Brown soybean milk and preparation method thereof

A soy milk and brown technology, applied in dairy products, milk substitutes, applications, etc., to achieve the effect of harmonious valley flavor, strong bean flavor, and full taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0067] This embodiment provides a brown soy milk, which is prepared by the following steps:

[0068] The preparation process of soy milk is the same as in Example 1;

[0069] Soymilk blending and browning:

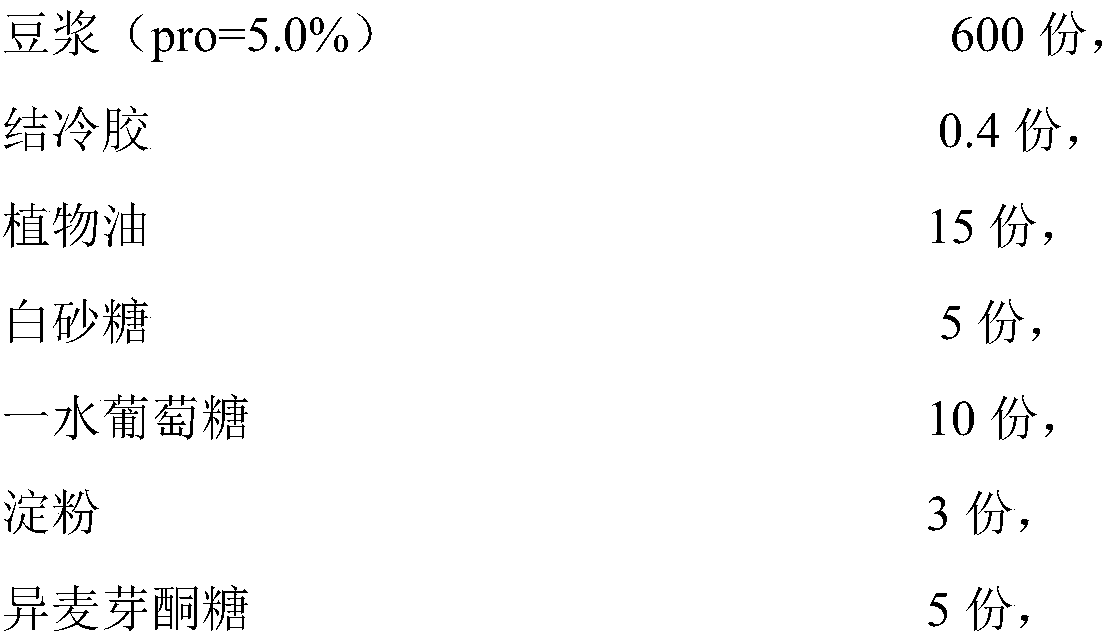

[0070] Various raw materials are mixed with each other to obtain soy milk, based on 1000 parts by weight, the soy milk in this embodiment includes the following raw materials by weight:

[0071]

[0072] The balance is water.

[0073] Homogenize the soymilk prepared above (the homogenization pressure is 160bar at the first stage and 50bar at the second stage), and then browned at 90℃ for 5h;

[0074] The brown soy milk is homogenized twice (first-stage pressure 200bar, second-stage pressure 50bar), and then subjected to ultra-high temperature sterilization (temperature is 137℃, time is 4 seconds) to obtain a typical browning reaction flavor Soy milk products.

Embodiment 3

[0076] The preparation process of soy milk is the same as in Example 1.

[0077] Soy milk blending and browning:

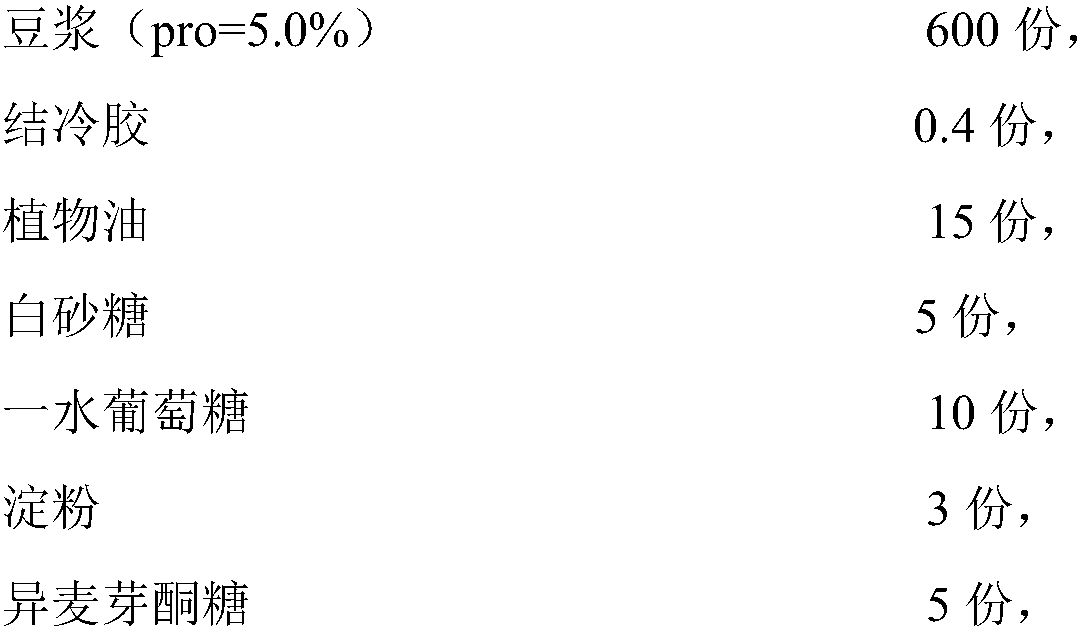

[0078] Various raw materials are mixed with each other to obtain soy milk, based on 1000 parts by weight, the soy milk in this embodiment includes the following raw materials by weight:

[0079]

[0080]

[0081] The balance is water.

[0082] Homogenize the soymilk prepared above (the homogenization pressure is 250bar at the first level and 50bar at the second level), and then browned for 2h at 98°C;

[0083] The brown soy milk is homogenized twice (first-stage pressure 200bar, second-stage pressure 50bar), and then subjected to ultra-high temperature sterilization (temperature is 137℃, time is 4 seconds) to obtain a typical browning reaction flavor Of soy milk products.

[0084] Sensory analysis:

[0085] According to the ranking method of GBT12315-2008 sensory analysis method, the samples of the above three examples were ranked and analyzed, and the scores from good to ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com