A kind of transparent high temperature resistant flame retardant silicone sealant and its preparation method

A silicone sealant, high temperature resistant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of limitation, long-term use, and large amount of calcium carbonate added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

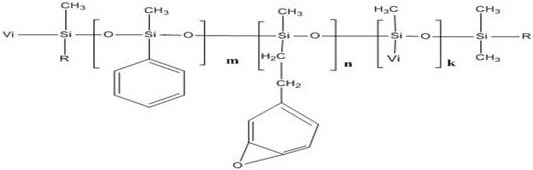

Image

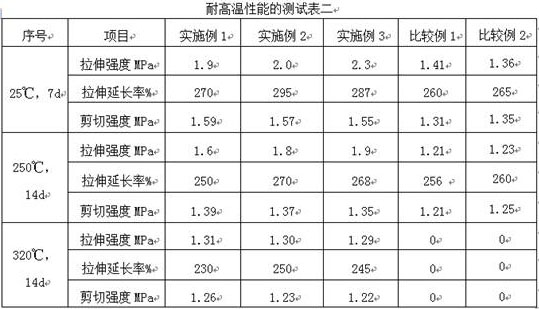

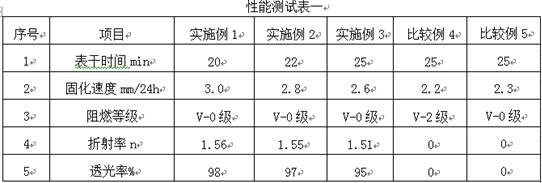

Examples

Embodiment 1

[0027] (a) Preparation of semi-finished base material 1

[0028] According to the formula in parts by weight, 25 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 20000 mPa s, 10 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 300000 mPa s, and 20 parts of epoxy vinyl phenyl silicone resin , 10 parts of dimethyl silicone oil, glass powder: white carbon black SiO 2 : A total of 20 parts of the mixture of ZnO=30:1:1 are added to the rubber machine together, the temperature of the feed liquid is controlled at 110-150°C, the vacuum degree is required to be -0.08MPa-0.1MPa, dehydration is 3-4h, and storage after discharge Store in sealed storage tanks.

[0029] (b) Preparation of a transparent high temperature flame retardant silicone sealant

[0030] Under the condition that the temperature of the semi-finished base material 1 is lower than 50°C, the base material is added to the mixer, and after stirring and mixing, ...

Embodiment 2

[0032] (a) Preparation of semi-finished base material 2

[0033] According to the formula in parts by weight, 43.9 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 80000 mPa s, 18 parts of epoxy vinyl phenyl silicone resin, 8.1 parts of vinyl silicone oil, glass powder: white carbon black SiO 2 : A total of 15 parts of the mixture of ZnO=15:3:2 are added to the rubber making machine together, the temperature of the feed liquid is controlled at 110-150°C, the vacuum degree is -0.08MPa-0.1MPa, dehydration is 3-4h, and the material is stored after discharge Store in sealed storage tanks.

[0034] (b) Preparation of a transparent high temperature flame retardant silicone sealant

[0035]Under the condition that the temperature of the semi-finished base material 2 is lower than 50°C, the base material is added to the mixer, and after stirring and mixing, 8 parts of tributyl phosphate modified by hydroxyl polysiloxane and methyl benzimidazole carbamat...

Embodiment 3

[0037] (a) Preparation of semi-finished base material 3

[0038] According to the formula in parts by weight, 49.5 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 80000 mPa s, 5 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 150000 mPa s, and 15 parts of epoxy vinyl phenyl silicone resin parts, 5 parts of methyl phenyl silicone oil, glass powder: white carbon black SiO 2 : ZnO=10:5:5 mixture of 10 parts is added to the glue making machine together, the temperature of the feed liquid is controlled at 110-150°C, the vacuum degree is required to be -0.08MPa-0.1MPa, dehydration is 3-4h, and the material is stored after discharge Store in sealed storage tanks.

[0039] (b) Preparation of a transparent high temperature flame retardant silicone sealant

[0040] When the temperature of the semi-finished base material 3 is lower than 50°C, add the base material into the mixer, stir and mix well, then add 5 parts of trip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com