Two-dimensional bimetallic site conductive metal organic framework material and preparation method thereof

A conductive metal, organic framework technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, electrodes, etc., can solve problems such as difficulty in generating electrocatalytic activity, and achieve good electrochemical stability. , The method is simple and green, and the preparation conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of nickel-hexaaminohexaazabenzene

[0032] Dissolve 162mg (0.684mmol) of nickel chloride in 30mL of ethanol, adjust the pH to 4 with hydrochloric acid, then add 100mg (0.210mmol) of hexaaminohexaazabenzene, and reflux in a water bath at 70°C for 4 hours. After the reaction The temperature was lowered, the obtained solution was rotary evaporated to dryness, and the obtained solid was dissolved in ethanol for recrystallization, and the obtained black solid was dried on a watch glass to obtain nickel-hexaaminohexaazabenzene powder.

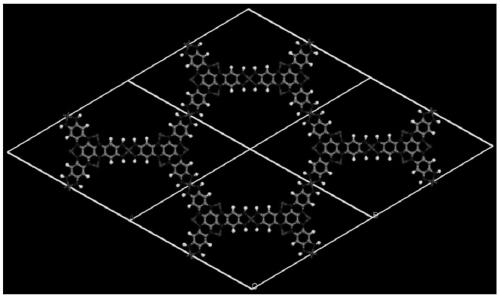

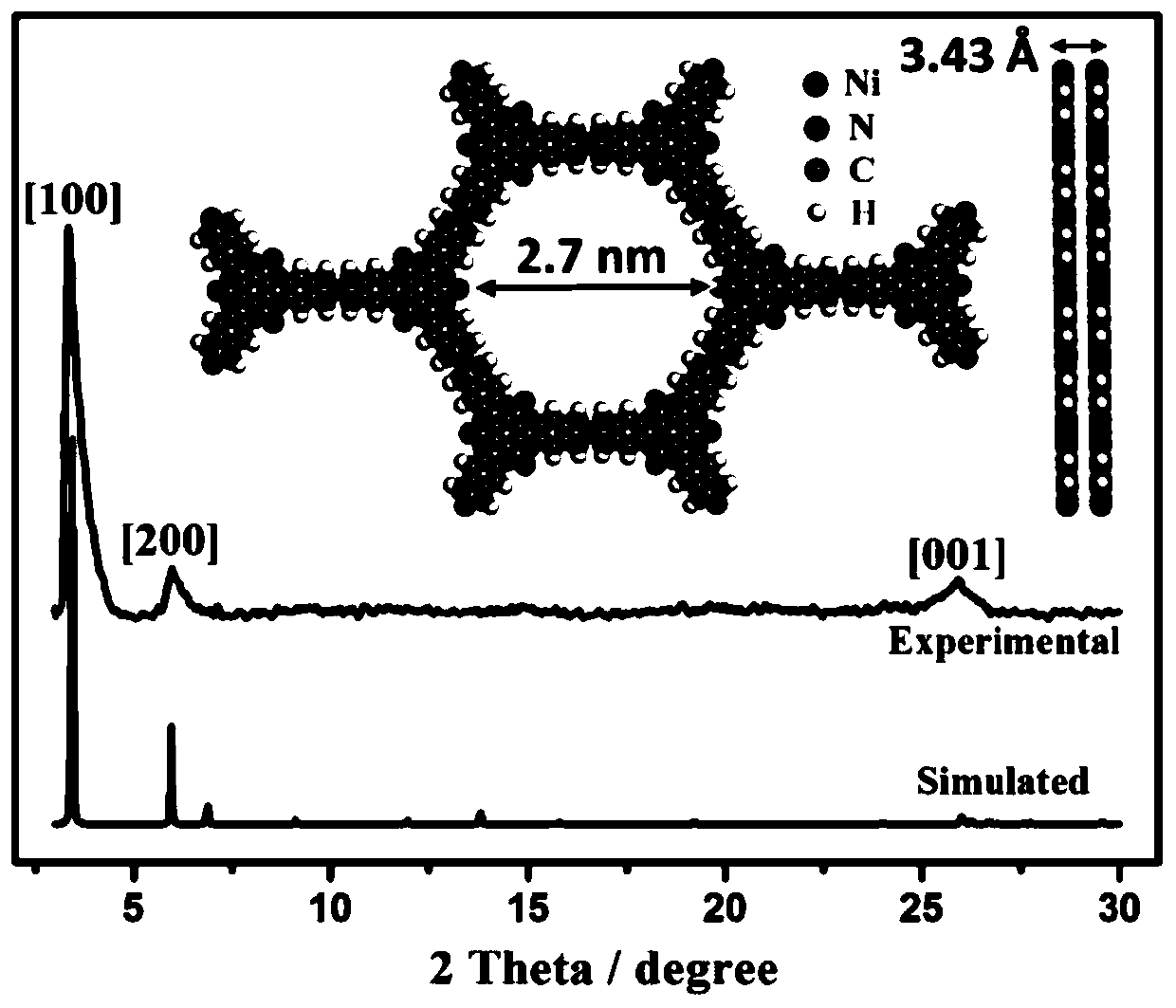

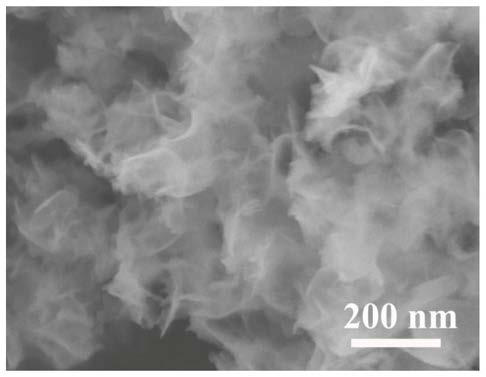

[0033] 2. Two-dimensional bimetallic dot-site conductive metal-organic framework materials

[0034] Dissolve 51mg (0.216mmol) of nickel chloride in 40mL of deionized water, add 2mL of ammonia water, and stir evenly at 65°C in an air environment, then add 100mg (0.147mmol) of nickel-hexaaminohexaazabenzene powder to it, continue Stir and reflux at this temperature for 2 hours. After the resulting solution was concentrated under...

Embodiment 2

[0036] In step 1 of this embodiment, the nickel chloride in step 1 of embodiment 1 is replaced with equimolar cobalt chloride to obtain cobalt-hexaaminohexaazabenzene powder, and then prepared in step 2 with the structural formula Ni 3 (Co 3 ·HAHATN) 2 Two-dimensional bimetallic point-site conductive metal-organic framework materials (see Figure 5 ), which belongs to the hexagonal crystal system, P6 / mmm space group, and the unit cell parameters are: α=90°, β=90°, γ=120°.

Embodiment 3

[0038] In step 1 of this embodiment, the nickel chloride in step 1 of embodiment 1 is replaced with equimolar copper chloride to obtain copper-hexaaminohexaazabenzene powder, and then prepared in step 2 with the structural formula of Ni 3 (Cu 3 ·HAHATN) 2 Two-dimensional bimetallic point-site conductive metal-organic framework materials (see Figure 6 ), which belongs to the hexagonal crystal system, P6 / mmm space group, and the unit cell parameters are: α=90°, β=90°, γ=120°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com