Fiber laser power control method and device

A fiber laser and power control technology, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as inaccurate adjustment, and achieve the effects of precise adjustment, high adjustment accuracy, and accurate output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

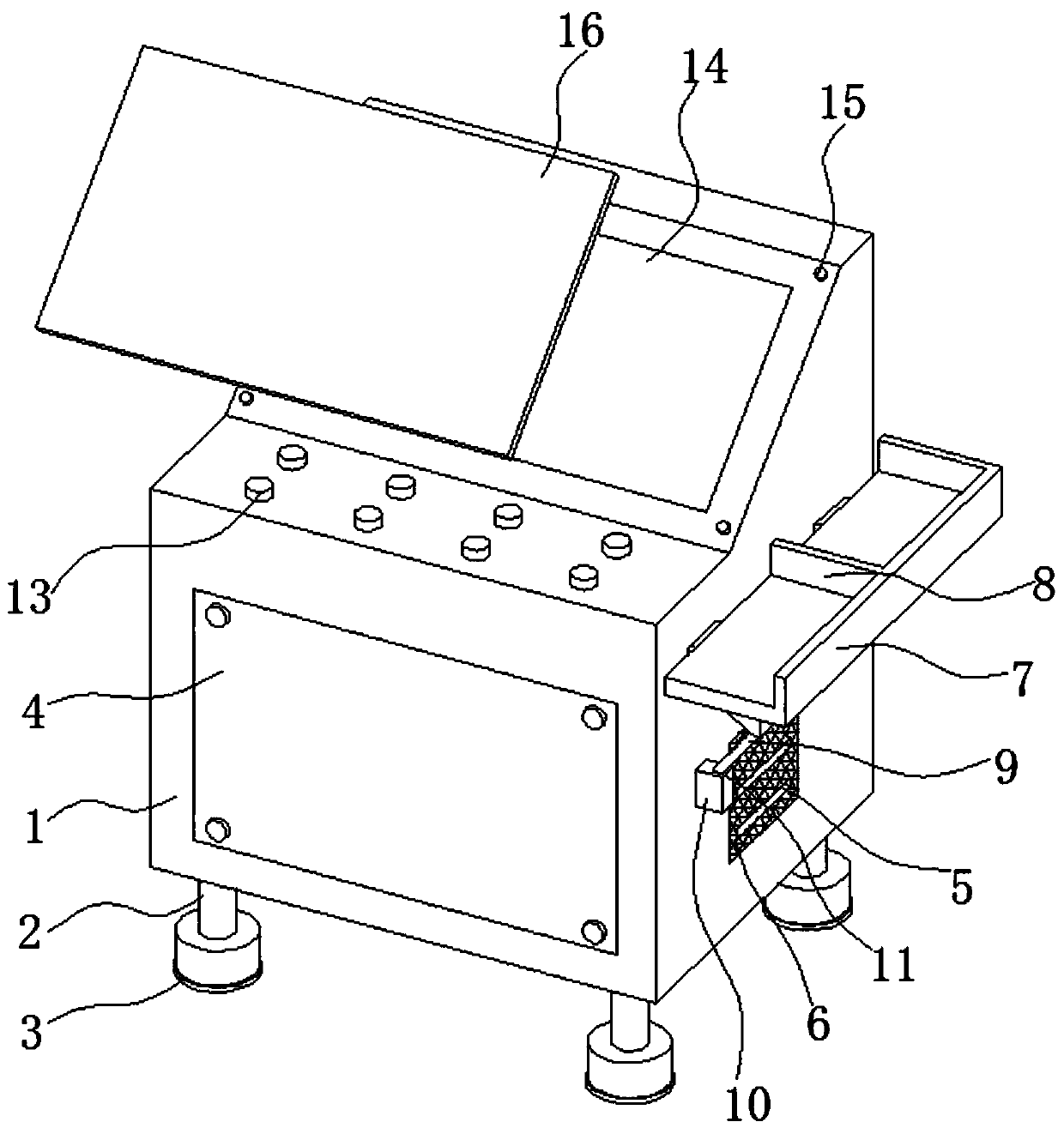

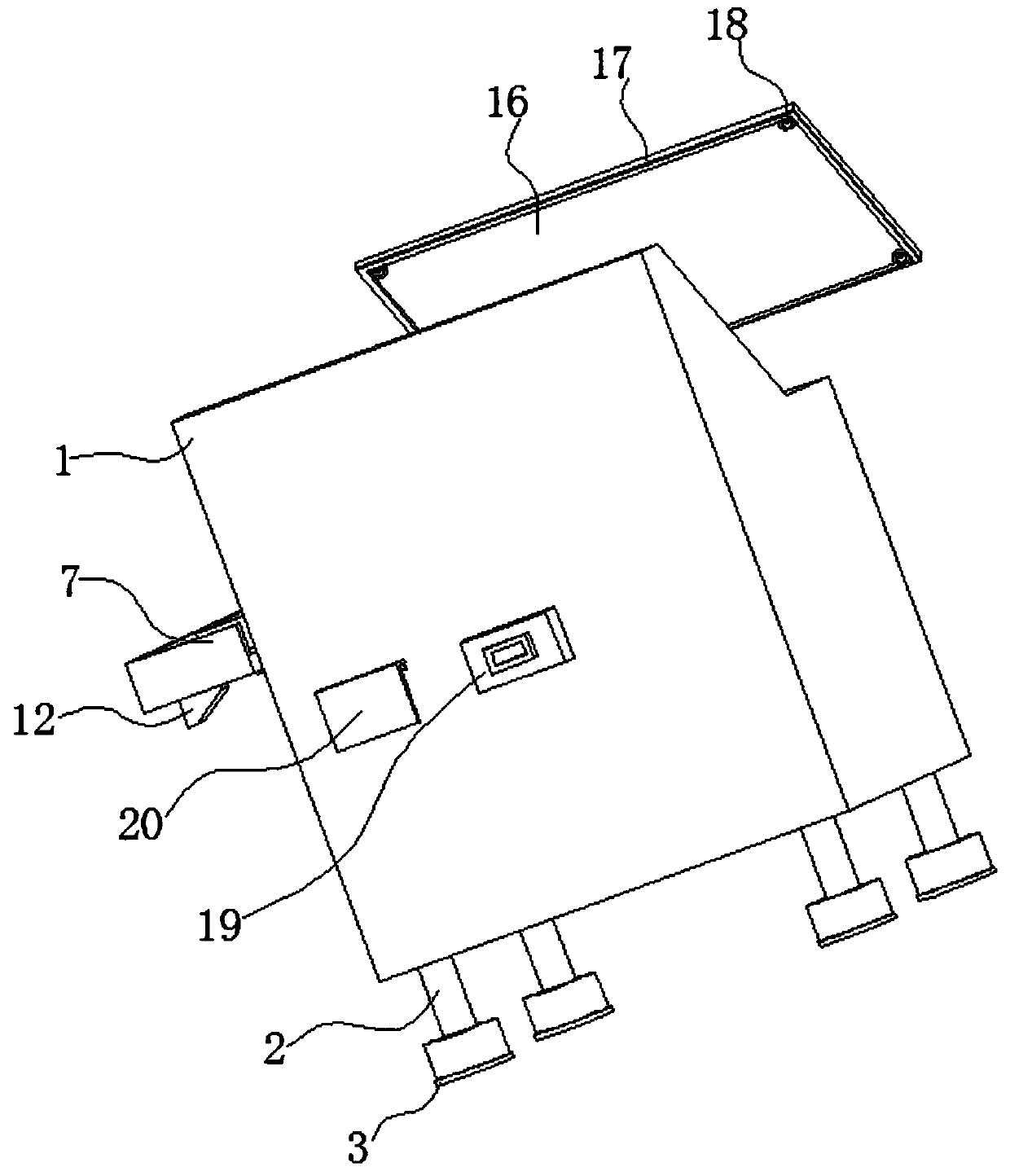

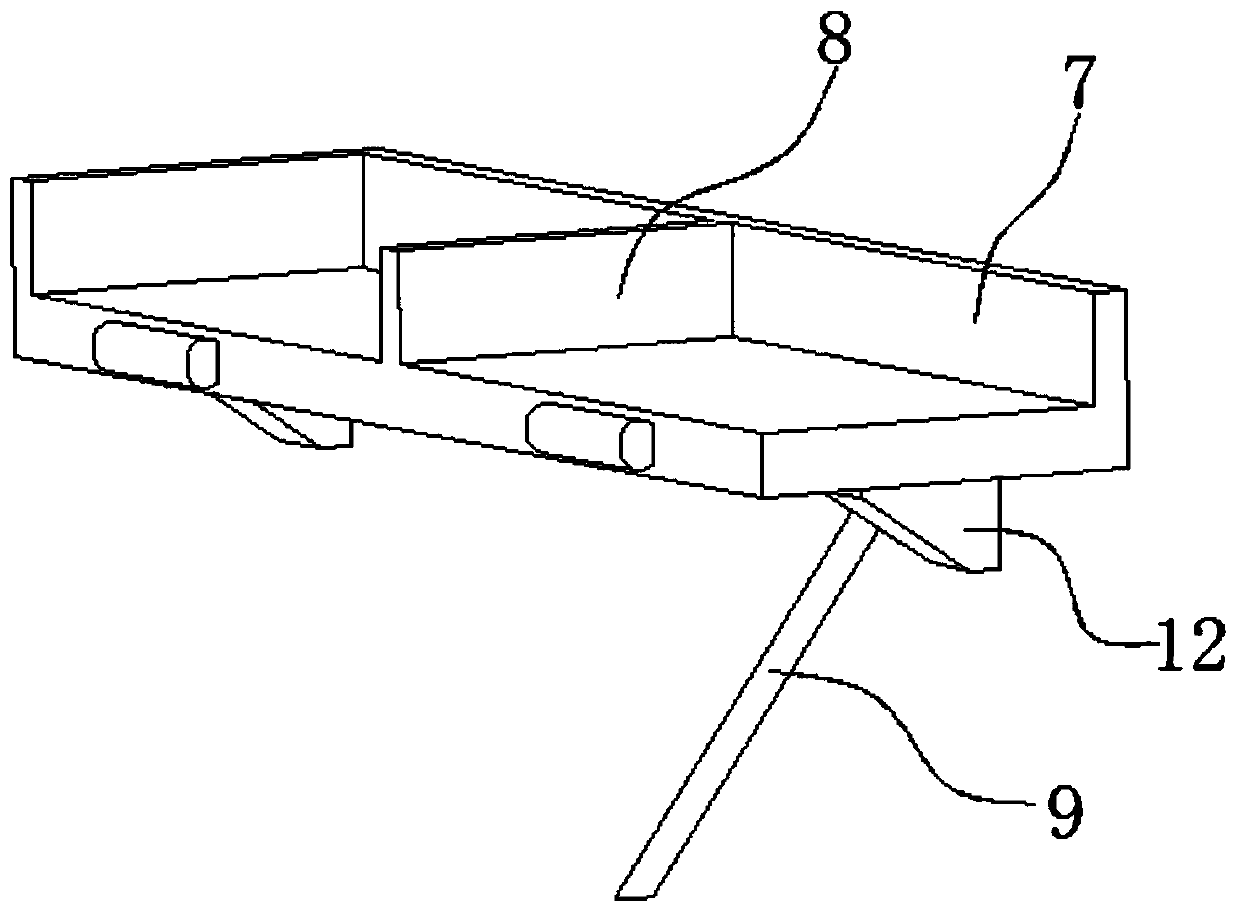

[0026] refer to Figure 1-4 , a fiber laser power control device, comprising a housing 1, the bottom end of the housing 1 is connected with several support mechanisms, the function of the support mechanism is to support the housing 1, the housing 1 is fixedly connected with an access panel 4, the access panel The function of 4 is to facilitate the maintenance of the internal mechanism of the shell 1. The control component is connected to the shell 1. The control component includes a processor, and the signal