Patents

Literature

36results about How to "Prevent problems such as damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

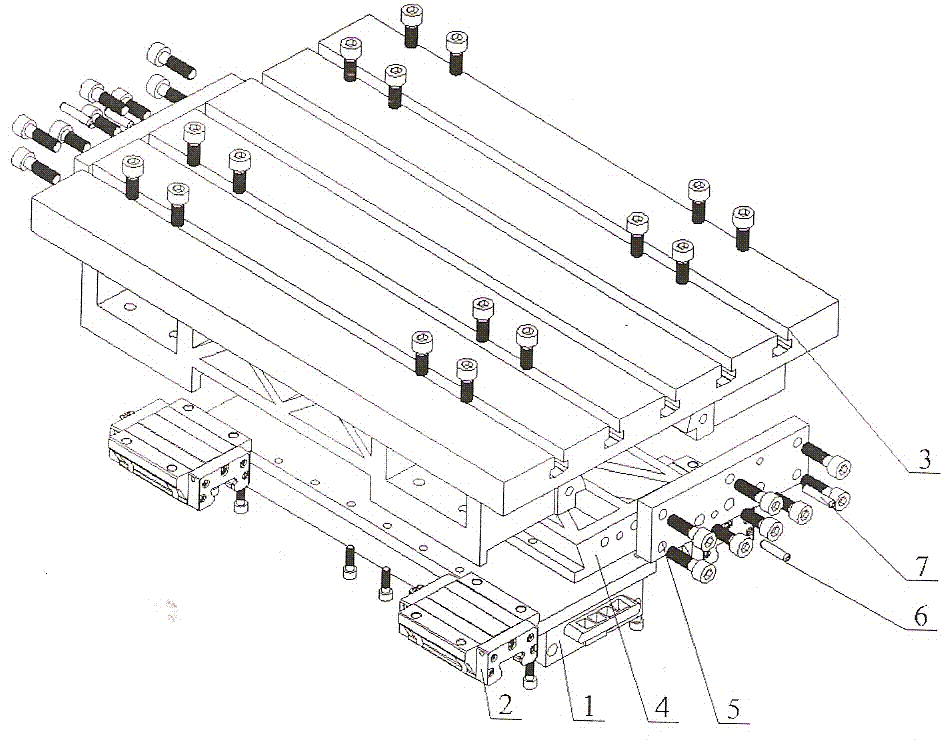

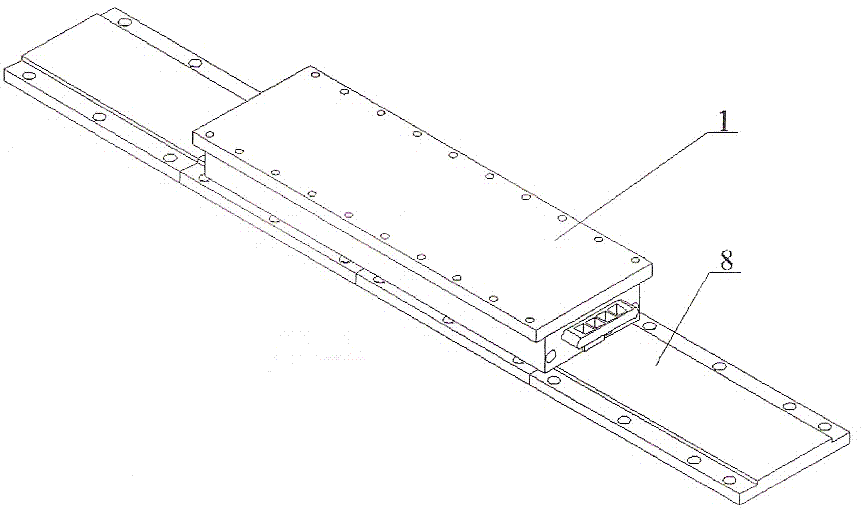

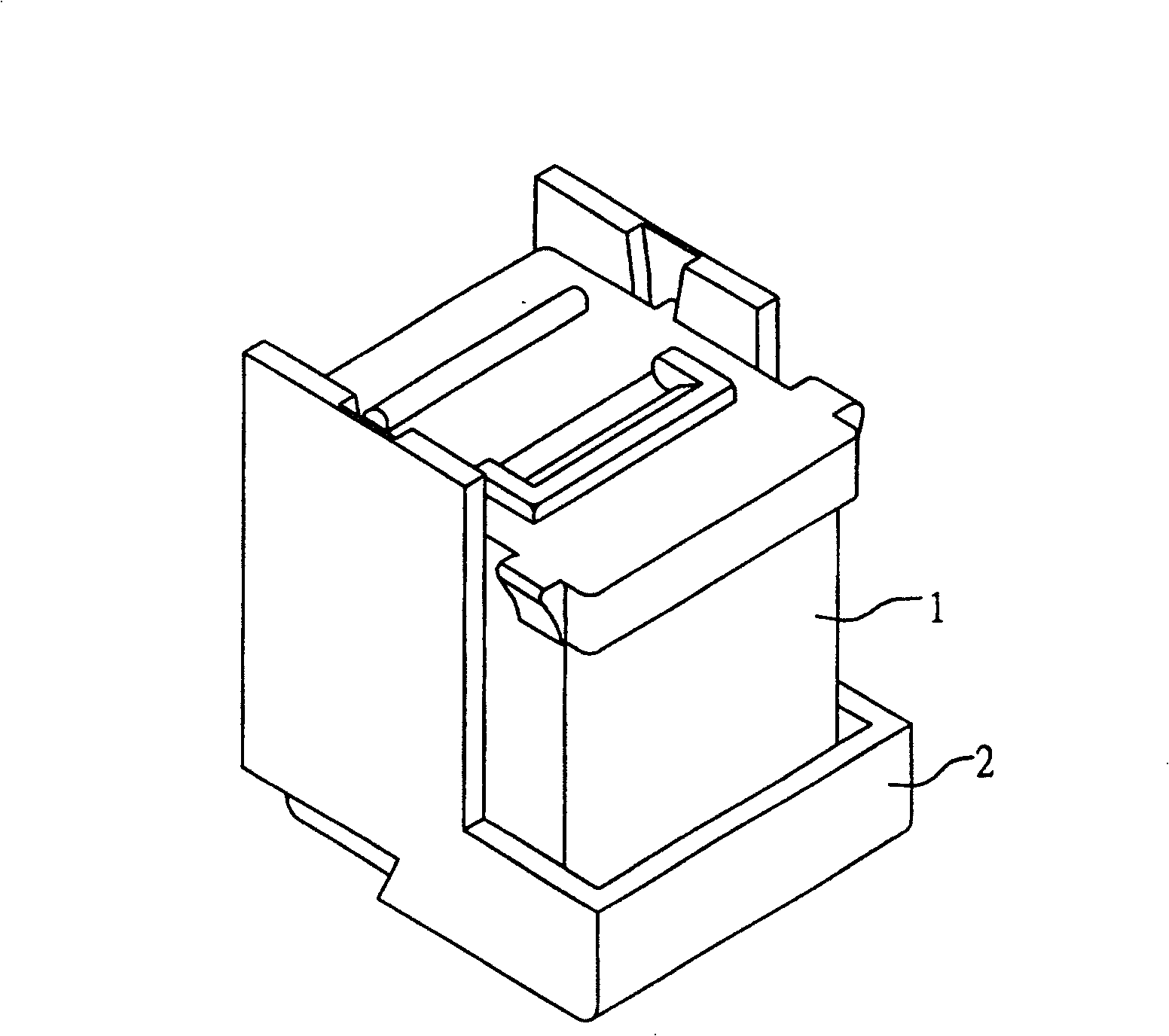

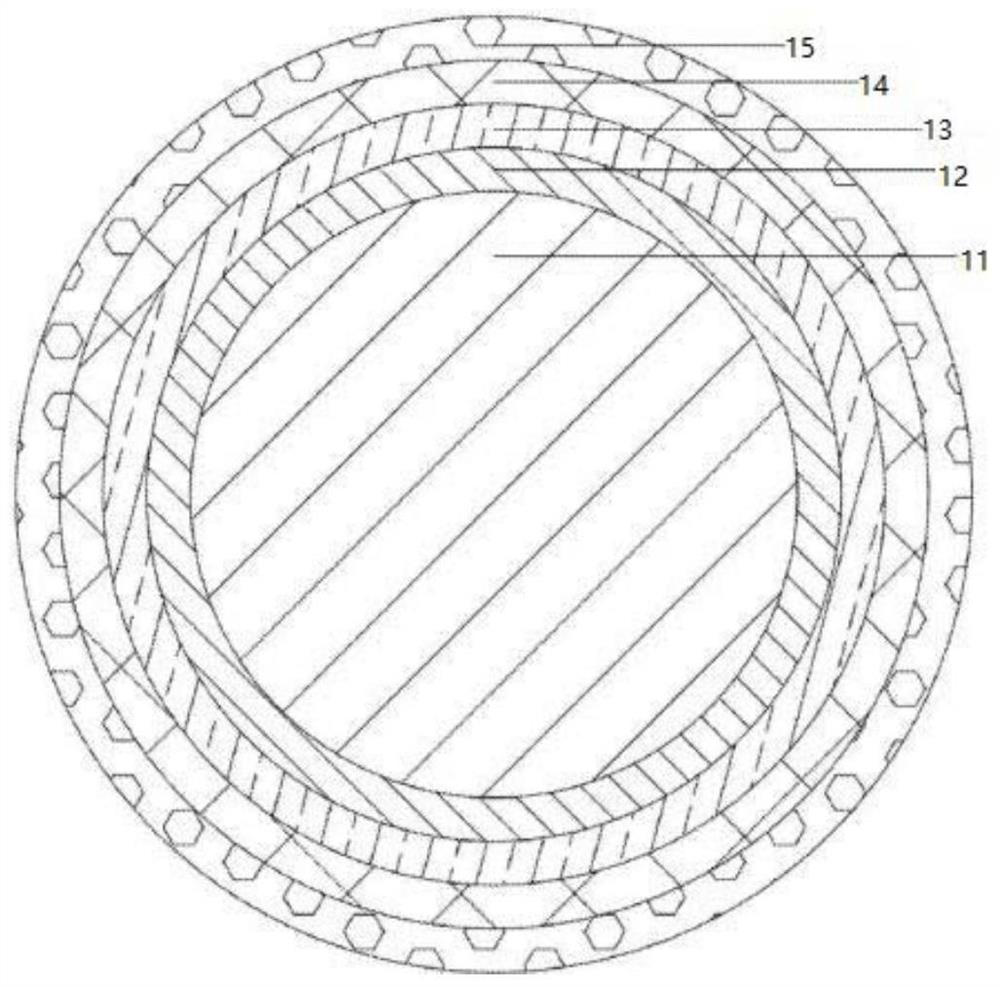

Method for installing and maintaining numerical control machine tool split type working table for installing linear motor

ActiveCN103801942APrevent problems such as damageAvoid corrosionLarge fixed membersMaintainance and safety accessoriesNumerical controlEngineering

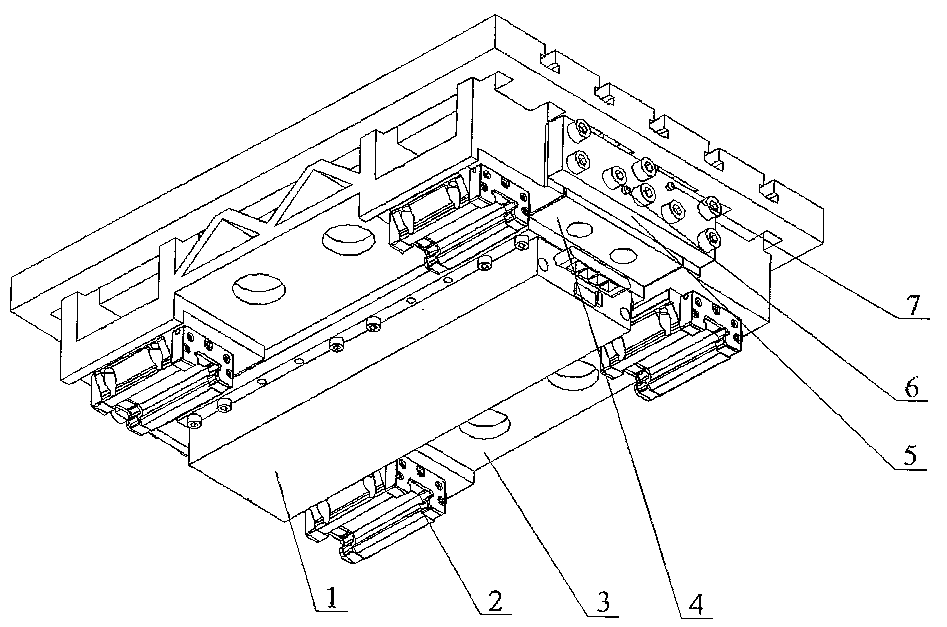

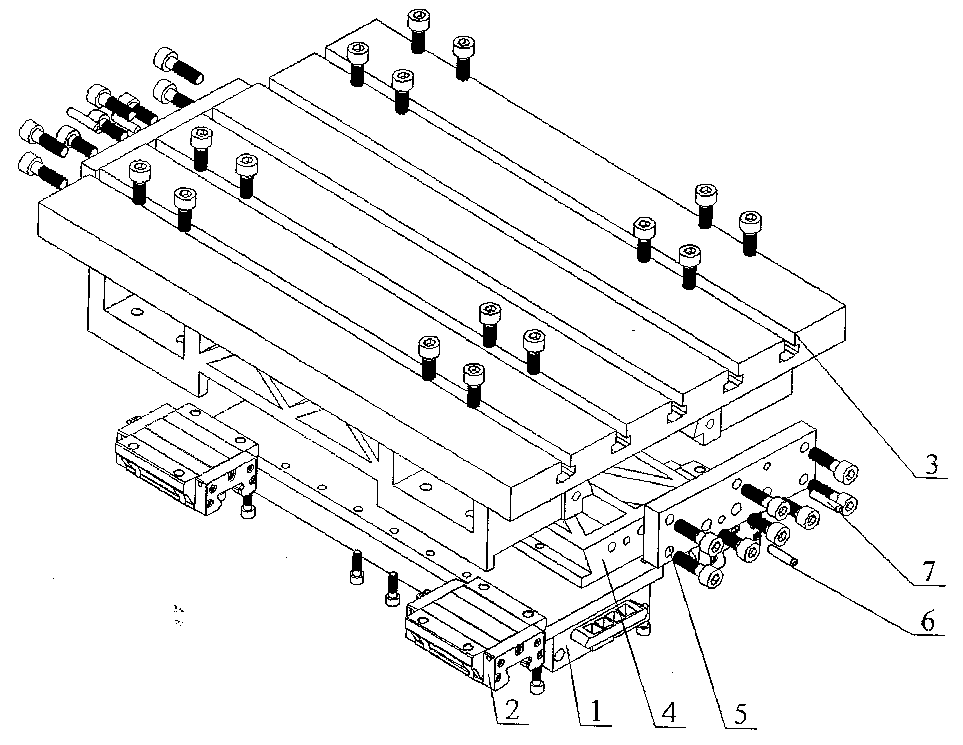

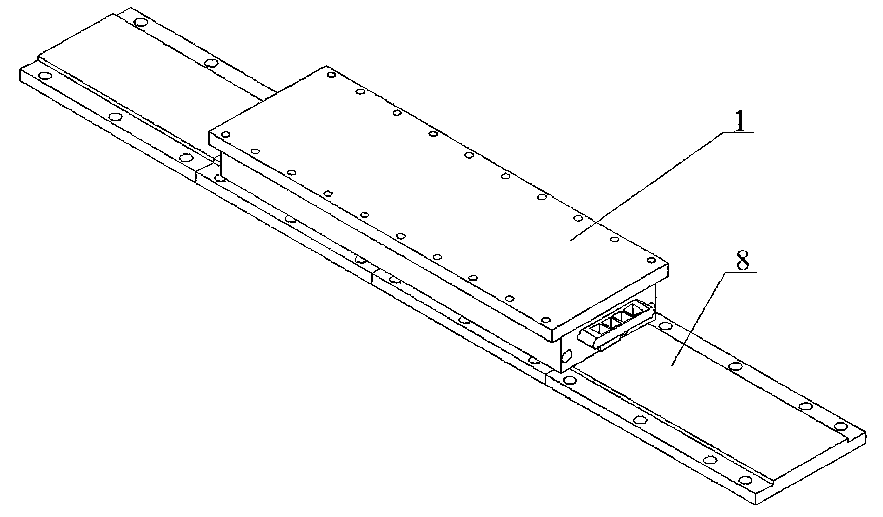

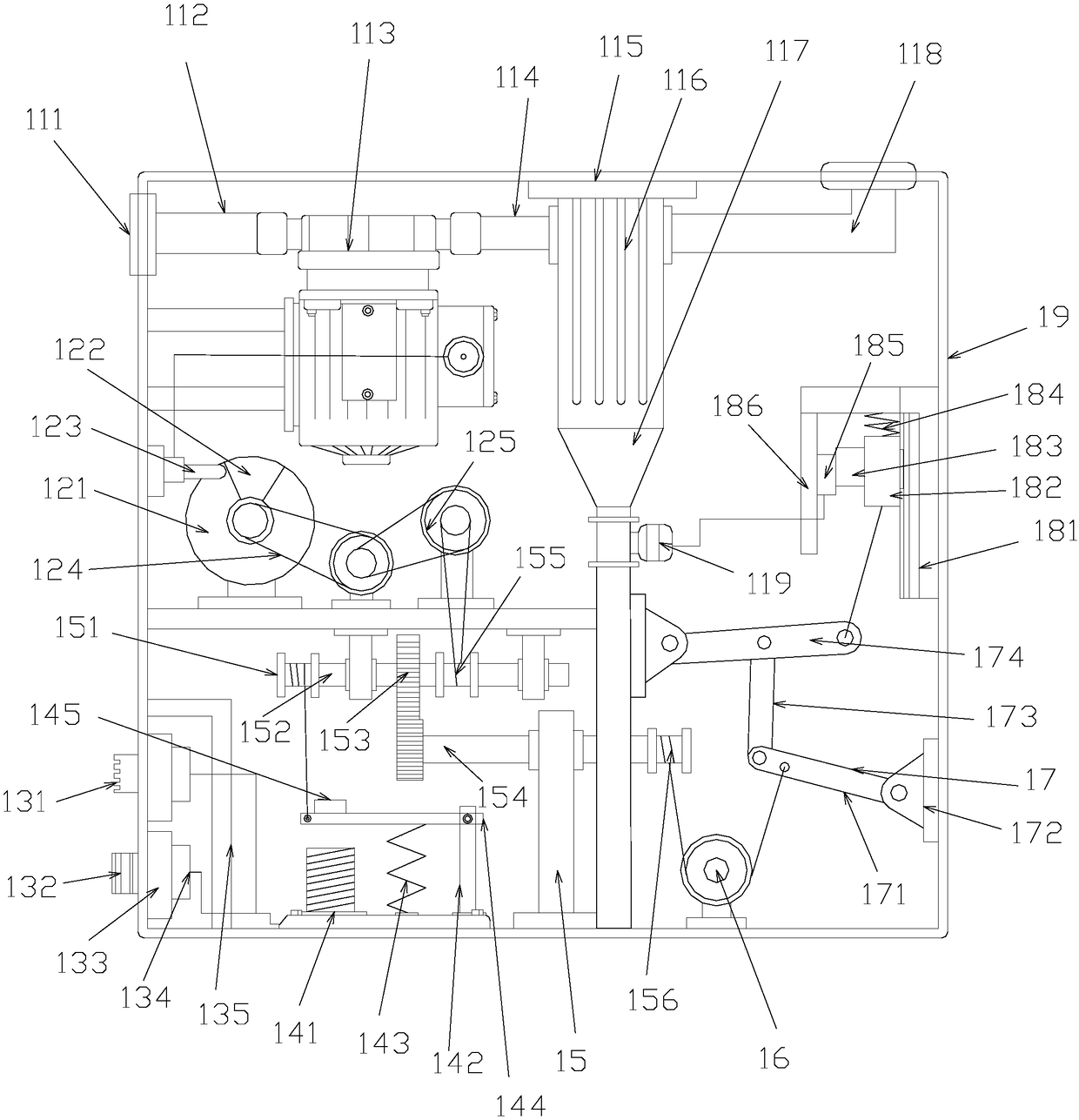

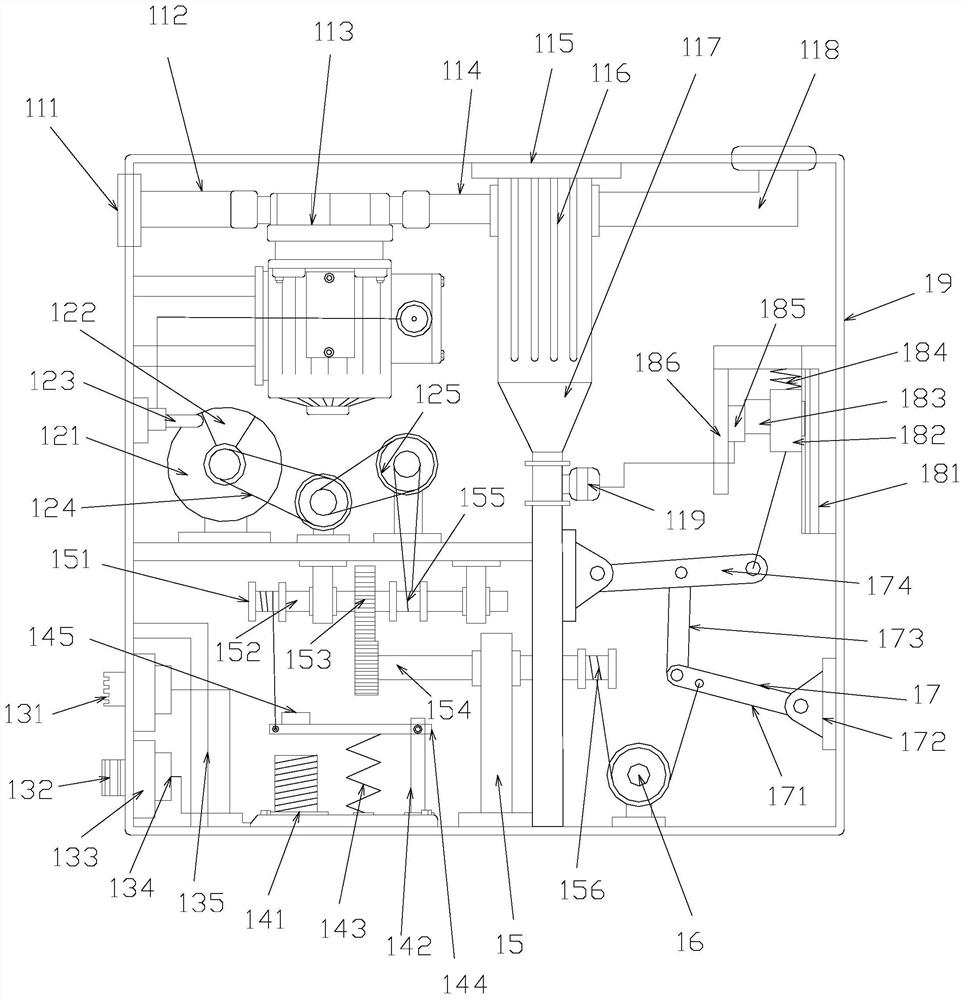

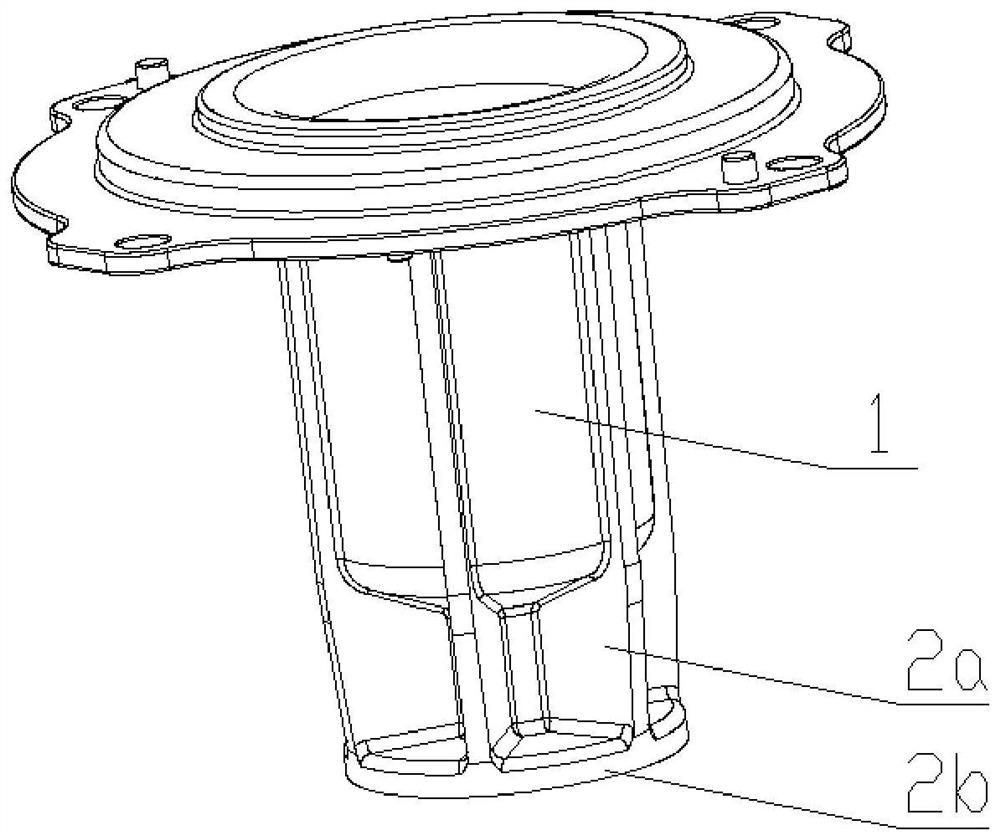

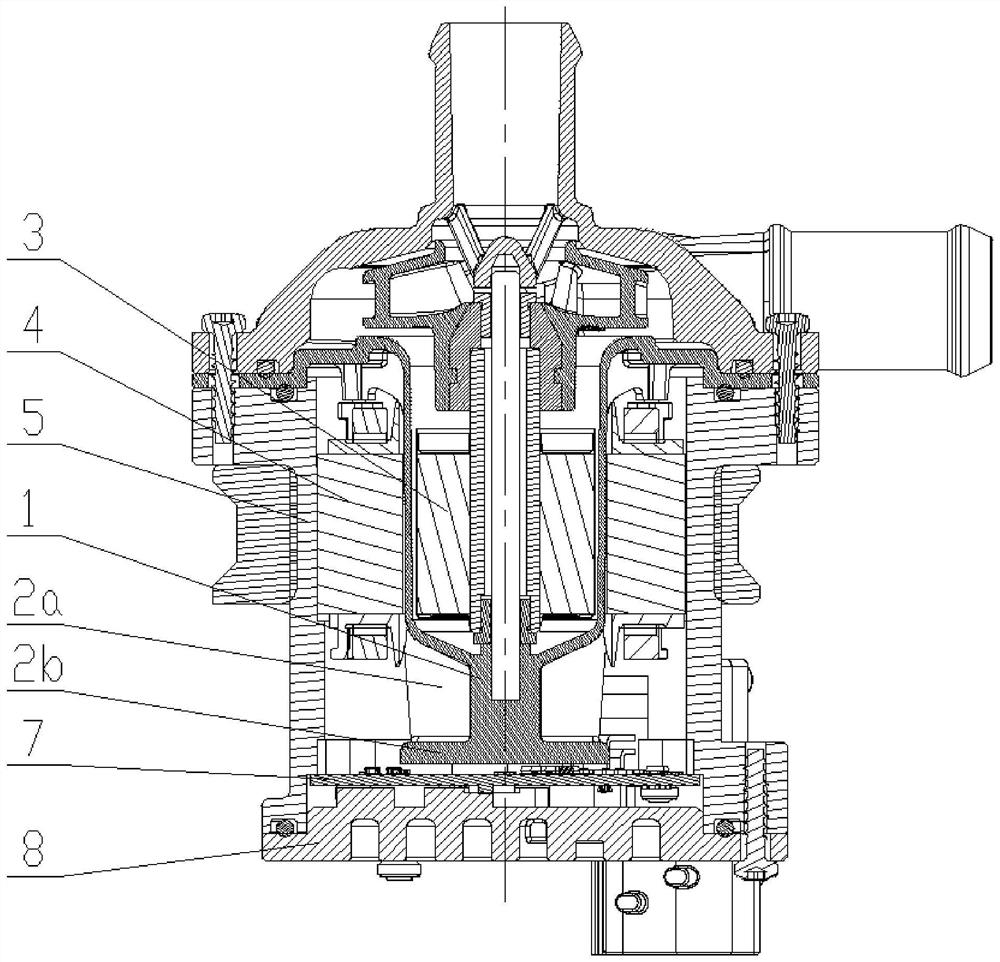

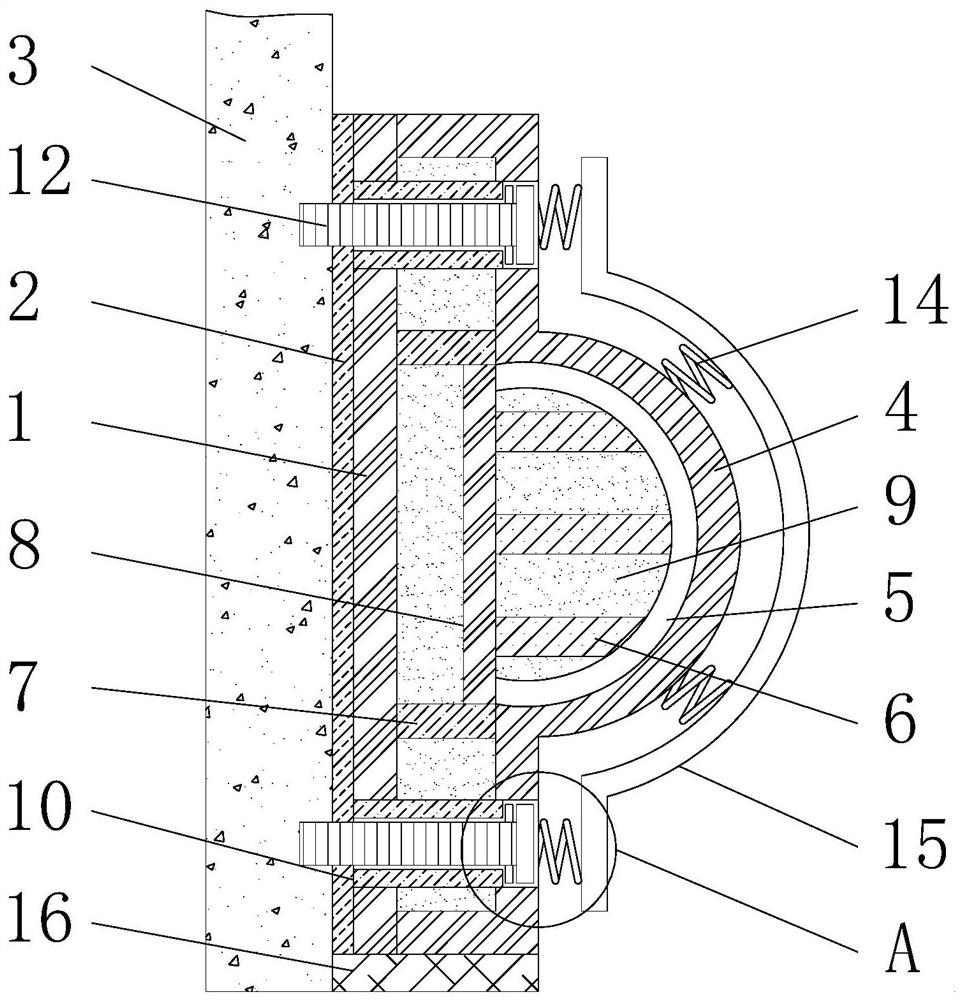

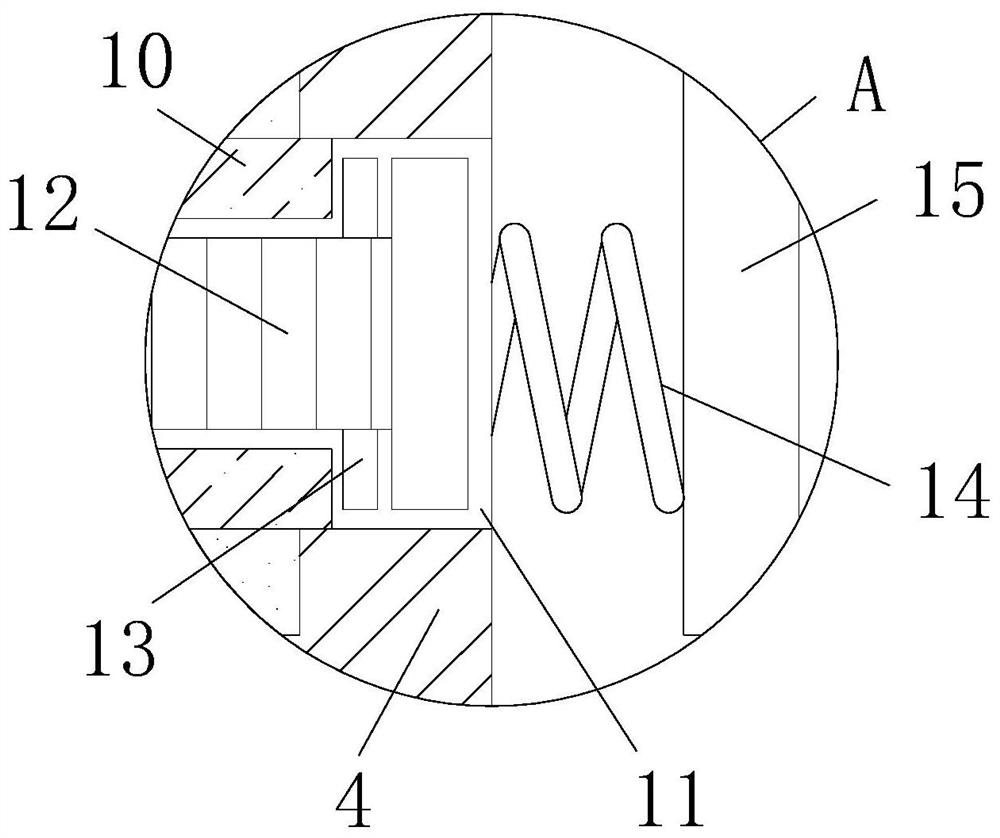

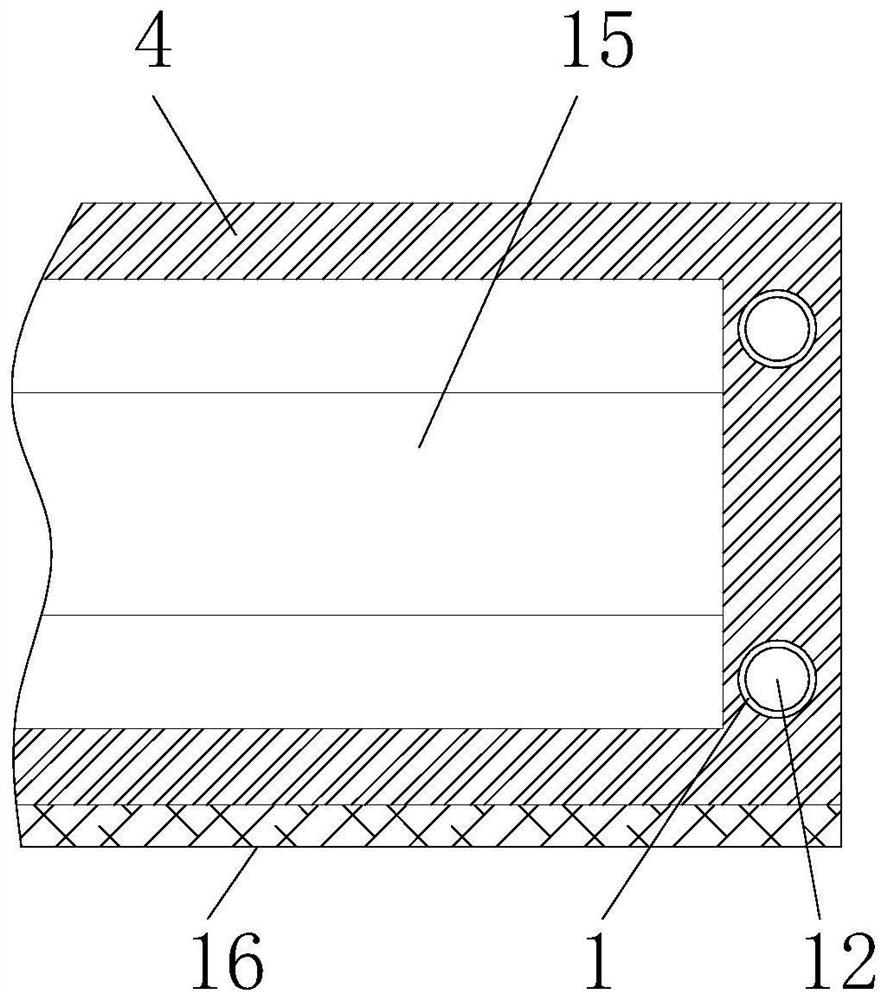

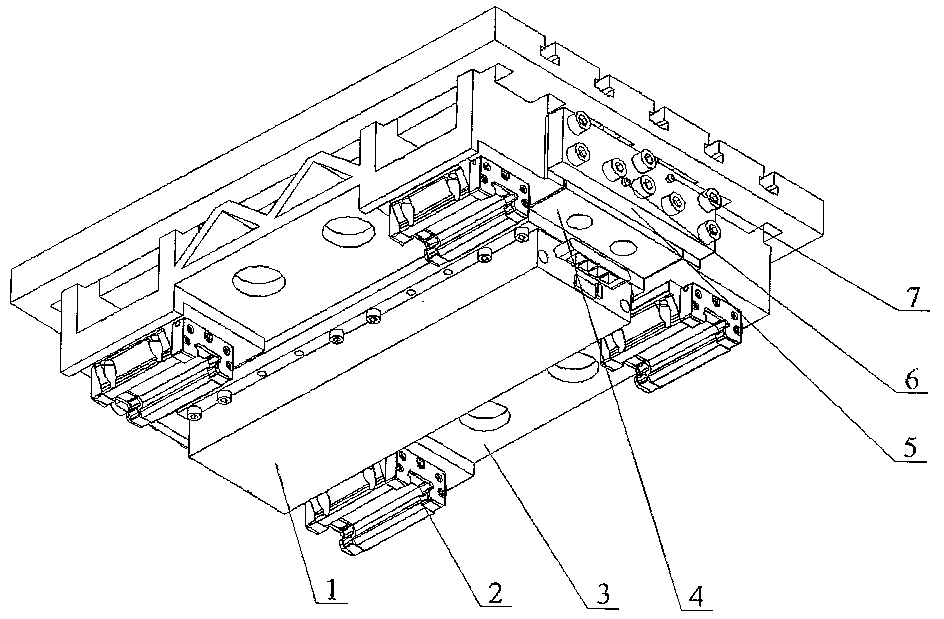

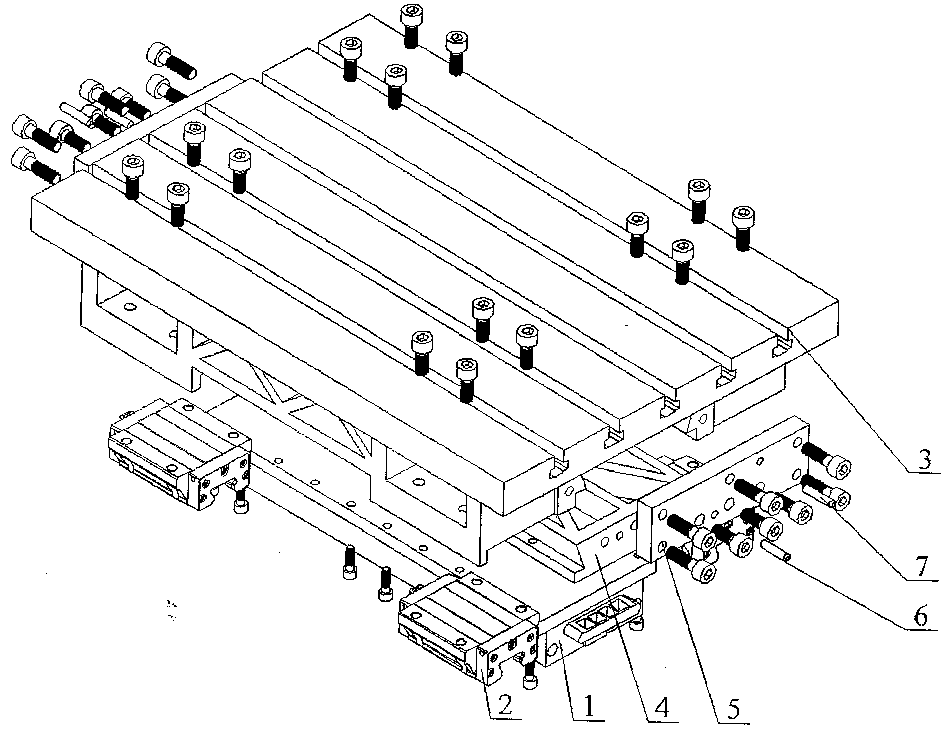

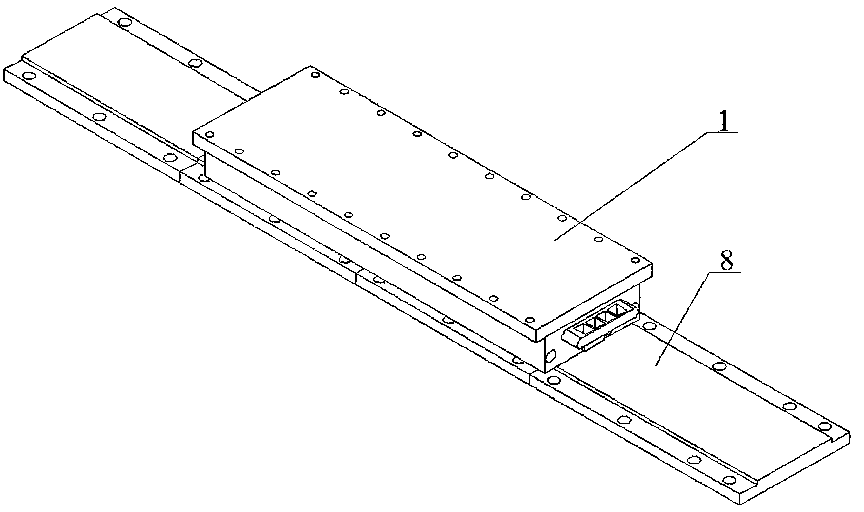

The invention discloses a method for installing and maintaining a numerical control machine tool split type working table for installing a linear motor. The working table is installed on linear guide rail sliding blocks through four notches in the lateral sides of the working table, a linear motor primary coil is fixedly connected to the bottom face of a motor coil installation plate through screws, and a dovetail groove in the lateral side of the motor coil installation plate is coincident with a dovetail groove of the working table. According to the method, under the condition that the geometric accuracy of a machine tool is not destroyed, work such as disassembling, examining and maintaining can be conveniently carried out on a motor, the maintenance cost is reduced, the maintenance time is shortened, the service life of a working table unit is prolonged, a power line, a signal line, a cooling pipe and a lubricating pipe can be laid from the interior of the working table, and the structure is compact; due to dovetail type contact, attraction force between the linear motor primary coil and a secondary permanent magnetic plate is evenly distributed on the working table, the structural rigidity is good, and deformation is small.

