Storage device electrode, storage device and manufacturing method of storage device electrode

A manufacturing method and technology for accumulators, which are applied in electrode manufacturing, battery electrodes, electrical components, etc., to achieve the effect of not easy to wrinkle or warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The electrode for an electrical storage device of the present invention will be described below using the drawings, but the electrode for an electrical storage device of the present invention is not limited to the description below.

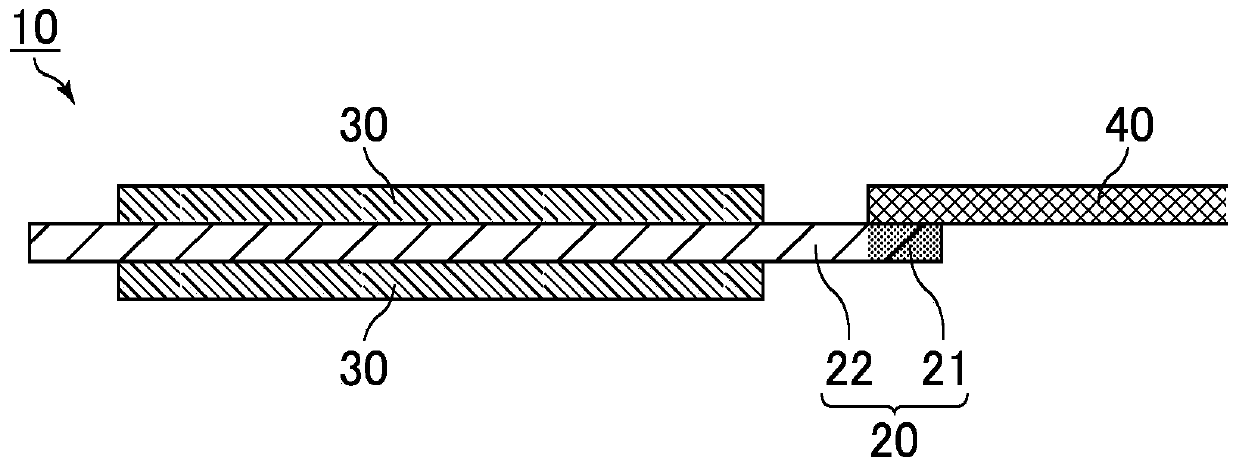

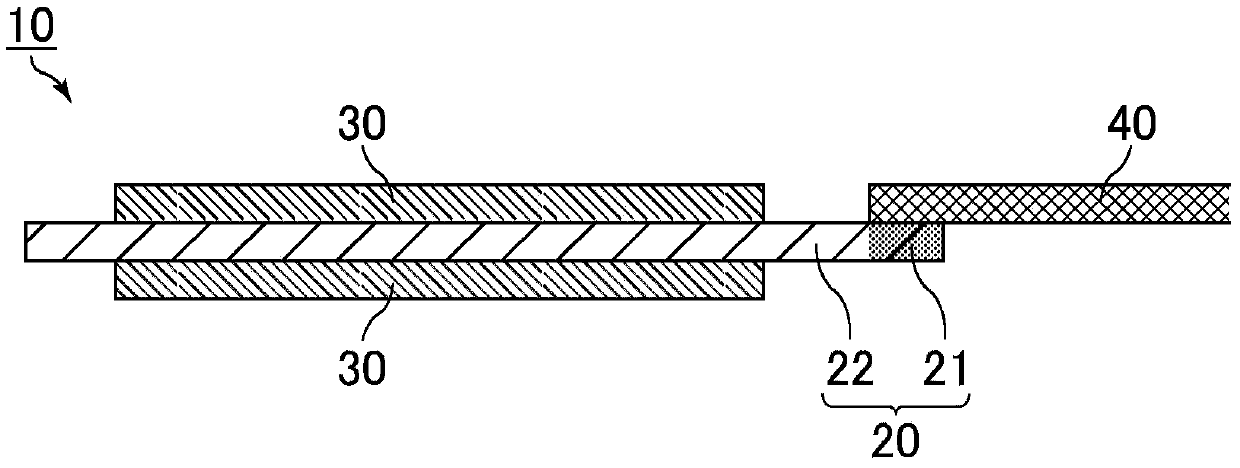

[0068] figure 1 It is a cross-sectional view schematically showing an example of the electrode for an electrical storage device of the present invention.

[0069] like figure 1 As shown, the electrode 10 for an electrical storage device includes a current collector plate 20 , electrode portions 30 formed on both surfaces of the current collector plate 20 , and lead wires 40 connected to ends of the current collector plate 20 .

[0070] In addition, the lead-out part 21 and the main body part 22 are formed of the same quality stainless steel.

[0071] In addition, the stainless steel forming the current collector plate 20 is austenitic stainless steel including a martensitic structure.

[0072] In addition, the electrode portion 30 conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com