Hard-core cable breakpoint detection and repair device

A technology for breakpoint detection and cables, which is applied to measuring devices, equipment for connecting/terminating cables, measuring electricity, etc., can solve problems such as cable disconnection, large space occupation, and impractical devices, so as to improve work efficiency and shape Small size, material and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

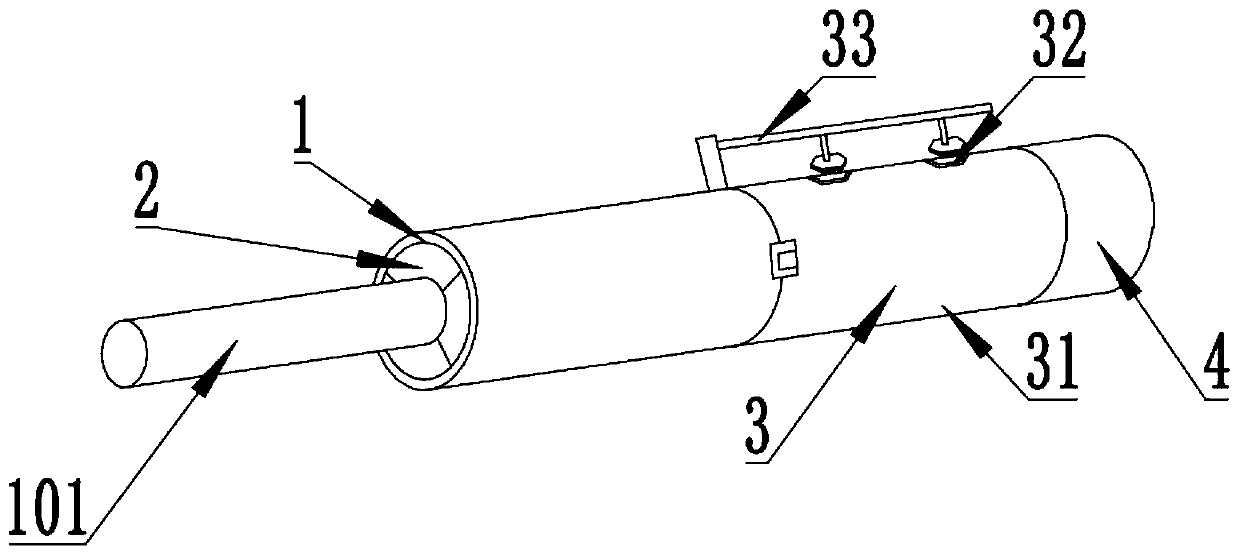

[0038] As an embodiment, the crimping mechanism 3 includes a crimping tube 31, which forms a detachable connection with the housing 1. The crimping tube 31 is provided with fastening bolts 32, and the outside of the crimping tube 31 is provided with a fastener 33. The fastener 33 is used to fasten the fastening bolt 32 , and the fastener 33 is connected with the housing 1 . The crimping tube 31 can be replaced after each use, and the fastening bolt 32 and the fastener 33 can fasten the wire core of the spare cable 241 and the wire core of the cable 101 to be tested in the crimping tube 31 .

[0039] As an embodiment, the crimping tube 31 is connected to the housing 1 through a lock, and when the lock is opened, the crimping tube 31 falls off from the housing 1 .

[0040] As an embodiment, both ends of the crimping tube 31 are covered with heat-shrinkable tubes, and one side of the fastener 33 is also connected to a heating part 4. The heating part 4 is used to heat the heat-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com