A medium-pressure steam efficient utilization system

A low-pressure steam and steam technology, applied in the field of textile fabrics, can solve the problems of unutilized discharge and low utilization rate of medium-pressure steam, and achieve the effects of reducing energy consumption, improving utilization rate and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

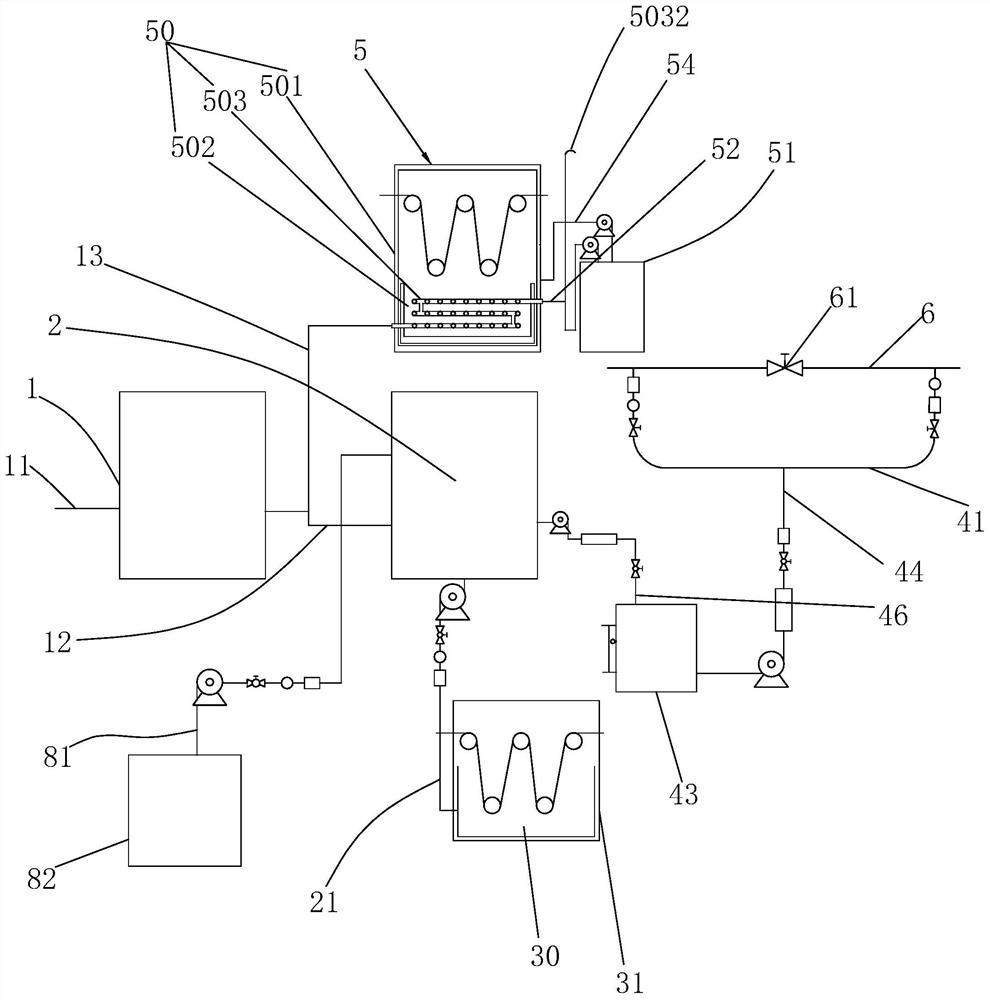

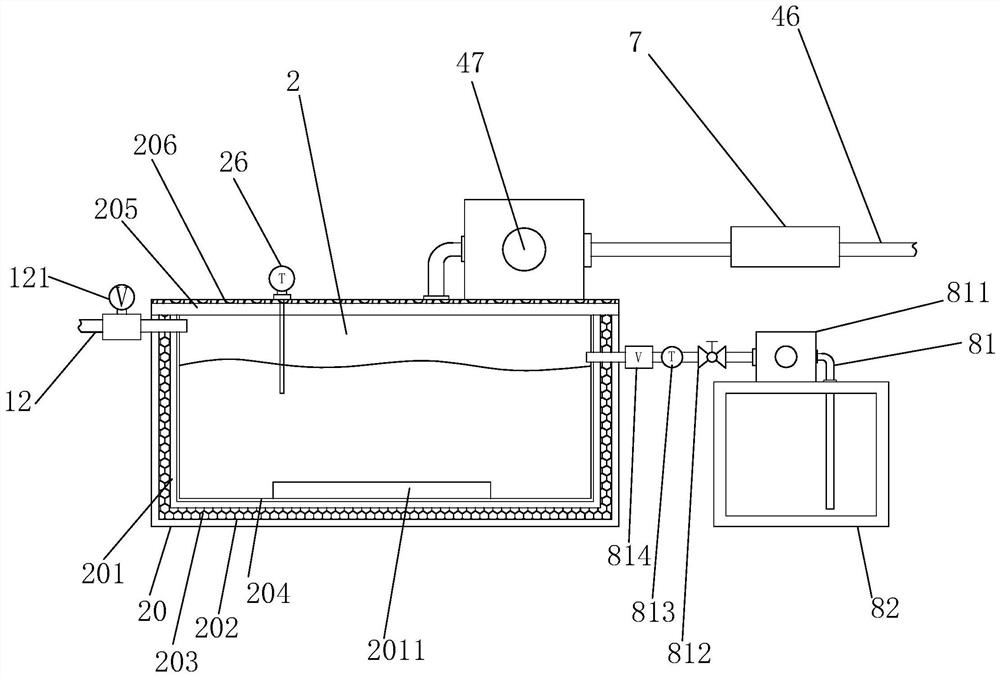

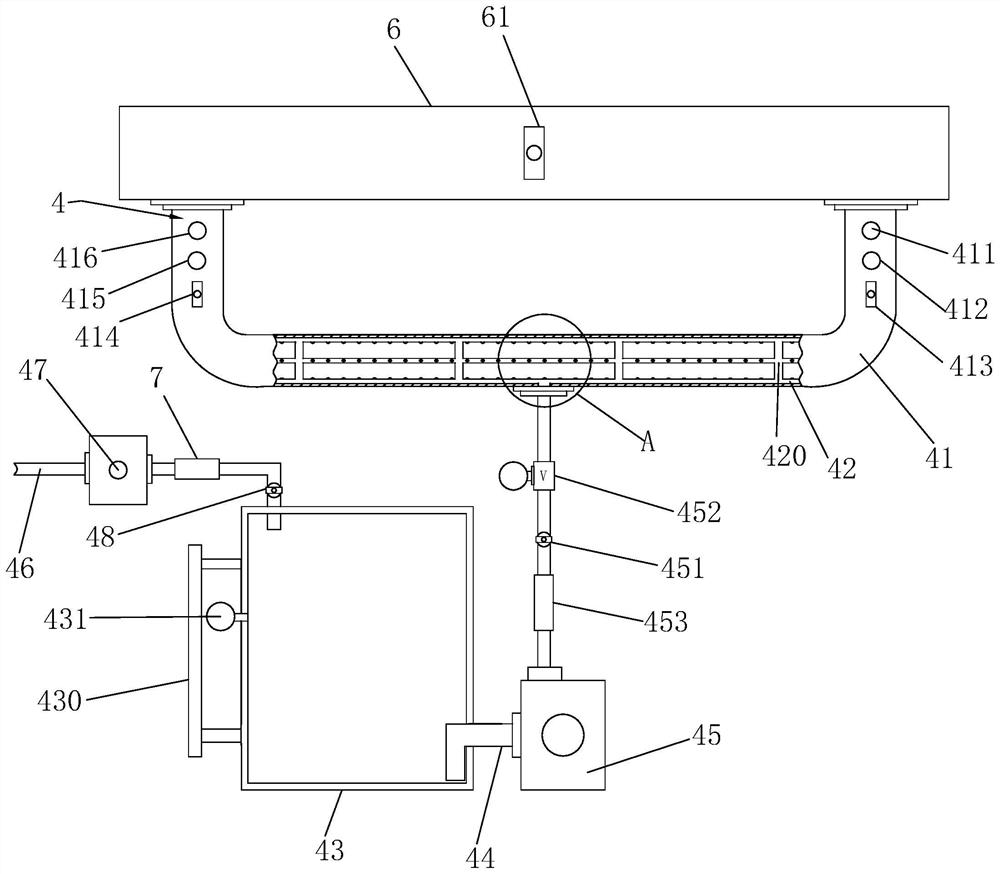

[0036] The present invention will be further described in detail below with reference to the accompanying drawings.

[0037] refer to figure 1 , is an efficient utilization system of medium-pressure steam disclosed in the present invention, comprising a setting machine 1, a medium-pressure steam conveying pipe 11 connected to the setting machine 1, and the medium-pressure steam conveyed by the medium-pressure steam conveying pipe 11 is used as the setting machine 1. A heat source for drying fabrics to be shaped. The setting machine 1 is communicated with a condensed water pipe 12 for exporting the condensed water produced by the heat exchange of the medium pressure steam; In the condensed water storage tank 2 for collecting the condensed water generated by the heat exchange of the medium pressure steam, the condensed water in the condensed water pipe 12 can be pumped to the condensed water storage tank 2 by a centrifugal pump for storage and reuse. The condensed water stora...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap