Automatic production line for press-forming sintering preparation furnace of cemented carbide

An automated production line and press molding technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem of manual operation in the production method, and achieve the effect of high degree of automation, improving production efficiency and enterprise capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

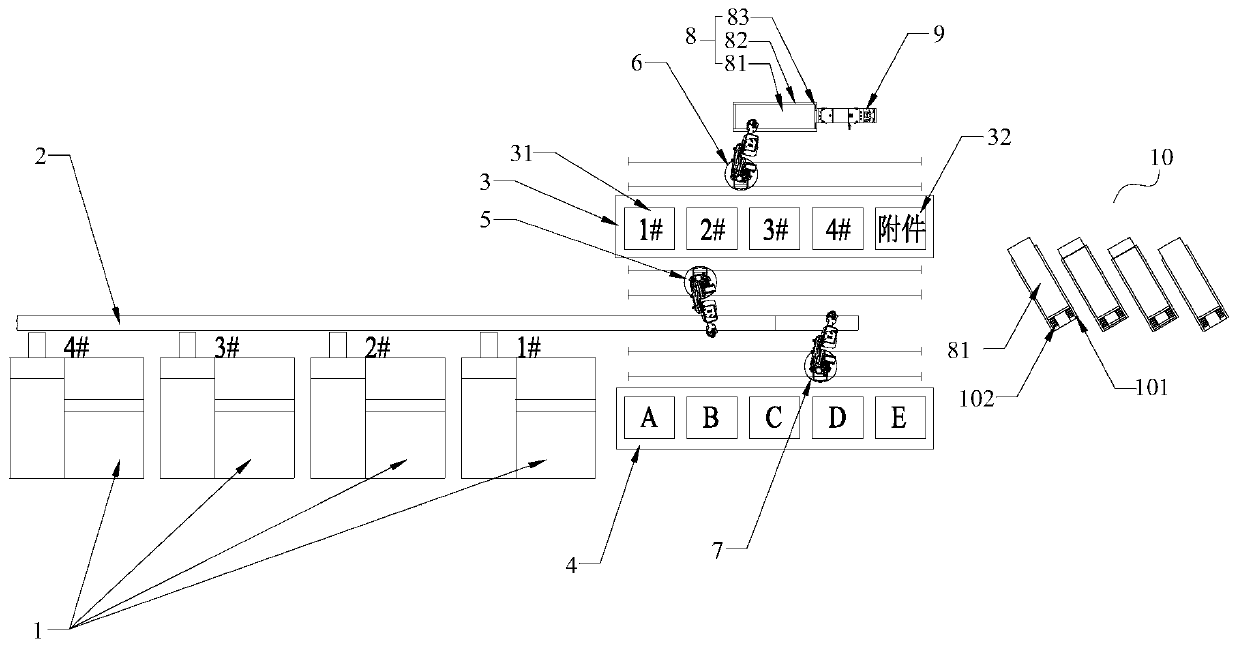

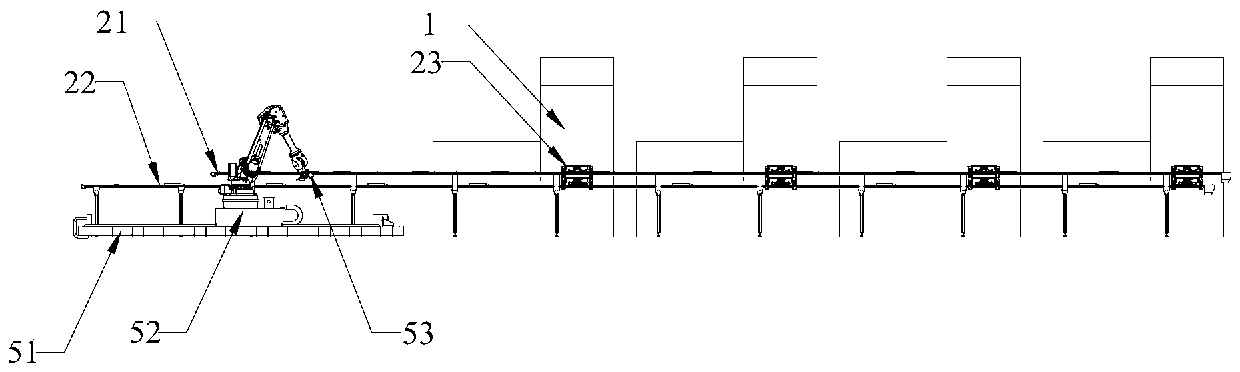

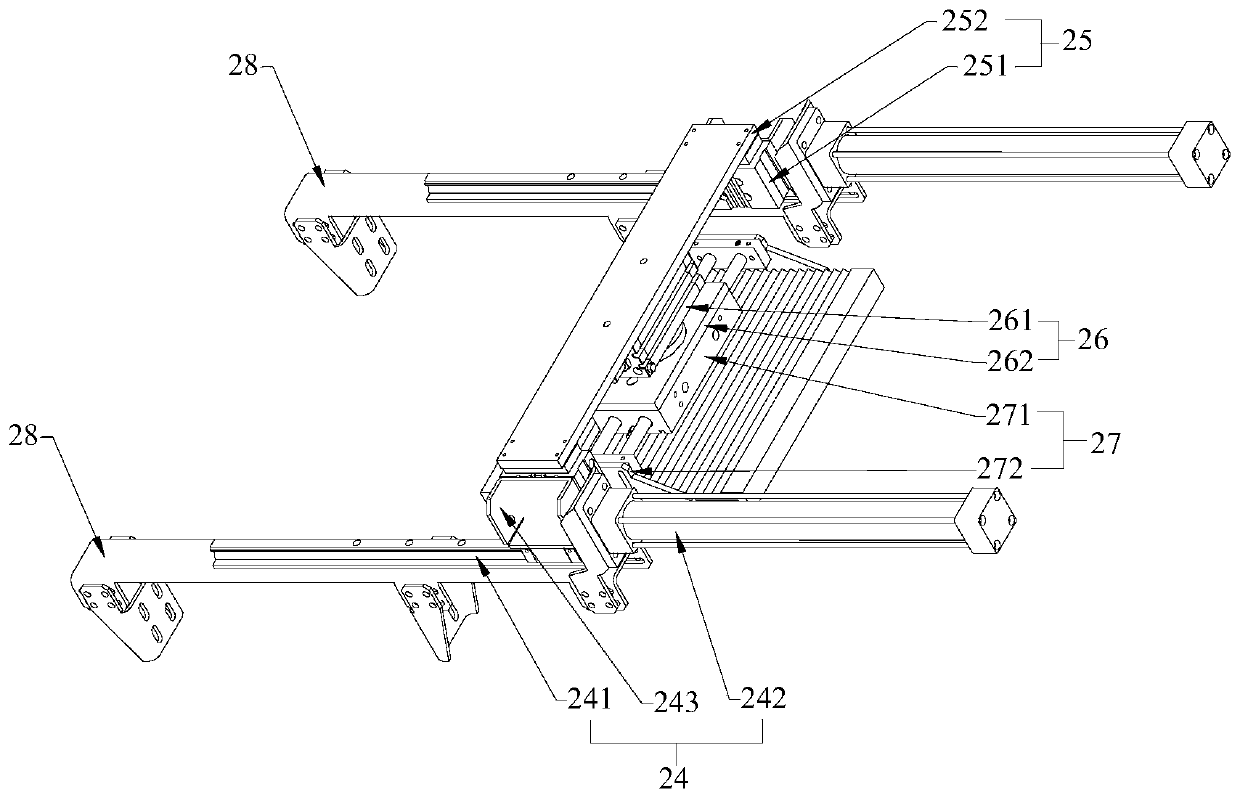

[0032] For ease of understanding, such as figure 1 and figure 2As shown, the preferred embodiment of the present invention provides a kind of cemented carbide press-molding sintering furnace preparation automatic production line, has realized the on-line and off-line of the boat, the feeding and receiving of the boat by the press, the assembly operation, and the whole process of furnace preparation. Automation can greatly improve production efficiency, increase enterprise production capacity, and realize the automation upgrade of production lines. The automatic production line for pressing, forming, sintering and furnace preparation of cemented carbide includes several presses 1, a double-layer conveying line 2, a first boat storage table 3 for storing full boat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com