On-board seismic wave fuse self-checking system

A self-inspection system and seismic wave technology, applied in geophysical measurement, instruments, etc., can solve the problems of inconvenience of rapid self-inspection of magnetic detection system, lack of self-inspection result display ability, complex hardware system of self-inspection system, etc. The effect of manual self-checking process, improving human-computer interaction ability, huge engineering application value and theoretical guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

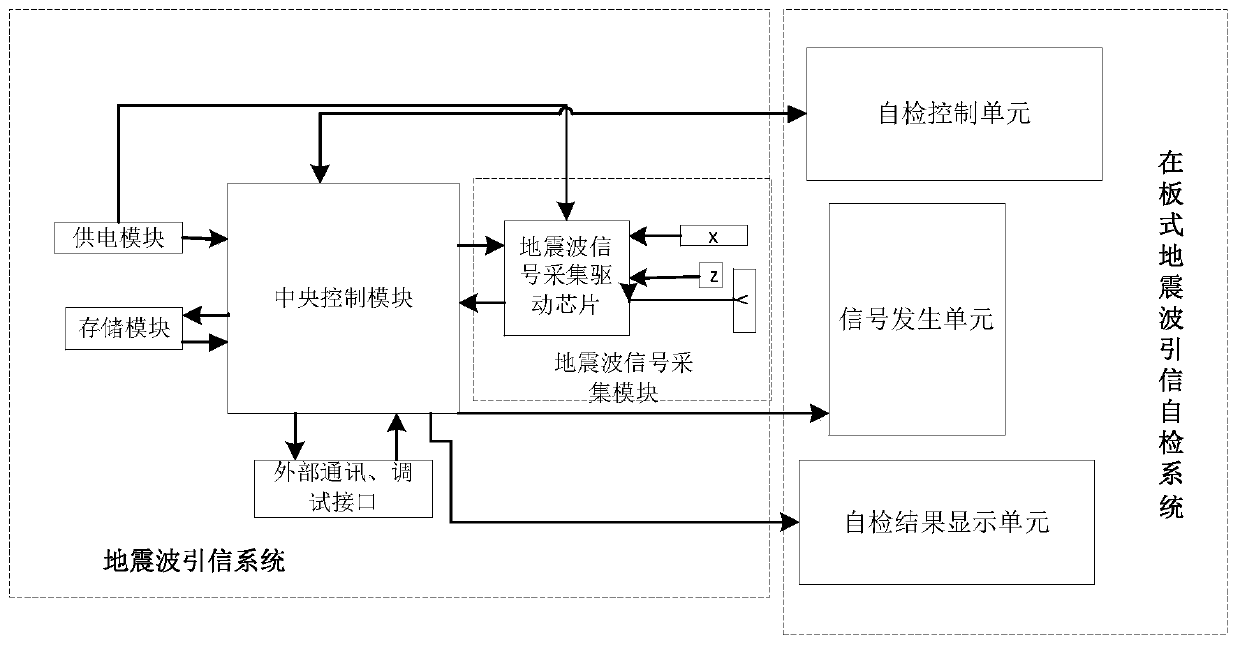

[0137] 1.1 Principle of self-testing of on-plate seismic wave fuze

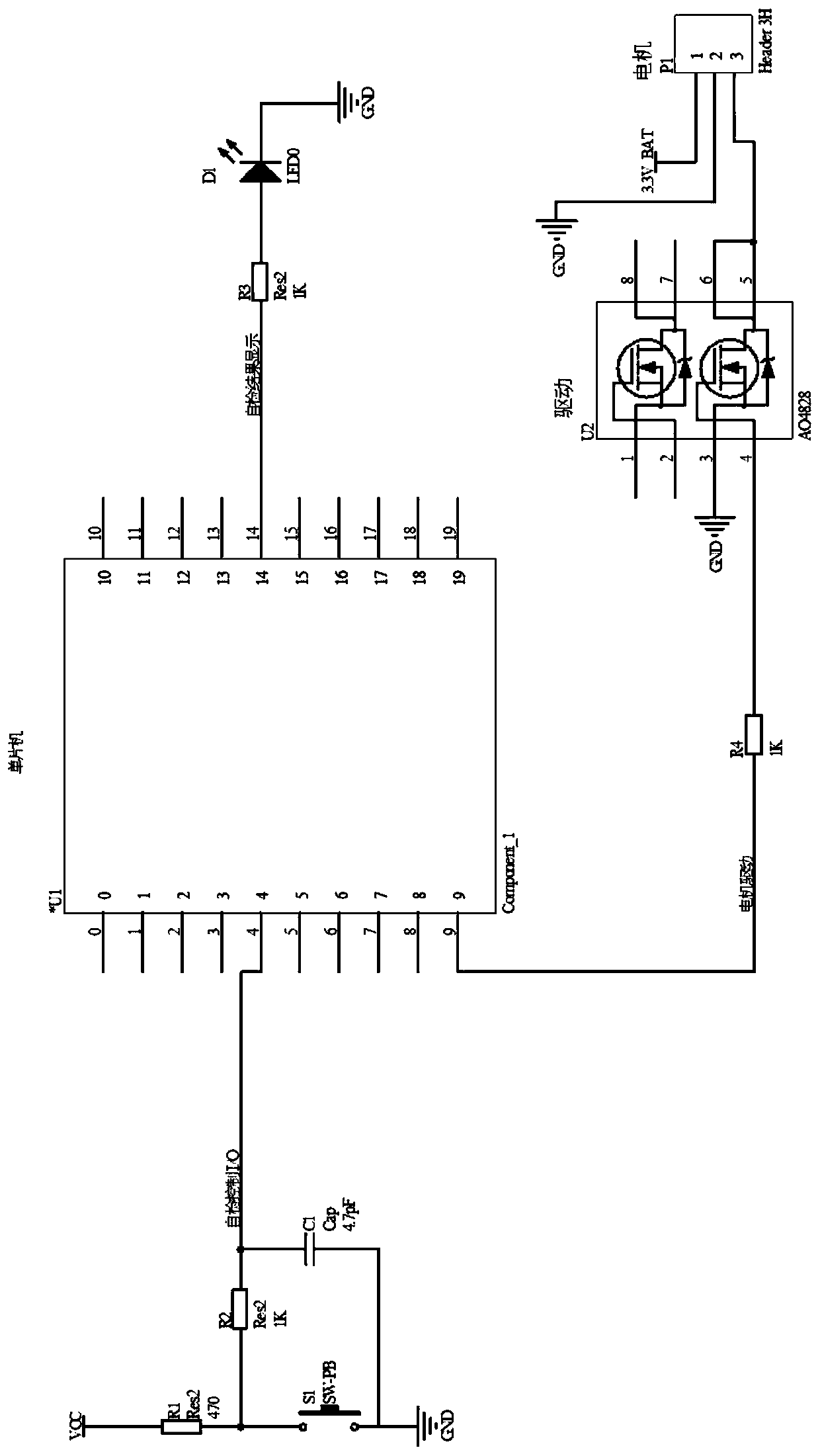

[0138] The main working principle of the plate seismic wave fuze self-inspection system is: the seismic wave fuze system itself generates a specific seismic wave signal, and the self-inspection signal is collected through the signal acquisition module of the fuze itself, and then the collected signal is judged, and according to The results of the evaluation further judge whether the function of the seismic wave fuze is complete. Its biggest feature is that the self-test is integrated into the fuze system, and the additional self-test equipment of the fuze is omitted.

