Current transformer assembly

A technology of current transformers and components, applied in the direction of inductors, transformer/inductor shells, electrical components, etc., can solve the problems of easy failure of insulating sleeves and affect the accuracy of current transformers, and achieve the effect of avoiding the impact of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

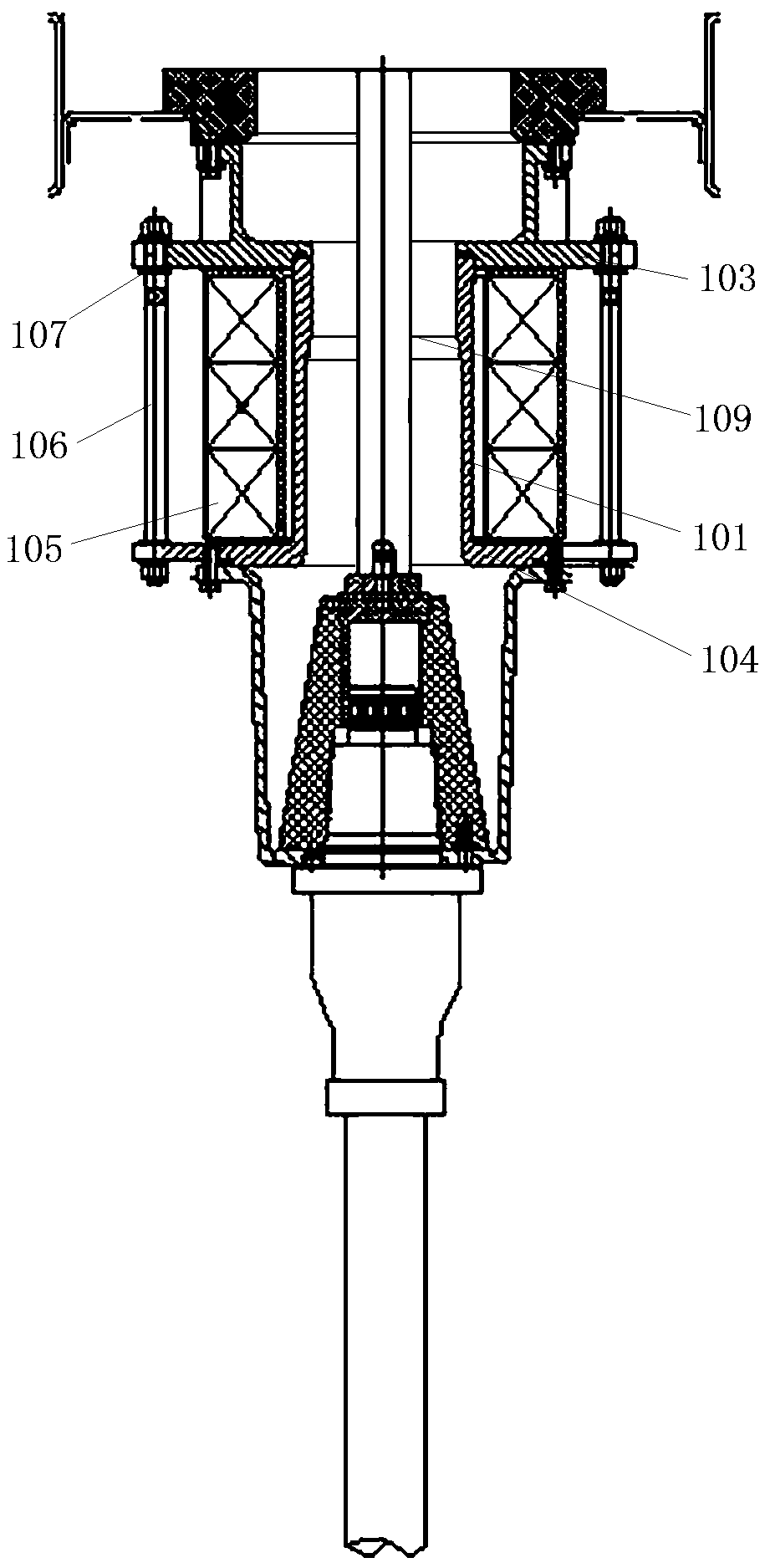

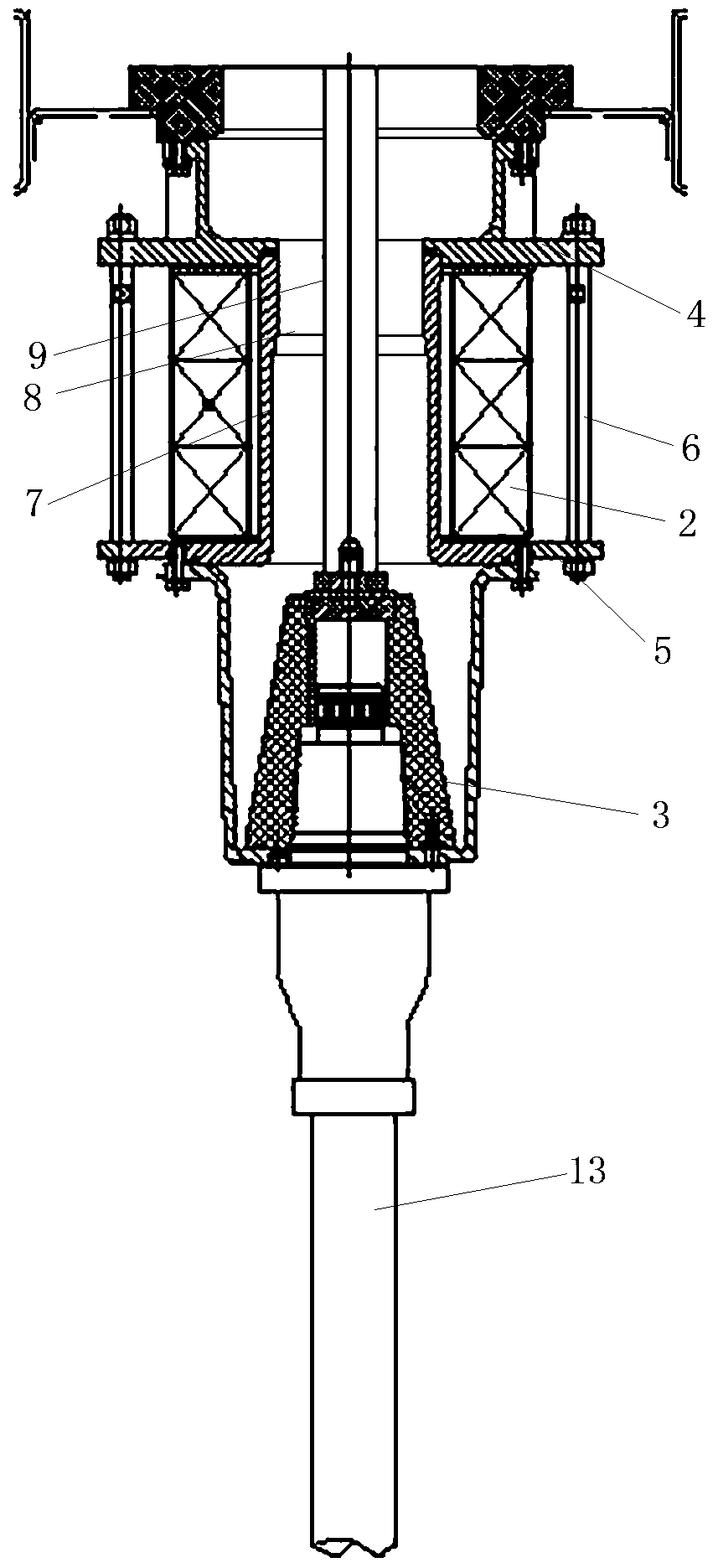

[0025] Current transformer components are used in GIS switchgear, such as figure 2 As shown, the current transformer assembly is assembled between the circuit breaker and the outlet terminal 3 of the switchgear. In other embodiments, the current transformer assembly is assembled between the circuit breaker and the inlet terminal of the switchgear.

[0026] Such as figure 2 As shown, the current transformer assembly includes a first flange 4 for fixing on the circuit breaker and a second flange 5 for fixing on the outlet terminal 3 of the switchgear, the second flange 5 and the first flange 4 Fixedly connected by threaded fasteners 6, the second flange 5 is integrally provided with a main circuit protection shell 7 near its center, and the main circuit protection shell 7 protrudes toward the first flange 4, and is connected with the first flange. 4 seal fit.

[0027] Such as figure 2 As shown, the main circuit protection shell 7 is provided with a channel 8 for the conduc...

specific Embodiment 2

[0036] The difference from Embodiment 1 is that the metal threaded joint and the rod body are fixedly connected by bolts, so that the metal threaded joint and the rod body have better connection strength and meet the strength requirements of threaded fasteners.

specific Embodiment 3

[0038] It differs from Example 1 in that:

[0039] Before the metal threaded joint and the rod body are riveted, the metal threaded joint and the rod body may not be pre-fixed by glue. Riveted on a riveting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com