Owner:NANTONG UNIVERSITY

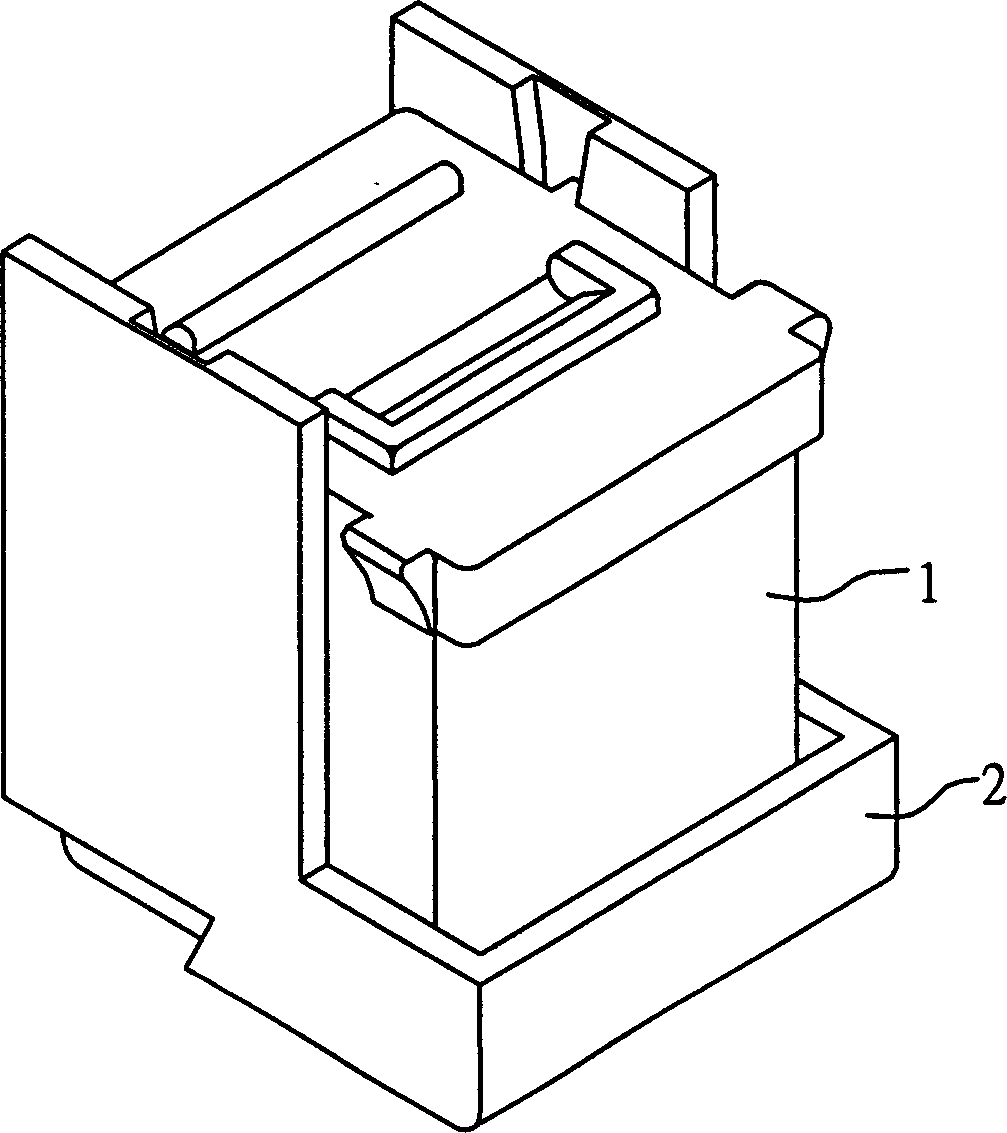

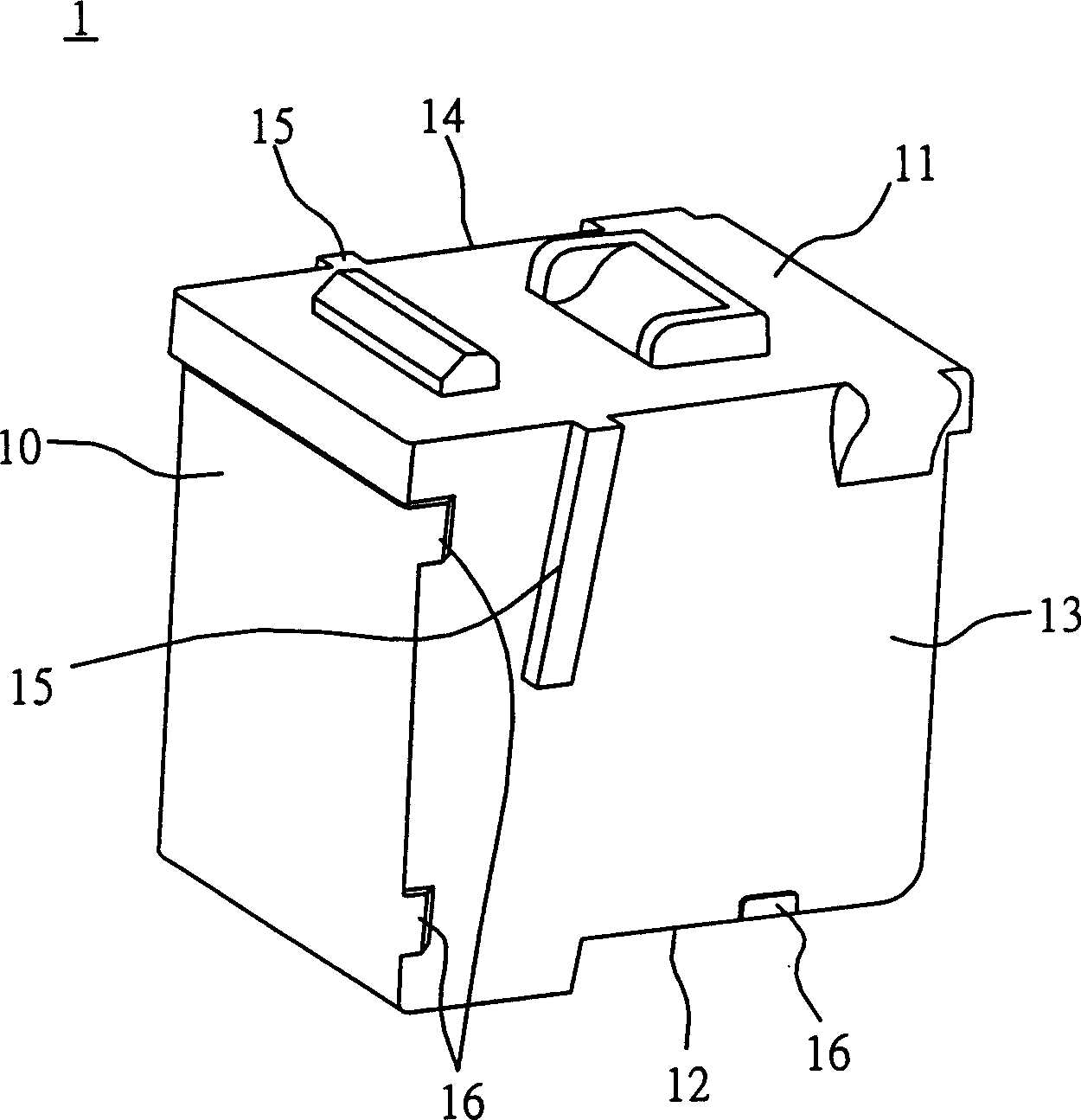

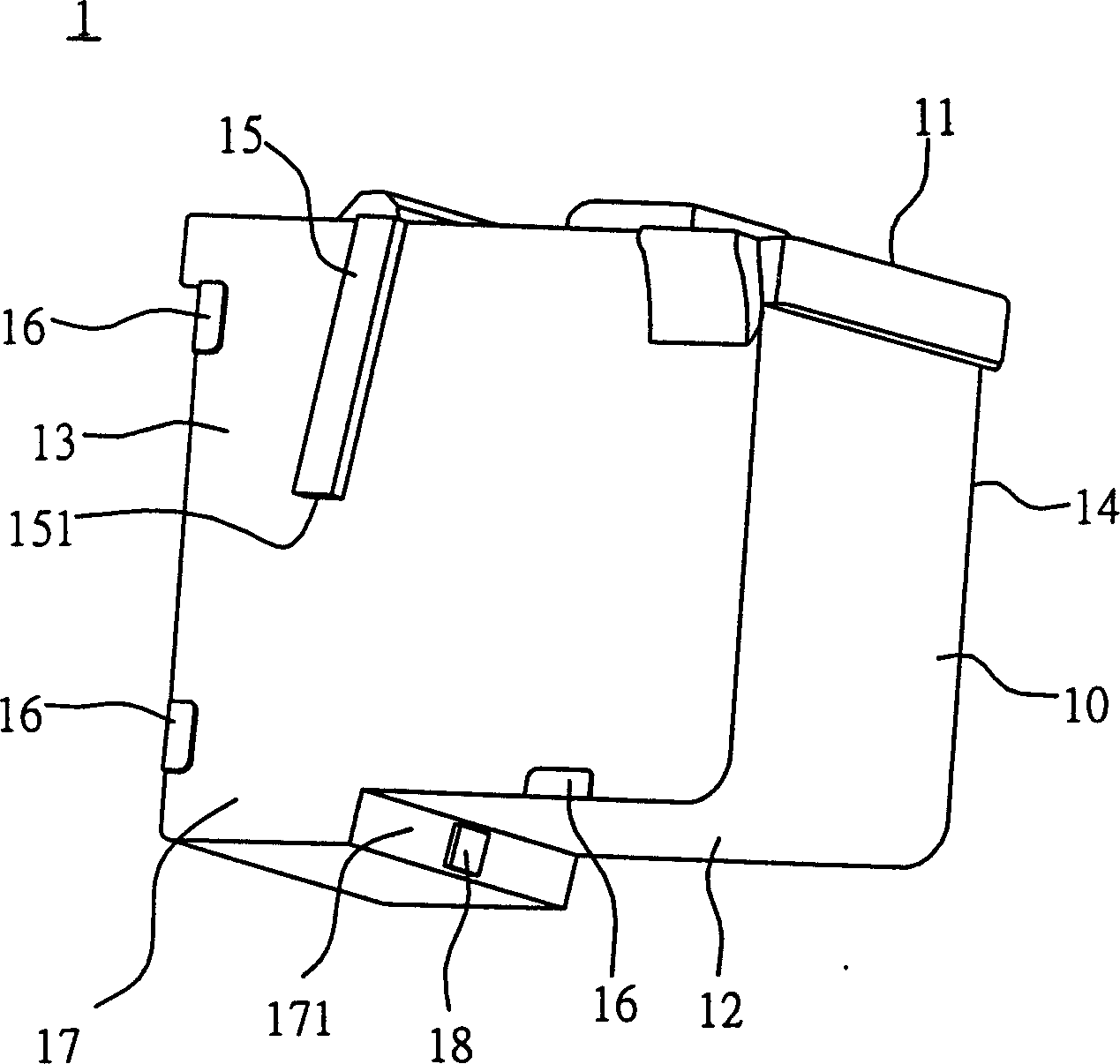

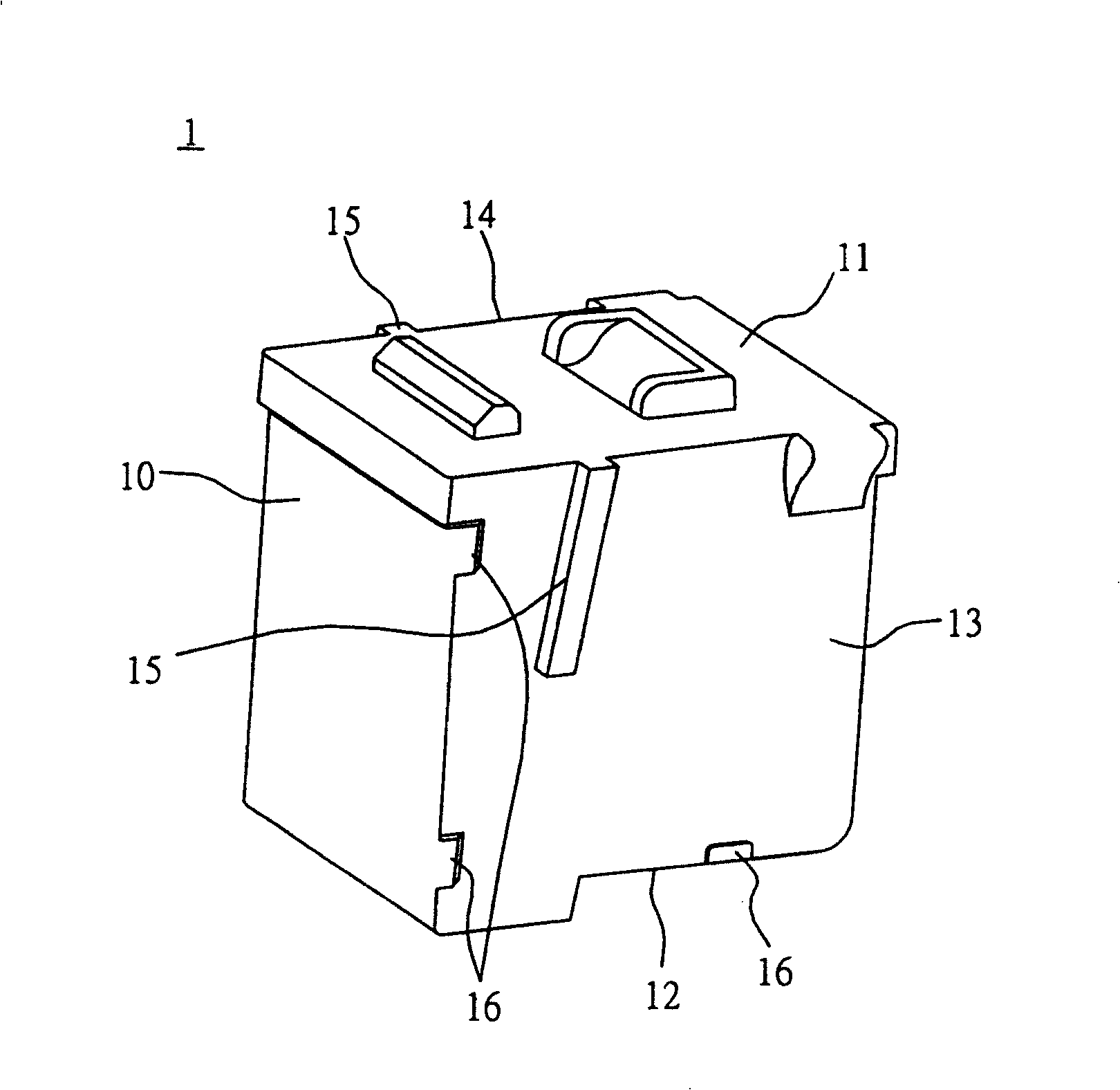

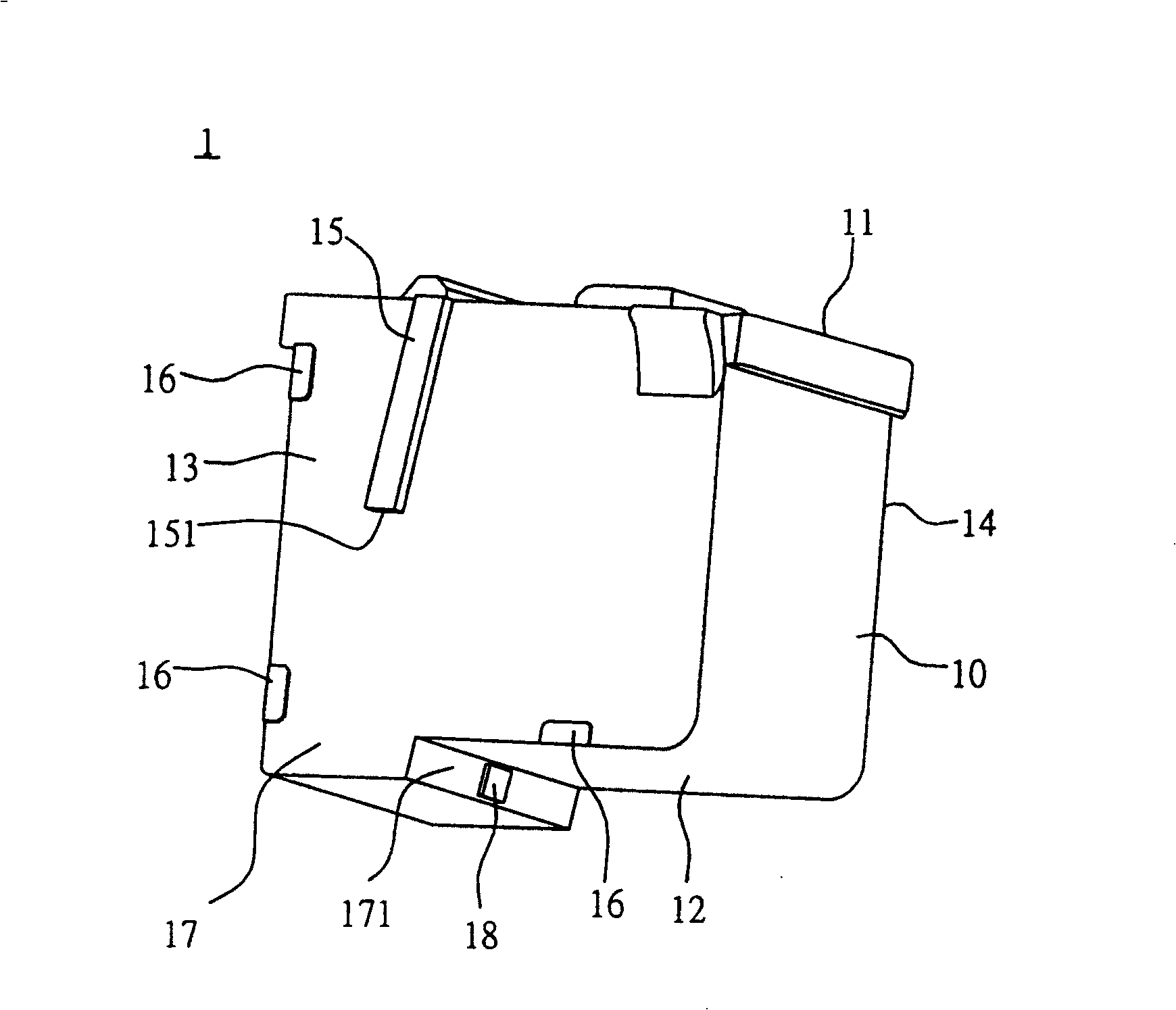

Printing mechanism, its ink box and bearing seat

Owner:MICROJET TECH

Medical optical fiber and laser therapeutic device

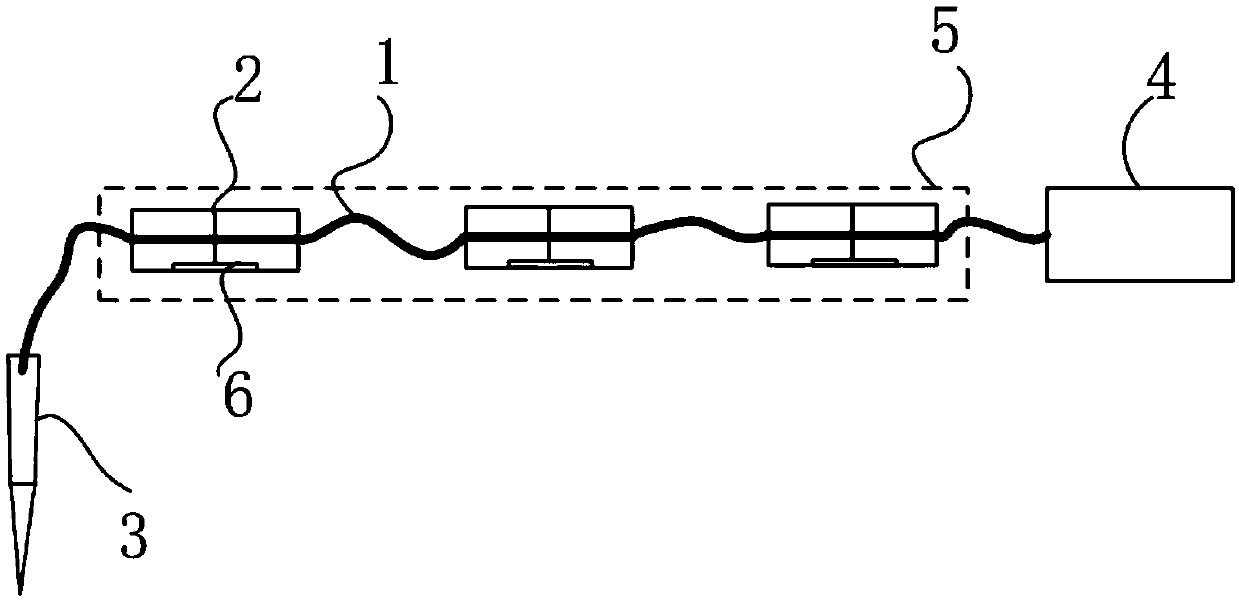

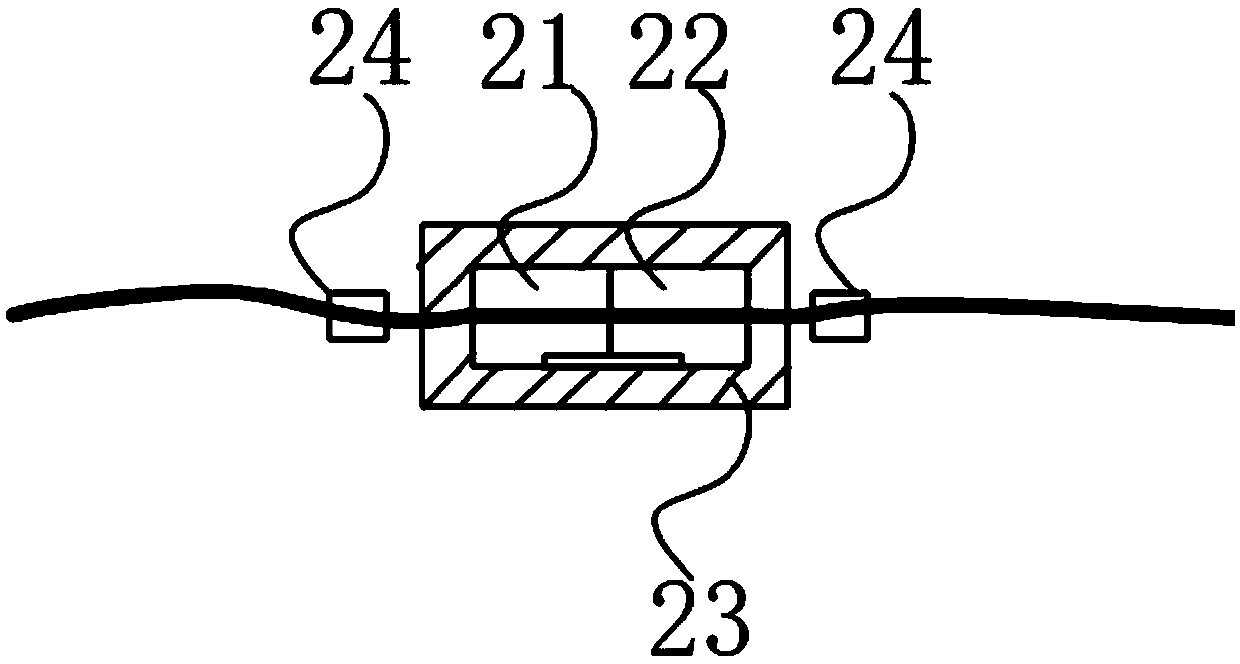

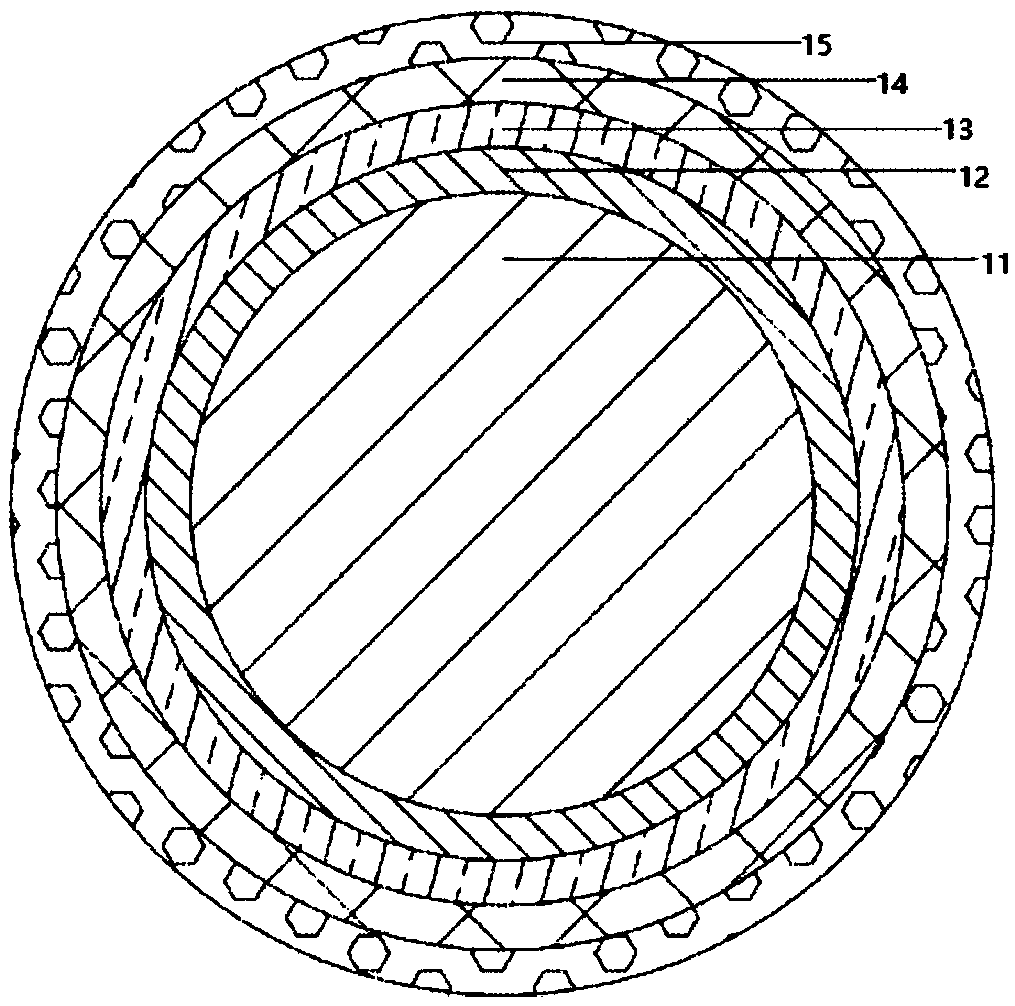

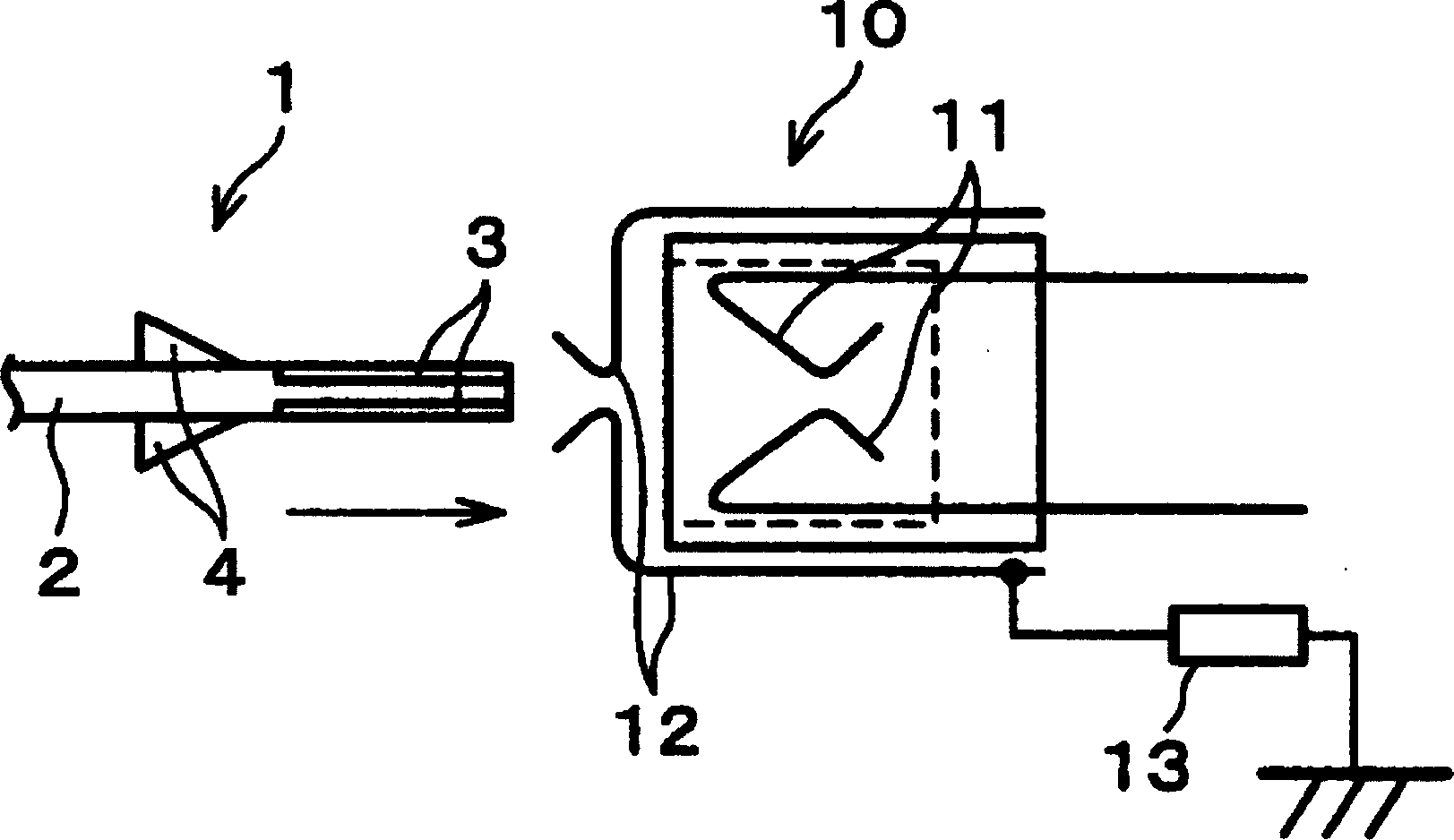

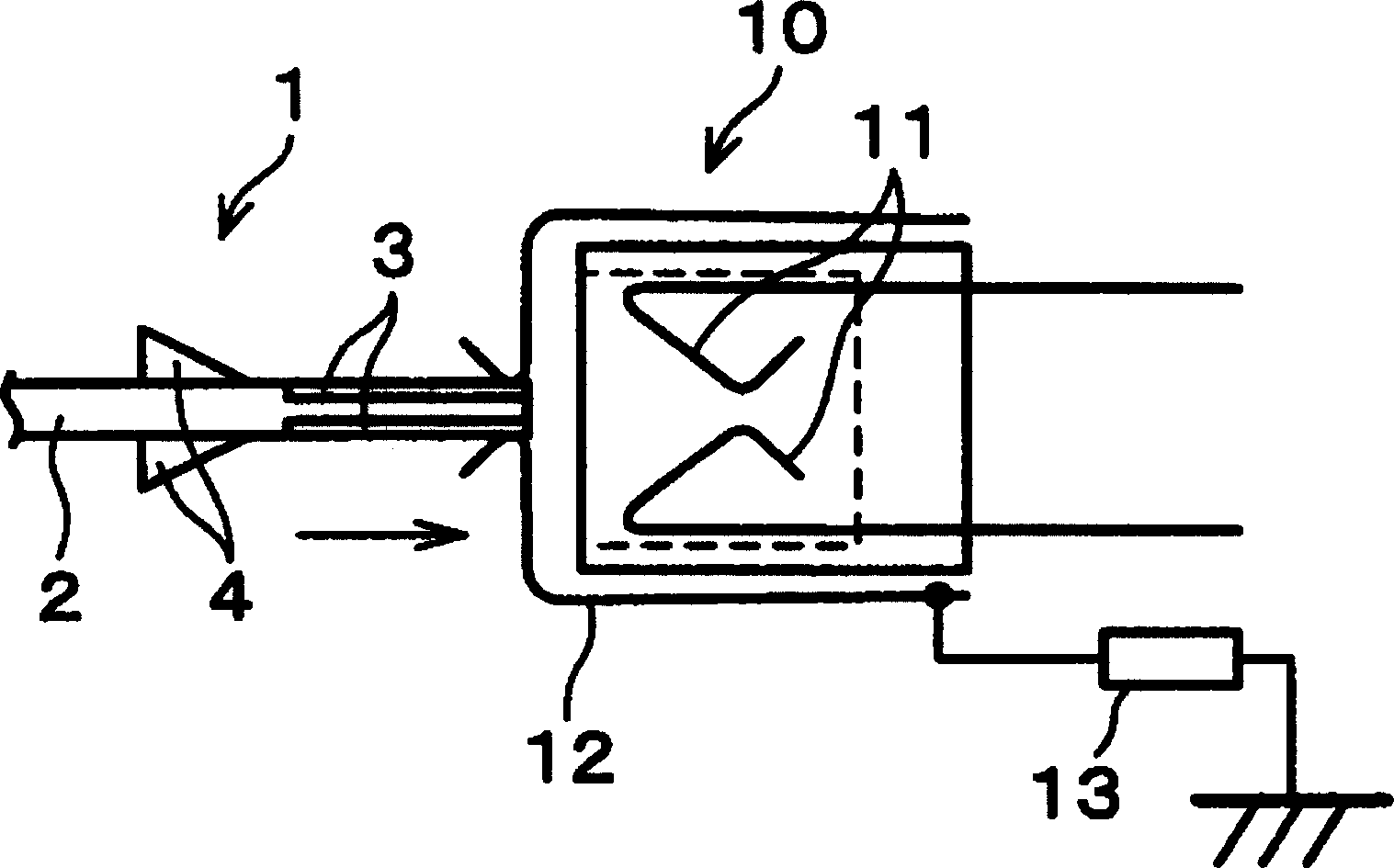

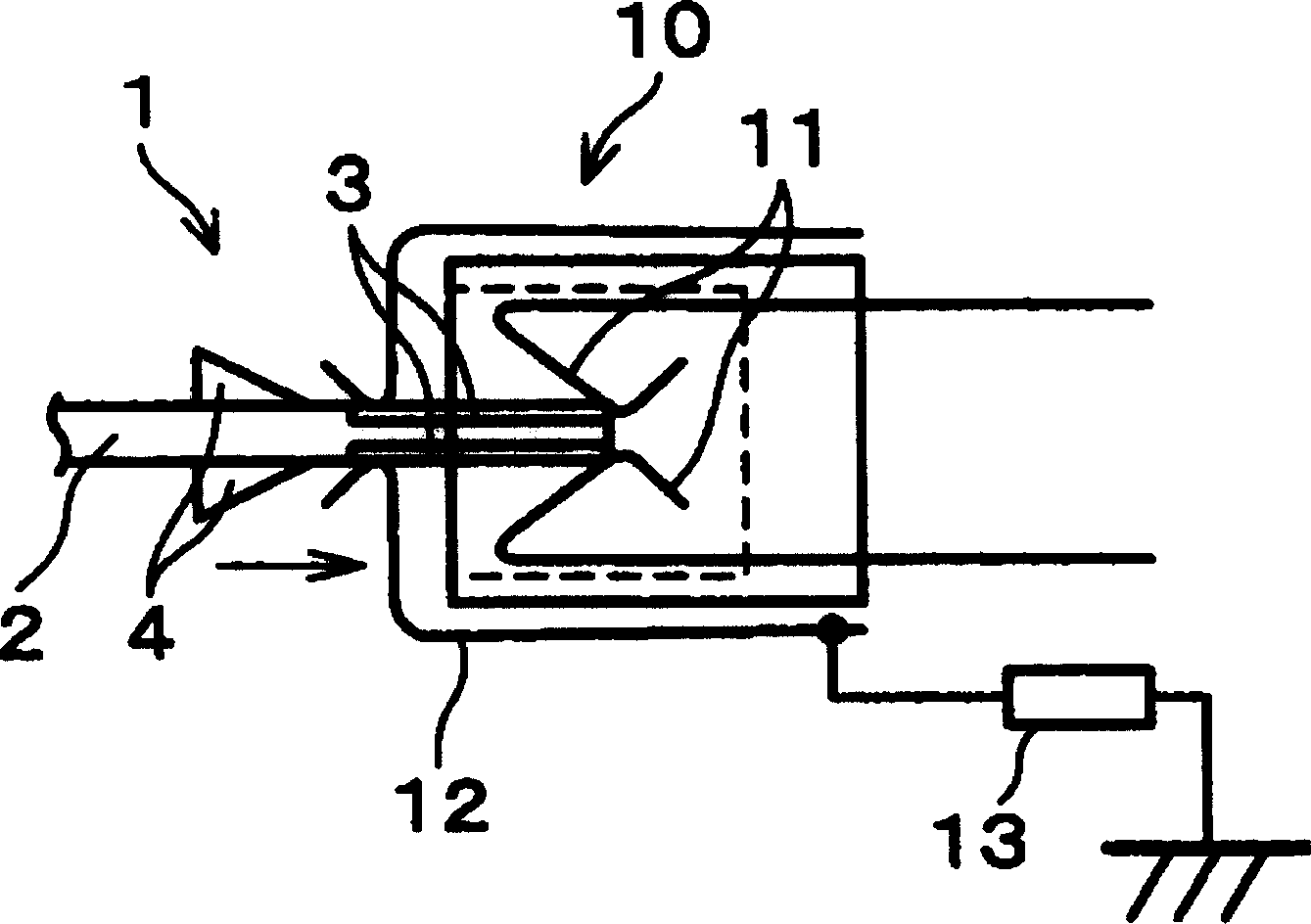

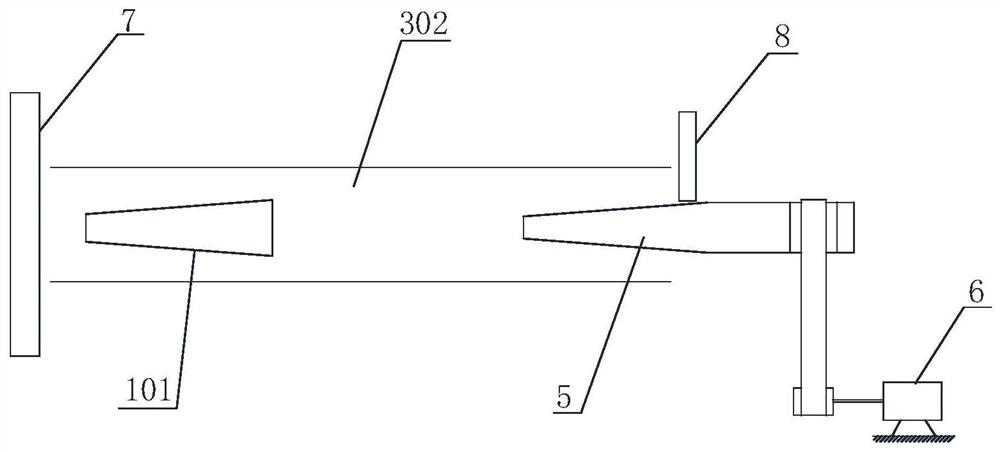

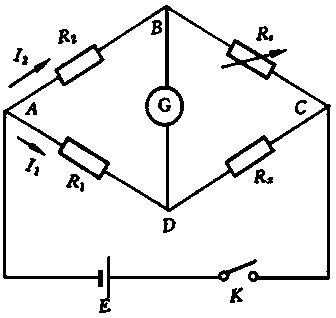

ActiveCN108671415AIncrease mobilityImprove controllabilityLight therapyTherapeutic DevicesEngineering

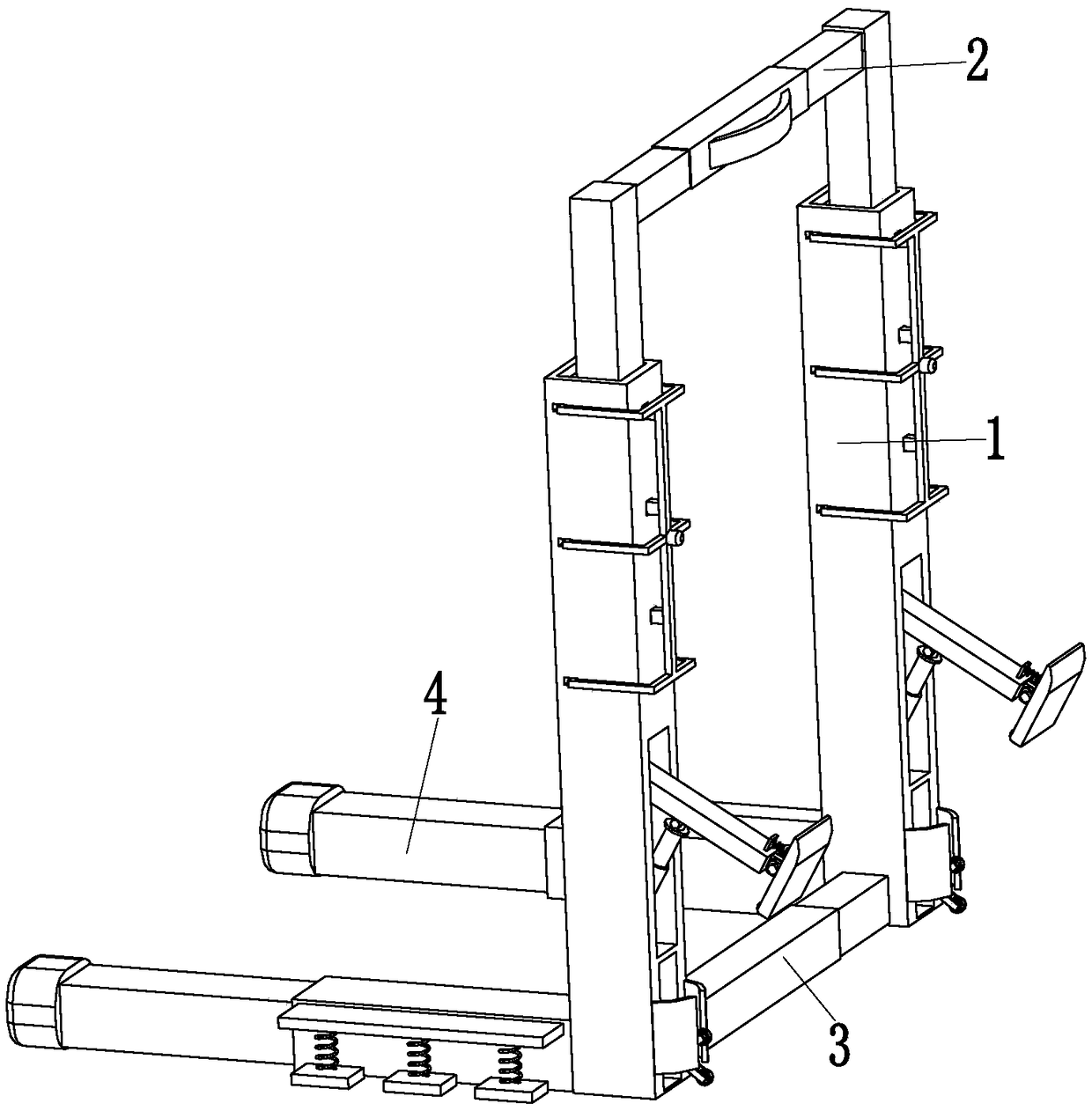

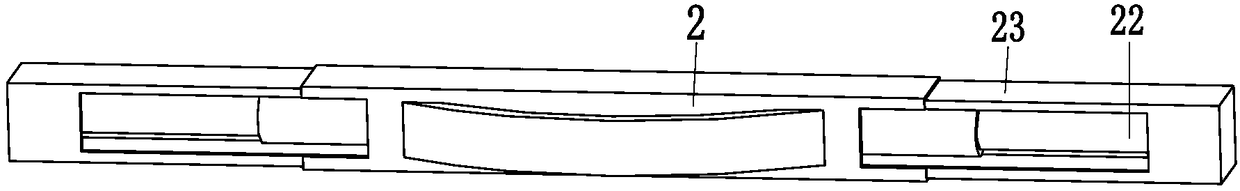

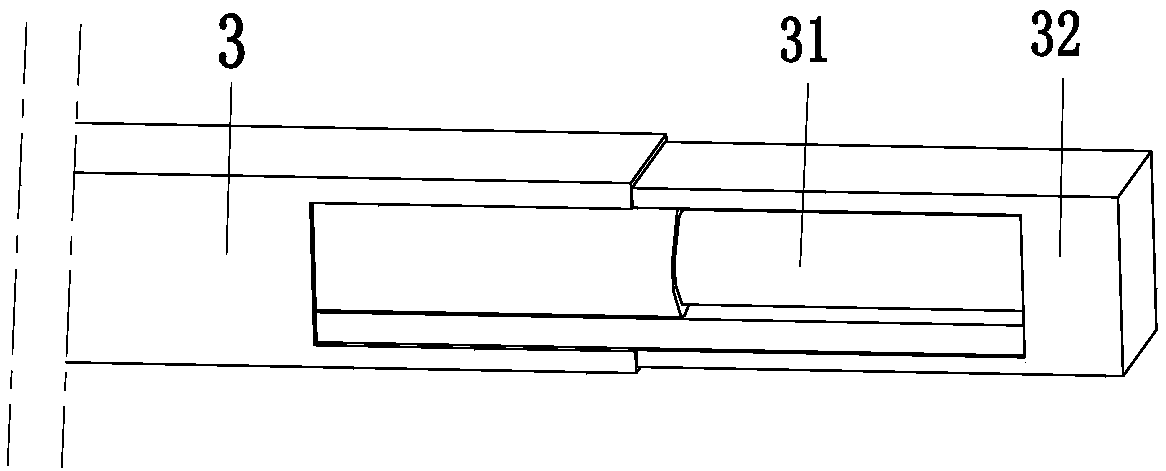

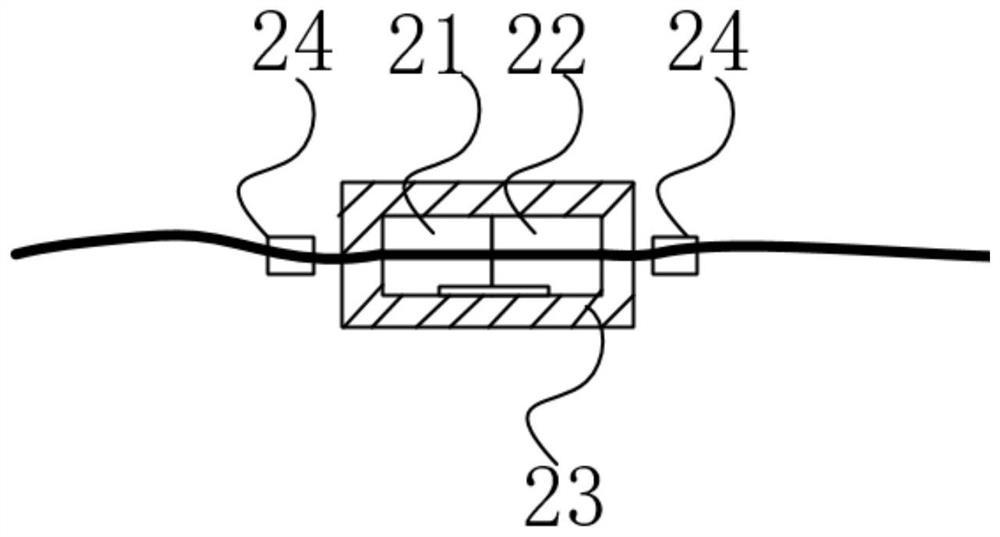

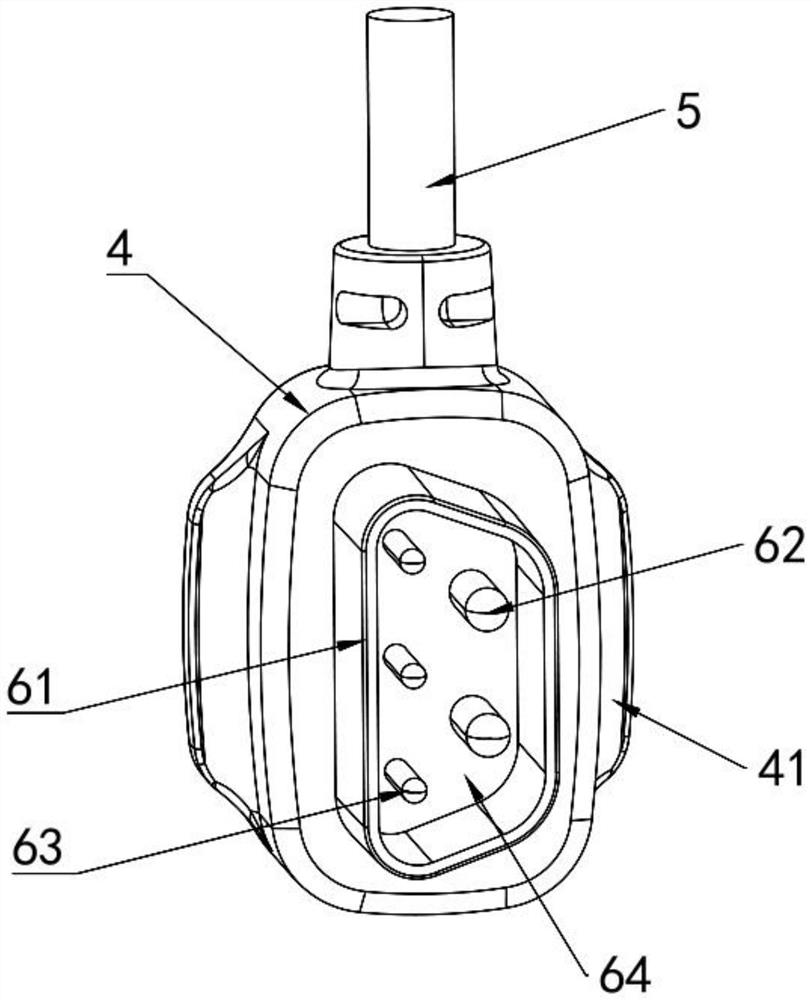

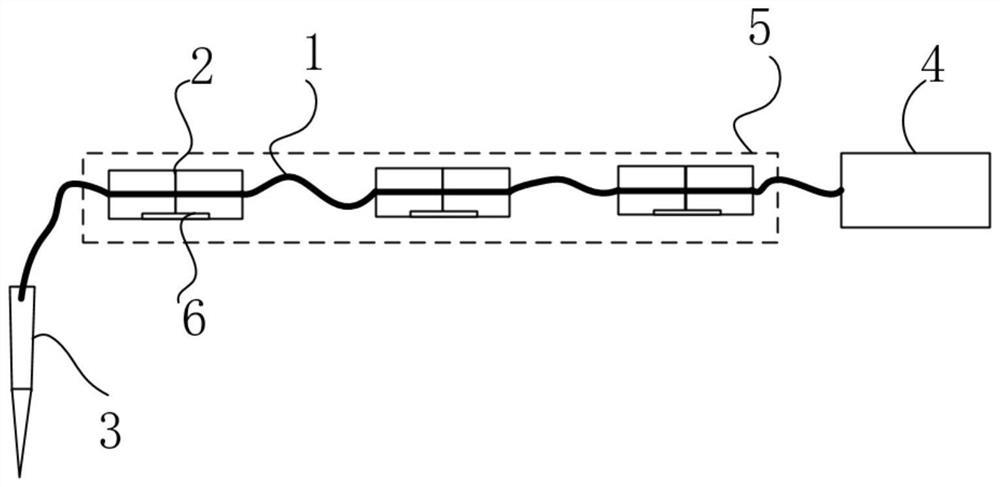

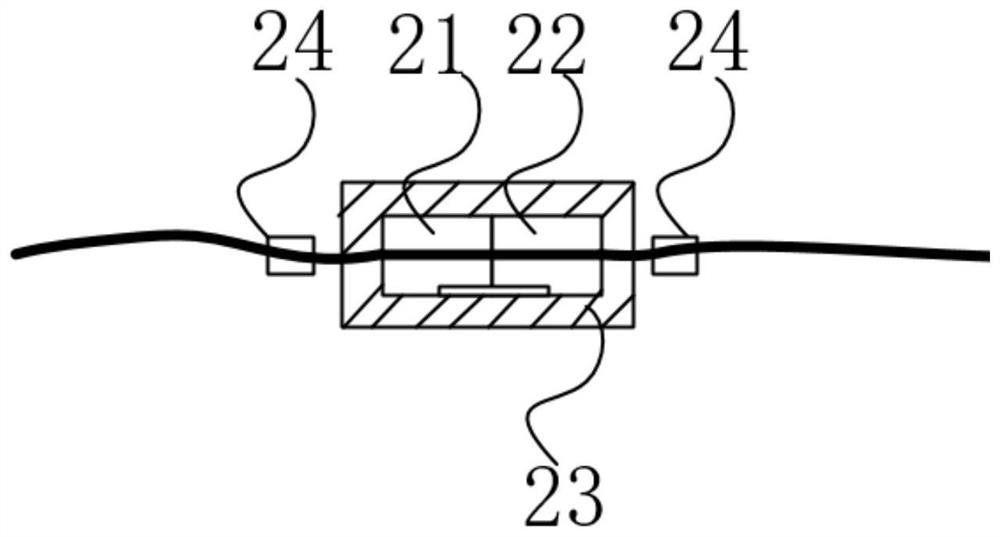

The invention discloses a medical optical fiber comprising N laser fibers (1) with predetermined lengths, N-1 fiber connecting components (2), a fiber guiding structure (3) and a fiber controller (4).The N laser fibers (1) are connected through the N-1 fiber connecting components (2), and a serial fiber structure (5) is sequentially formed. One end of the serial fiber structure (5) is connected to the fiber guiding structure (3), the other end is connected to the fiber controller (4), and N is a positive integer. Each of the fiber connecting components (2) is provided with a pressure sensor (6) which is connected to the fiber controller (4) and is used for detecting the pressure data of the fiber connection components (2). The fiber controller (4) is used for judging the coupling state ofthe medical optical fiber according to the pressure data. According to the medical optical fiber of the invention, the controllability of the optical fiber in a human body is enhanced, problems suchas damage of the optical fiber are prevented, and the risk of treatment is reduced.

