Alloy wire with shape memory characteristics and super elasticity and manufacturing method and application thereof

A technology for alloy wires and manufacturing methods, applied in the field of alloy wires and their manufacturing, capable of solving problems such as twists and turns of human blood vessels and complicated guiding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

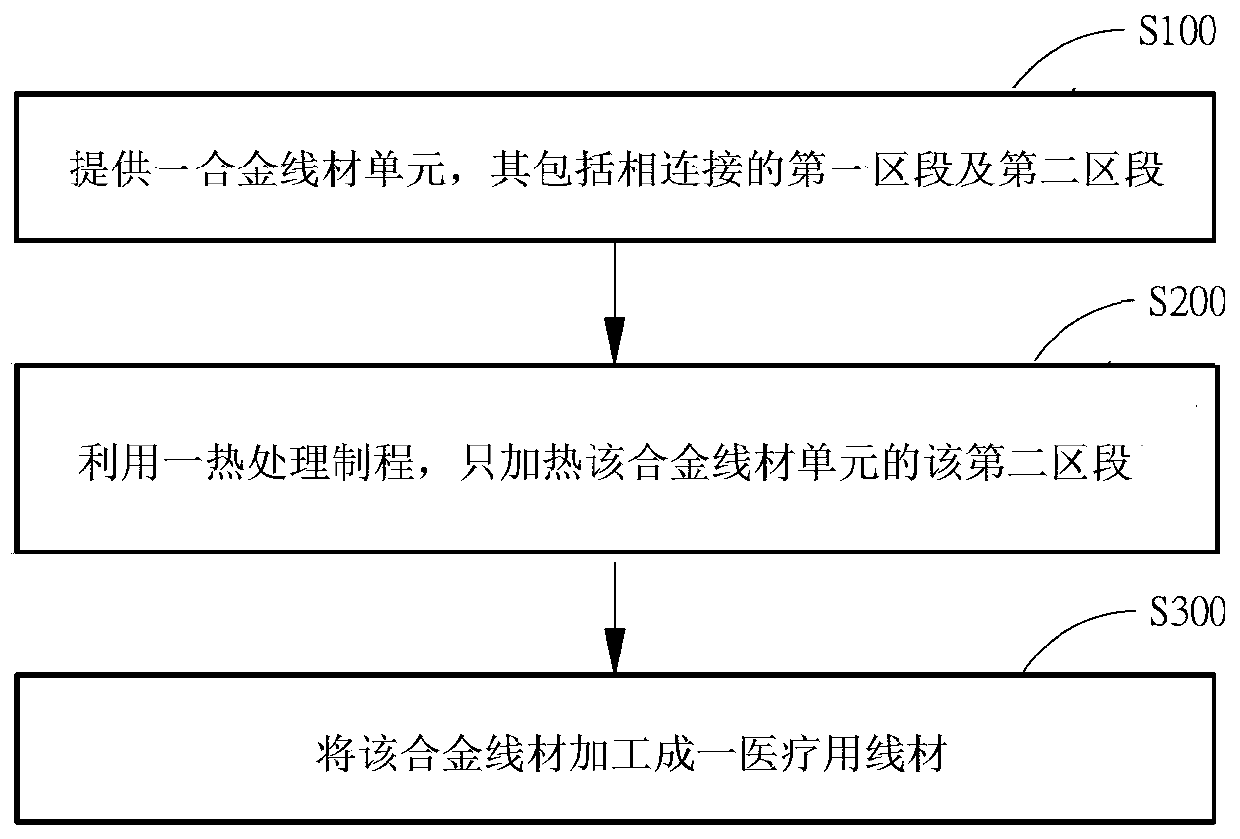

[0022] In order to make the above-mentioned objects, features and characteristics of the present invention more comprehensible, the relevant embodiments of the present invention are described in detail as follows in conjunction with the drawings.

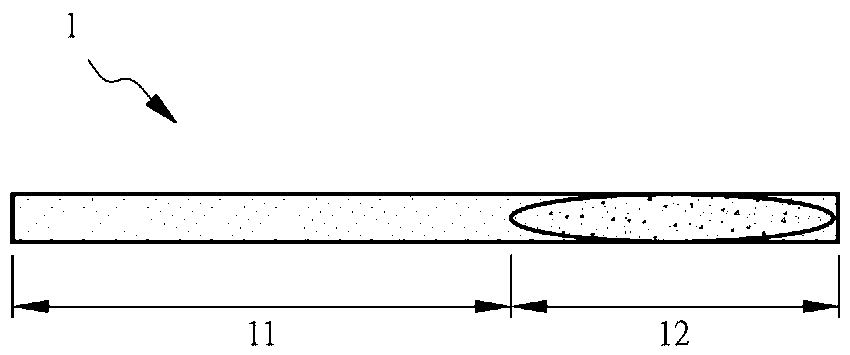

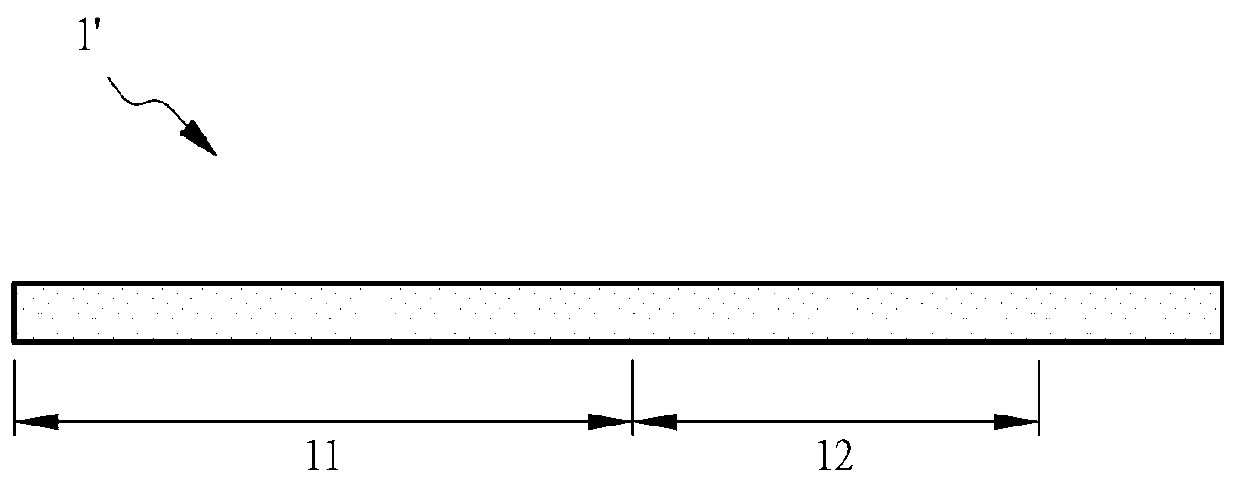

[0023] Please refer to figure 1 Shown is a schematic cross-sectional view of an alloy wire having shape memory properties and superelasticity according to an embodiment of the present invention. The alloy wire 1 with shape memory properties and superelasticity (hereinafter referred to as the alloy wire 1 ) includes a first segment 11 and a second segment 12 connected. The first phase change temperature of the first section 11 is between -30°C and 15°C, and the first phase change temperature is lower than an operating environment temperature to provide superelasticity. The second phase change temperature of the second section 12 is between 25°C and 90°C, and the second phase change temperature is higher than the ambient temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com