Hydroelectric power generation tower utilizing vertical potential energy

A vertical and potential energy technology, applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve problems such as inability to improve power supply efficiency and consume large water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

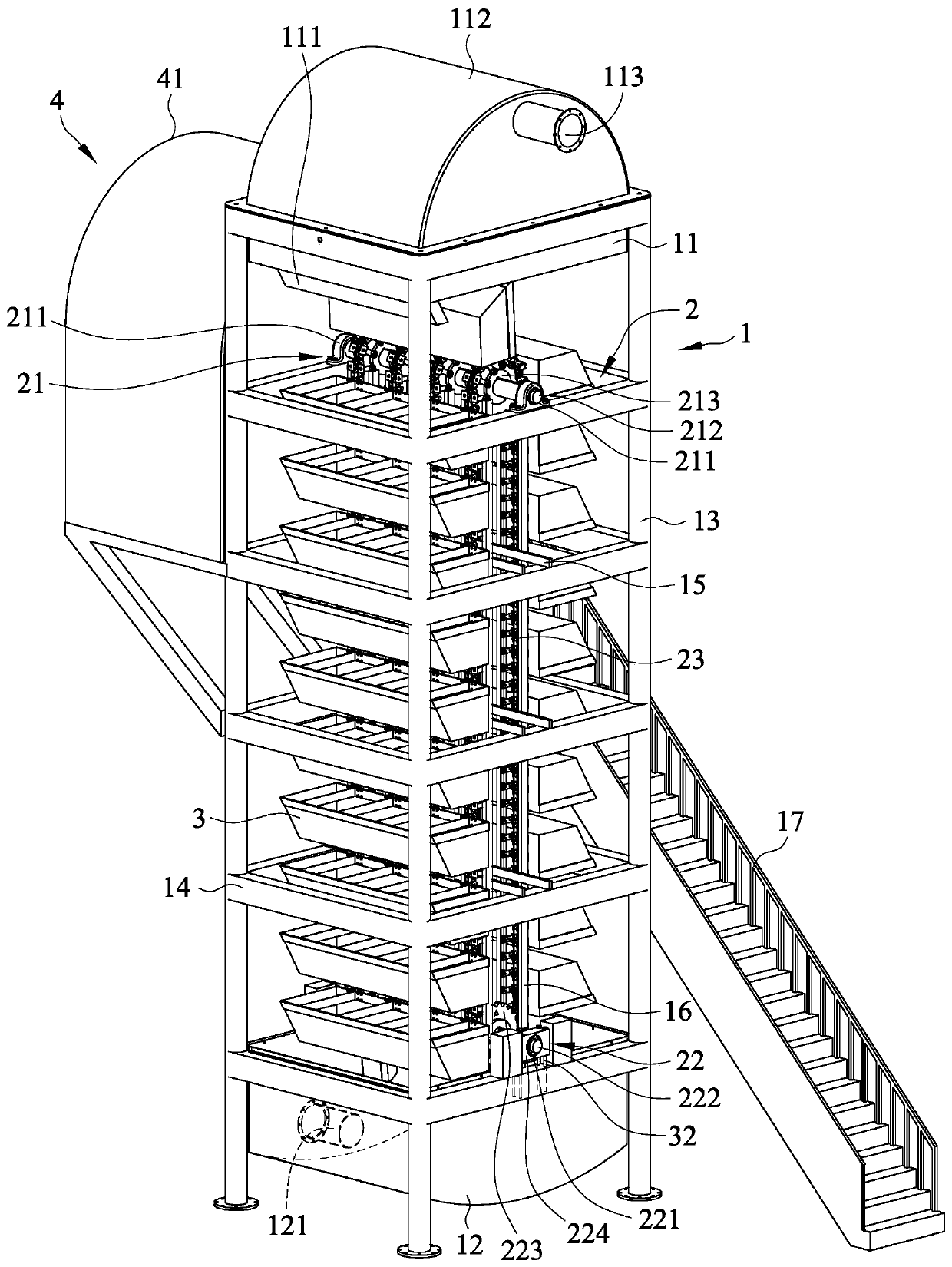

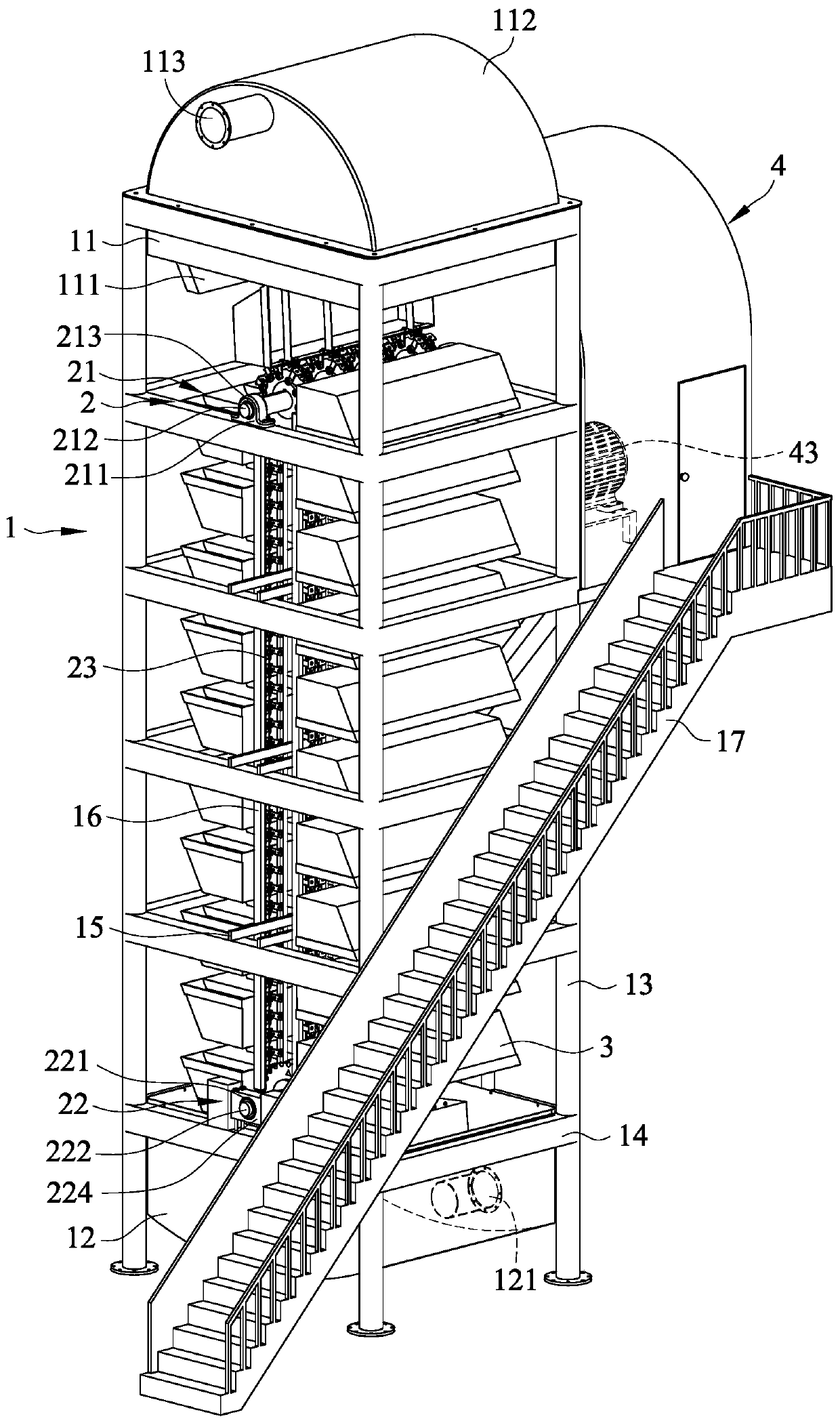

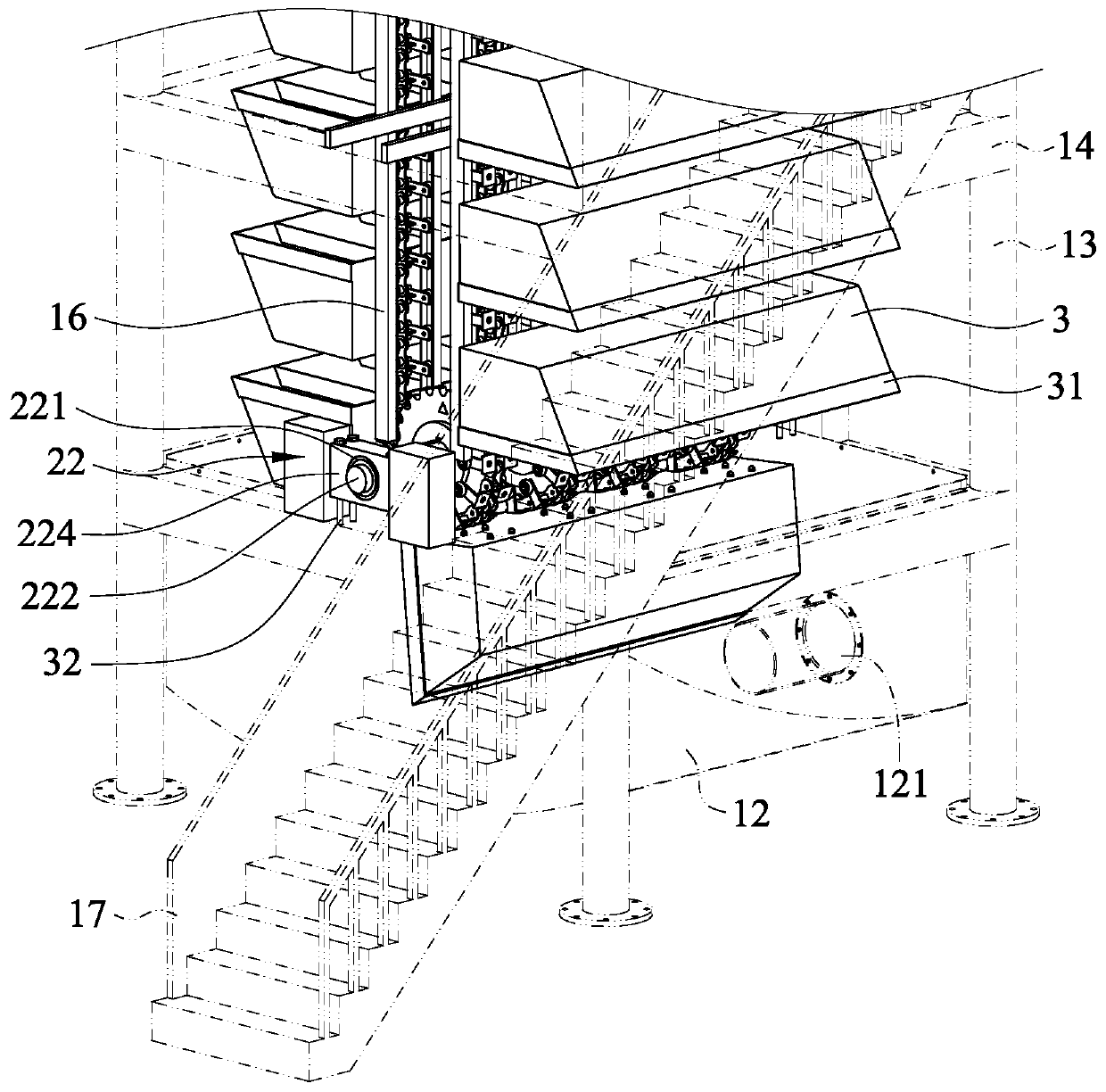

[0027] see Figure 1 to Figure 8 As shown, they are the schematic diagram of the appearance of the present invention, the schematic diagram of the appearance of another angle of the present invention, the partially enlarged schematic diagram of the top of the present invention, the partially enlarged schematic diagram of the bottom of the present invention, the schematic diagram of the first guide wheel set of the present invention, the schematic diagram of the second The schematic diagram of the guide wheel set, the schematic diagram of the combined water tank of the first guide wheel set and the second guide wheel set of the present invention, and the schematic diagram of another angle of the combined water tank of the first guide wheel set and the second guide wheel set of the present invention. As shown in the figure: a kind of vertical potential energy hydropower generation tower of the present invention, it is at least formed by a pedestal 1, a transmission mechanism 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com