Owner:XIAN LASER TECH MEDICAL TECH CO LTD

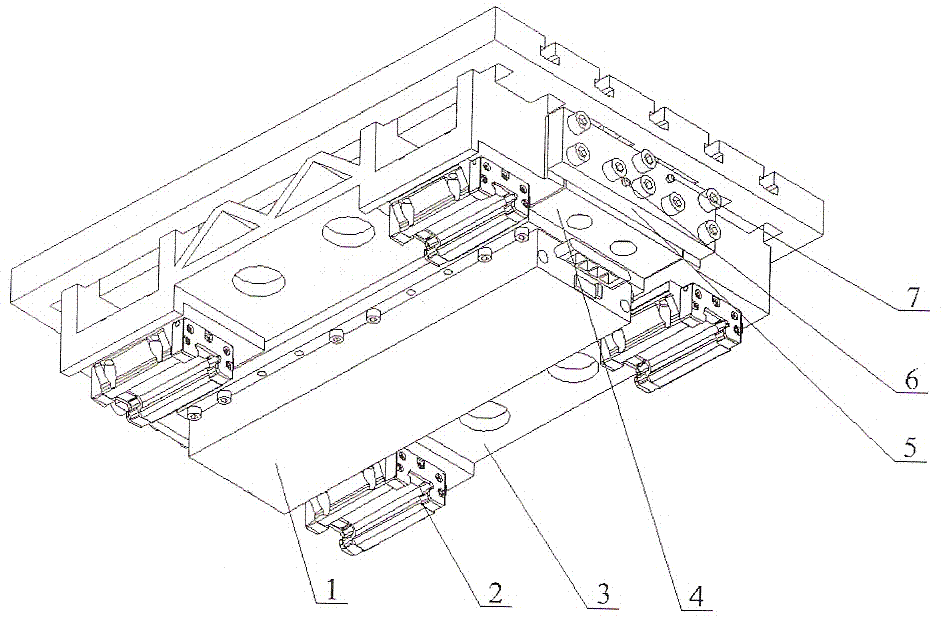

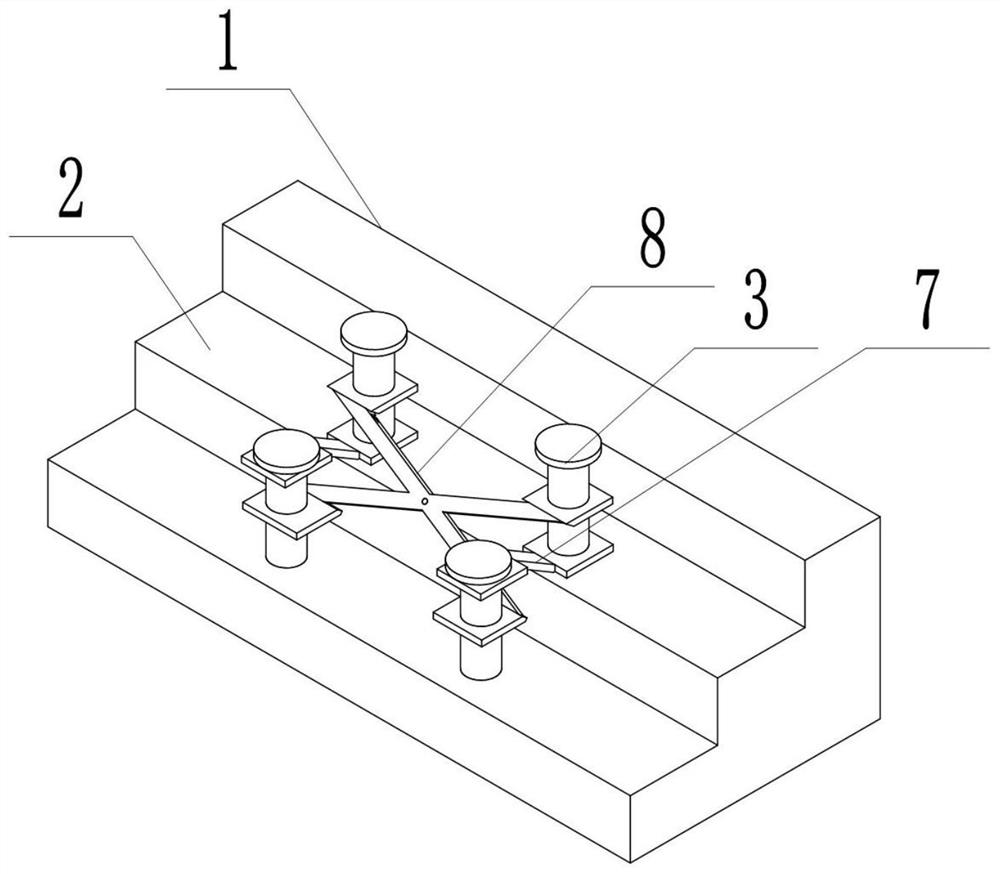

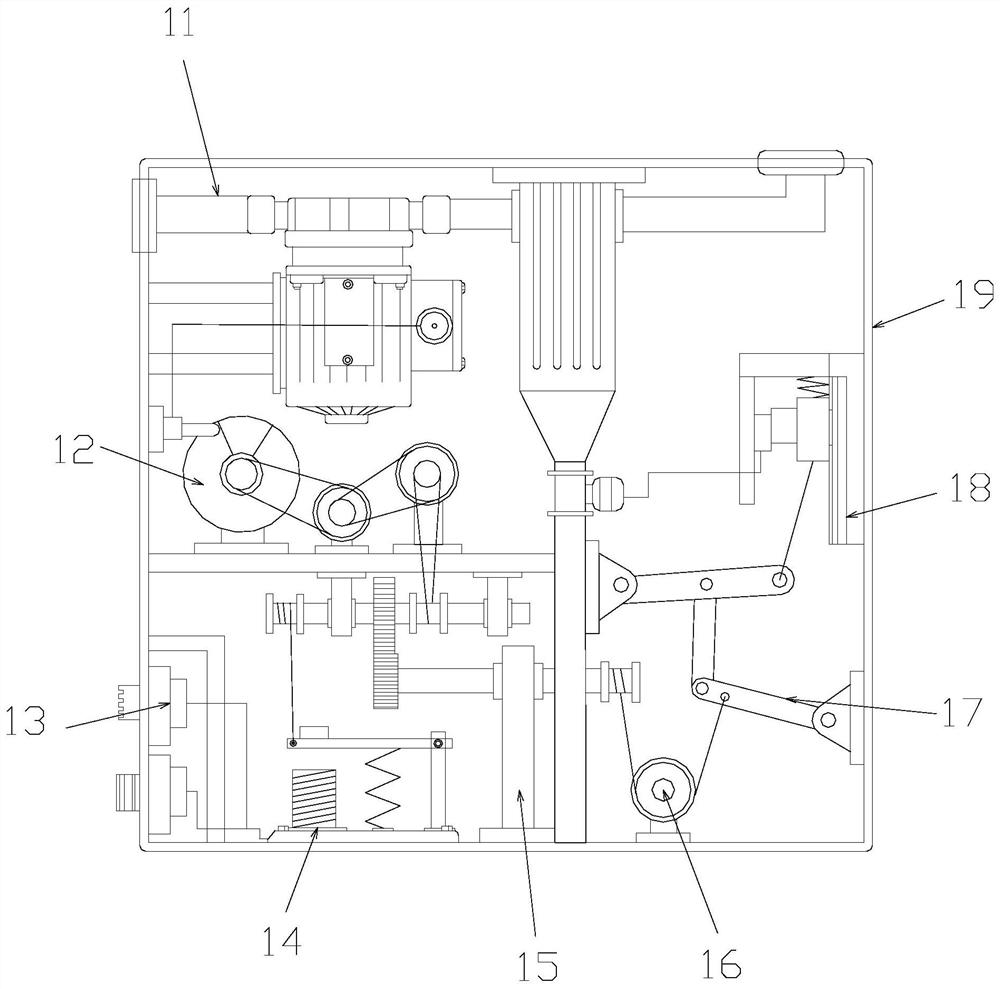

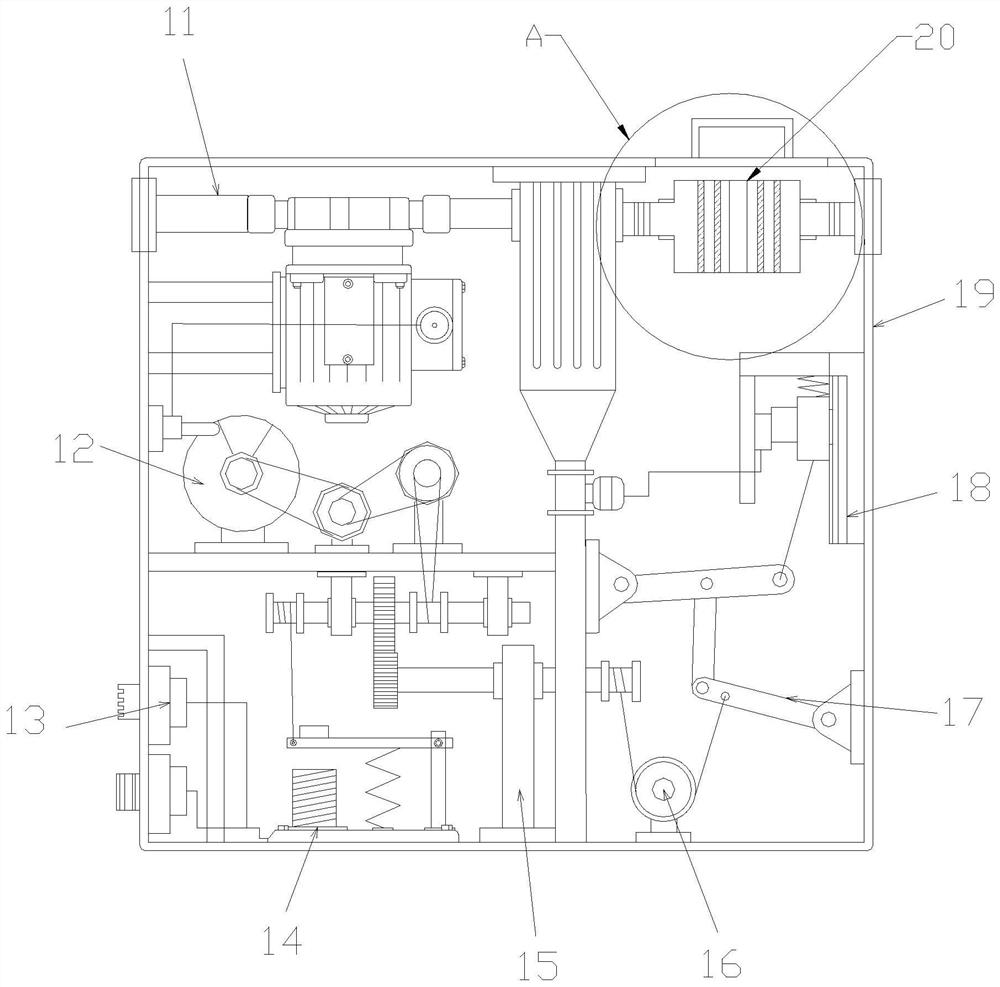

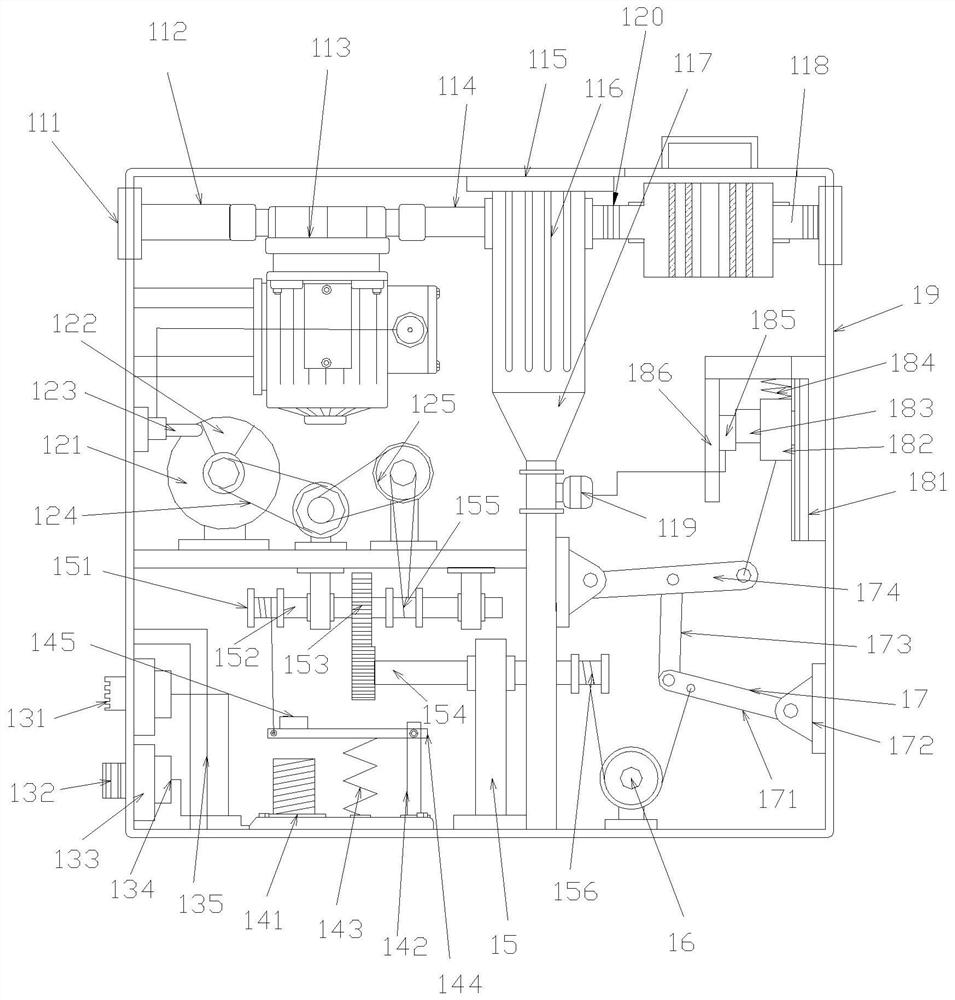

Numerical control machine tool split-type operating platform for installing linear motor

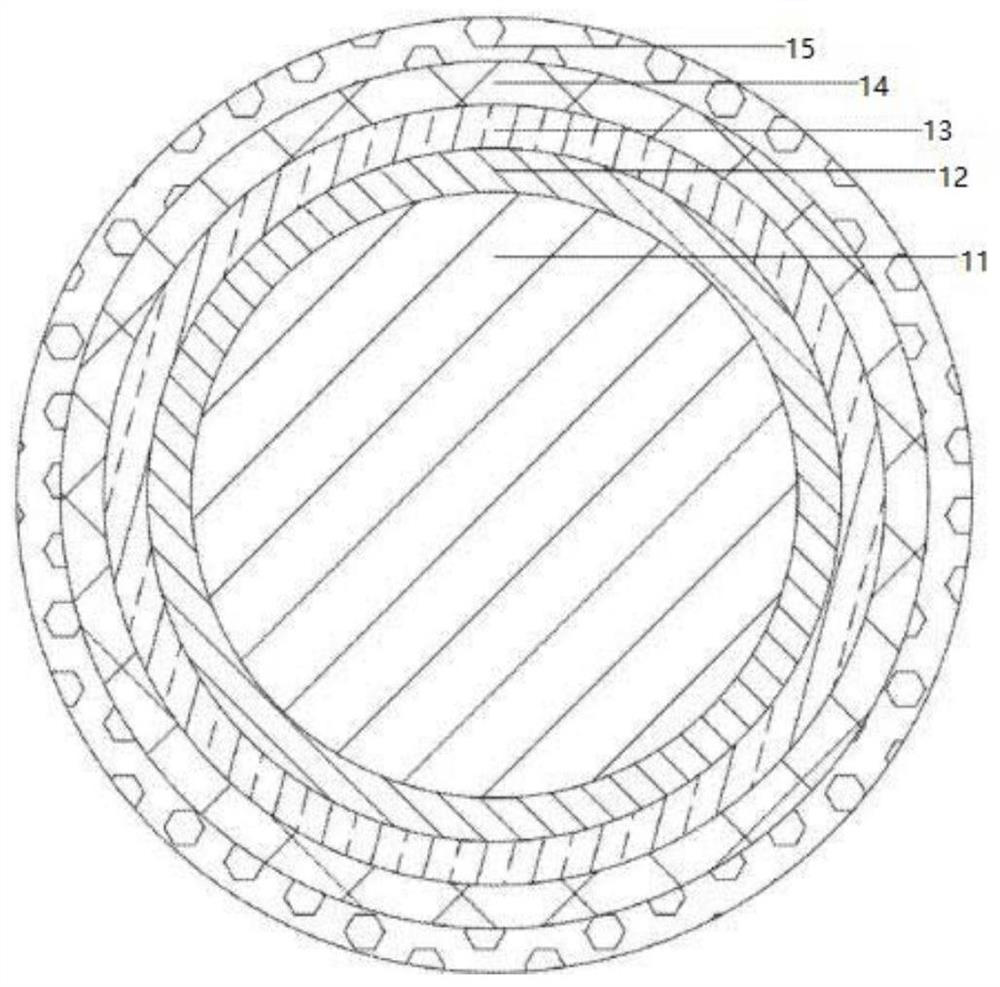

ActiveCN103084856APrevent problems such as damageAvoid corrosionLarge fixed membersMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a numerical control machine tool split-type operating platform for installing a linear motor. The numerical control machine tool split-type operating platform for installing the linear motor comprises a water-proof operating platform, an electrical machine coil mounting plate, a linear motor primary coil, a connecting plate, an operating platform locating pin, an electrical machine coil mounting plate locating pin and linear guide way slide blocks, wherein the four linear guide way slide blocks are arranged on a linear guide way of a saddle. The operating platform is arranged on the linear guide way slide blocks through four notches formed in side edges of the operating platform. The linear motor primary coil is fixedly connected on the bottom surface of the electrical machine coil mounting plate through screws. Dovetail grooves formed in side edges of the electrical machine coil mounting plate coincide with dovetail grooves of the operating platform. The numerical control machine tool split-type operating platform for installing the linear motor is reasonable in structure. The fact that cutting fluid leaks the underside of the operating platform to corrode the operating platform and main castings of the saddle is avoided.

Owner:NANTONG UNIVERSITY

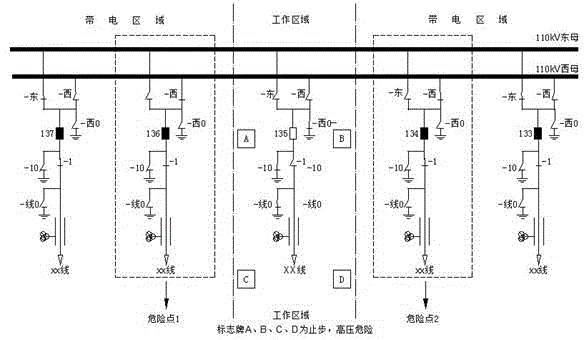

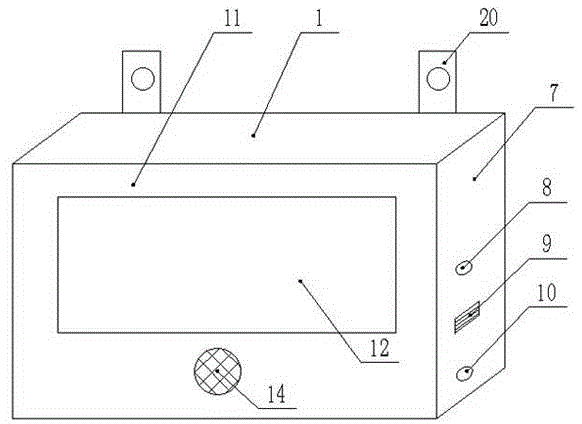

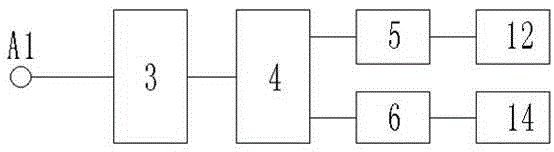

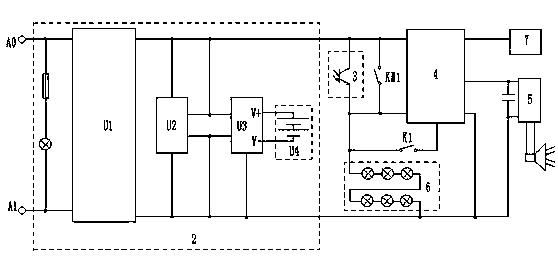

Live-line region LED alarm device

InactiveCN104966377AAvoid personal accidentsThe warning function is intuitiveAlarmsElectric transmission signalling systemsLoudspeakerPower circuits

The invention discloses a live-line region LED alarm device, and belongs to the technical field of power safety protection. A solved technical problem is to provide the live-line region LED alarm device which can give a sound-light alarm protect when a maintenance worker gets close to a dangerous point. An employed technical scheme is that the device comprises a box body and a sound-light alarm circuit board disposed in the box body; the sound-light alarm circuit board is provided with a power circuit board, an induction processing circuit board, an LED alarm display circuit board, a voice alarm circuit board, and a power input terminal A1; a front panel of the box body is provided with an LED display screen and a loudspeaker; a side panel of the box body is provided with a power input connector, a USB data reading-writing connector, and a power switch; the LED display screen, the loudspeaker, the power input connector, the USB data reading-writing connector and the power switch are respectively connected with the sound-light alarm circuit board; and the device is suitable for the power field.

Owner:STATE GRID CORP OF CHINA +1

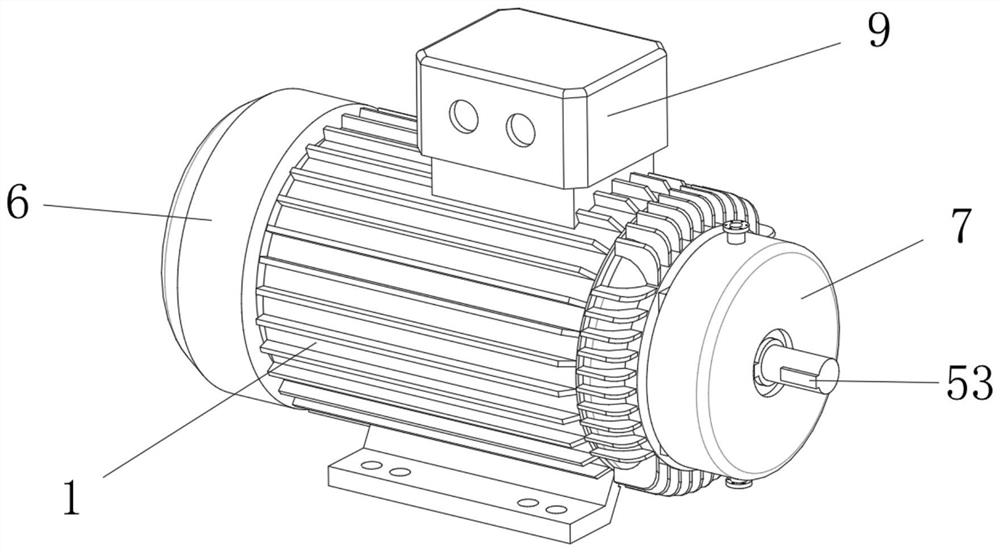

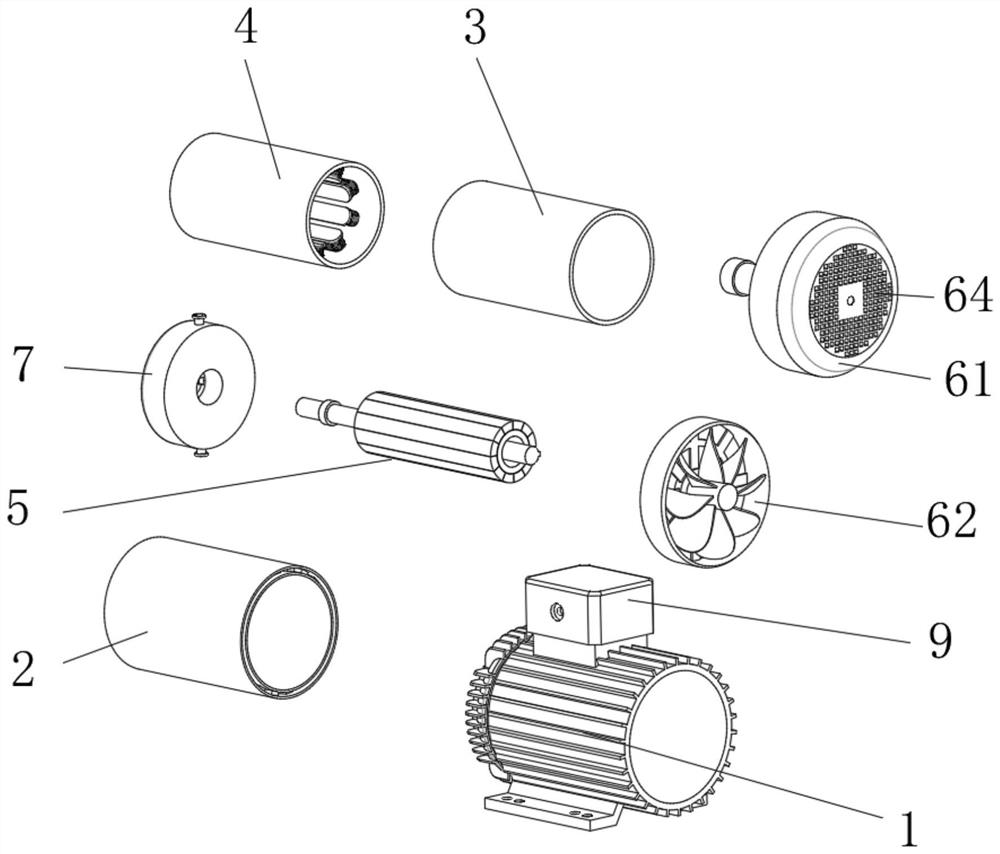

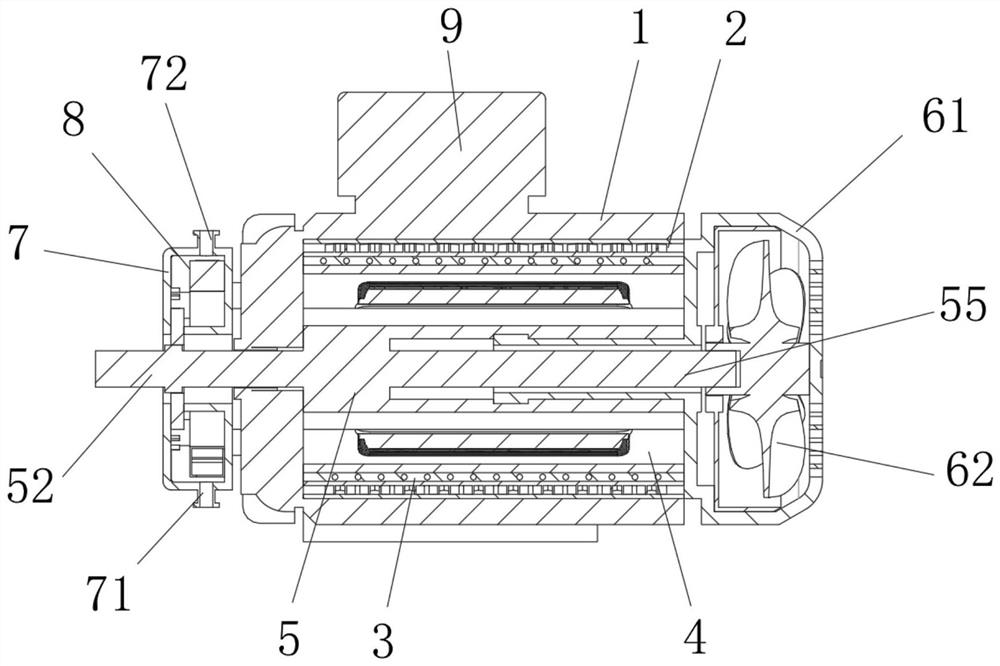

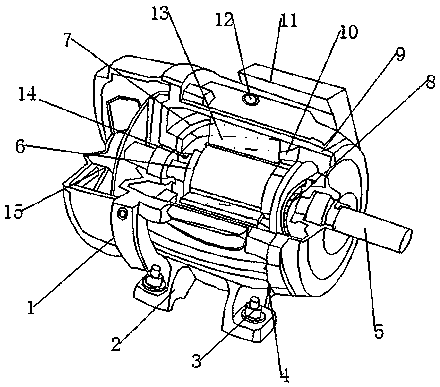

Environment-friendly energy-saving motor

ActiveCN113300526AGuaranteed normal operationPrevent problems such as damageElectric machinesCooling/ventillation arrangementElectric machineGear wheel

The invention relates to the technical field of energy-saving motors, and discloses an environment-friendly energy-saving motor which comprises a motor shell and a controller, a heat exchanger is fixedly arranged on one side of the motor shell, a flow speed adjusting mechanism is arranged in the heat exchanger, and the flow speed adjusting mechanism comprises a flow speed control disc, a flow speed control gear and a plurality of speed adjusting impellers. Power is output outwards through the magnet rotor via the output key, and meanwhile, the rotating speed is output outwards through the heat dissipation driving key and the flow speed control key at the two ends of the magnet rotor, so that the magnet rotor can output power to the flow speed adjusting mechanism and the radiator. The flow speed adjusting mechanism and the radiator are driven to correspondingly change according to the change of the output power, so that the heat dissipation efficiency of the environment-friendly energy-saving motor is changed along with the change of the output power, the internal temperature of the environment-friendly energy-saving motor is maintained at a low level, the normal operation of the energy-saving motor is ensured, and the problems of damage and the like caused by overhigh internal temperature of the energy-saving motor are prevented.

