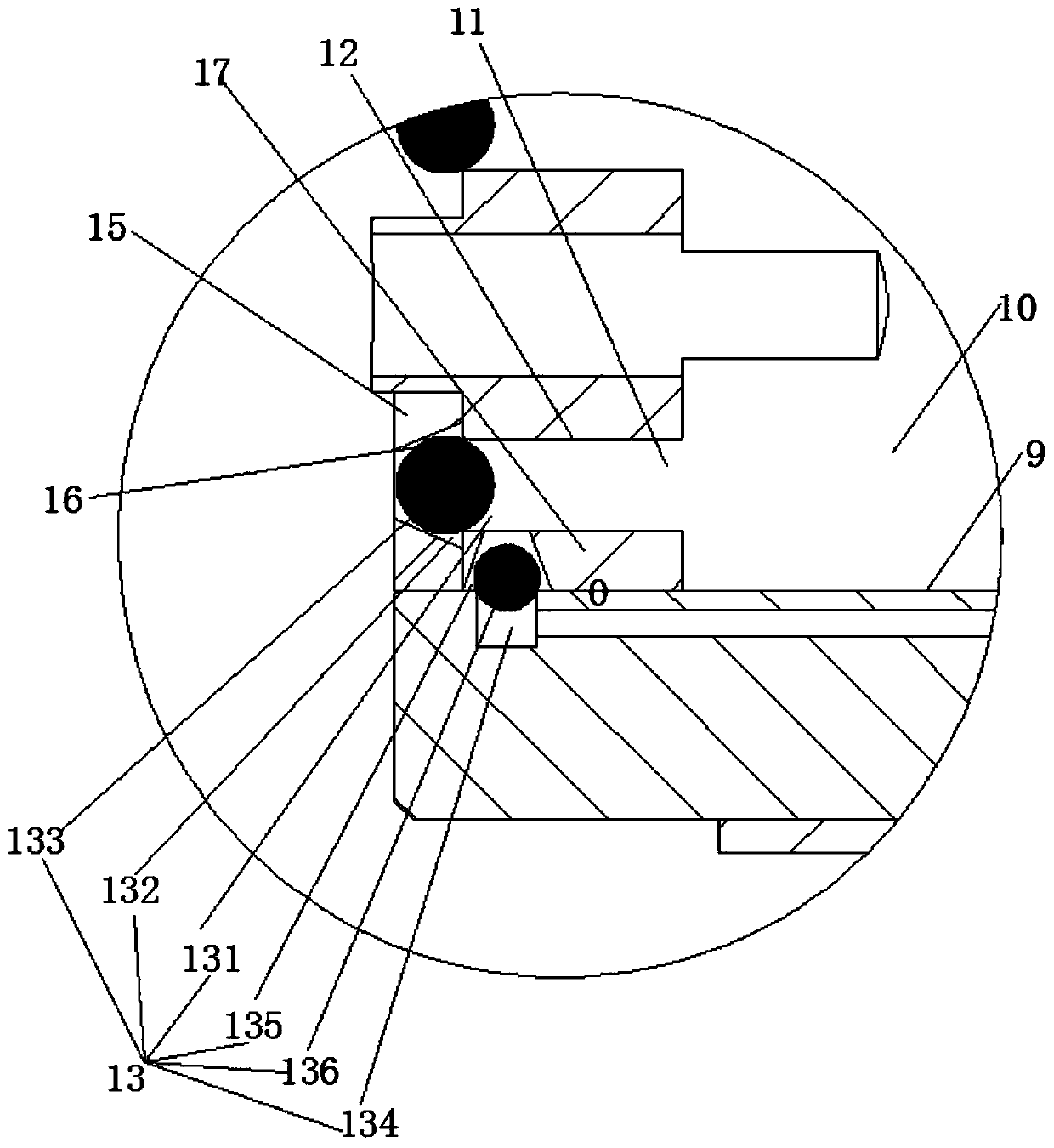

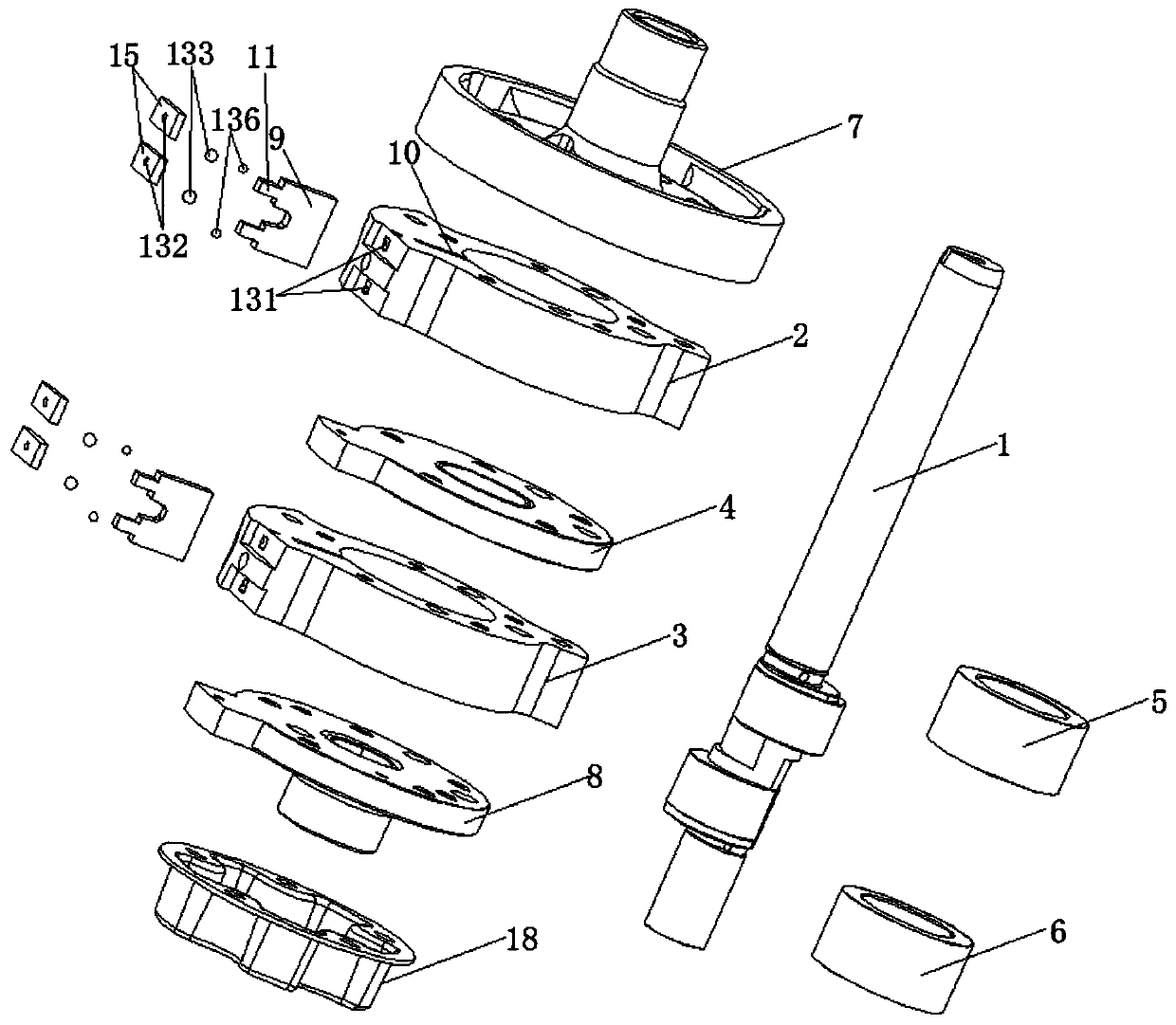

[0048] Such as Figure 1 to Figure 8 , a rotary compressor with a pump lubricating structure, comprising a crankshaft 1, an upper cylinder 2, a lower cylinder 3, a separator 4, an upper roller 5, a lower roller 6, an upper flange 7 and a lower flange 8; The rotary compressor with pump lubricating structure also includes sliding vane 10 , groove 9 , sliding vane 10 , reciprocating piston 11 , reciprocating closed cavity 12 , one-way on-off structure 13 and oil guiding groove 14 . Wherein, the upper cylinder 2 and the lower cylinder 3 are all provided with the slide plate 10 groove 9; the slide plate 10 is arranged in the slide plate 10 groove 9 and can reciprocate along the slide groove; The upper and lower sides of the rear end of the sheet 10 are provided with the reciprocating piston 11; The reciprocating closed cavity 12; each of the one-way on-off structures 13 communicates ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap