Rocker arm assembly

A technology of rocker arm assembly and rocker arm shaft, which is used in the lubrication of engine components, valve accessories, machine/engine, etc. Flexibility, improved space utilization, safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

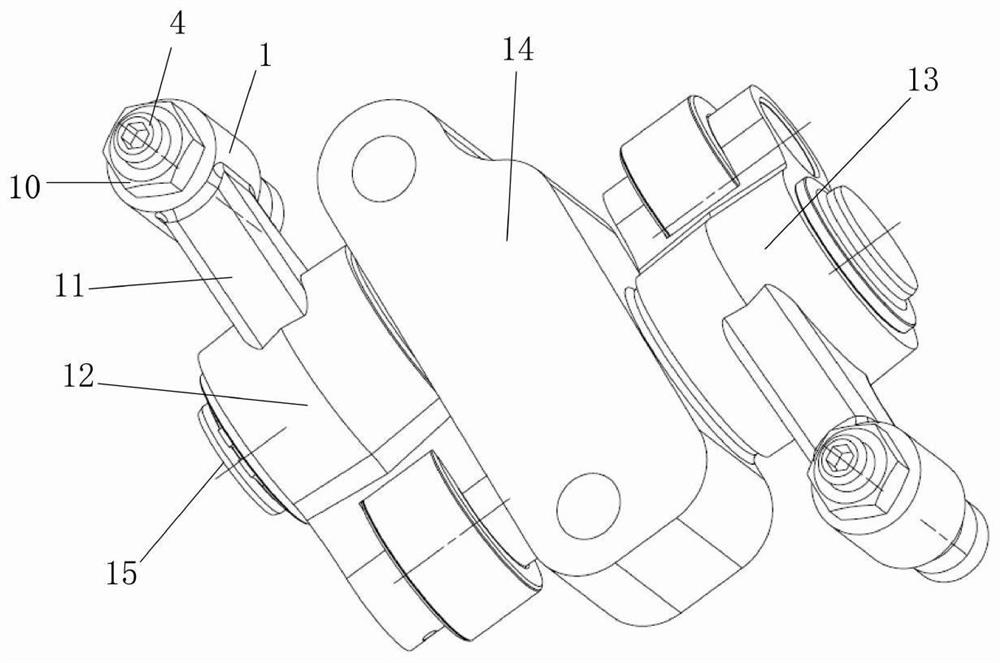

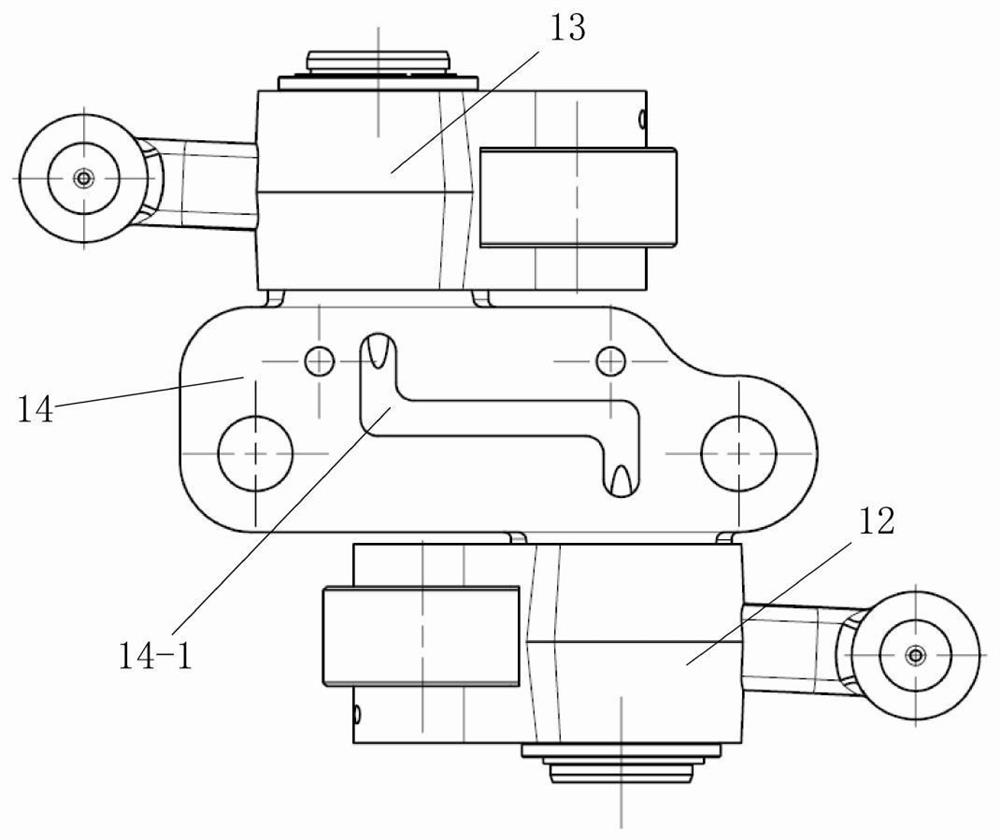

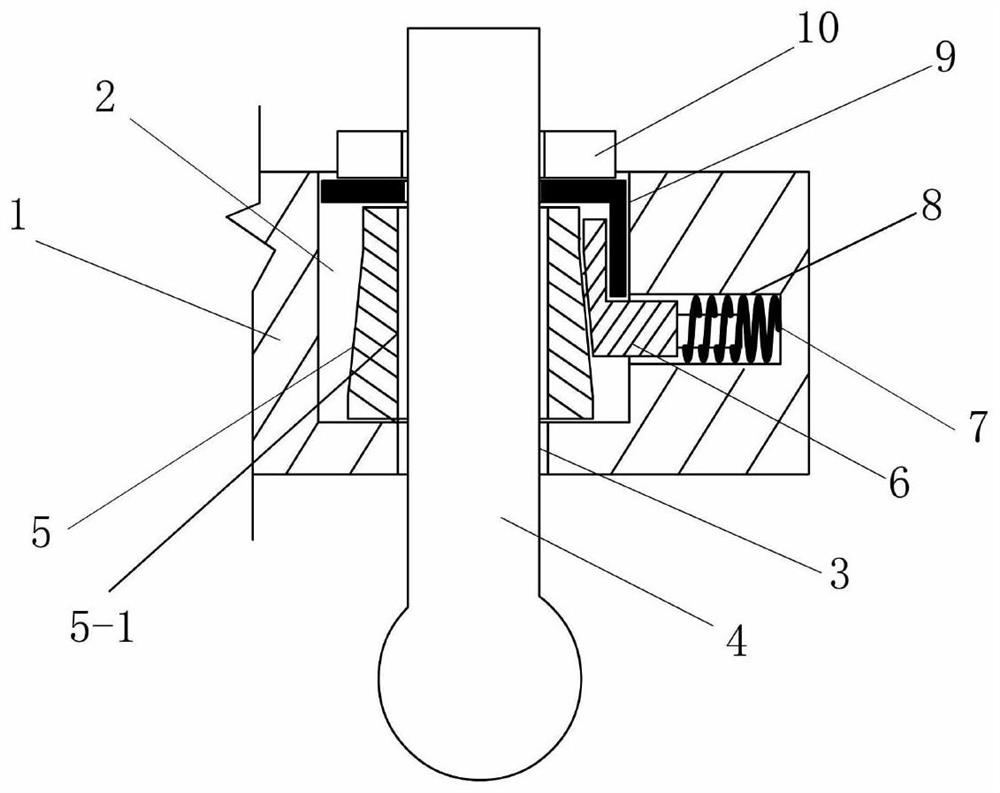

[0024] like Figure 1~6 As shown, a rocker arm assembly includes a rocker arm, a rocker arm shaft 15 , and a rocker arm seat 14 , and each of the rocker arms is distributed on one side of the rocker arm seat 14 through an independent rocker arm shaft 15 . The left and right sides of the rocker arm base 14 are respectively distributed with one rocker arm through one rocker shaft, and the rocker shaft on the left is distributed at the front end, and the rocker shaft on the right side is distributed at the rear end. In this embodiment, two rocker arms are distributed on the same rocker arm seat, wherein one rocker arm 13 is used to control the exhaust valve, and the other rocker arm 12 is used to control the intake valve. Of course, the rocker arm seat 14 is also provided with a lubricating oil passage 14-1 for lubricating effect. Further, one end of the lever arm 1 of the rocker arm is provided with a safety block resting groove 2, and a valve clearance adjustment screw outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com