Owner:浙江方特智能传动有限公司

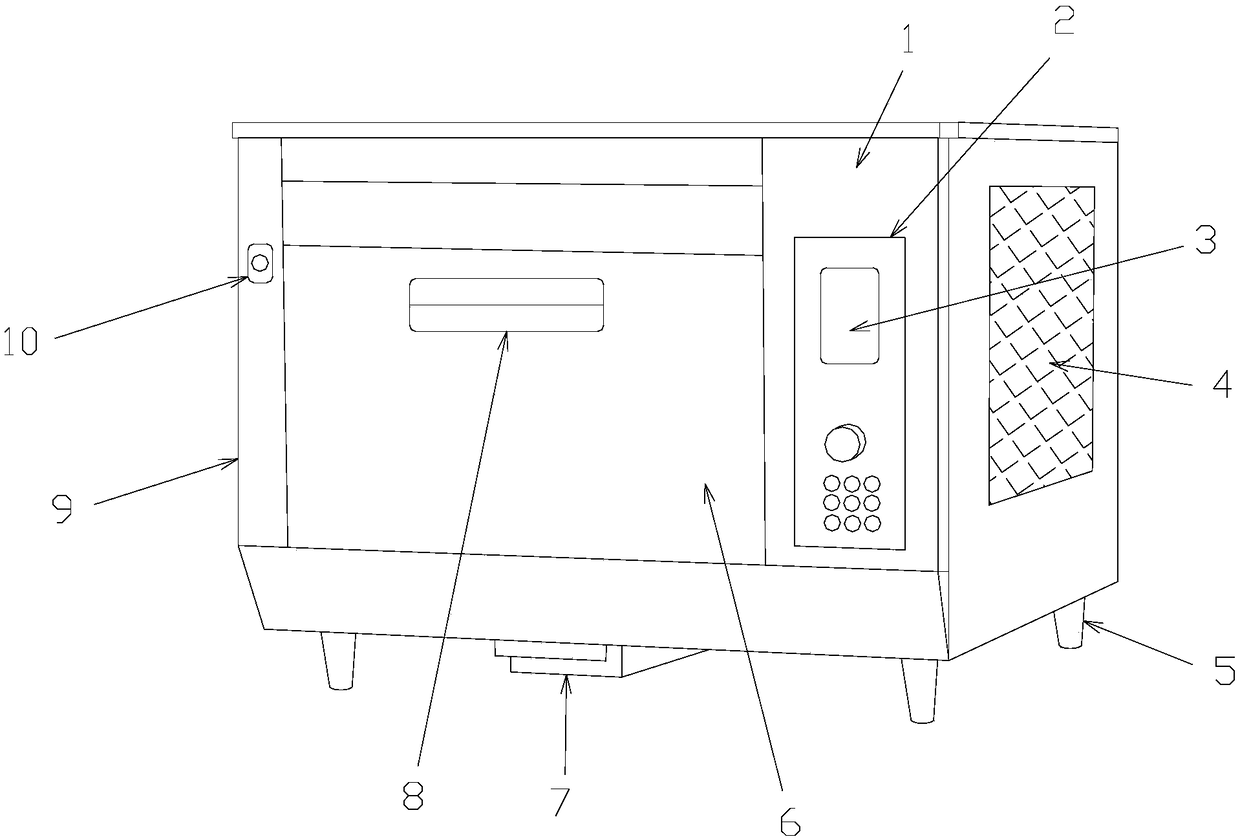

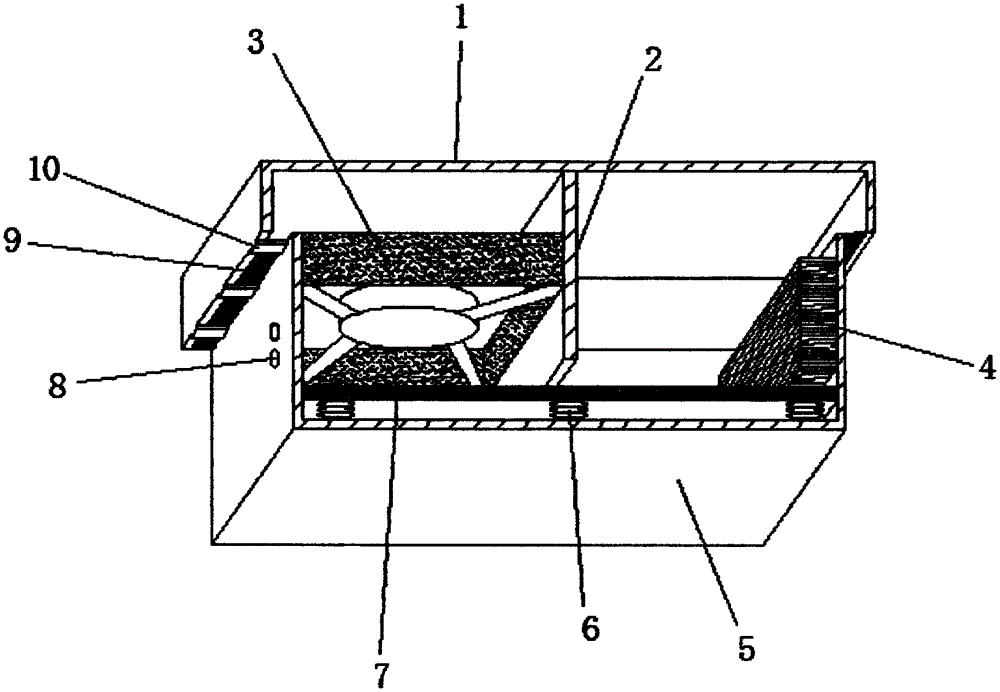

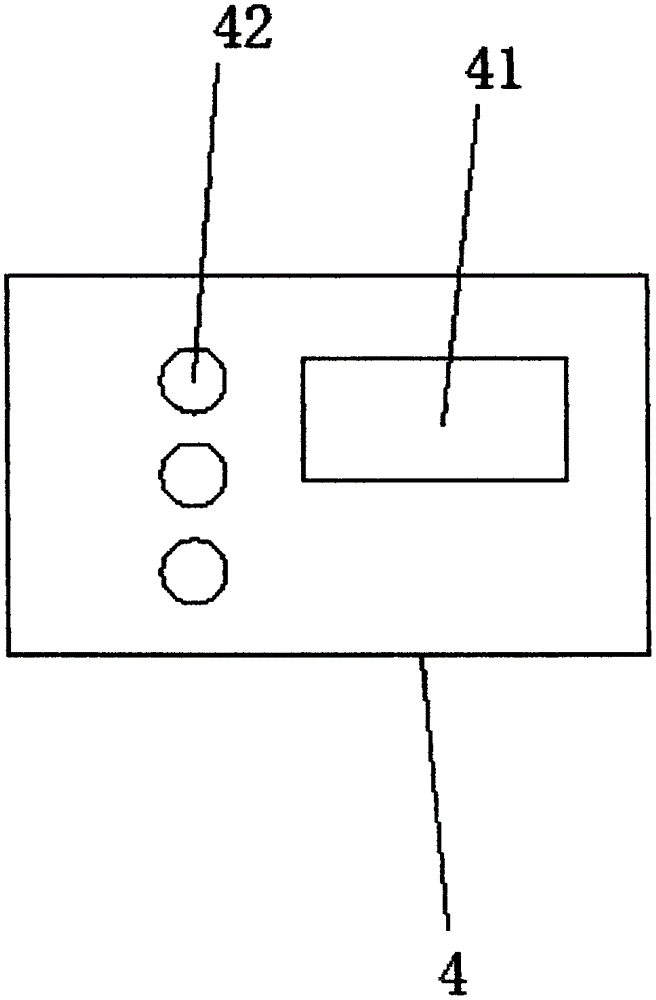

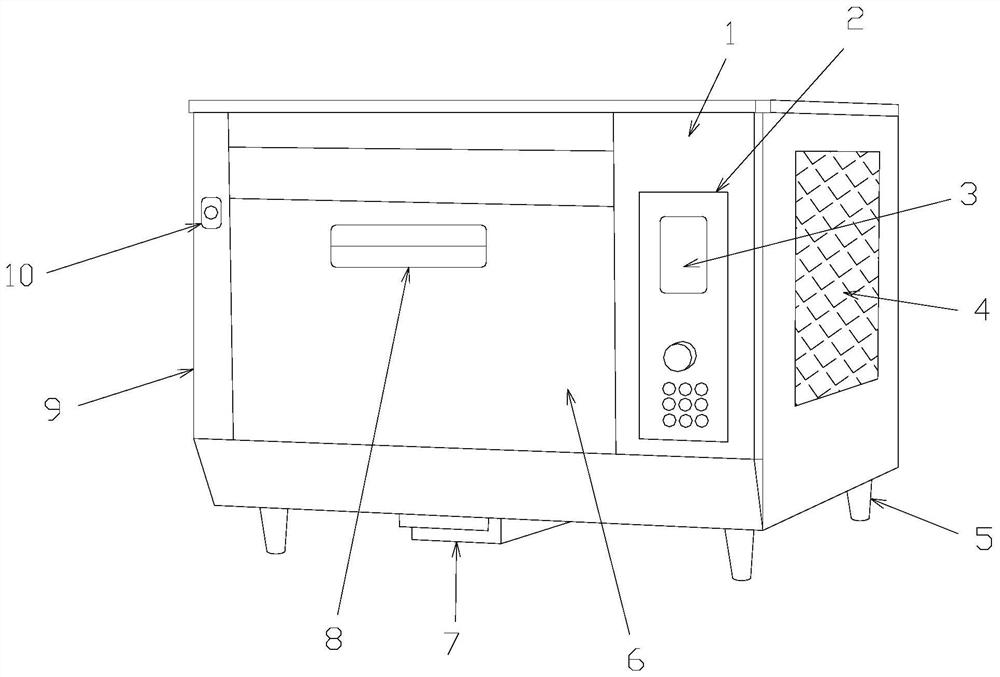

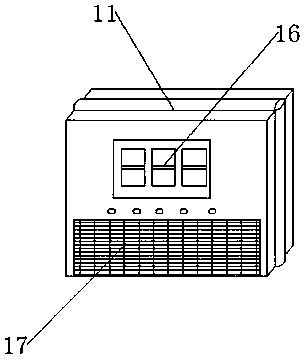

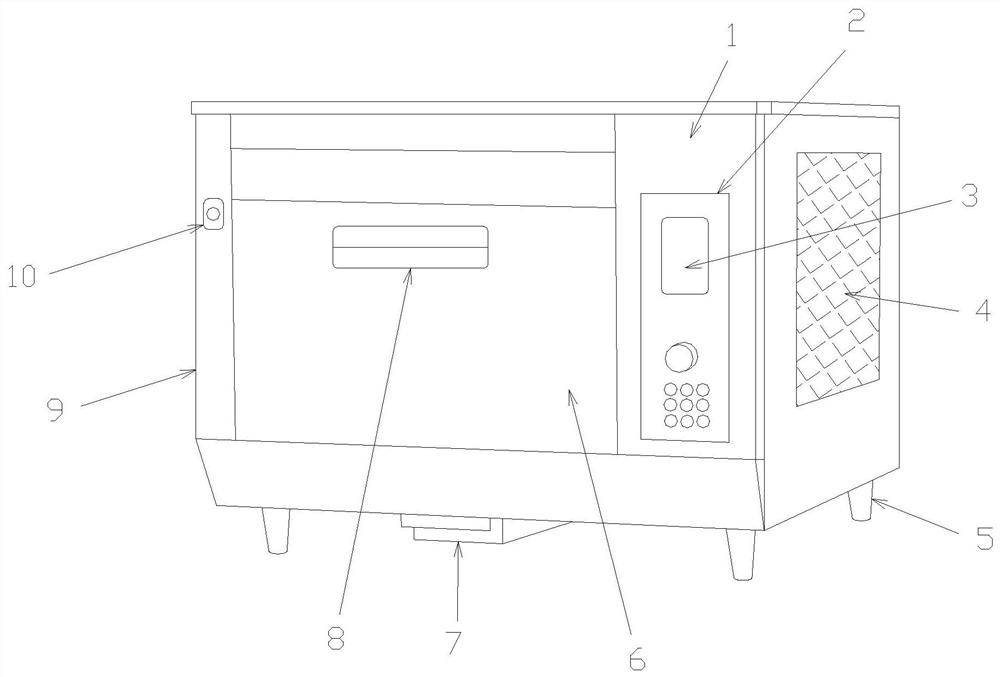

Multifunctional freezing device

ActiveCN108917257AExtended service lifePrevent problems such as damageLighting and heating apparatusDomestic refrigeratorsWater vaporWater storage tank

The invention discloses a multifunctional freezing device. The multifunctional freezing device structurally comprises a freezing and dehumidifying device, a control panel, a working state display screen, a heat dissipation port, a bottom adjustable support frame, a quick freezing box door, a dehumidifying water storage tank, a quick freezing box door handle, a main machine body and a power switch.The left front portion of the main machine body is provided with the power switch, and the power switch is fixedly connected with the main machine body through bolts. The right portion of the main machine body is provided with the freezing and dehumidifying device, and the control panel is arranged at the front portion of the freezing and dehumidifying device. The control panel is fixedly connected to the main machine body by bolts, and the control panel is connected with components through signal lines. The multifunctional freezing device can effectively prevent water vapor from entering theinside of the device and causing damage due to freezing, effectively improves the working stability and reliability and prolongs the service life of a refrigerating device.

Owner:端黎明

Flexible and convenient track and field hurdle

ActiveCN109331486AHeight adjustableAdjustable lengthRace-coursesRidingEngineeringTrack and field athletics

The invention relates to a flexible and convenient track and field hurdle. The flexible and convenient track and field hurdle comprises two hurdle columns, a hurdle transverse rod, a hurdle bottom pillar and supporting pillars, the hurdle transverse rod is installed between the upper ends of the two hurdle columns, the hurdle bottom pillar is installed between the lower ends of the two hurdle columns, and each supporting pillar is installed at the left end of the corresponding hurdle column; each hurdle column comprises the corresponding supporting pillar, a moving pillar, telescopic clampingteeth, a clamping tooth spring, a limiting clamping plate, a limiting connecting pillar, a tilting prevention mechanism, a pushing mechanism, a limiting spring and a pressing shelf. By means of the flexible and convenient track and field hurdle, the problems can be solved that when an existing hurdle is in use, the height and length of the hurdle cannot be adjusted, the hurdle cannot be conveniently moved, the hurdle may be deformed when falling off, and the hidden safety hazard that people may get hurt when the hurdle falls off exists; the height and length of the hurdle can be adjusted, andthe hurdle can be conveniently moved.

Owner:NANJING FORESTRY UNIV

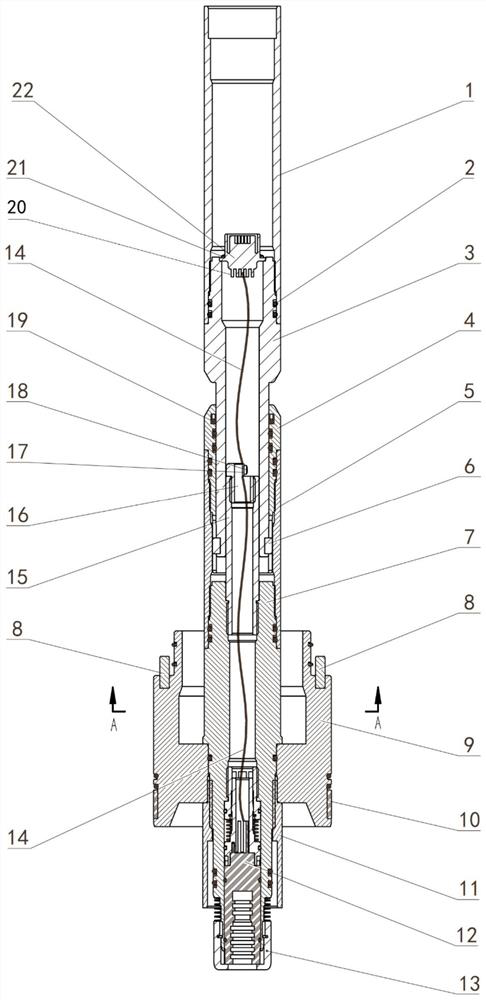

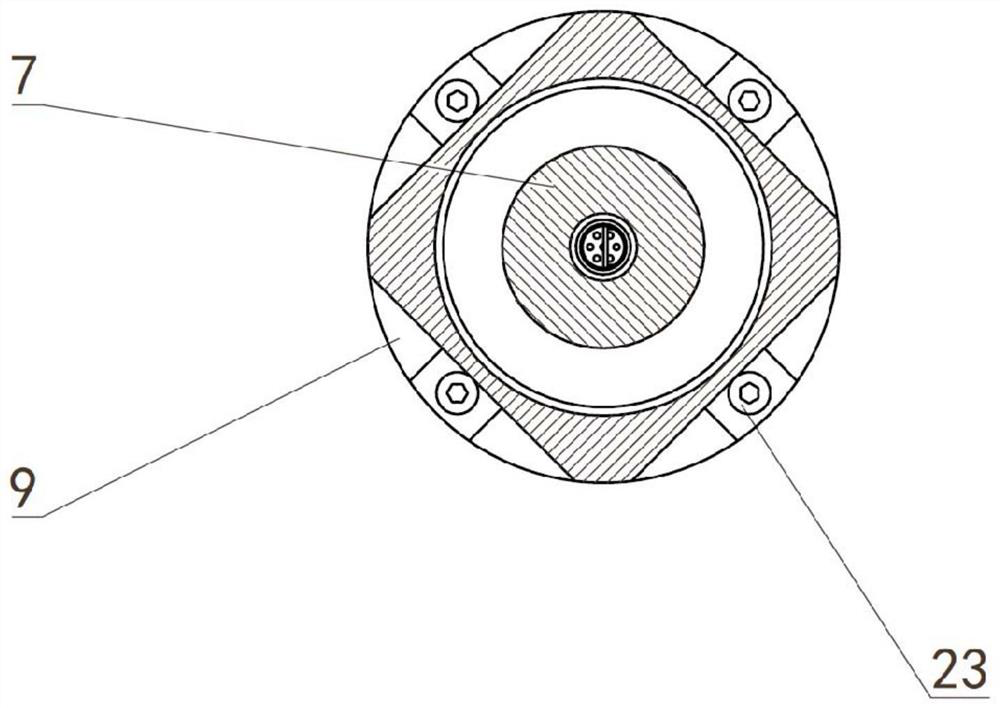

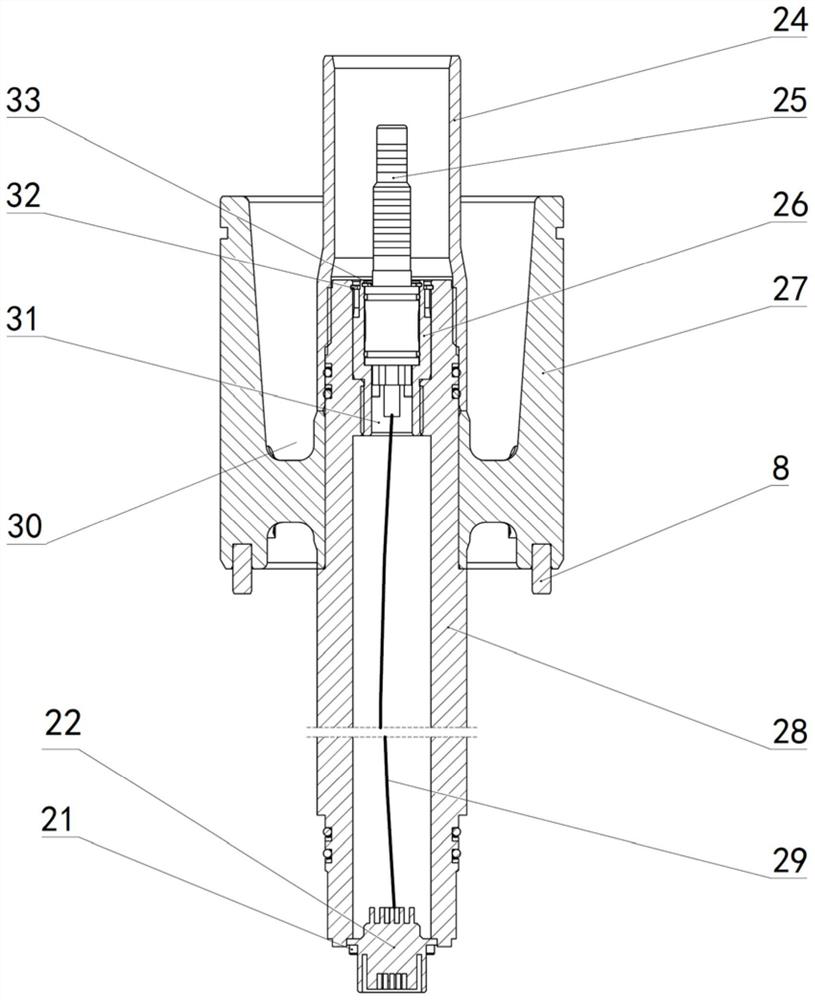

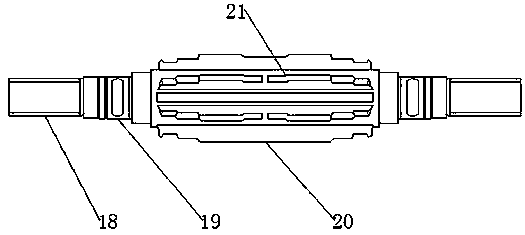

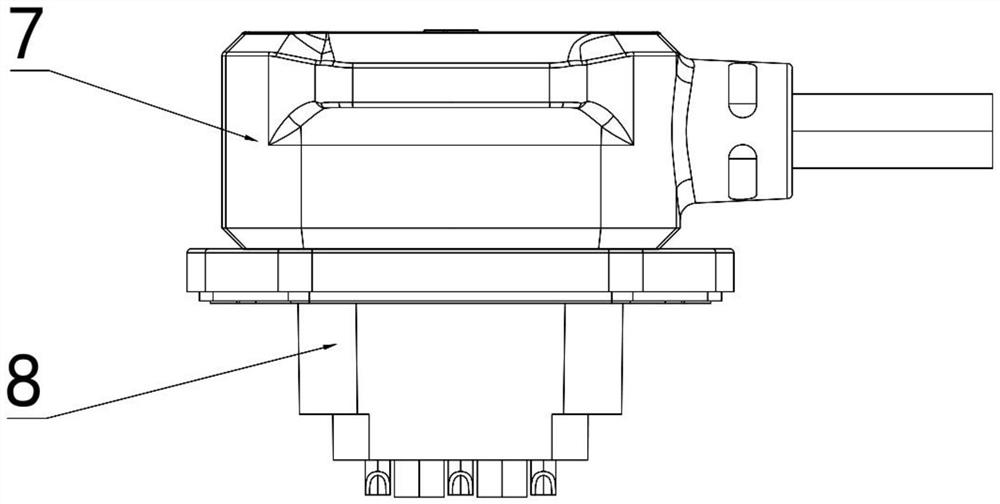

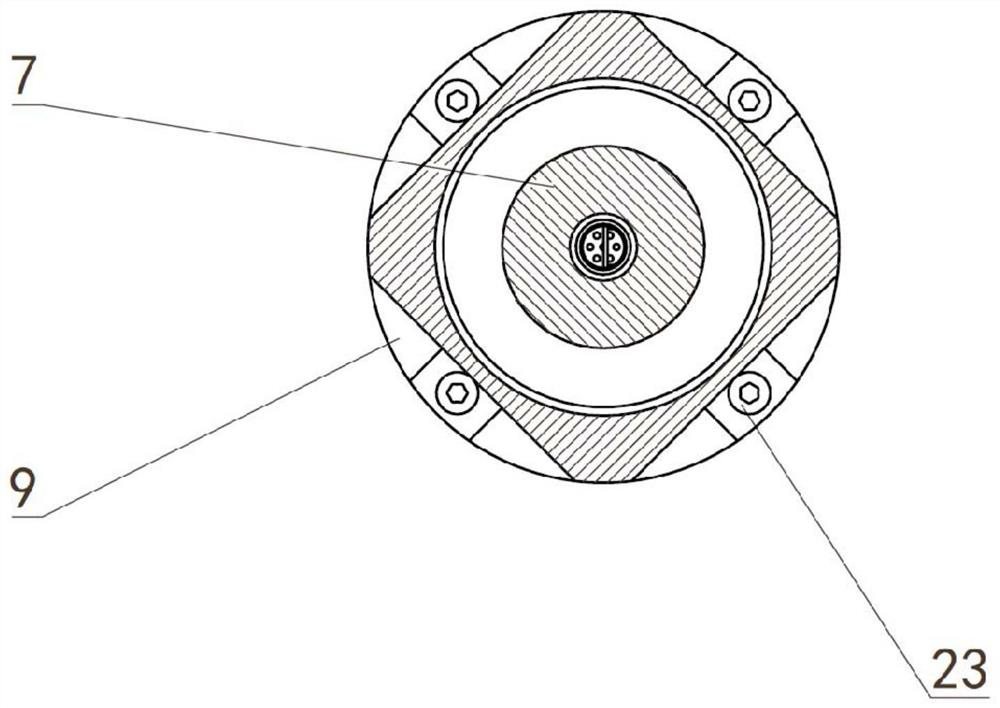

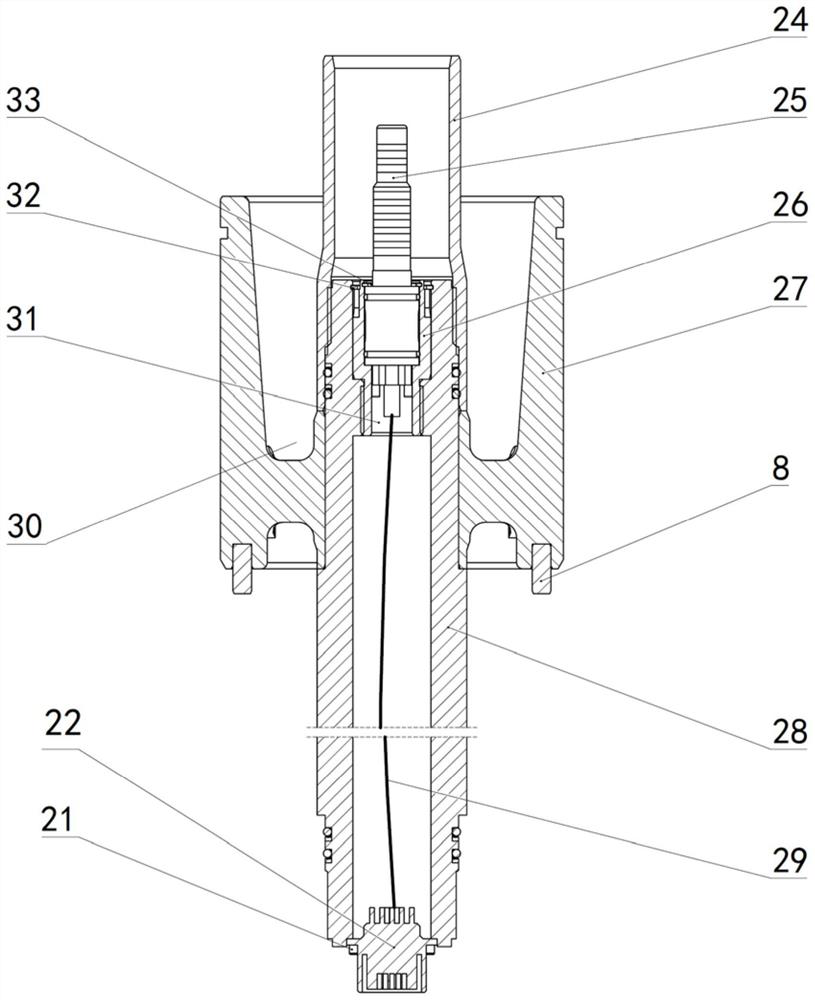

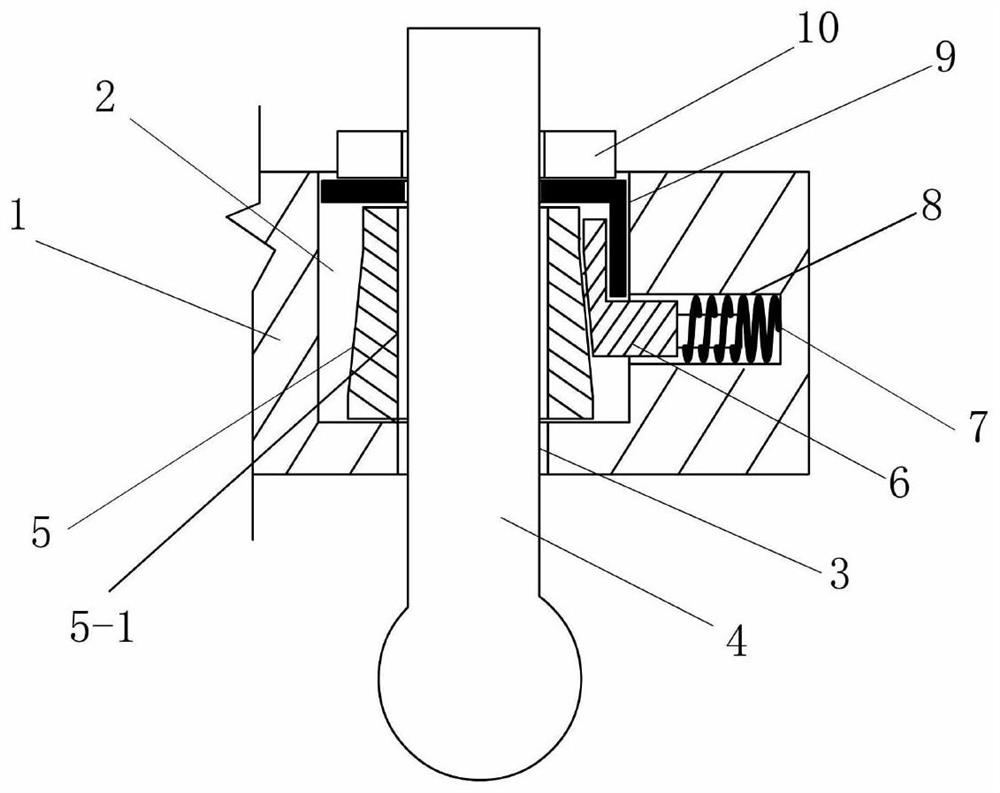

Integrated short connector of instrument while drilling

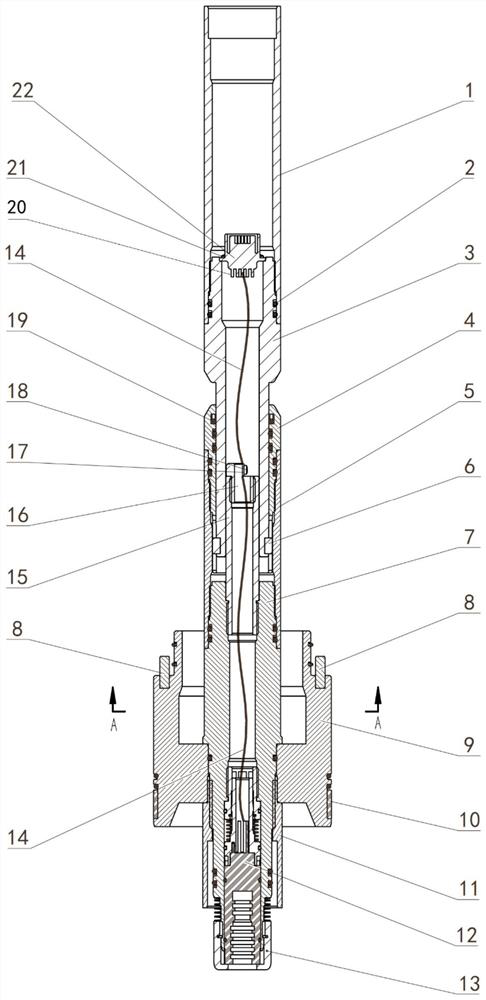

ActiveCN111878001AMating operation is simpleMeet the mating requirementsSurveyDrilling rodsEngineeringDrill

The invention relates to an integrated short connector of an instrument while drilling. The integrated short connector comprises a telescopic connector assembly, a fixed connector assembly and a drillcollar adapter substitute, wherein the drill collar adapter substitute comprises an upper drill collar adapter substitute and a lower drill collar adapter substitute; the telescopic connector assembly is mounted in the upper drill collar adapter substitute, and the fixed connector assembly is mounted in the lower drill collar adapter substitute; and the telescopic connector assembly is in butt joint with the fixed connector assembly. The connector is integrated with drill collar nipples of all instruments of a rotary geosteering system, and power supply communication in the instruments is achieved while threaded connection of the drill collars of all the instruments is achieved. In the manner of achieving internal communication in the instruments through direct connection of the drill collars, on one hand, the link of manual connection of a field operation is omitted, so that the construction safety risk is reduced, and the operation efficiency is improved; and besides, the threaded connection torque of the drill collars is utilized to ensure the reliability of internal connection power supply communication of the instruments, so that the use and assembly difficulty of the connector is reduced, the overall structure of the connector is simplified, and the length of the connector is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

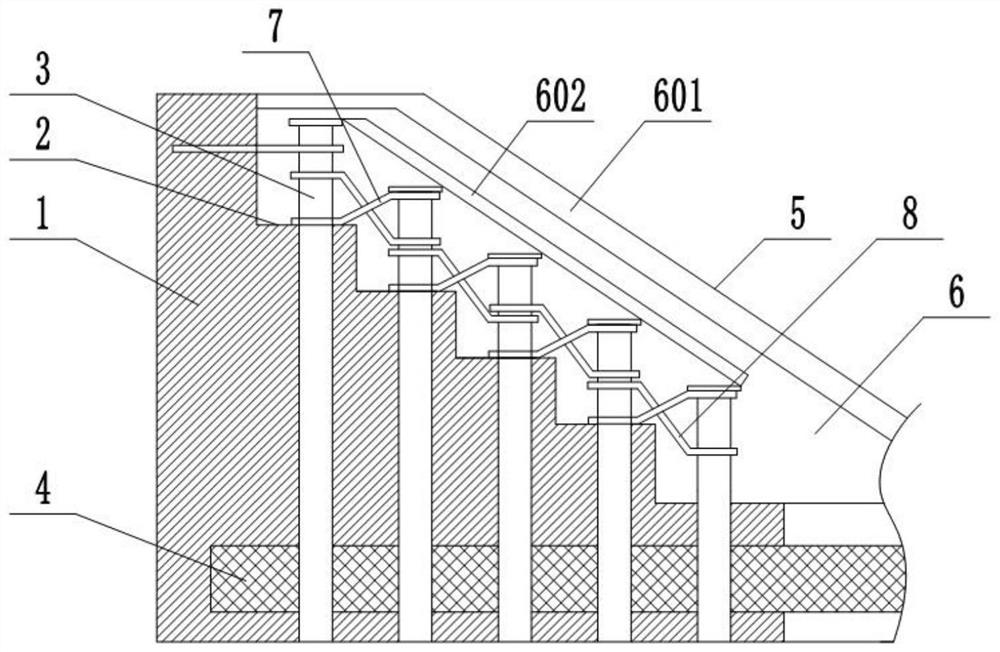

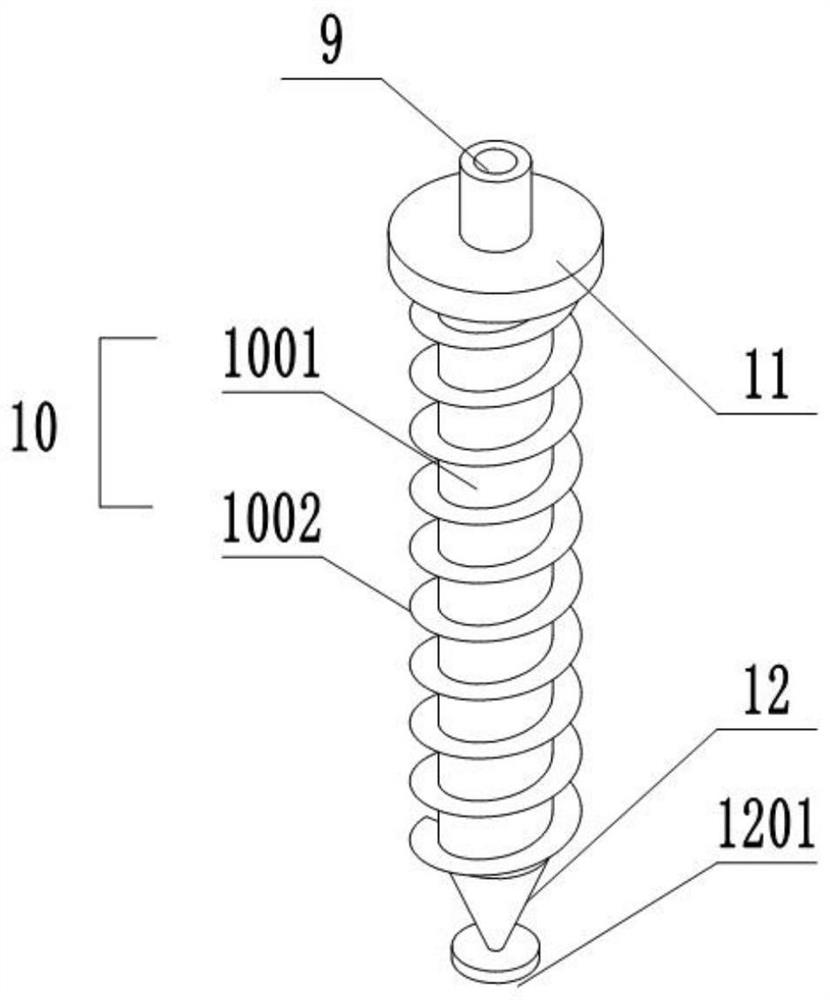

A kind of highway widened roadbed structure and construction method thereof

ActiveCN113622238BImprove stabilityReduce the probability of sinkingRoadwaysBulkheads/pilesRoad surfaceSubgrade

The invention discloses a highway widened subgrade structure, comprising an original subgrade, the slope of the original subgrade is provided with a number of steps, fixed piles are arranged longitudinally on the upper part of the steps, and connecting components are arranged between the fixed piles; A new roadbed is arranged on the top surface of the fixed pile, and the new roadbed is fixedly connected with the original roadbed; a filler layer is arranged between the new roadbed and the original roadbed, and the filler layer is fixedly connected with the fixed pile. The highway widened subgrade structure and the construction method thereof provided by the invention are simple in construction and high in construction efficiency, and the original subgrade and the new subgrade are effectively combined through fixed piles, connecting components and reinforcing layers, thereby reducing the occurrence of occurrences between the new subgrade and the original subgrade. The probability of sideslip is reduced, and the new roadbed instability, road surface damage, uneven settlement at the junction of the new and old roadbeds, and overall performance decline in the widened expressway are reduced. It has important theoretical significance and practical value.

Owner:广西北投交通养护科技集团有限公司

Charger with timing and shock prevention functions

InactiveCN106712147AEasy maintenanceExtended service lifeBatteries circuit arrangementsElectric powerDisplay deviceEngineering

The invention discloses a charger with timing and shock prevention functions, which comprises an upper shell. The middle of the upper shell is fixedly provided with a separator; the left side of the separator is provided with a cooling fan; the lower part of the cooling fan is provided with a circuit board; the cooling fan and the circuit board are electrically connected through a wire; a certain gap exists between the separator and the bottom circuit board; the lower part of the circuit board is movably connected with the lower shell via springs; the upper part of the lower shell is fixedly connected with the upper shell through ribs; an air screen is arranged between the ribs; the left side of the lower shell is provided with indicating lamps; the indicating lamps and the circuit board are electrically connected through a wire; the right side of the lower shell is provided with a timer; the timer comprises a display; and the left side of the display is provided with operation buttons. The structure is simple, the operation is convenient and practical, the real charging time of the battery can be recorded, timely maintenance of a battery is facilitated, the service life of the battery is prolonged, and accidental breaking can be prevented.

Owner:岑利娜

Connecting clamp of package board edge connector and connecting structure for package board edge connector

InactiveCN1469510AProper connection statusImprove reliabilityIncorrect coupling preventionTwo-part coupling devicesEngineeringContact position

The short circuit metal fitting 12 is made to realize such an arrangement that the distance from the contact position of the connection terminals 3 of the electronic circuit board 1 and the short circuit metal fitting 12 in the opening section of the short circuit metal fitting 12 to the contact position of the electronic circuit board 1 and the connector pin 11 of the card edge connector 10 is shorter than the length of the connection terminals 3 in a connection direction and longer than the distance from the contact position of the connector pin 11 and the connection terminals 3 to the back ends of the connection terminals 3 when the electronic circuit board 1 is completely inserted in the card edge connector 10 . On this account, it is possible to provide a card edge connector connection jig and a card edge connector connection mechanism capable of preventing breakage of an electronic device etc. due to transient current generated at the time of connection between the electronic circuit board and the card edge connector.

Owner:ESPEC CORP

Printing mechanism, its ink box and bearing seat

InactiveCN100421953CPrevent problems such as damageLow costPrintingEngineeringMechanical engineering

Owner:MICROJET TECH

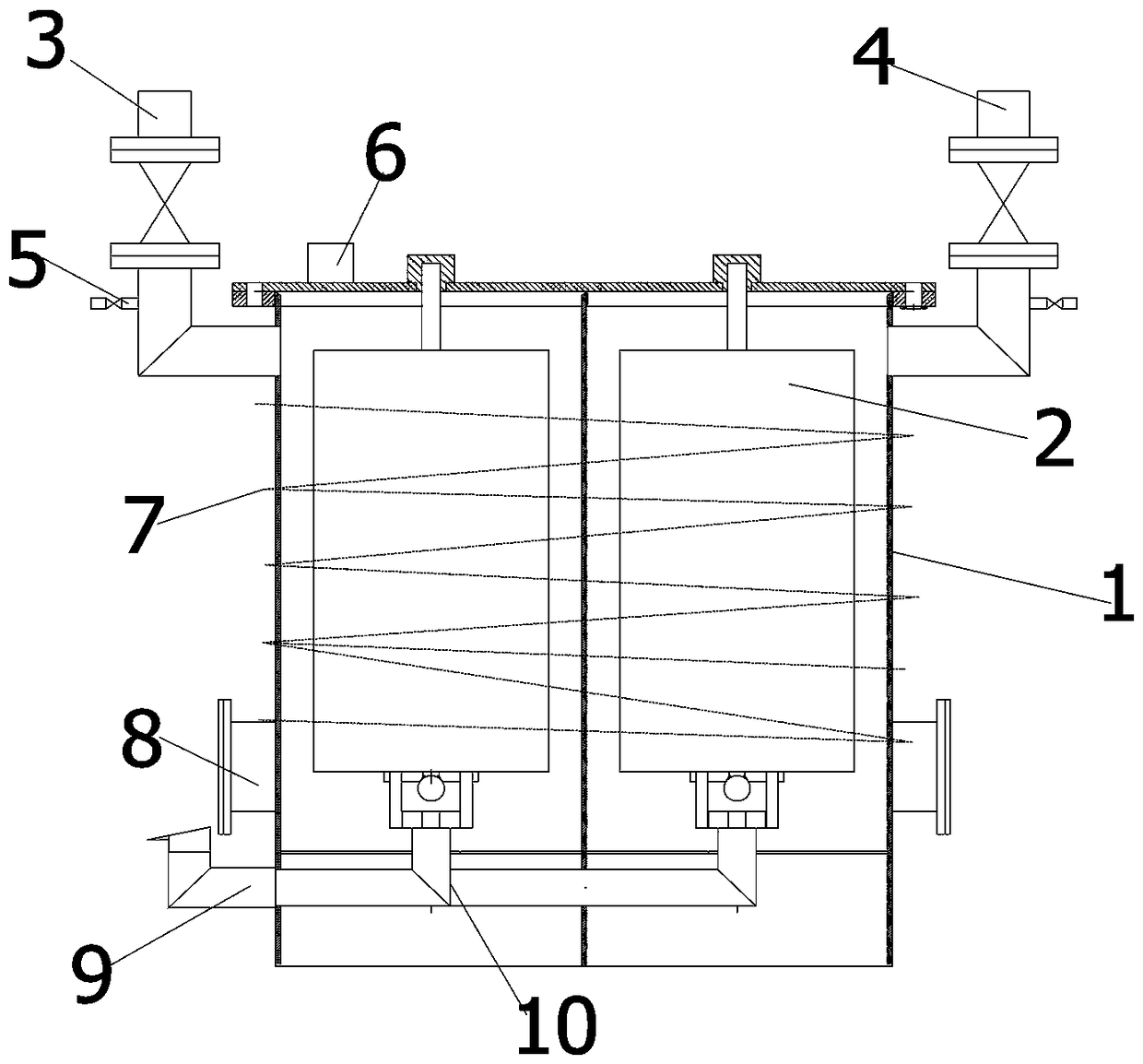

Air conditioner high pressure filter

InactiveCN108375253APrevent water leakageAvoid tightnessRefrigeration componentsDraining tubeEngineering

The invention provides an air conditioner high pressure filter, and relates to the technical field of air conditioners and air conditioner accessories. The air conditioner high pressure filter comprises a casing, chamber bodies, a high pressure water inlet pipe, a low pressure water inlet pipe, an inspection valve, an explosive-proof wiring box, condensed water nets, hand holes and a drain pipe, wherein the casing is internally provided with two chamber bodies, and the chamber bodies are independently separated from each other; the upper end of the casing is provided with the high pressure water inlet pipe and the low pressure water inlet pipe, the high pressure water inlet pipe is connected with the inspection valve, and the low pressure water inlet pipe is connected with the inspection valve; the inspection valve is connected with the chamber bodies; the condensed water nets are distributed inside the chamber bodies, and the two ends of the lower parts of the chamber bodies are designed with the hand holes, and the bottoms of the chamber bodies are connected with the drain pipe.

Owner:佛山市投纸软件有限公司

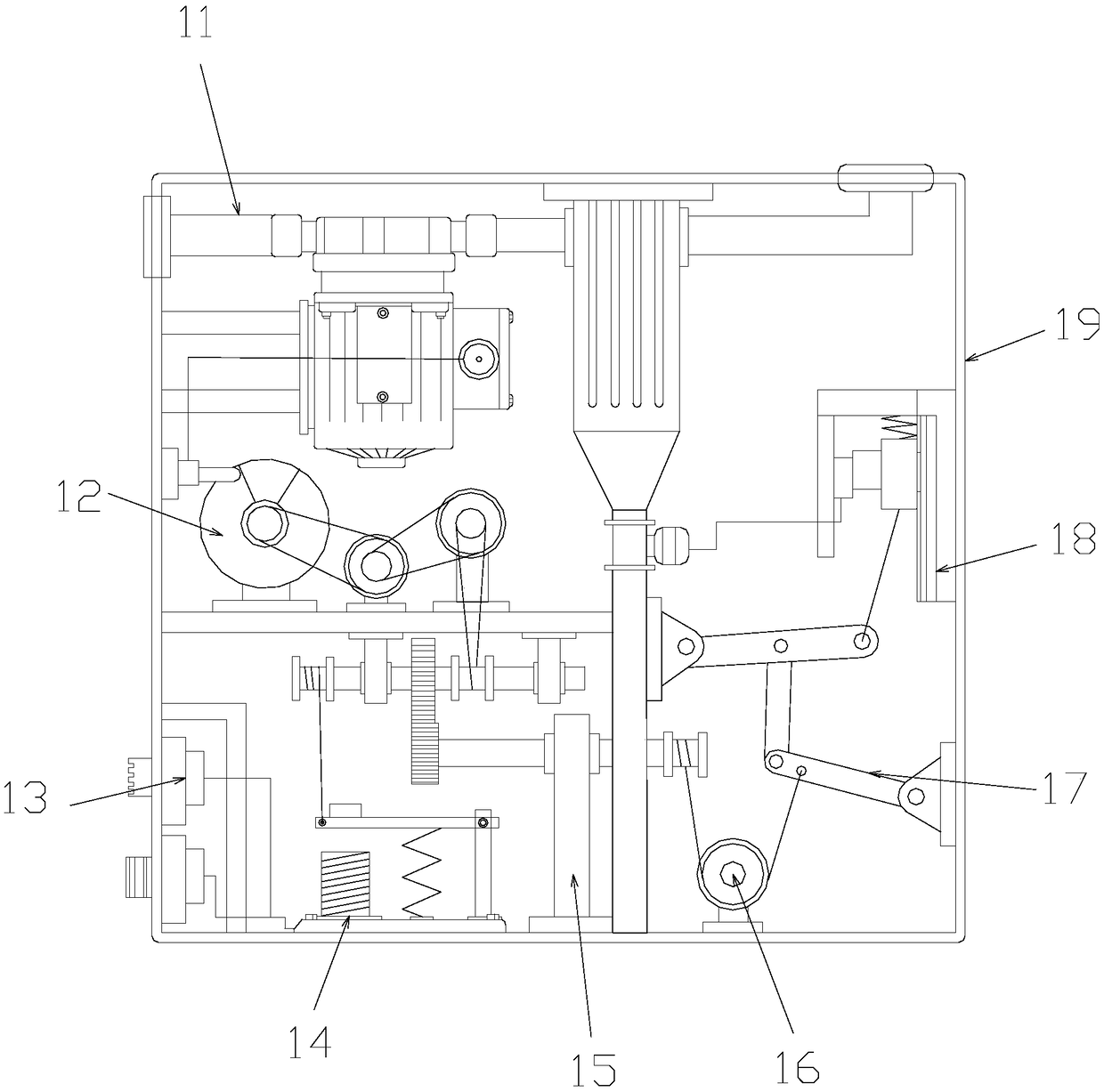

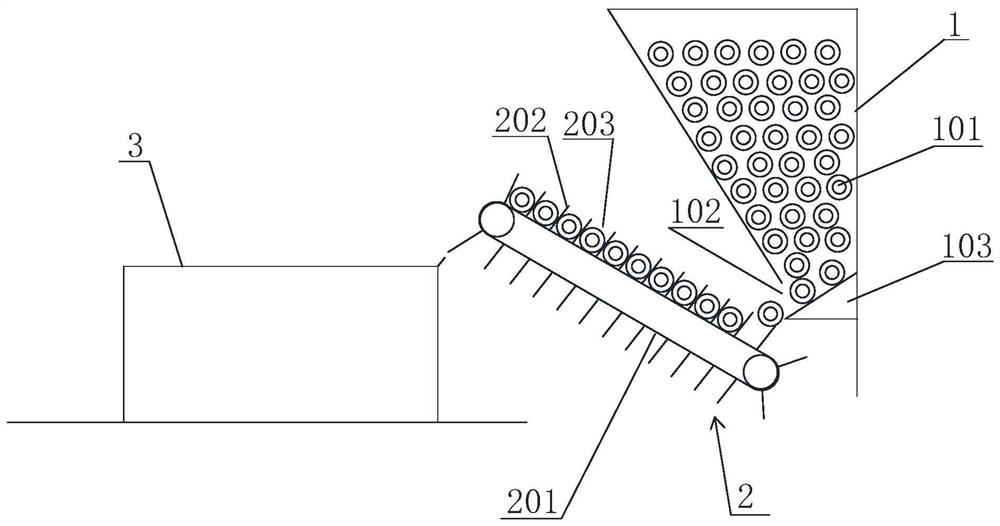

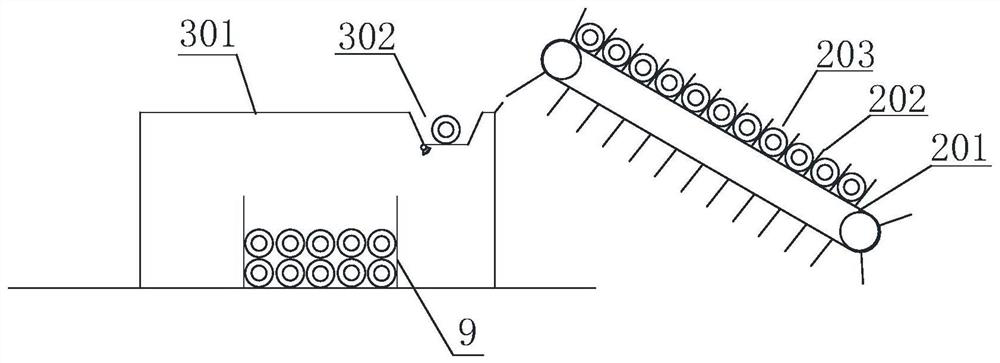

Apparatus and method for engraving marks on spun bobbins

The invention discloses a marking marking device for spun yarn bobbins, which comprises an empty bobbin box, an empty bobbin conveyor belt and an engraving workbench. Several empty bobbin bobbins are stacked in the empty bobbin box, and the empty bobbin bobbins are transported through the empty bobbins. The belt is transported to the engraving workbench, which includes a worktable, and a yarn bobbin empty tube drop slot is arranged on the side of the workbench close to the conveyor belt body, and the yarn bobbin empty tubes are transported to the worktable by the conveyor belt body Roll and fall into the trough of the bobbin empty bobbin; above the working table, there is an inkjet printer or code engraving machine for marking the bobbin empty bobbin, and on one side of the working table is a The driving device for the rotation of the bobbin empty bobbin. The present invention can directly engrave markings such as codes on the empty tubes of the bobbins, which facilitates the positioning and tracking of the bobbins, and the quick search when the detected yarns on the bobbins do not meet the requirements, and has the advantages of simple and convenient mark engraving and low cost , has no effect on bobbin structure and spinning quality.

Owner:QINGDAO UNIV

A multifunctional freezer

ActiveCN108917257BExtended service lifePrevent problems such as damageLighting and heating apparatusDomestic refrigeratorsWater storage tankPower switching

The invention discloses a multifunctional freezing device. The multifunctional freezing device structurally comprises a freezing and dehumidifying device, a control panel, a working state display screen, a heat dissipation port, a bottom adjustable support frame, a quick freezing box door, a dehumidifying water storage tank, a quick freezing box door handle, a main machine body and a power switch.The left front portion of the main machine body is provided with the power switch, and the power switch is fixedly connected with the main machine body through bolts. The right portion of the main machine body is provided with the freezing and dehumidifying device, and the control panel is arranged at the front portion of the freezing and dehumidifying device. The control panel is fixedly connected to the main machine body by bolts, and the control panel is connected with components through signal lines. The multifunctional freezing device can effectively prevent water vapor from entering theinside of the device and causing damage due to freezing, effectively improves the working stability and reliability and prolongs the service life of a refrigerating device.

Owner:端黎明

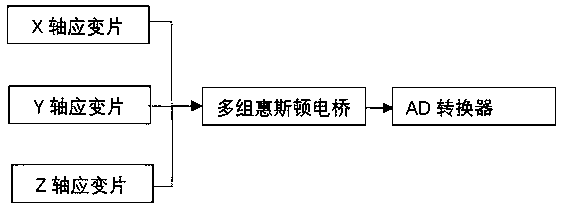

Dental sensor capable of measuring force feedback

InactiveCN107655594APrevent problems such as damageSolve the accuracy problemForce measurement by permanent gauge deformationForce measurement by elastic gauge deformationEngineeringRain gauge

The invention discloses a dental sensor capable of measuring force feedback. The dental sensor is in a sleeve type design, and comprises a body, wherein the body is composed of an internal cylinder and an external outer barrel, two groups of strain gauges perpendicular to each other are arranged on the inner side wall of the cylinder, a group of strain gauges is arranged at the bottom part of thecylinder, the three groups of strain gauges are positioned on X-axis, Y-axis and Z-axis of a cylinder body separately, so that the three groups of strain gauges are perpendicular to one another, the outer barrel is a supporting structure and supports a deformable structure connected with the strain gauges, and supporting structures at positions of three strain gauges are independent of one anotherand are connected on measuring rods separately, such that the supporting structures of the strain gauges on the X-axis, Y-axis and Z-axis are independent of one another. The dental sensor disclosed by the invention can measure the magnitude of forces in multiple axial directions simultaneously, and can calculate the size of moment in each direction precisely by means of an embedded system.

Owner:安徽省微云机器人有限公司

A laser therapy device

ActiveCN108635044BIncrease mobilityImprove controllabilitySurgical needlesSurgical instrument detailsLuminous intensityMedicine

The invention discloses a laser therapeutic apparatus. The apparatus comprises a medical optical fiber, a power source, a processor, a laser output circuit, an input control circuit, a fiber controller and a laser light source; the processor is connected to the input control circuit and the laser output circuit, and is used for controlling the laser output circuit according to a control instruction input by the input control circuit; the laser output circuit is electrically connected to the laser light source for controlling a luminous intensity and a luminous duration of the laser light source; the power source is electrically connected to the laser output circuit for providing drive current for the laser output circuit; the fiber controller is connected to the processor for transmittingpressure data to the processor; the processor is further used for controlling the laser light source to be adjusted to a first luminous intensity when it is judged that the pressure data is greater than a predetermined pressure. The therapeutic apparatus enhances the controllability of optical fibers in a human body, prevents problems such as damages of the optical fibers and the like, and reducesthe risk of treatment.

