Efficient and smokeless wok realizing uniform heating

A frying pan and soaking technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problem of large difference in specific heat capacity and thermal deformation between aluminum base and iron base, limited heat absorption area of excellent thermal conductors, and easy heating Quick cooling and other issues, to solve the contradiction between health and energy consumption, significant thermal efficiency, not easy to stick to the effect of the pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

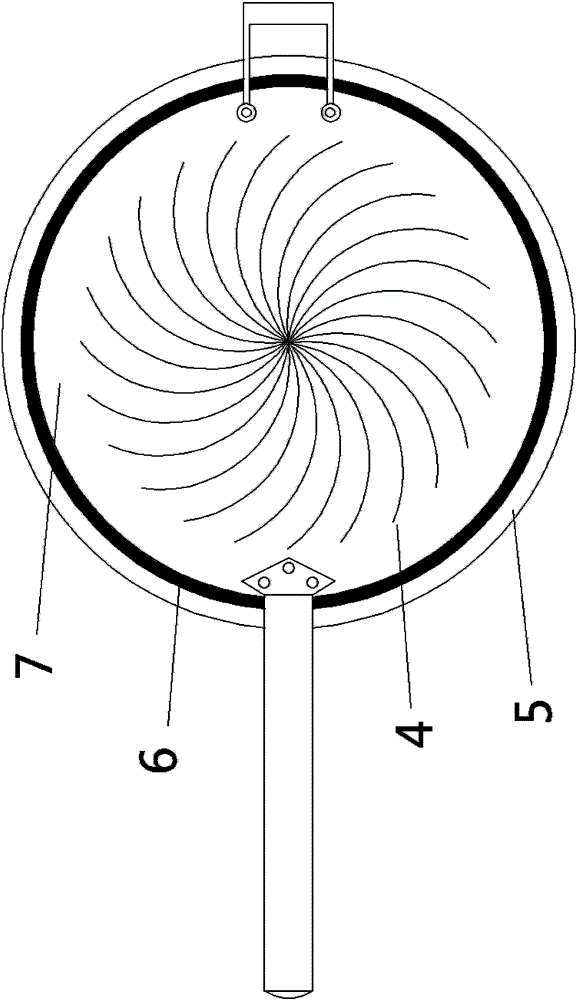

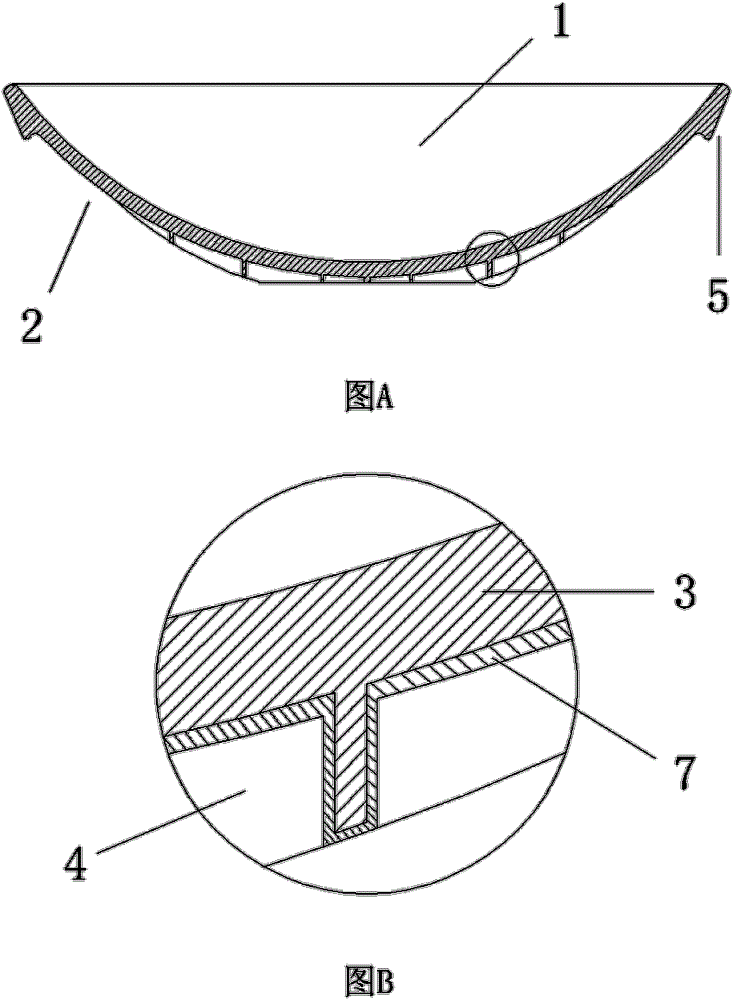

[0029] figure 1 , figure 2 A. figure 2 In B, the fins (4) are integrated with the inner layer of the wok (1) and the iron-based material (3), the fins (4) are set on the outer layer (2) of the wok, and the fins (4) are actually iron The base material, both of which are formed by casting, and the integral structure is formed by the pot eaves (5) located along the outer wall of the pot, and the surface of the fins (4) and the outer layer (2) of the iron base material (3) are all electroplated Nickel-copper alloy (7) is added to improve the high-temperature oxidation resistance and corrosion resistance of the outer layer of the frying pan (2). Although the thermal conductivity of nickel-copper alloy (7) is slightly lower than that of pure copper, the specific heat capacity is lower than that of aluminum. The temperature gradient is small, the overall performance is better than that of aluminum or aluminum alloy, and it is more suitable for the kitchen oil and salt environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com