Four-corner steel pipe, corrugated side plate and flat side plate combined column

A four-corner steel pipe and combined column technology, which is applied in civil engineering and construction fields, can solve the problems of complicated construction, poor economy, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

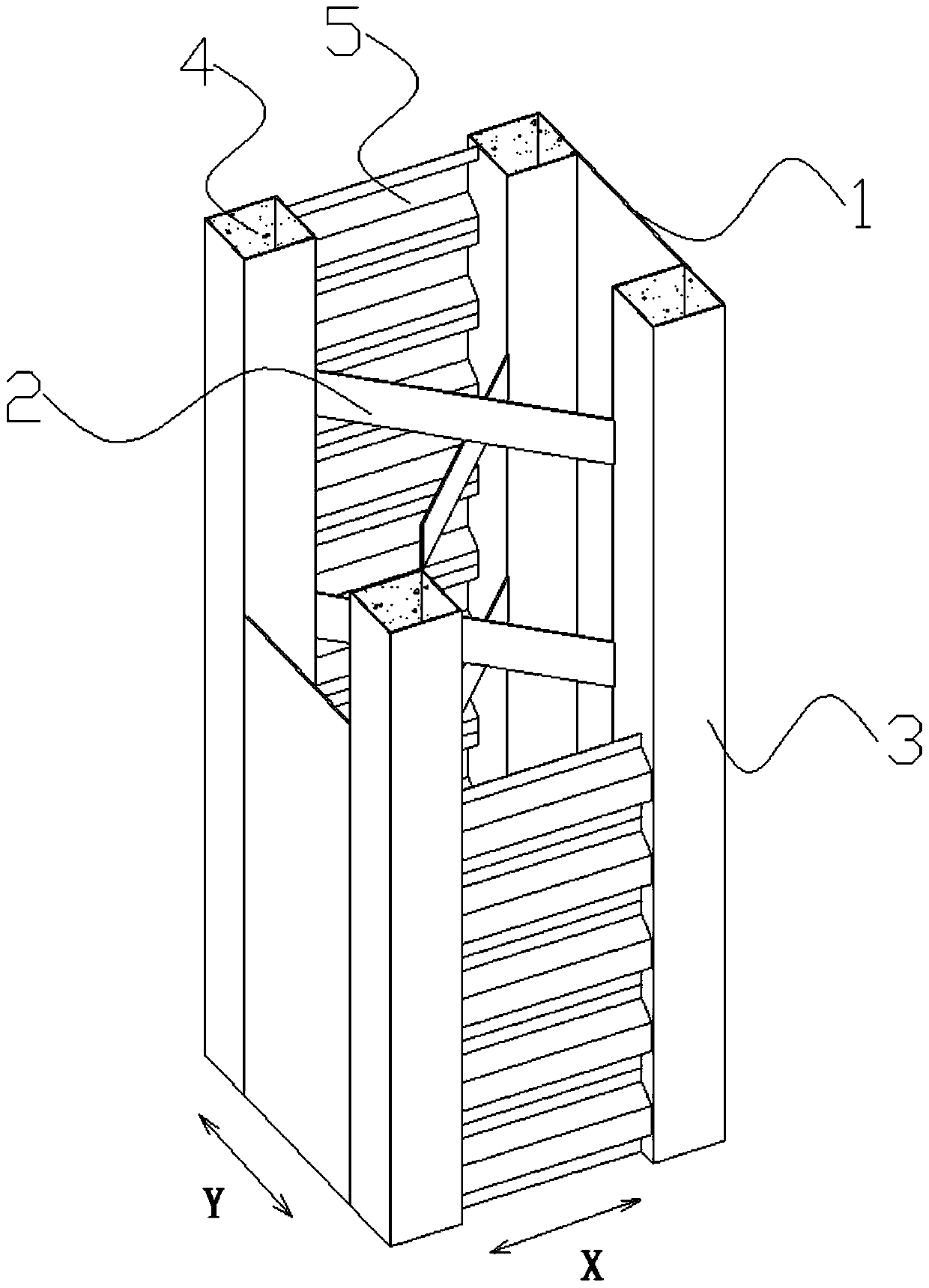

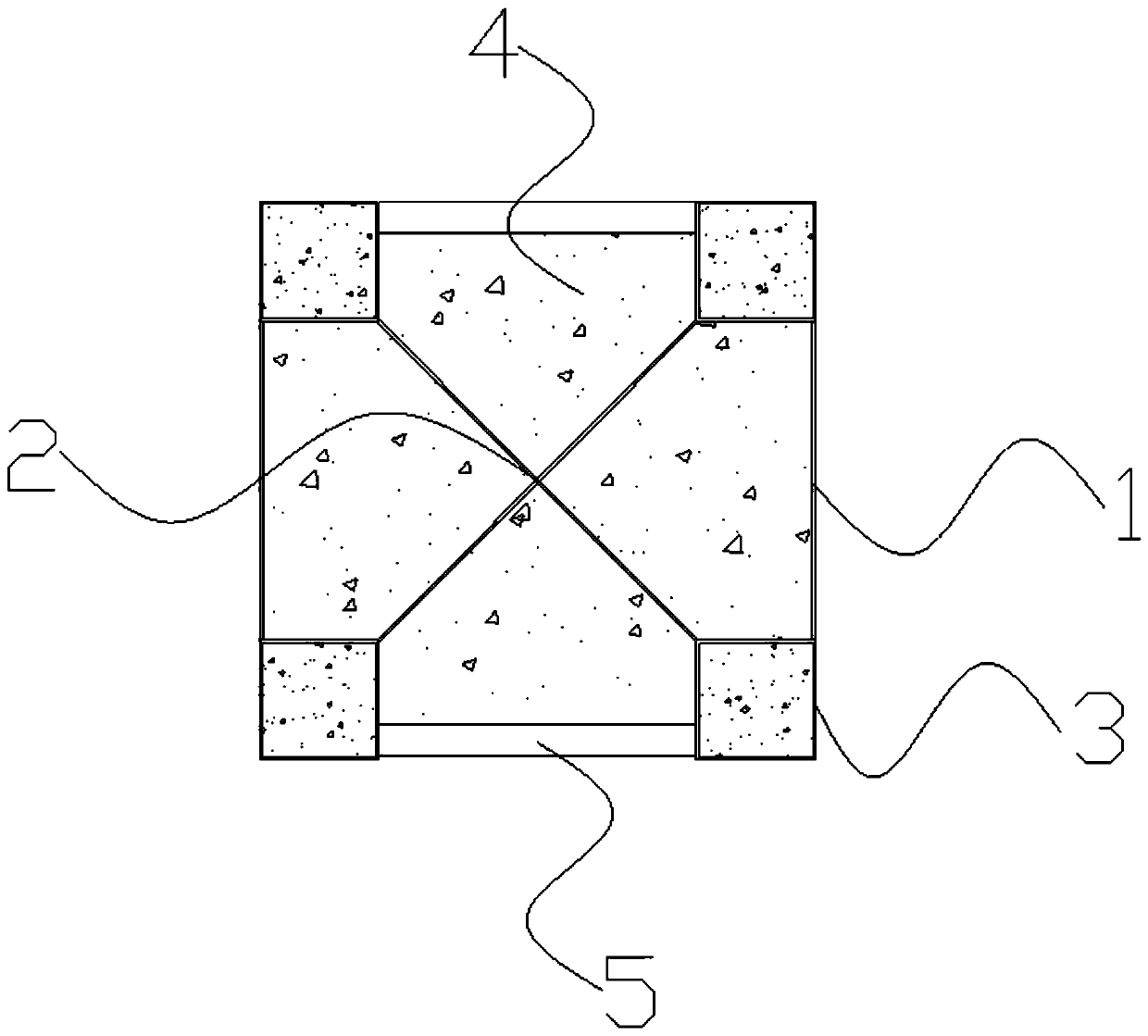

[0023] The first embodiment of the present invention provides a combination column of square steel pipes, corrugated side plates and flat side plates, see figure 1 , which includes a flat web 1 , a cross stiffener 2 , a corner steel pipe 3 , and a corrugated side plate 5 .

[0024] exist figure 1 The corner steel pipes 3 include four, and the forms of the corner steel pipes include but are not limited to square, and other forms such as rectangles can also be used. In this embodiment, the corner steel pipes are square steel pipes. Since the four corner steel pipes are evenly arranged and distributed at the four corners of the composite column, they constitute the edge constraint body of the composite column. figure 1 The X direction and Y direction of the composite column are given in , and the corner steel pipes along the X direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com