High-precision and high-stroke tensile machine and operating system thereof

An operating system, high-precision technology, applied in the direction of strength characteristics, using stable tension/pressure testing material strength, measuring devices, etc., can solve problems such as troublesome preparation process, improve efficiency, prevent irregular throwing, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

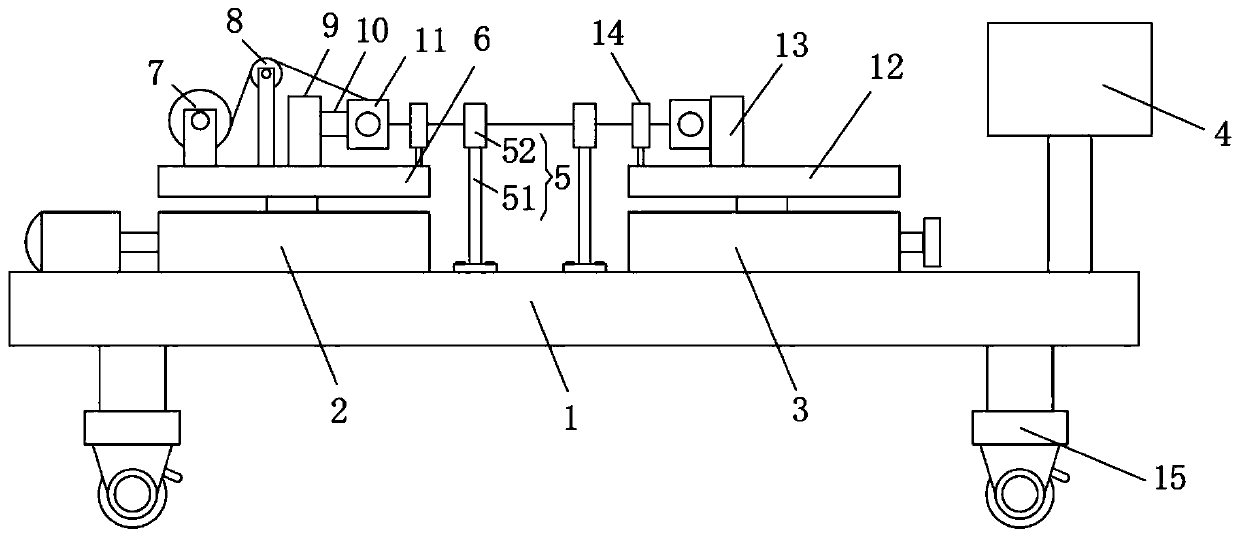

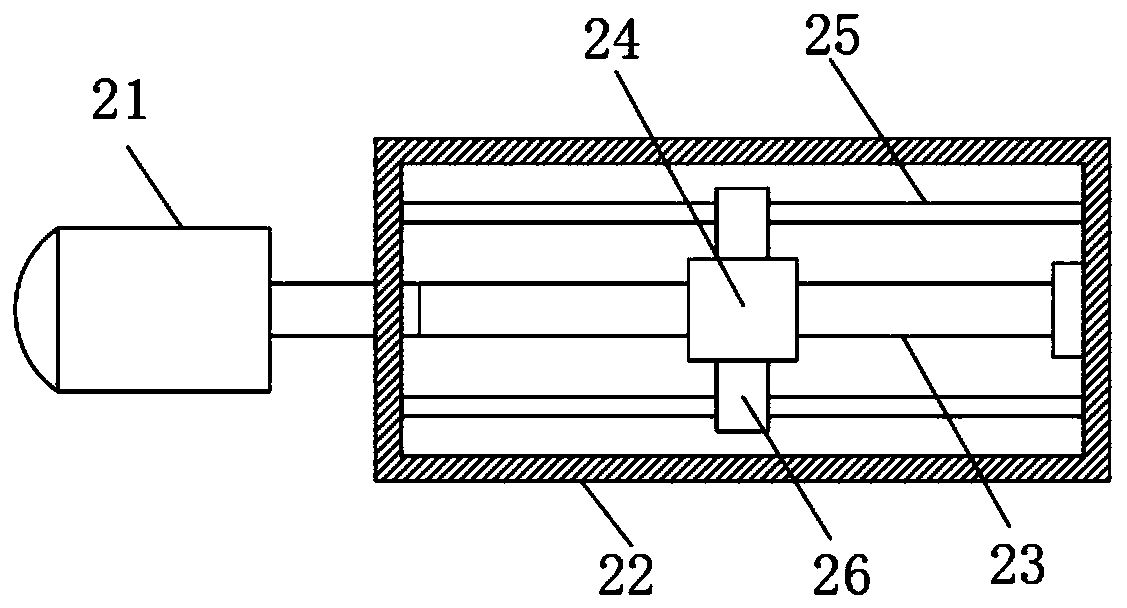

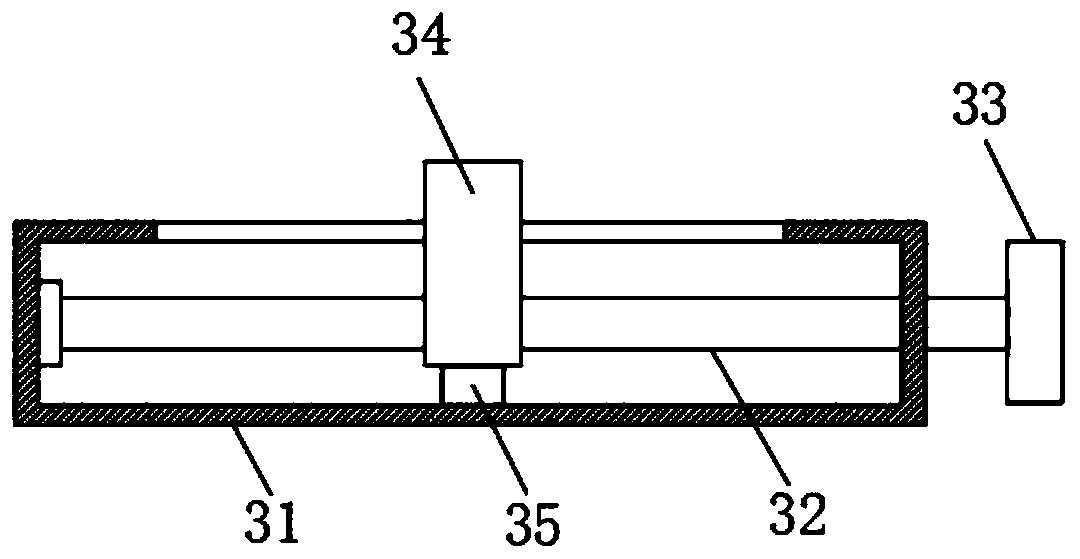

[0029] Such as Figure 1-7 As shown, the embodiment of the present invention provides a high-precision high-stroke tensile machine, including a workbench 1, a first adjustment mechanism 2, a second adjustment mechanism 3 and a PLC controller 4 are fixedly installed on the upper surface of the workbench 1, and the first A plurality of first auxiliary components 5 are arranged in the middle of the adjustment mechanism 2 and the second adjustment mechanism 3, the top of the first adjustment mechanism 2 is fixedly connected with the first moving plate 6, and the upper surface of the first moving plate 6 is fixedly installed with an unwinding Device 7, guiding device 8 and the first fixed plate 9, the top of the second adjustment mechanism 3 is fixedly connected with the second moving plate 12, the upper surface of the second moving plate 12 is fixedly connected with the second fixed plate 13, the first fixed plate 9 and the second fixed plate 13 are provided with two clamping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com