Owner:XIAN LASER TECH MEDICAL TECH CO LTD

A permanent magnet motor with long service life

InactiveCN109256885AExtended service lifeReduce overheating damageStructural associationMechanical energy handlingEngineeringPermanent magnet motor

The invention discloses a permanent magnet motor with long service life, including a motor body, the outside of the motor body is provided with a motor shell, A motor support is arranged at the bottomend of the motor shell, the middle end of the motor support is provided with a fixing bolt, A top middle end of the motor shell is provided with an oil filling hole, A motor protector is arranged atthe top end of the motor shell, A display panel is arranged in the middle of one end of the motor protector, the bottom end of the display panel is provided with an alarm, An oil groove is arranged onthe inner side of the motor housing, A motor shaft is arranged in the middle of the side end of the motor body, The built-in sensor is arranged on the side of the rotor winding, and the temperature sensor can detect the temperature of the rotor winding, so that the detection is more sensitive, and the connected motor protectors are more sensitive, and can respond to the overheating more quickly,so that the overheating damage of the motor can be reduced to a certain extent, and the service life of the motor is prolonged.

Owner:CHANGZHOU INST OF TECH

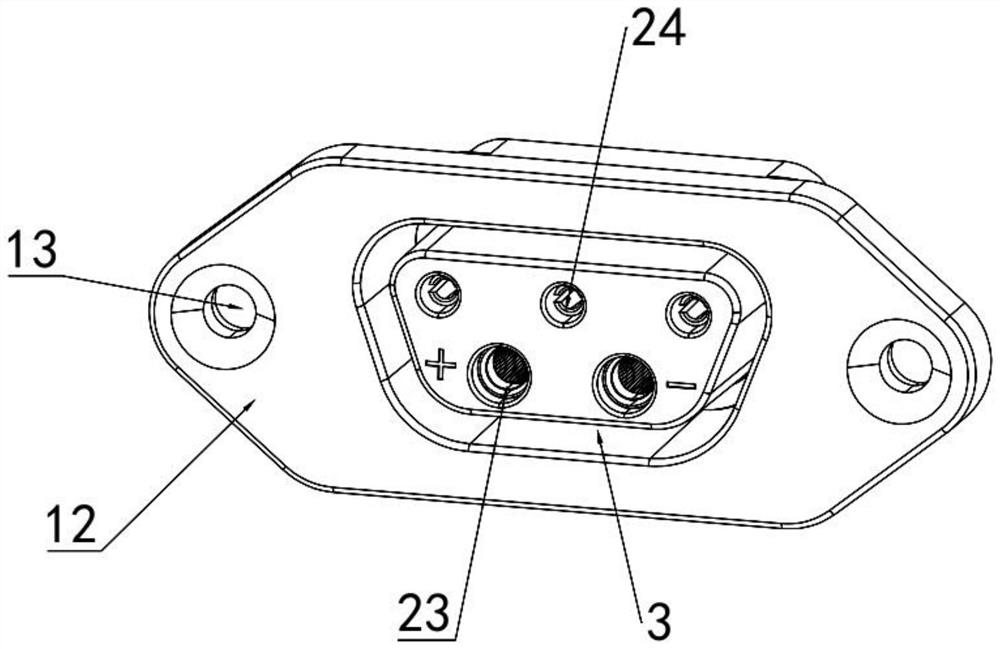

High-temperature-resistant connector for charging pile and manufacturing and assembling method of high-temperature-resistant connector

PendingCN114865397AImprove stability and securityImprove vibration resistanceVehicle connectorsContact member assembly/disassemblyElectrically conductiveStructural engineering

The invention discloses a high-temperature-resistant connector for a charging pile. The high-temperature-resistant connector comprises a connector male head and a connector female seat, the connector male head comprises a male head body and a component accommodating part, and the communication component accommodating part is provided with a power line butt joint part and a terminal arrangement part; the connector female seat comprises a female seat body and a terminal accommodating part, and a male head inserting part is arranged around the terminal accommodating part; the terminal setting part is detachably inserted into the male head insertion part in a sealed manner, so that the terminal setting part is electrically connected with the terminal accommodating part; the connector male head and the connector female seat are made of high-temperature-resistant materials, so that the butt-joint power-on stability of the terminal arrangement part and the terminal accommodating part is prevented from being affected. The invention further discloses a manufacturing and assembling method of the high-temperature-resistant connector for the charging pile. According to the charging pile connector, an embedded assembly mode is adopted, the stability and safety of conductive charging can be enhanced, the problems of poor contact, interface damage and the like caused by loosening can be prevented, and then the mechanical properties of vibration resistance, impact resistance and the like of the charging pile connector are improved.

Owner:东莞市领亚智能科技有限公司

Water insulation cup for electronic water pump and electronic water pump

PendingCN114439777ATo achieve the purpose of coolingAvoid failureAssociation with control/drive circuitsPump componentsThermodynamicsEngineering

According to the water insulation cup for the electronic water pump and the electronic water pump, the bottom of the water insulation cup for the electronic water pump extends to form a circular boss, a hollow shape is formed between the circular boss and the bottom of the water insulation cup, and a heat dissipation silica gel layer is arranged on the surface of the circular boss; the electronic water pump comprises a water insulation cup, a rotor assembly, a stator assembly, a pump body, a controller and a rear cover, the water insulation cup is arranged in the pump body, the rotor assembly is arranged in the water insulation cup, the stator assembly is arranged between the water insulation cup and the pump body, and the controller is arranged on the rear cover and located below the water insulation cup. The surface of the circular boss at the bottom of the water insulation cup is coated with the heat dissipation silica gel layer, and the heat dissipation silica gel layer on the surface of the circular boss is tightly attached to the controller heat dissipation component, so that heat generated by the controller component in continuous work is conducted into the hollow cavity formed between the bottom of the water insulation cup and the circular boss through the heat dissipation silica gel layer on the circular boss; and heat can be quickly and efficiently dissipated through the hollow cavity, so that the purpose of cooling is achieved.

Owner:HUNAN OIL PUMP

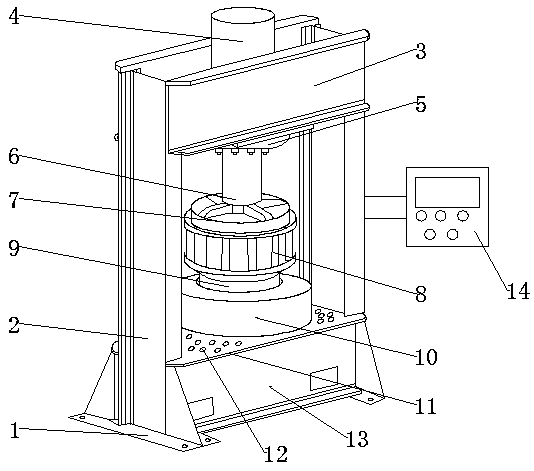

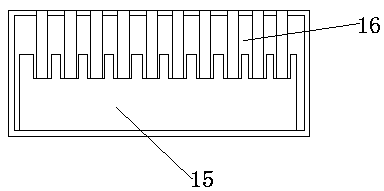

Novel tire pressing machine

The invention discloses a novel tire pressing machine. The novel tire pressing machine comprises bottom plates, supports, hydraulic supports, hydraulic systems, a working panel and hydraulic column holes; the bottom plates are made of metal materials and are uniformly and symmetrically distributed on the two sides, bolt holes are formed in the bottom plates, and the bottom plates are fixedly connected to the ground through bolts; the upper sides of the bottom plates are connected to supports through welding, one hydraulic support is arranged at the middle position of the uppermost portion of each of the two supports in a welding mode, and the middle position of the each hydraulic support is connected to one cylindrical hydraulic system through bolts; the lower side of each hydraulic systemis connected to a baffle through bolts, and the lower side, located on the hydraulic system, of the baffle is provided with a hydraulic column; and the lower side of each hydraulic column is connected to a cylindrical hydraulic disc through bolts, and a fixing column is arranged on the lower side of a steel ring. According to the novel tire pressing machine, supporting columns are arranged, so that the problem that when the steel ring is extruded into the tire, the position of the tire is changed can be solved; and the problems that the position of the tire is changed caused by too large extrusion force, the steel ring cannot enter the tire and even the tire is damaged are solved.

Owner:惠州市新明海科技有限公司

A kind of anti-collision and fall-off wood-plastic decorative line

ActiveCN111139997BMeet the needs of useFlexible and stable structureBuilding constructionsStructural engineeringMechanical engineering

The invention relates to the technical field of wood-plastic lines, and discloses a wood-plastic decorative line with anti-collision and falling off, comprising a fixing plate, one side of the fixing plate is fixedly connected with an adhesive layer, and one side of the adhesive layer is fixed A wall is connected, the other side of the fixing plate is fixedly connected with a wood-plastic line body, an inner wall of the wood-plastic line body is fixedly connected with a reinforcement ring, an outer wall of the reinforcement ring is fixedly connected with a reinforcement rib, and the wood-plastic line body is fixedly connected with a reinforcement ring. The inner wall of the plastic line body is fixedly connected with a connecting block. The anti-collision and falling-off WPC decorative line achieves the purpose of anti-collision and falling-off, and solves the problem that the general anti-collision and falling-off WPC decorative line is relatively simple in structure and easy to fall off from collision. The structure is flexible and stable, and plays a role of strengthening and fixing. The strength of the device is enhanced, the problems such as wear and falling off caused by the collision of the device are prevented, and the appearance and decoration of the device are ensured, and the use requirements of users are met.

Owner:颍上县方圆新材料有限公司

An integrated short connector for drilling tools

ActiveCN111878001BMating operation is simpleMeet the mating requirementsSurveyDrilling rodsEngineeringScrew thread

An integrated short connector for drilling tools, including a telescopic connector assembly, a fixed connector assembly, and a drill collar adapter; the drill collar adapter includes an upper drill collar adapter and a lower drill collar adapter, and the telescopic connector assembly It is installed in the upper drill collar conversion joint, and the fixed connector assembly is installed in the lower drill collar conversion joint; the telescopic connector assembly and the fixed connector assembly are butted; The integration of the instrument realizes the internal power supply and communication of the instrument through the threaded connection of the drill collars of each instrument. This method of realizing the internal communication of the instrument through the direct connection of the drill collar saves on the one hand the artificial connection link of the on-site operation and reduces the construction cost. The safety risk is improved, and the operation efficiency is improved. At the same time, the reliability of the internal connection power supply and communication of the instrument is ensured by using the drill collar thread connection torque, which reduces the difficulty of using and assembling the connector, simplifies the overall structure of the connector, and shortens the length.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

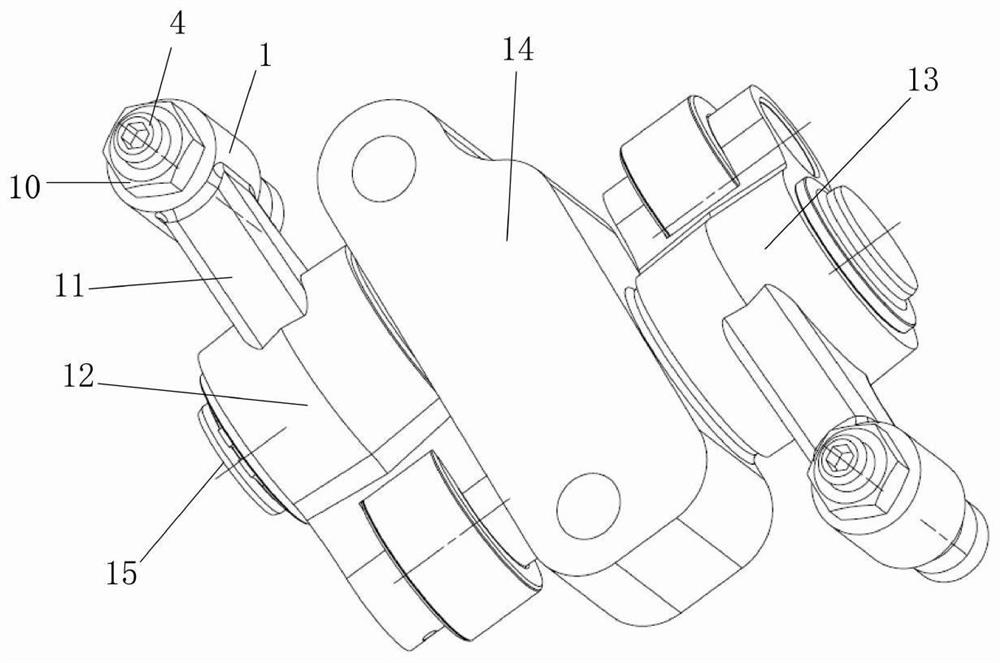

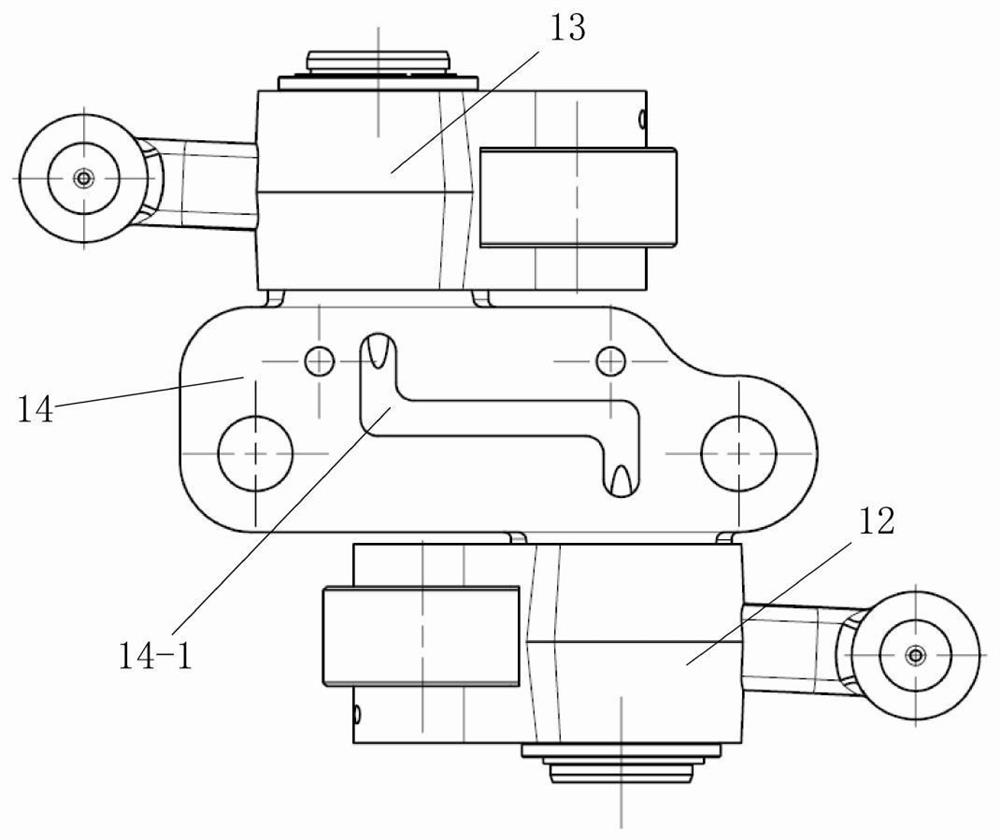

Rocker arm assembly

PendingCN113404566AImprove space utilizationImprove layout flexibilityValve arrangementsLubrication of auxillariesRocker armControl theory

The invention discloses a rocker arm assembly. The rocker arm assembly comprises rocker arms, rocker arm shafts and a rocker arm seat, and each rocker arm is distributed on one side of the rocker arm seat through the corresponding independent rocker arm shaft. The rocker arms are distributed on the left side and the right side of the rocker arm seat through the rocker arm shafts correspondingly, the rocker arm shaft on the left side is distributed at the front end, and the rocker arm shaft on the right side is distributed at the rear end. The rocker arm assembly has the advantages of being simple in structure, flexible to assemble, good in reliability and the like.

Owner:GUANGXI YUCHAI MASCH CO LTD

A medical optical fiber and laser therapy instrument

The invention discloses a medical optical fiber, comprising N laser optical fibers (1) of predetermined length, N-1 optical fiber connection assemblies (2), optical fiber guiding structures (3), and optical fiber controllers (4); N said The laser optical fiber (1) is connected through N-1 optical fiber connection components (2), sequentially forming a serial optical fiber structure (5), one end of the serial optical fiber structure (5) is connected to the optical fiber guiding structure (3) , the other end is connected to the optical fiber controller (4), N is a positive integer; wherein, each of the optical fiber connection components (2) is provided with a pressure sensor (6), and the pressure sensor (6) is connected to the The optical fiber controller (4), the pressure sensor (6) is used to detect the pressure data of the optical fiber connection assembly (2), and the optical fiber controller (4) is used to judge the medical optical fiber according to the pressure data coupling state. The medical optical fiber of the invention enhances the controllability of the optical fiber in the human body, prevents problems such as damage to the optical fiber, and reduces the risk of treatment.

Owner:XIAN LASER TECH MEDICAL TECH CO LTD

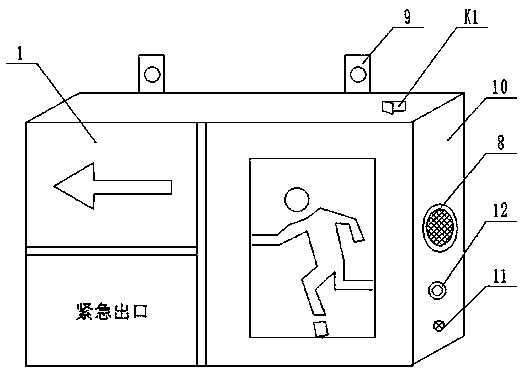

emergency exit indicator

ActiveCN106447973BSave powerPracticalSignalling system detailsElectric transmission signalling systemsLED displayEmergency exit

The invention provides an emergency exit indicating device, belongs to the technical field of safety protection, and solves the technical problem that the emergency exit indicating device which saves electric energy and performs sound-light prompting for work personnel in the early stage of fire is provided. The adopted technical scheme is the emergency exit indicating device comprising a box body. The front panel of the box body is provided with an evacuation mark. The box body is internally provided with a circuit board. The circuit board comprises a power supply unit, a light-sensitive unit, a control unit, a voice alarm unit, an LED display unit and a fire alarm controller. The signal output end of the light-sensitive unit is connected with the signal input end of the LED display unit. The signal input end of the control unit is connected with the signal output end of the fire alarm controller. The signal output end of the control unit is connected with the signal input end of the LED display unit and the signal input end of the voice alarm unit. The emergency exit indicating device is suitable for the field of electric power.

Owner:STATE GRID CORP OF CHINA +1

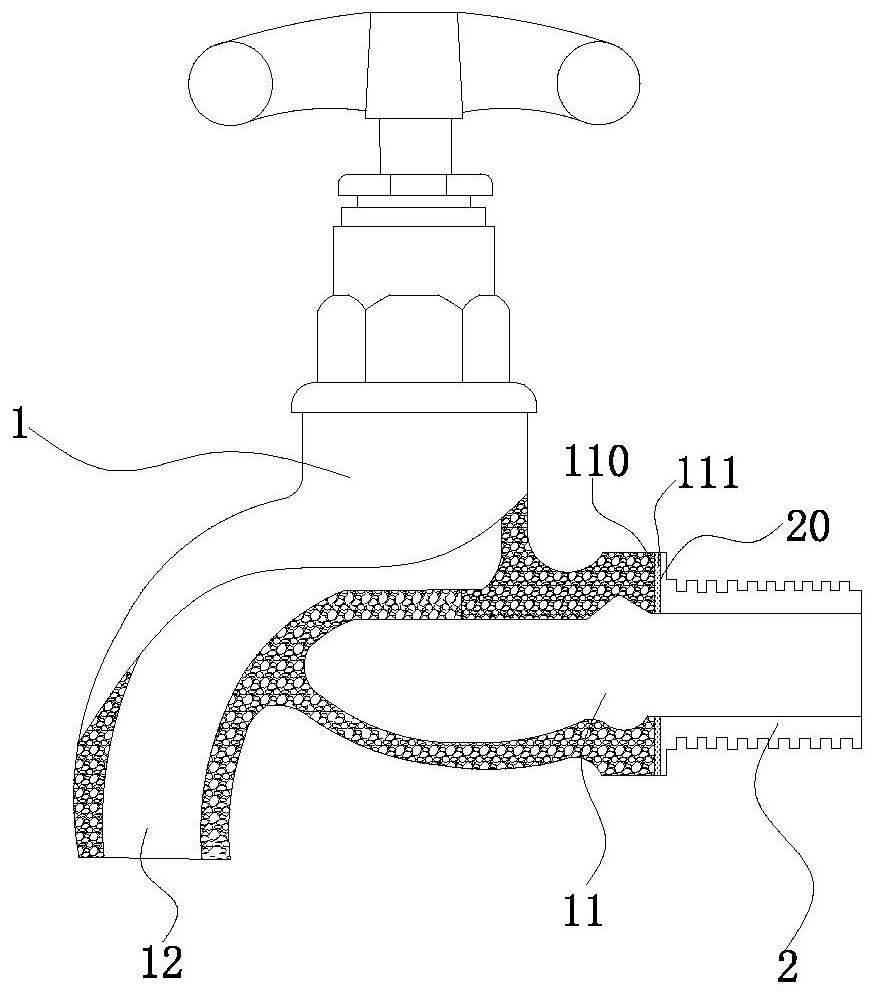

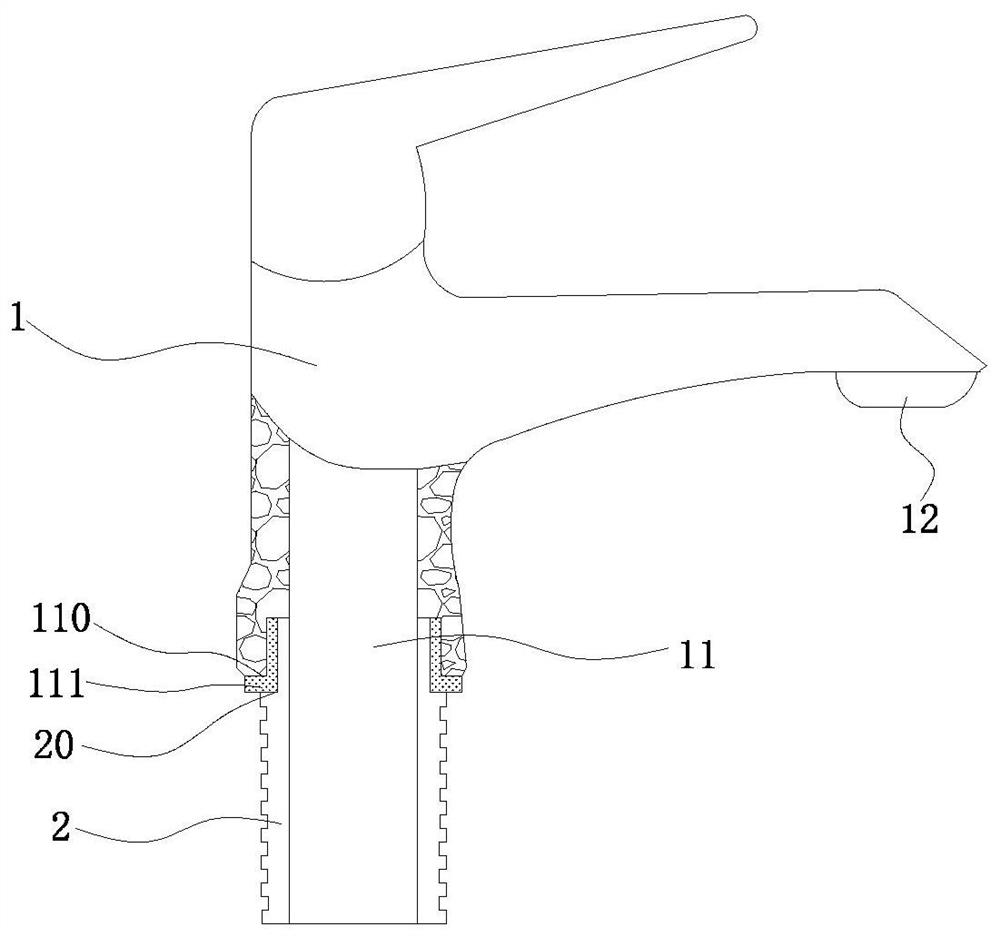

Ceramic faucet and manufacturing method thereof

PendingCN112984188ABeautiful appearanceLow costPipe connection arrangementsWelding/soldering/cutting articlesMetallic materialsEngineering

The invention relates to a ceramic faucet and a manufacturing method thereof. The ceramic faucet comprises a faucet body made of a ceramic material and a pipe connector made of a metal material, the faucet body is provided with a water inlet, a water outlet and a valve element assembly located in the faucet body, the water inlet of the faucet body is provided with a fixed connection face, a welding metal layer is arranged on the fixed connection face, the pipe connector is provided with a welding face matched with the fixed connection face, the welding face is welded and fixed to a water opening of the faucet body through the welding metal layer, and the pipe connector can serve as a water inlet pipe connector of the faucet body, so that the problem that when an existing ceramic faucet is directly connected with a metal pipeline, installation damage is prone to occurring is solved.

Owner:厦门精码信息技术有限公司

Numerical control machine tool split-type operating platform for installing linear motor

ActiveCN103084856BPrevent problems such as damageAvoid corrosionLarge fixed membersMaintainance and safety accessoriesNumerical controlElectric machine

The invention discloses a numerical control machine tool split-type operating platform for installing a linear motor. The numerical control machine tool split-type operating platform for installing the linear motor comprises a water-proof operating platform, an electrical machine coil mounting plate, a linear motor primary coil, a connecting plate, an operating platform locating pin, an electrical machine coil mounting plate locating pin and linear guide way slide blocks, wherein the four linear guide way slide blocks are arranged on a linear guide way of a saddle. The operating platform is arranged on the linear guide way slide blocks through four notches formed in side edges of the operating platform. The linear motor primary coil is fixedly connected on the bottom surface of the electrical machine coil mounting plate through screws. Dovetail grooves formed in side edges of the electrical machine coil mounting plate coincide with dovetail grooves of the operating platform. The numerical control machine tool split-type operating platform for installing the linear motor is reasonable in structure. The fact that cutting fluid leaks the underside of the operating platform to corrode the operating platform and main castings of the saddle is avoided.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com