A fully automatic laminating machine for prefabricated panel maintenance

A fully automatic, laminating machine technology, used in manufacturing tools, ceramic forming machines, auxiliary forming equipment, etc., can solve the problems of inability to directly complete lamination, lamination and film cutting, many power devices, and film damage costs. To achieve the effect of good adhesion, high transmission, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

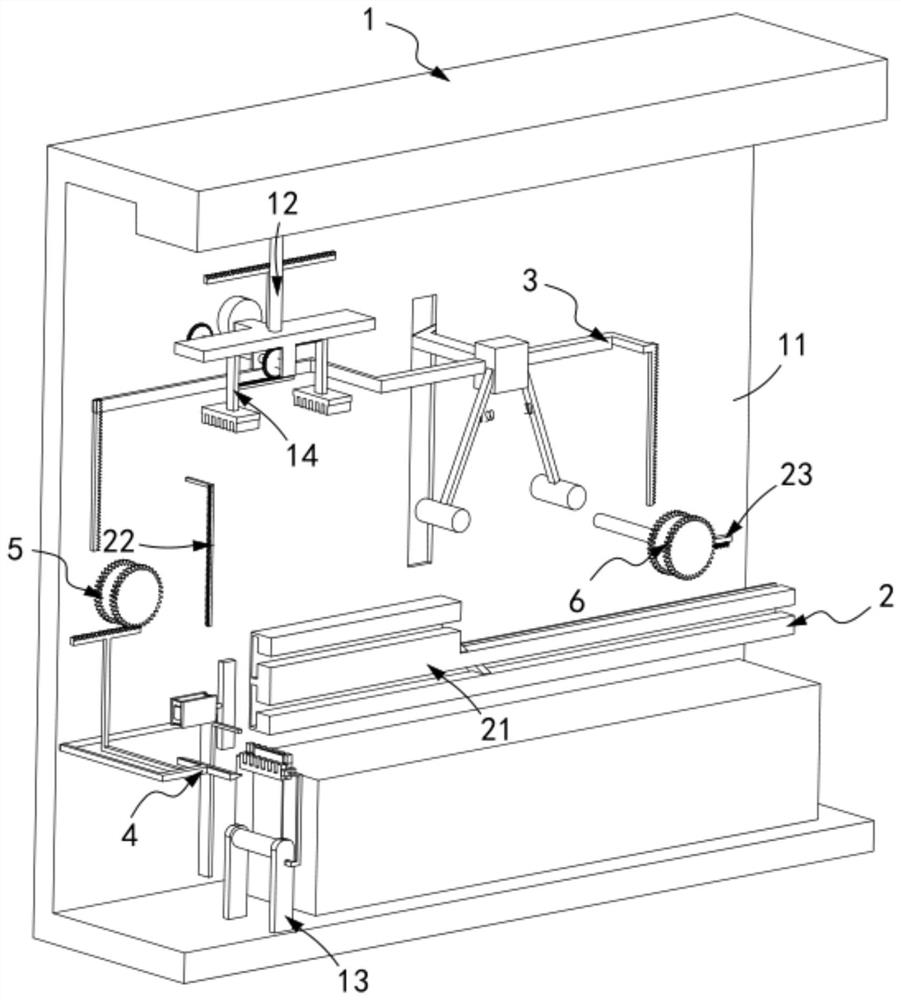

[0078] Such as figure 1 , Figure 16 As shown, a fully automatic laminating machine for prefabricated panel maintenance, including:

