High-temperature-resistant connector for charging pile and manufacturing and assembling method of high-temperature-resistant connector

A connector, high temperature resistant technology, applied in the direction of the two-part connection device, the parts of the connection device, the assembly/disassembly of the contact, etc. Instability and other issues, to improve the overall security performance and durability of use, optimize docking adaptability and reliability, and enhance stability and security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

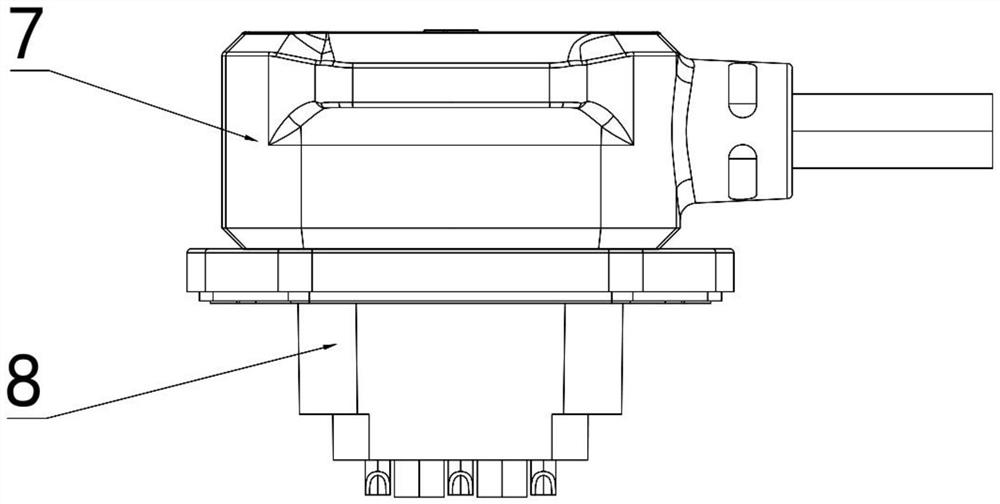

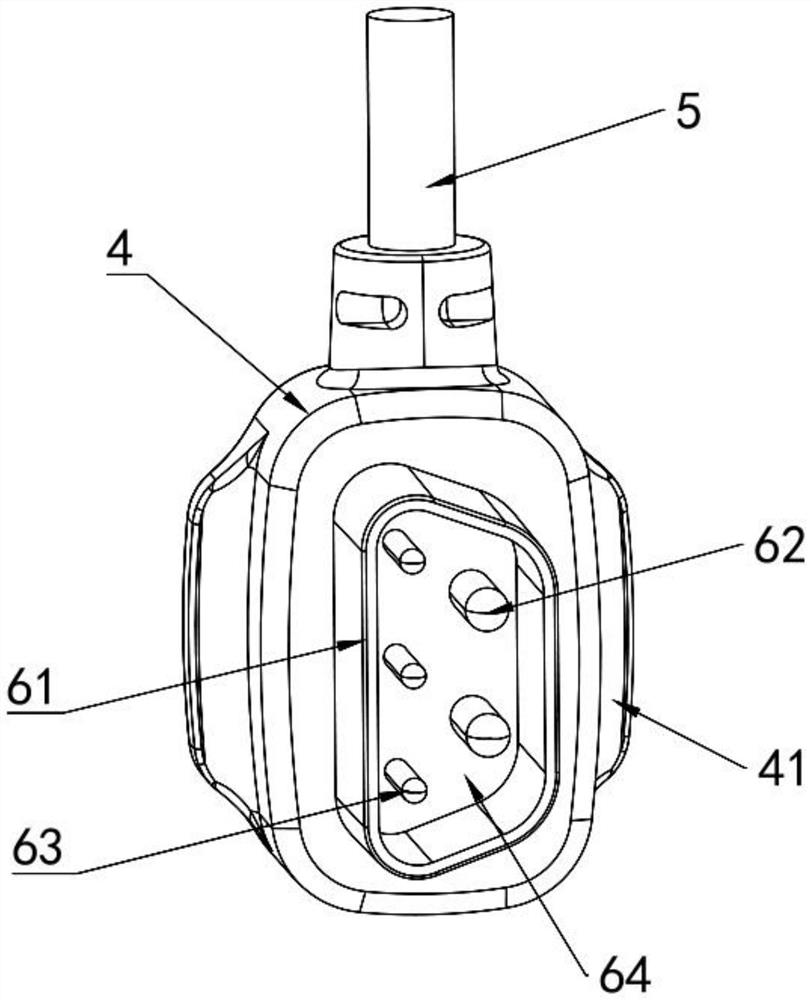

[0040] Example: see Figure 1 to Figure 4 , this embodiment provides a high-temperature-resistant connector for a charging pile, which includes a connector male head 7 and a connector female seat 8 that are fitted and assembled;

[0041] The connector male head 7 includes a male head body 4 and a component accommodating portion arranged inside the male header body 4. A power cord docking portion and a terminal setting portion are connected to the component accommodating portion. The wire butting portion is perpendicular to the terminal setting portion;

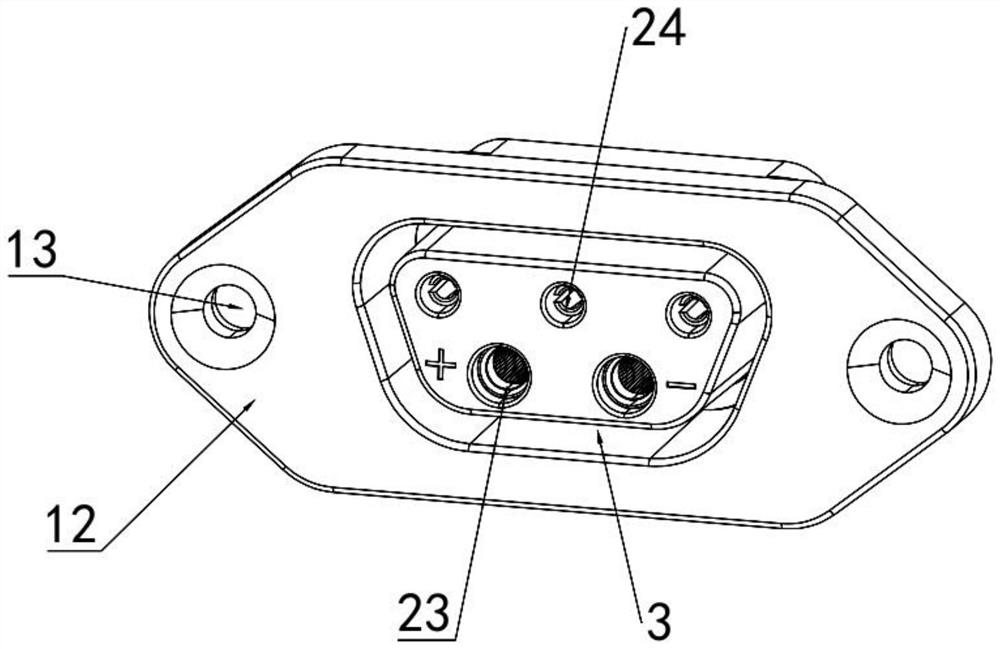

[0042] The connector receptacle 8 includes a receptacle body 1 and a terminal accommodating portion disposed inside the receptacle body 1, and a male plug accommodating portion is arranged around the terminal accommodating portion;

[0043] The terminal setting part is detachably sealed and inserted in the male plug insertion part, so as to realize the electrical connection between the terminal setting part and the terminal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com