Forced lithium battery charger

A lithium battery and charger technology, applied in battery circuit devices, current collectors, charging/discharging current/voltage regulation, etc., can solve the problems of unsatisfactory charging, slow charging speed, etc., to increase charging speed, reduce charging time, improve The effect of charge saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0022] Example 1:

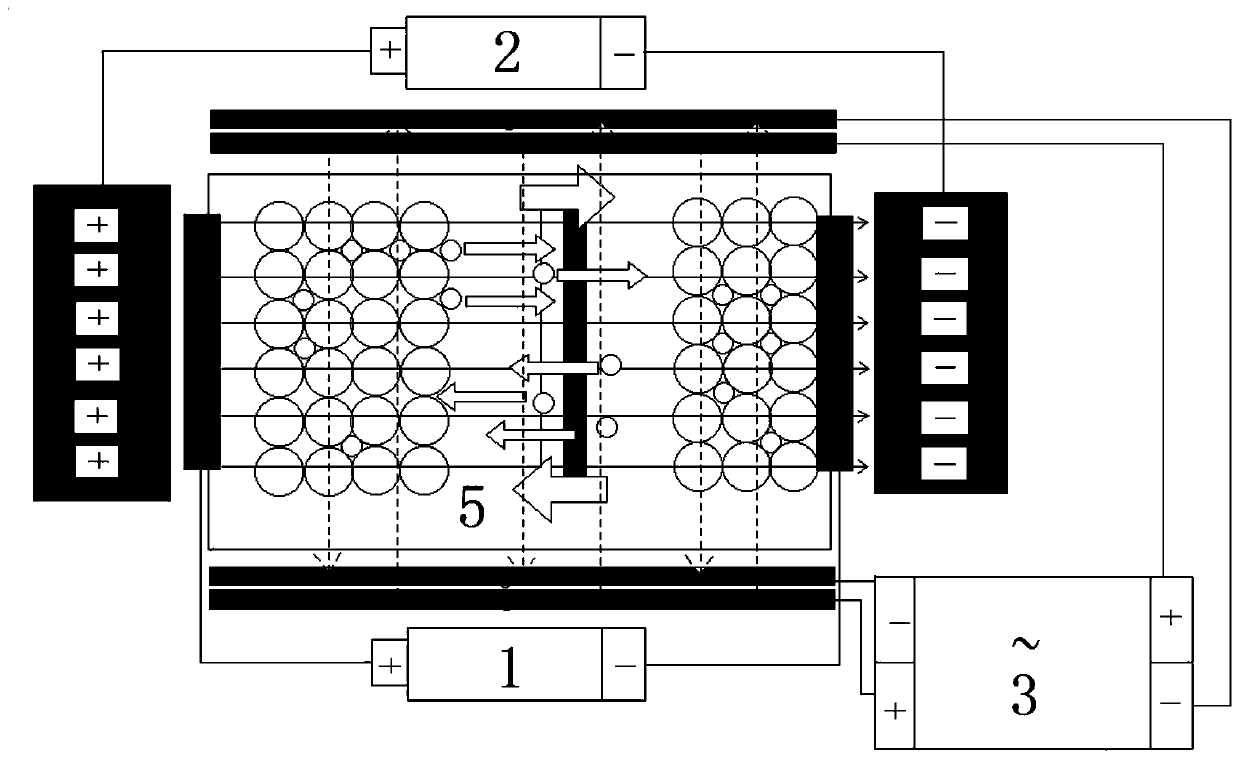

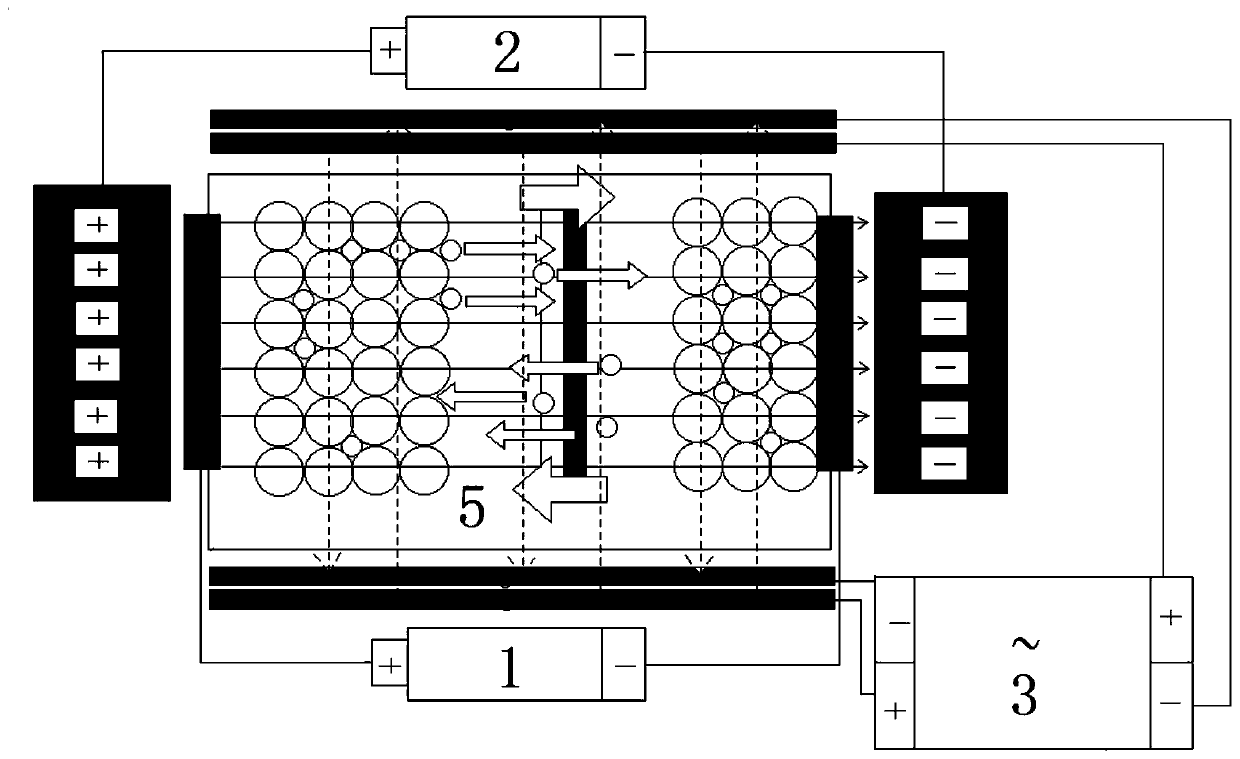

[0023] Existing lithium battery chargers use simple positive and negative poles to charge the lithium battery 5. Due to battery resistance and other reasons, the charging speed is slow, and the congestion at the negative pole makes the charging speed slow and the charging capacity is not enough.

[0024] The present invention reduces the resistance of the original charging electrode 1 ( figure 1 ), to speed up the charging speed and reduce...

Embodiment 2

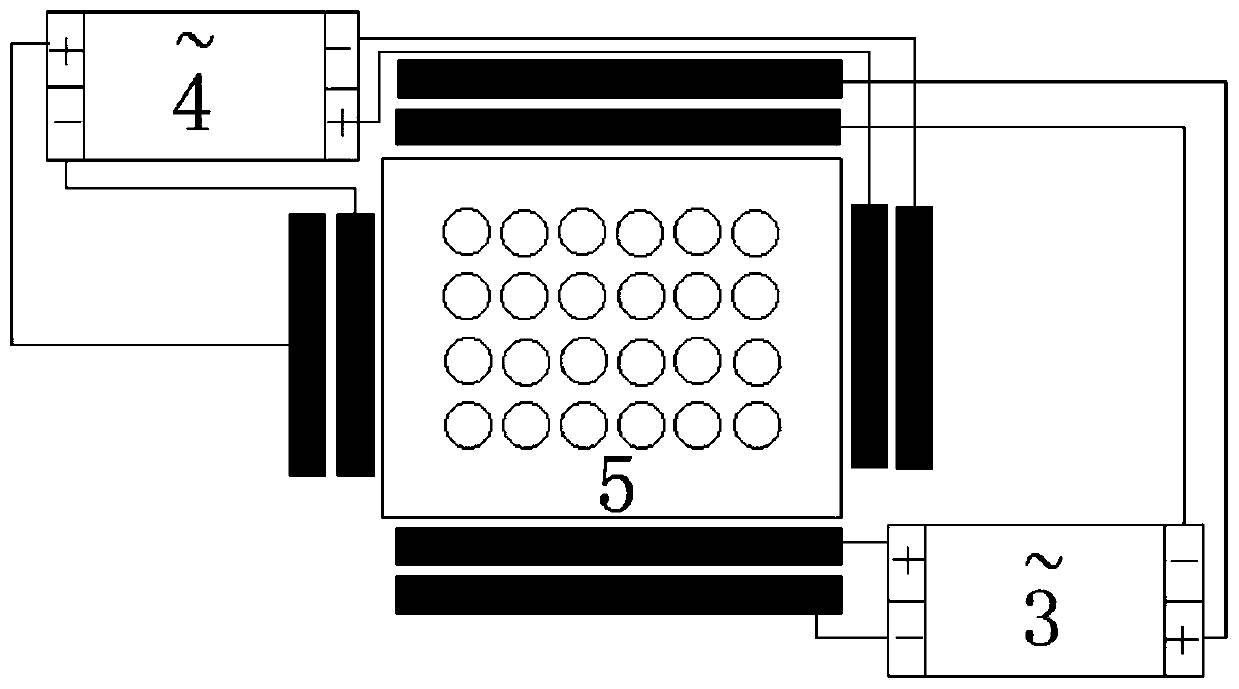

[0031] In the existing lithium battery charger, the lithium battery 5 is located between the original charging poles 1, the original charging pole 1 applies a common charging electric field 1-1 to the lithium battery 5, and the two sides of the polymer diaphragm in the middle of the lithium battery 5 are respectively provided with The positive electrode material and the negative electrode material, the positive plate of the original charging electrode 1 is arranged on the outside of the positive electrode material of the battery, the negative electrode plate of the original charging electrode 1 is arranged on the outside of the negative electrode material of the battery, when the original charging electrode 1 is energized, the lithium battery 5 is charged, and the positive electrode material ( LiCoO 2 ) Lithium ions in the negative electrode material slowly pass through the polymer membrane to form a charging process; on the contrary, lithium ions in the negative electrode mate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap