RFID tag with external binding area

An RFID tag and binding area technology, applied in the field of RFID tags, can solve the problems of increasing the complexity of the production process, occupying the internal size of the antenna, increasing the cost of the antenna, etc., to reduce the complexity and production cost, reduce the number of bridges, design handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

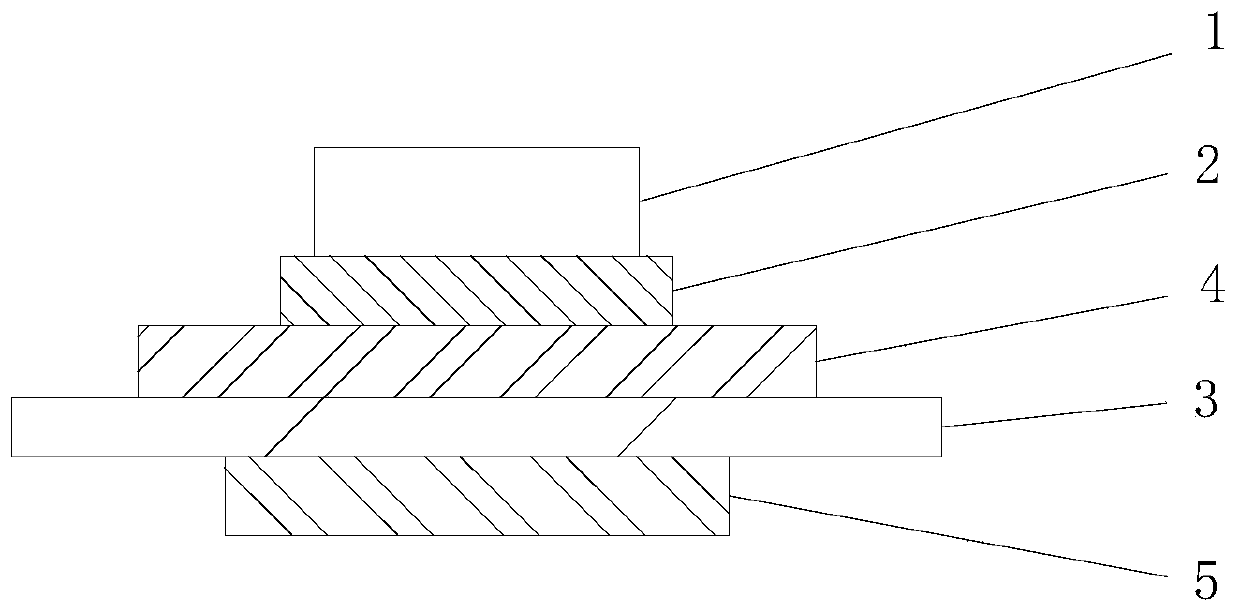

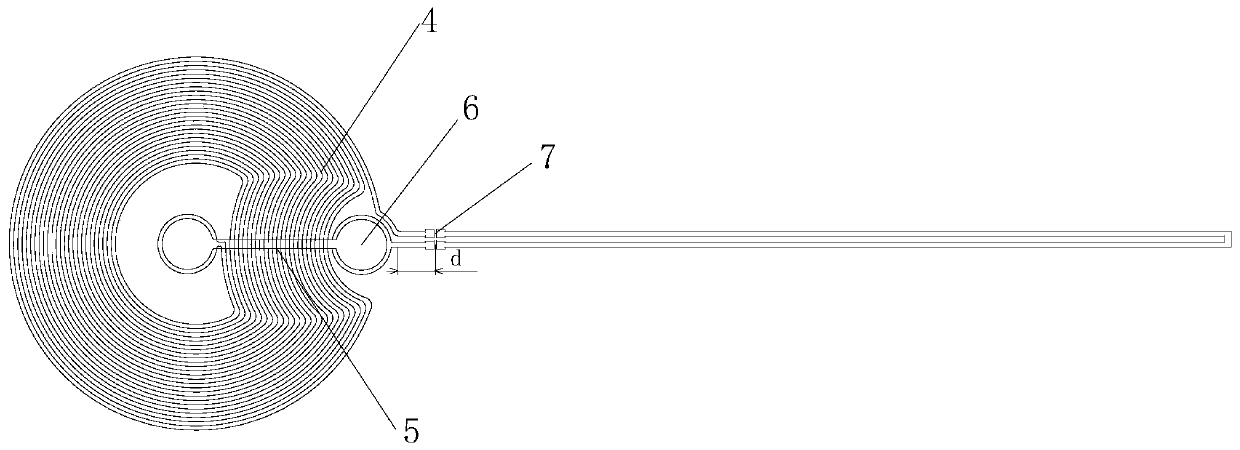

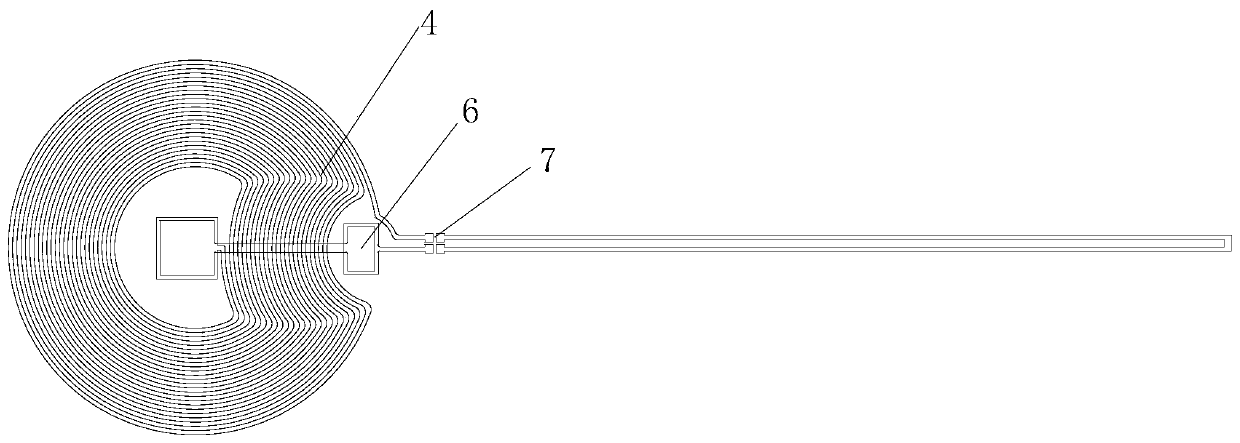

[0022] The present invention as Figure 1-4 As shown, it includes a tag antenna and a chip 1. The tag antenna includes a substrate 3, a front metal antenna 4, a back metal antenna 5 and two bridges 6. The front metal antenna is arranged on the front of the substrate and includes a metal coil. The back metal antenna is arranged on the back of the substrate and includes an inline transmission line, one end of the transmission line is connected to the inside of the metal coil through a bridge, and the other end is connected to the outside of the metal coil through another bridge;

[0023] The binding area of the chip (area for binding the chip) is set outside the tag antenna. The chip is connected to the front metal antenna through conductive glue 2.

[0024] The design of the binding area adjustment, the high-frequency antenna binding area is adjusted from the original internal position to the external position of the tag antenna, and can be adjusted to any position outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com