Method for installing and maintaining numerical control machine tool split type working table for installing linear motor

A technology of linear motors and workbenches, which is applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc. It can solve the problems of motor coil damage, difficult disassembly and maintenance, and long maintenance cycle, so as to save maintenance costs and shorten maintenance time , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

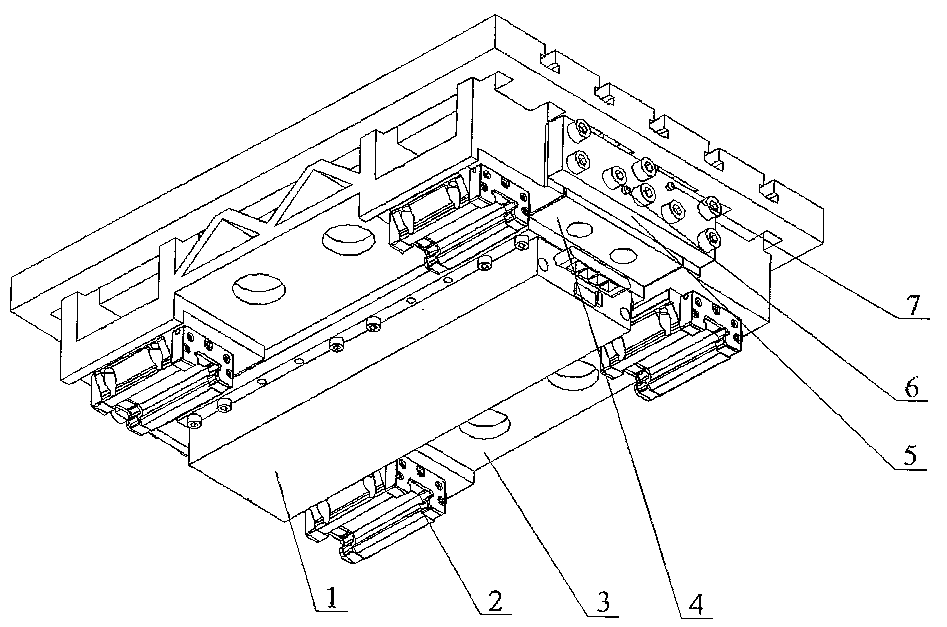

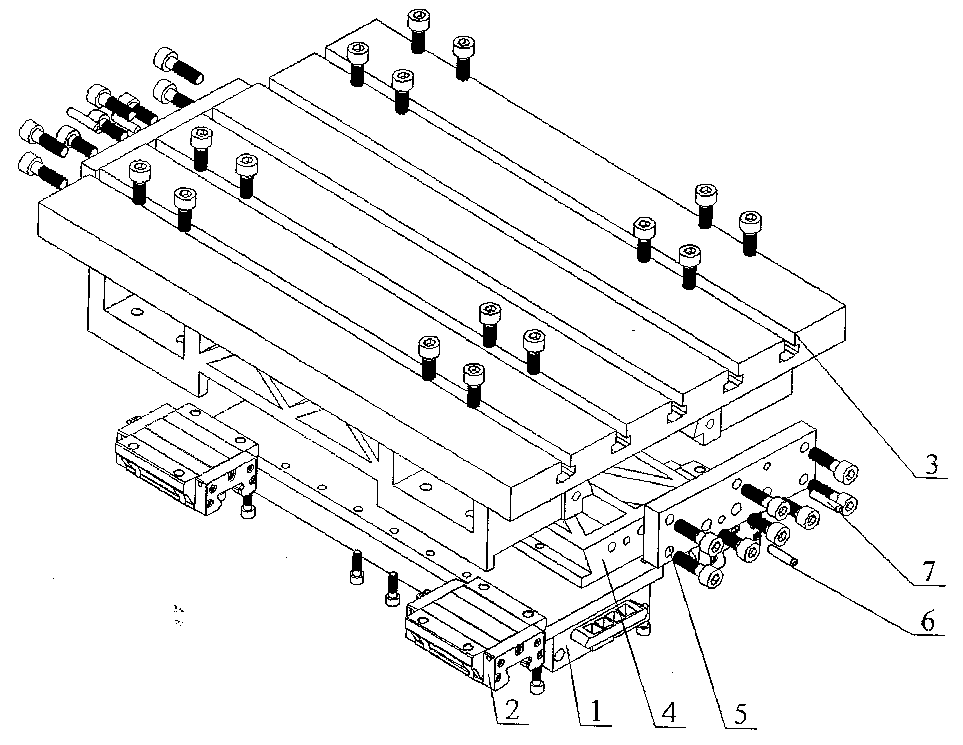

[0027] Such as figure 1 , figure 2 As shown, a method for installing a linear motor for a CNC machine tool and a split workbench, including a waterproof workbench 3, a motor coil mounting plate 4, a linear motor primary coil 1, two connecting plates 5, two workbench positioning pins 7, Two motor coil mounting plate positioning pins 6, four slide blocks 2.

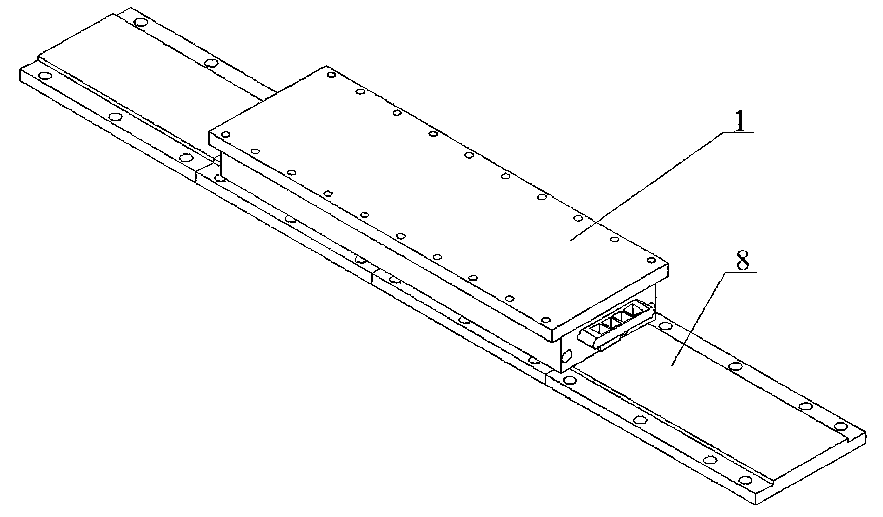

[0028] In normal use, such as figure 2 , image 3 , Figure 4 As shown, four linear guide rail sliders 2 are installed on the linear guide rail 9 of the bed saddle 10; the workbench 3 is installed on the linear guide rail slider 2 from the four gaps on the side of the workbench 3; the primary coil 1 of the linear motor passes through The screw connection is fixed on the bottom surface of the motor coil mounting plate 4, the dovetail groove on the side of the motor coil mounting plate 4 coincides with the dovetail groove of the worktable 3, adjust the geometric accuracy of the machine tool, and nail the positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com