Apparatus and method for engraving marks on spun bobbins

A yarn bobbin and labeling technology, applied in the textile field, can solve the problems of generating induced electromotive force, affecting the spinning quality, and high cost, and achieving the effects of preventing improper pushing, simple and convenient engraving, and convenient image collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

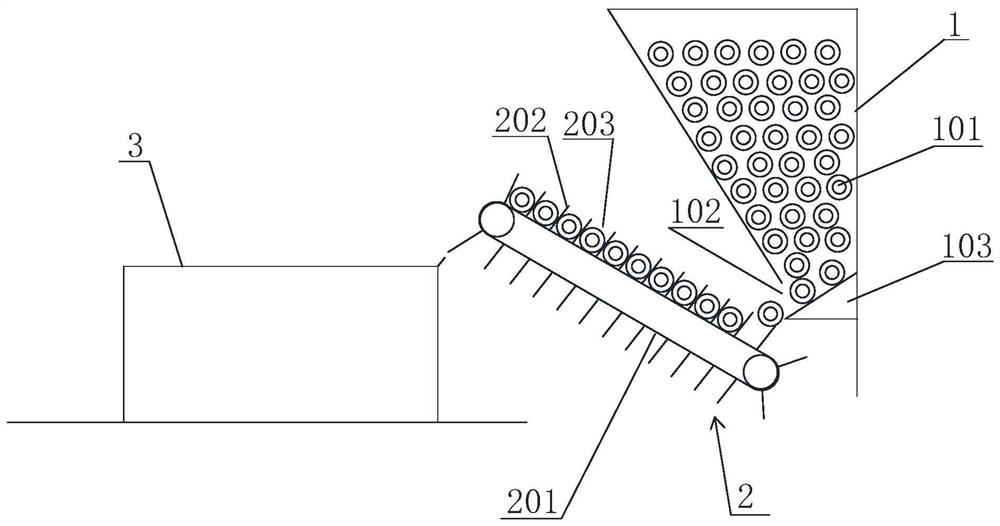

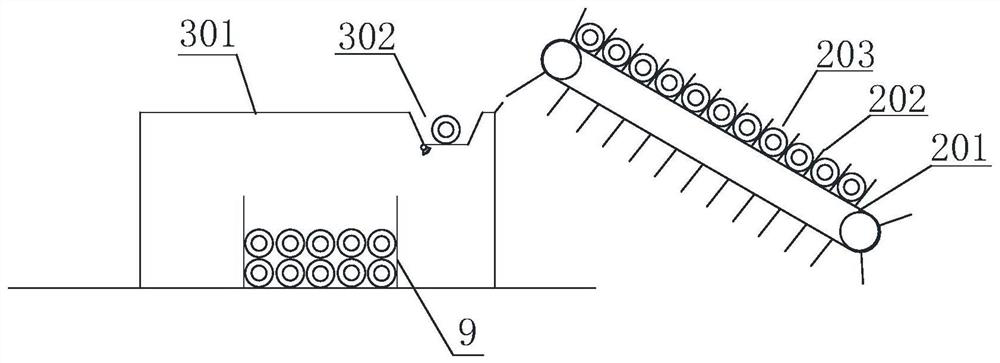

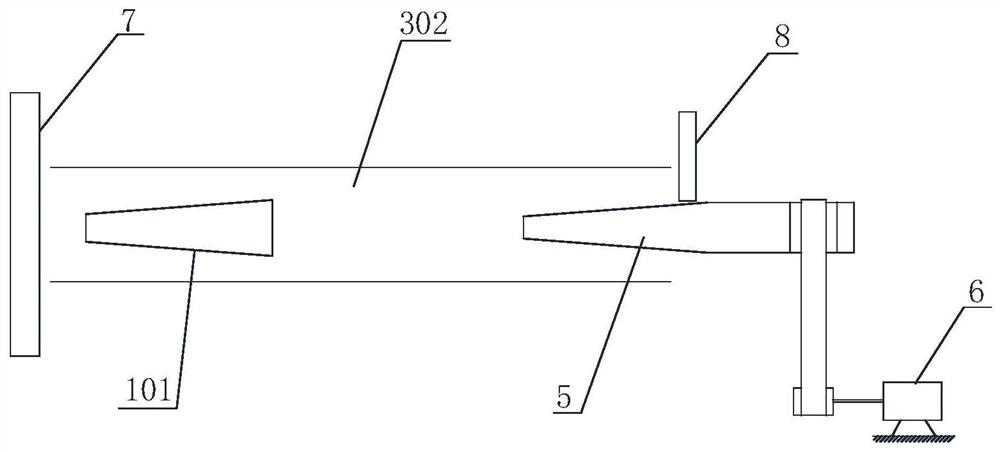

[0032] With reference to the accompanying drawings, a spun bobbin marking marking device includes an empty bobbin box 1, an empty bobbin conveyor belt 2 and an engraving workbench 3. There are several empty tubes 101 stacked in the empty tube box 1, and the empty tubes 101 are arranged horizontally in the empty tube box. The empty tube box is a tapered structure with a wide top and a narrow bottom. Bobbin empty bobbin outlet 102, under the bobbin empty bobbin outlet 102, a triangular plate 103 is arranged, and the inclined surface on the triangular plate can guide the bobbin empty bobbin to the empty bobbin conveyor belt.

[0033] Empty tube conveyor belt 2 comprises conveyor belt body 201, and conveyor belt body 201 is arranged obliquely, and the bottom end of conveyor belt body is positioned at the yarn tube empty tube outlet, and the top end of conveyor belt body is connected with engraving workbench. Baffles 202 are arranged at intervals on the conveyor belt body 201, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com