Vehicle-mounted mud solidification filter press

A solidification pressure, vehicle-mounted technology, applied in the direction of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of shortening the service life of filter plates, high labor intensity, and reducing filtration efficiency, etc., to achieve The effect of prolonging the service life, low labor intensity and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

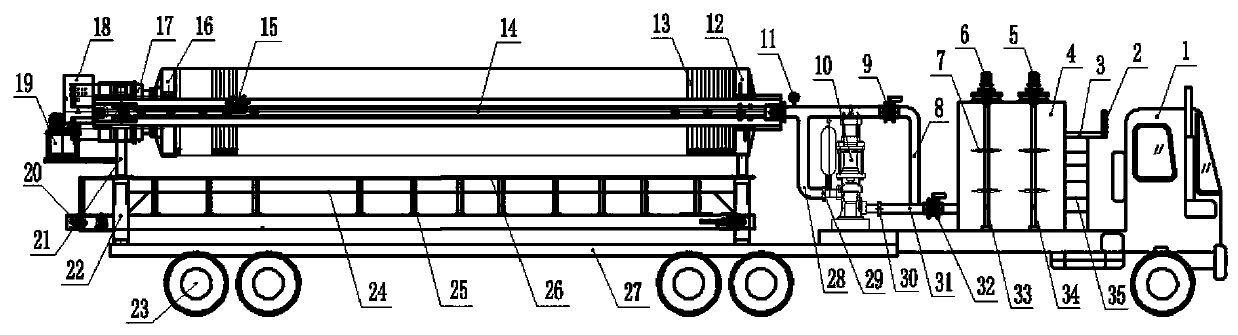

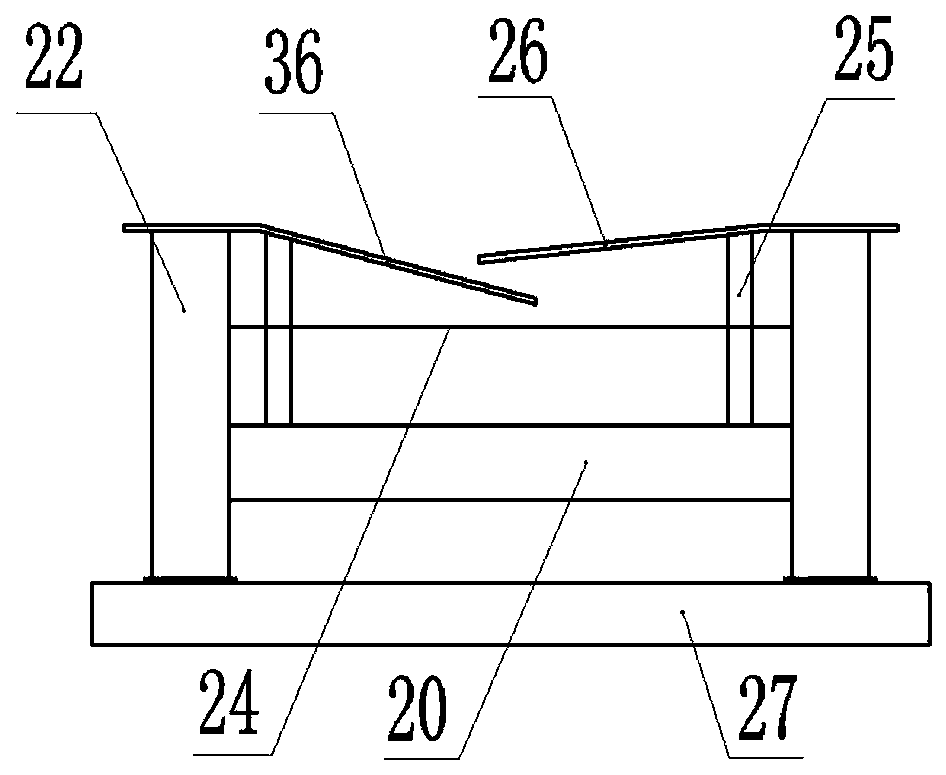

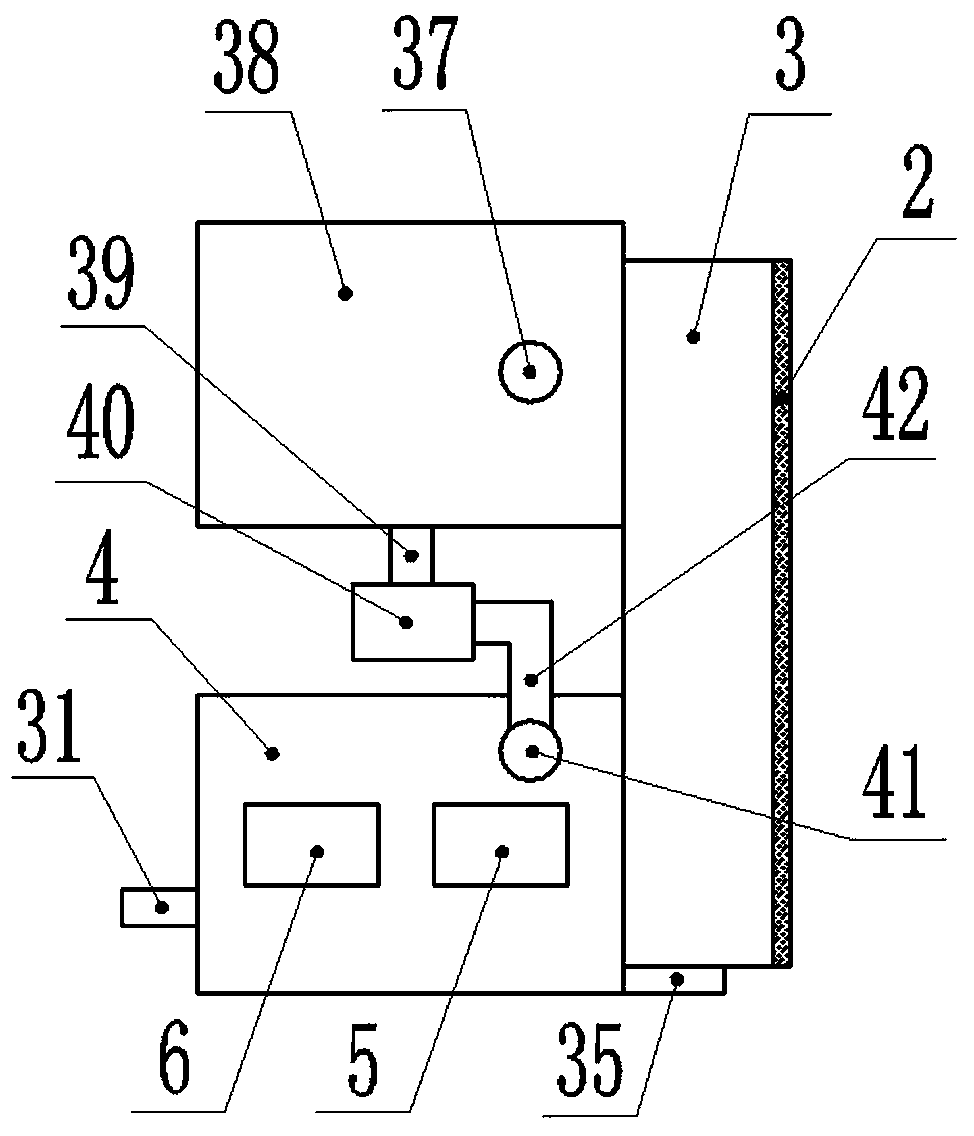

[0025] like Figure 1-4 As shown, a vehicle-mounted mud solidification filter press includes a cab 1, a base plate 27 and wheels 23, and the right side of the upper surface of the base plate 27 is provided with a miscellaneous removal box 38 and a mixing box 4, and the miscellaneous removal box 38 Located behind the mixing box 4, the platform 3 is fixedly connected to the upper right side of the miscellaneous removal box 38 and the mixing box 4, the front side of the platform 3 is fixedly connected to a ladder 35, and the right side of the upper surface of the miscellaneous removal box 38 is connected to There is a feed pipe A37, and a discharge pipe 39 is connected to the lower part of the front side of the miscellaneous removal box 38, and the other end of the discharge pipe 39 is connected to the inlet end of the feed pump 40, and the outlet end of the feed pump 40 is connected to There is a feeding pipe 42, the other end of the feeding pipe 42 is connected to the feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com