Atomizer

An atomizer and atomization component technology, applied in the field of atomizers, can solve the problems of atomized liquid leakage, easy to absorb impurities and heat dissipation effect, and achieve the effect of good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

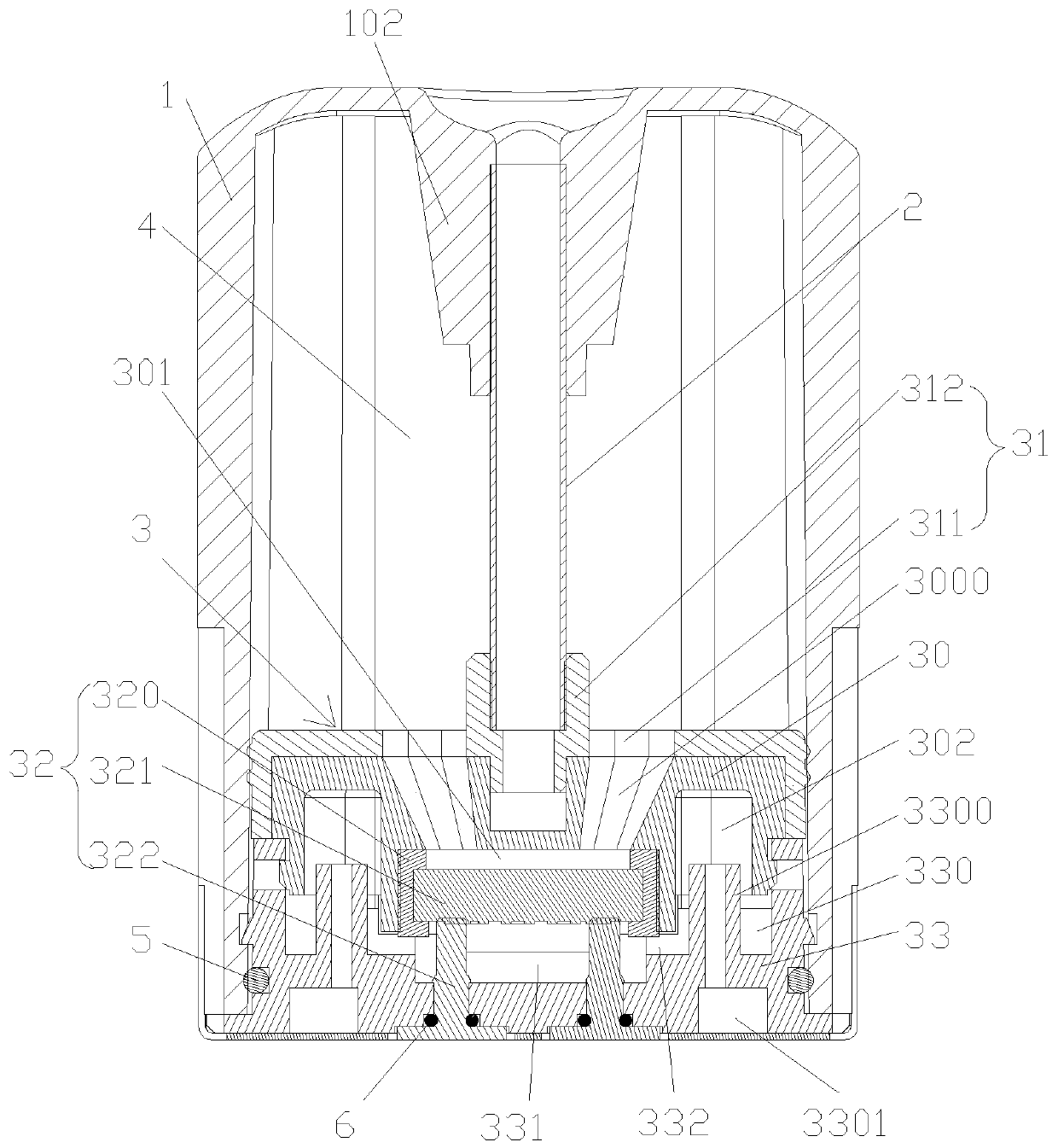

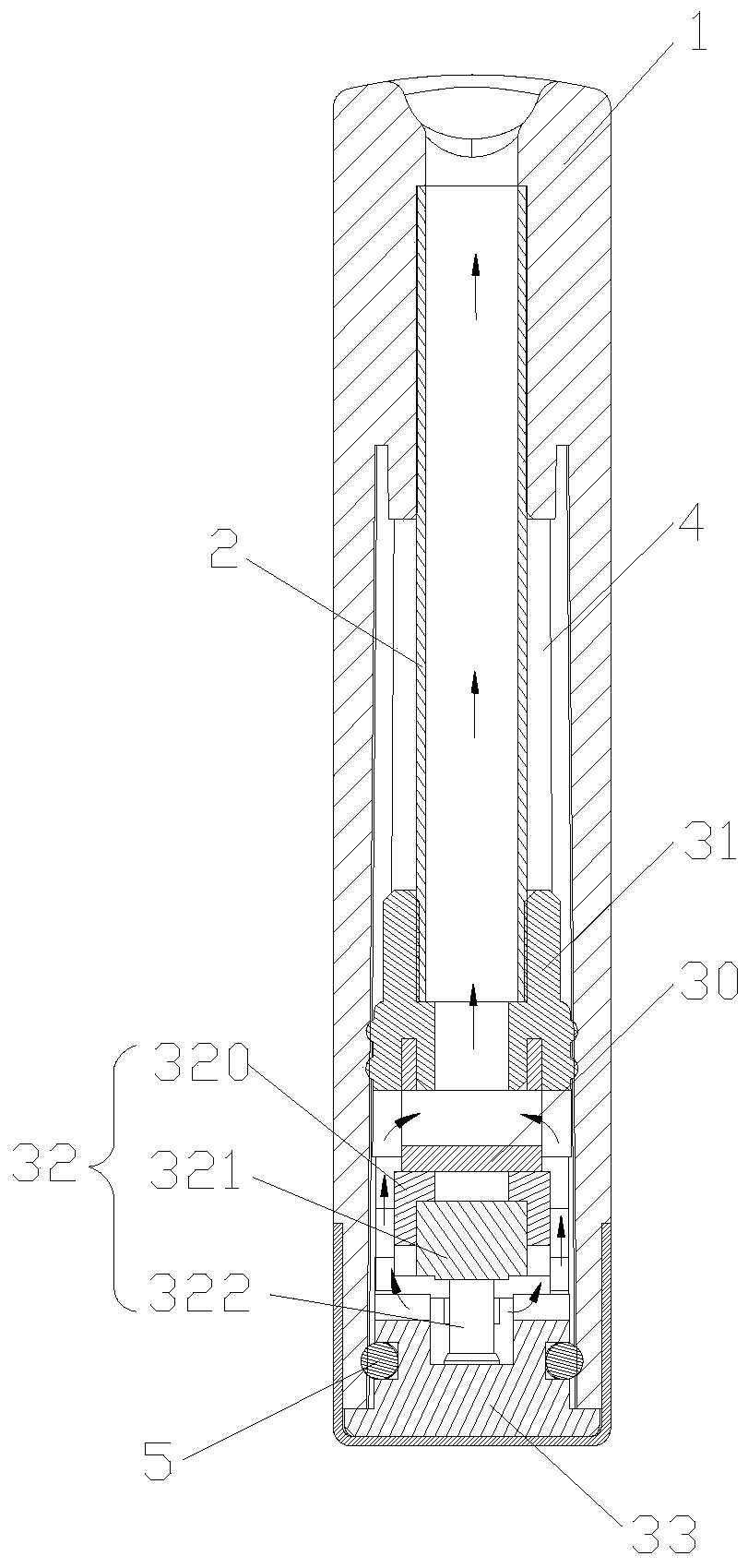

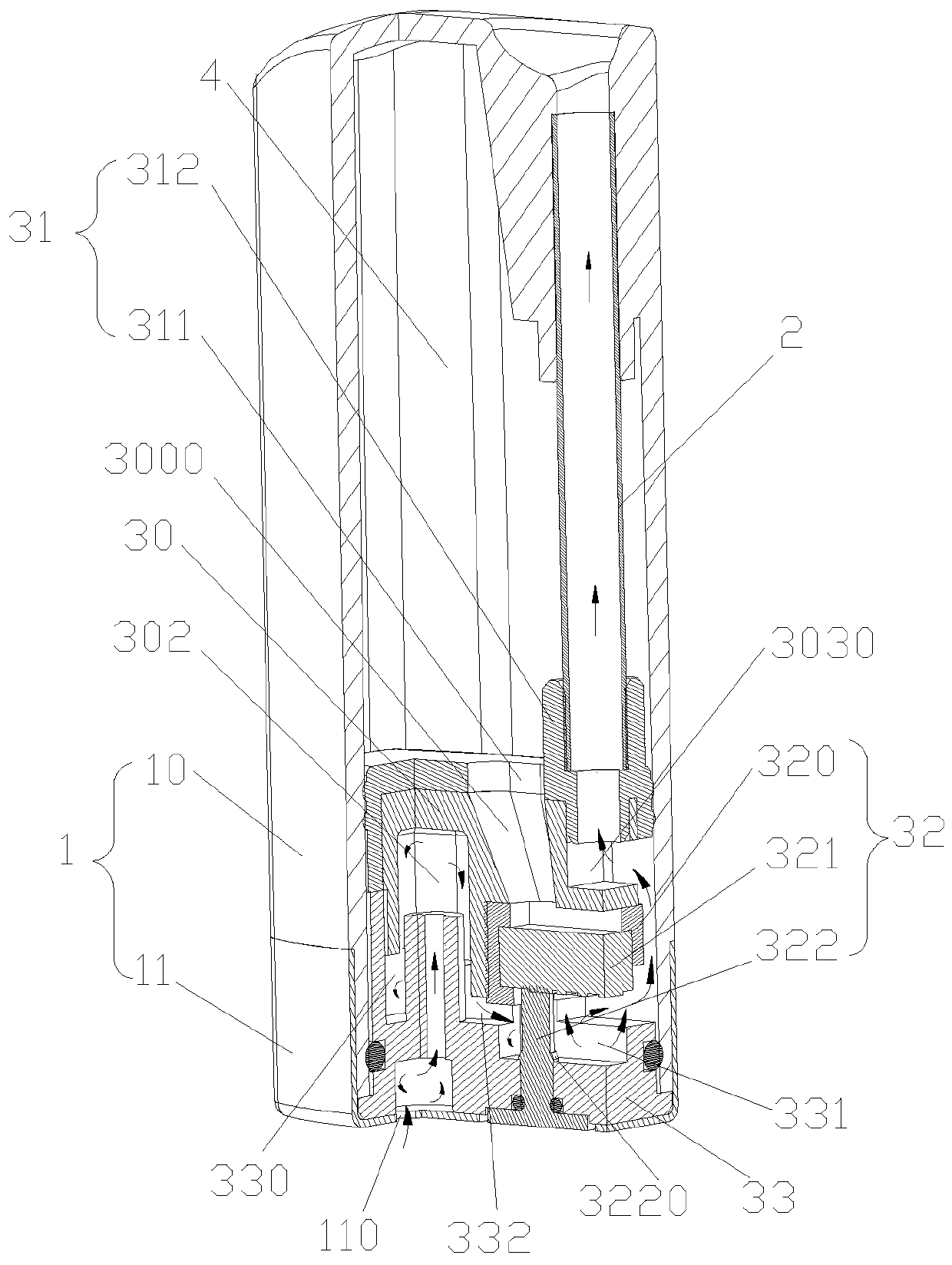

[0035] Such as Figure 1 to Figure 12 As shown, in one embodiment, the atomizer includes a casing 1, an air outlet pipe 2, an atomization assembly 3 and an oil tank 4, wherein the air outlet pipe 2 is arranged in the casing 1, and the atomization assembly 3 is provided It is located below the air outlet pipe 2 and sealed with the housing 1. The oil tank 4 is jointly surrounded by the housing 1, the air outlet pipe 2 and the atomization component 3. The oil tank 4 is used to hold the atomizing liquid for atomization. Assembly 3 includes an oil guide bracket 30, a seal 31, a heating device 32 and an air intake base 33, the oil guide bracket 30 includes a main bracket 300, a mounting seat 301 and two air intake grooves 302, the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com