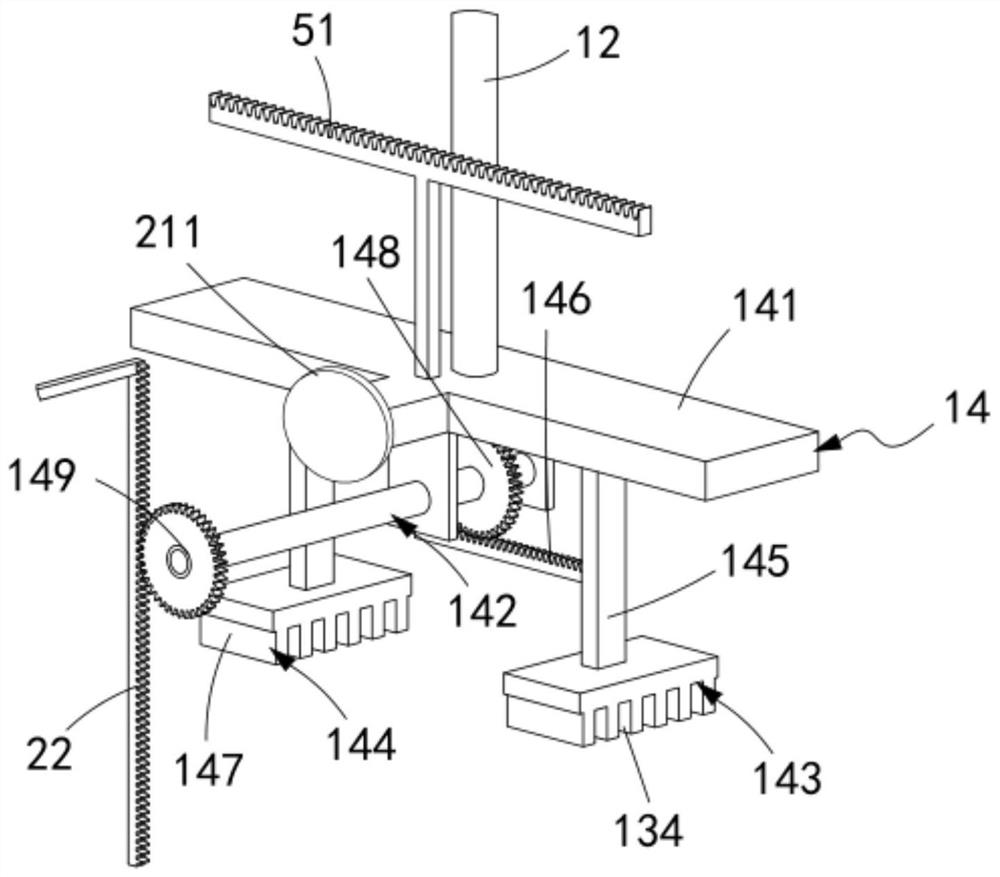

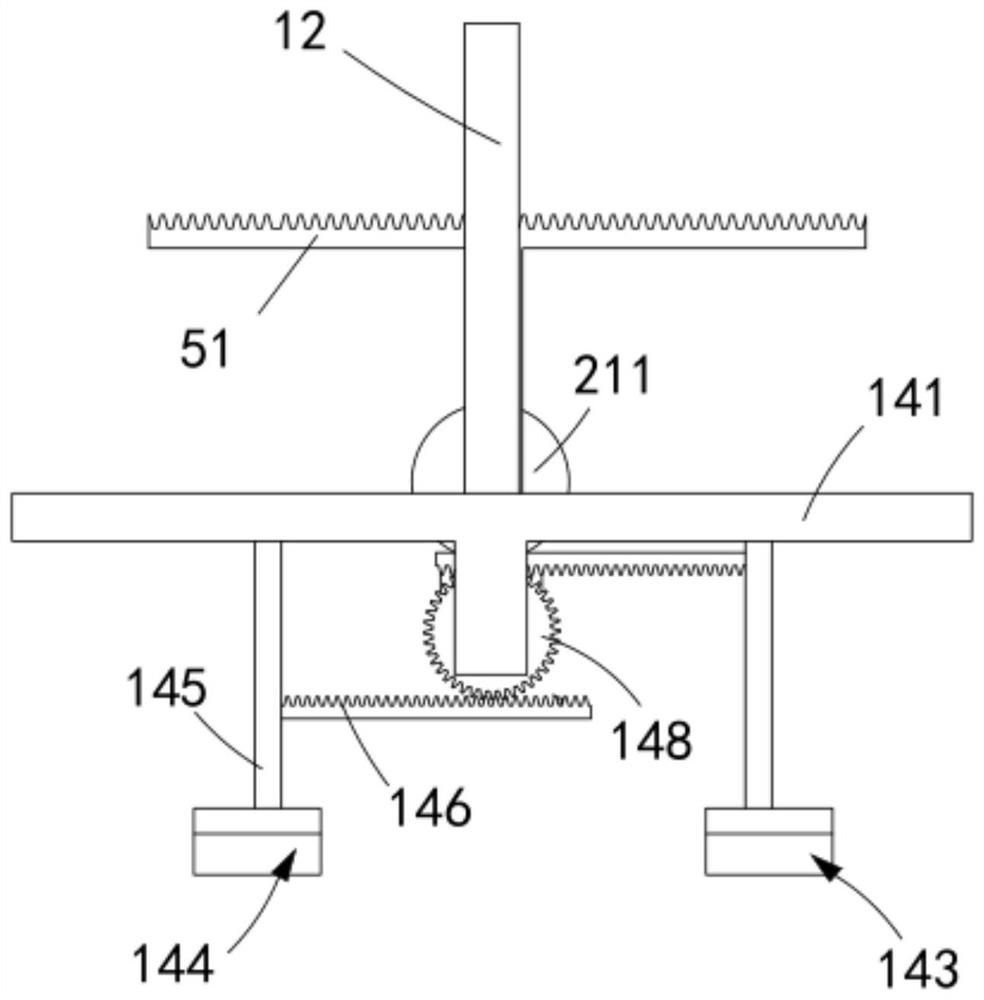

[0079] The film head positioning mechanism 1, the film head positioning mechanism 1 includes a frame 11, a vertical push assembly 12 installed on the top of the frame 11 and reciprocating horizontally on the frame 11, and a vertical push assembly 12 installed on the frame 11 The lower film loading assembly 13 and the clamping assembly 14 located above the film loading assembly 13 and fixedly connected to the telescopic end of the vertical pushing assembly 12;

[0080] A flattening mechanism 2, the flattening mechanism 2 includes a flat pushing assembly 21 installed on the frame 11 and arranged horizontally, a vertically arranged above the film loading assembly 13 and used to control the closing of the clamping assembly 14 The first driving member 22 and the second driving assembly 23 horizontally arranged at the output end of the horizontal pu...

Embodiment 2

[0135] Such as Figure 13 , Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0136] further, such as Figure 13 As shown, the film cutting mechanism 4 includes:

[0137] A translation rod 41, the translation rod 41 is slidably arranged on the frame 11, and one end thereof is fixed on the frame 11 by a spring c;

[0138] A cutting knife 42, said cutting knife 42 is fixedly arranged on the other end of said translation rod 41; and

[0139] The baffle 43 , the baffle 43 is fixedly arranged on the clamping plate a132 on the side close to the laminating mechanism 3 and arranged linearly with the cutter 42 .

[0140] It is worth mentioning here that by setting the film cutting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com