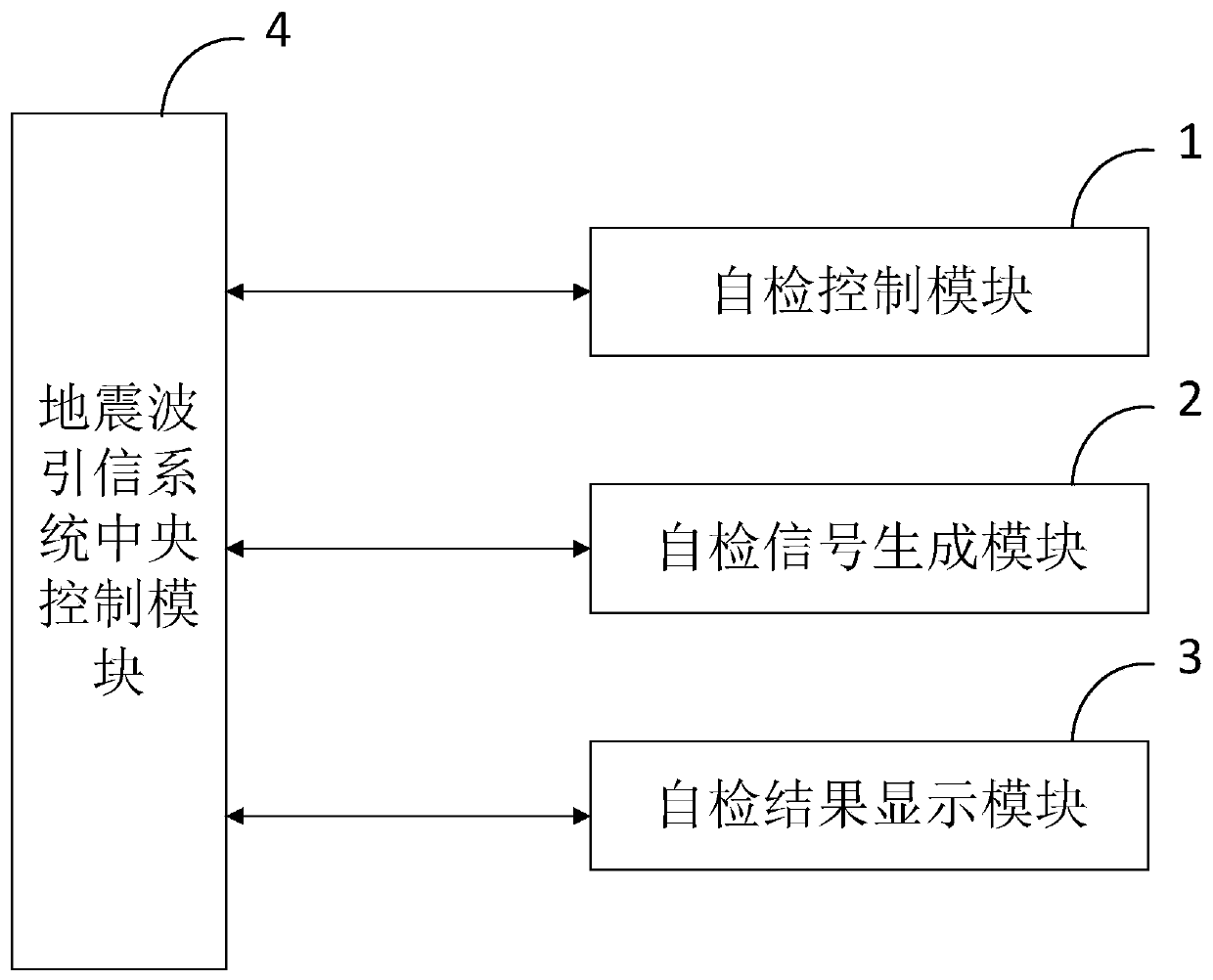

[0139] like figure 2 Shown is the functional block diagram of the on-board magnetic module self-test system. It mainly includes a self-inspection control unit, a self-inspection signal generation unit, and a self-inspection result display unit.

[0140] The self-test control unit is the circuit that controls the fuze system to start the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com