of the processor is connected to a conversion module. The function of the conversion module is to convert electrical signals into digital signals, convert The module signal is connected with a receiving module, the function of the receiving module is to receive the data transmitted by the fiber laser, the processor signal is connected with an adjustment module, the function of the adjustment module is to adjust the output power of the fiber laser, the processor signal is co...

Embodiment 2

[0034] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the support mechanism includes a support foot 2, the support foot 2 is connected to the housing 1, and the bottom end of the support foot 2 is fixedly connected with an anti-slip pad 3, and the bottom of the anti-slip pad 3 The effect is to increase the frictional force between the support foot 2 and the ground, and the anti-skid pad 3 is a rubber pad.

Embodiment 3

[0036] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the housing 1 is provided with a cooling hole 5, the cooling hole 5 is fixedly connected with a dust-proof net 6, and the upper end of the housing 1 is connected with a fixing mechanism, The effect of fixing mechanism is to fix transparent plate 16, and fixing mechanism is connected with transparent plate 16, and the effect of transparent plate 16 is to protect display screen 14, and transparent plate 16 is a glass plate, and sealing ring 17 is fixedly connected on transparent plate 16, and sealing ring 17 The function is to seal the gap between the transparent plate 16 and the housing 1, one side of the sealing ring 17 squeezes the housing 1, the fixing mechanism includes several connecting seats 15, the connecting seats 15 are fixed on the housing 1, and the transparent plate 16 is fixedly connected with several connectors 18, and the connectors 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com