Bragg reflector vertical cavity surface emitting semiconductor laser distributed on asymmetric annular structure

A technology of Bragg reflector and ring structure, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as device technology, achieve device process simplification, and avoid process damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

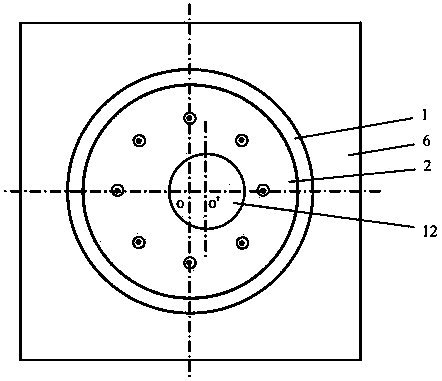

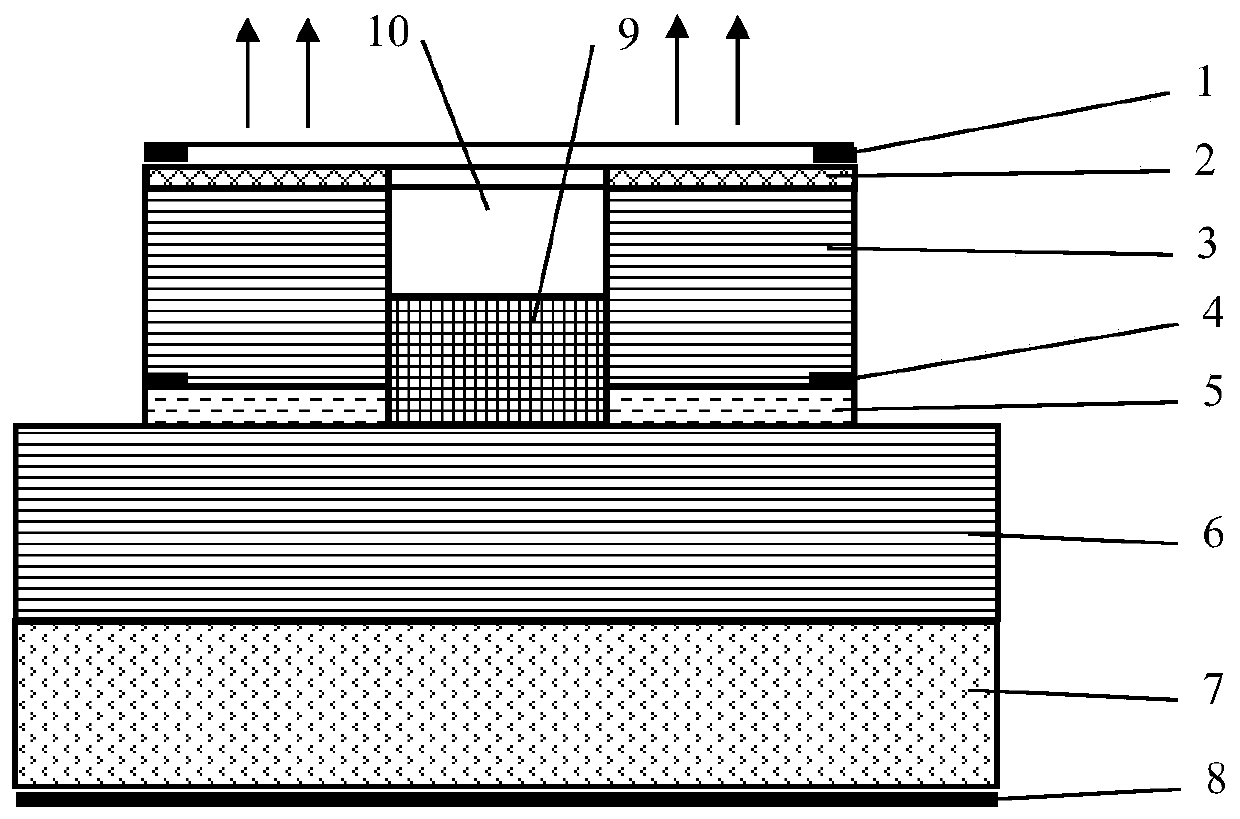

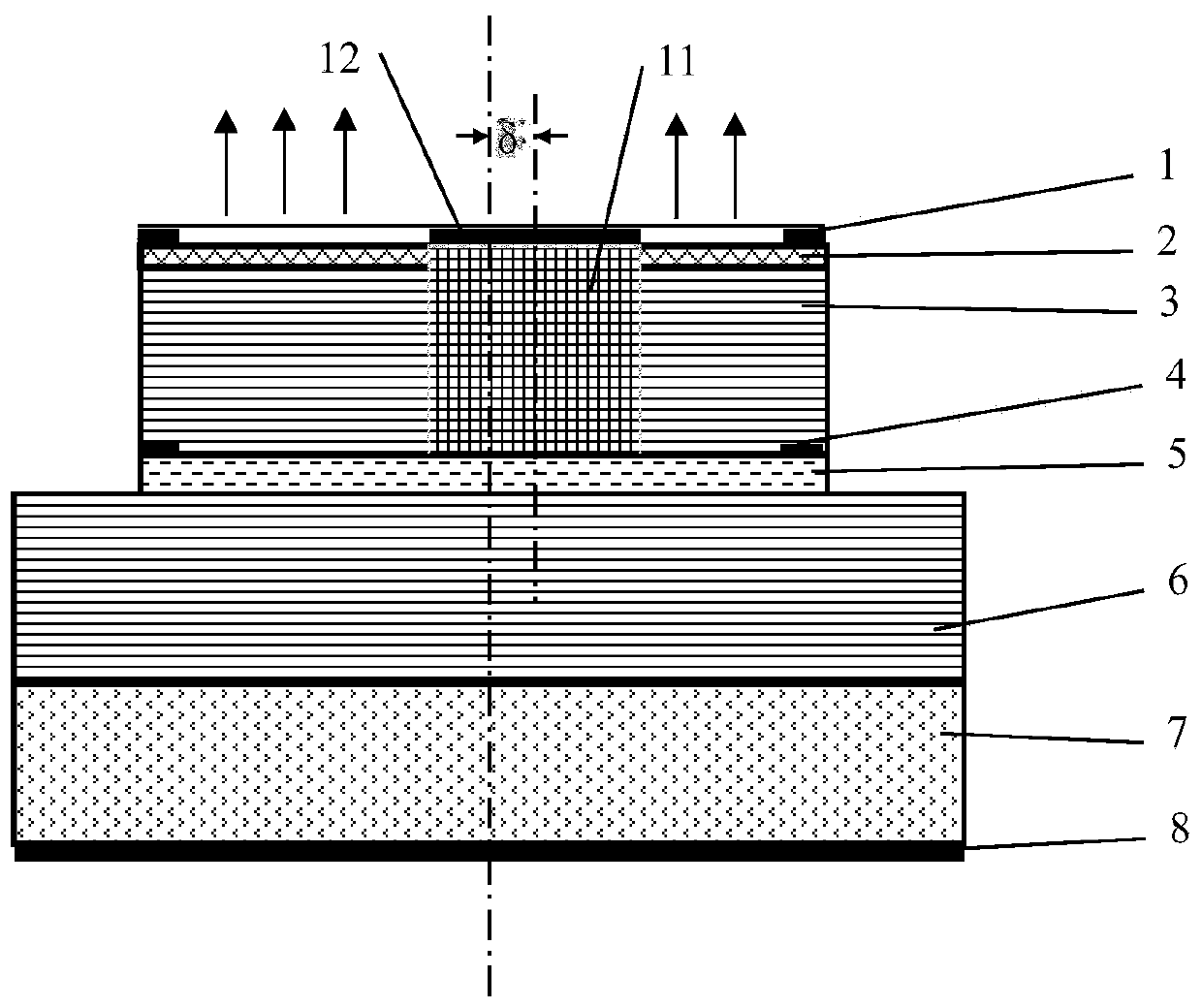

[0013] In the asymmetric annular structure distributed Bragg mirror vertical cavity surface emitting semiconductor laser of the present invention, the upper electrode 1, the ohmic contact layer 2, the upper distributed Bragg reflector 3, the oxide confinement layer 4, the active gain region 5, the lower The distributed Bragg reflector 6, the substrate 7, and the lower electrode 8 are arranged coaxially along the main axis of the device sequentially from top to bottom, as shown in figure 2 , image 3 shown. The material of the upper electrode 1 is Ti / Pt / Au, which is layered and then alloyed; the material of the ohmic contact layer 2 is GaAs; the material of the upper distributed Bragg reflector 3 is P-type Al 0.1 Ga 0.9 As / Al 0.8 Ga 0.2 As; the material of the oxide confinement layer 4 is Al 2 o 3 The material of the active gain region 5 is GaAs / AlGaAs; the material of the lower distributed Bragg reflector 6 is N-type Al 0.1 Ga 0.9 As / Al 0.8 Ga 0.2As; the material of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com