Cone crusher

A cone crusher and cone technology, which is applied in the field of mining machinery and equipment, can solve problems such as the inability to effectively reduce the friction coefficient, different particle sizes, and shortened service life, and achieve reduced lubricating oil consumption, low assembly strength, and less heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

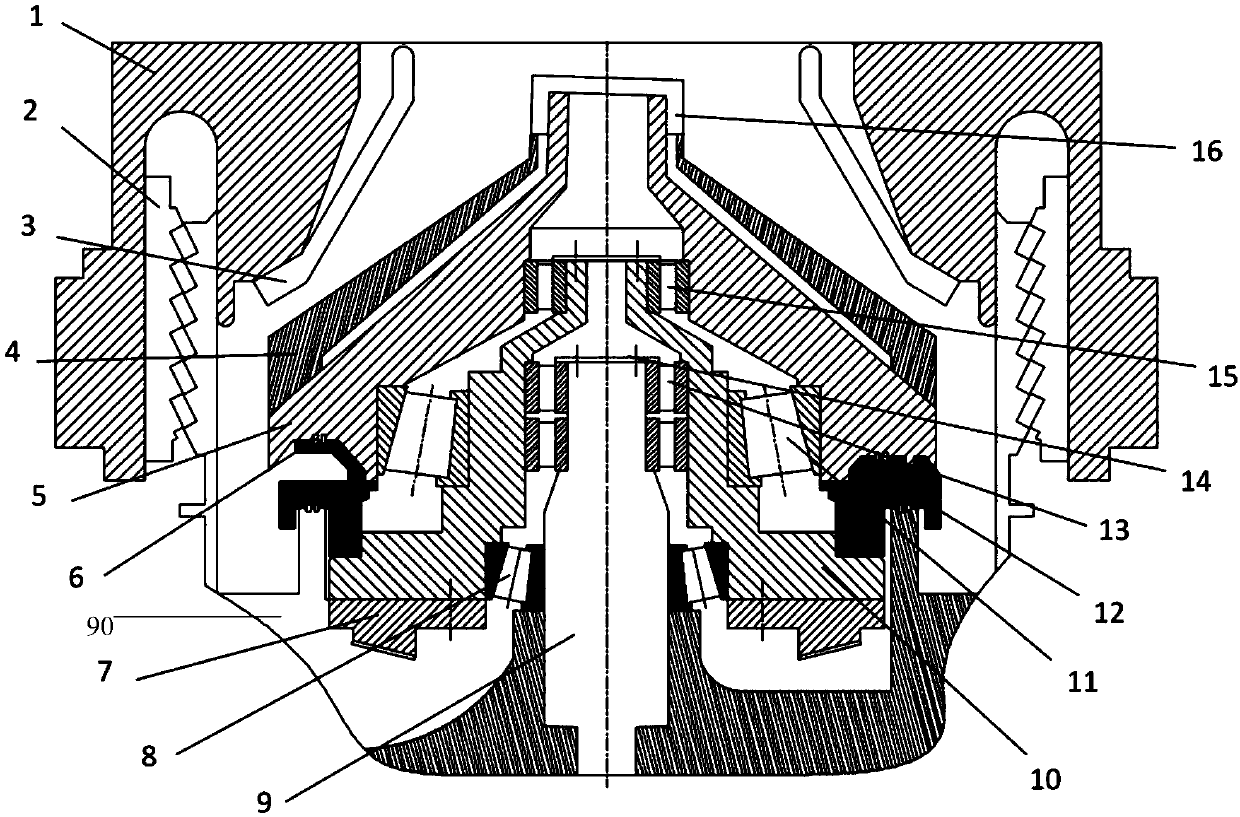

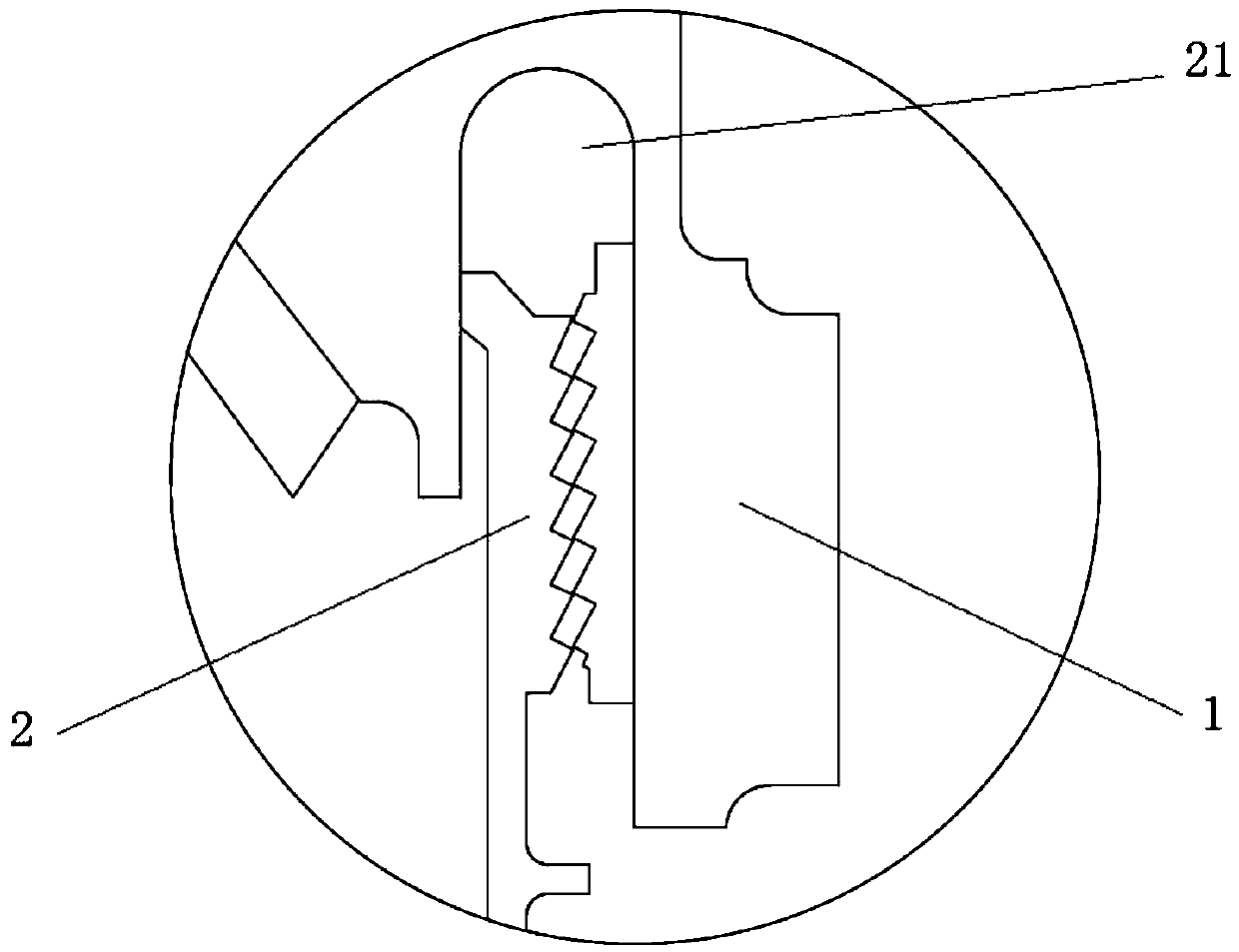

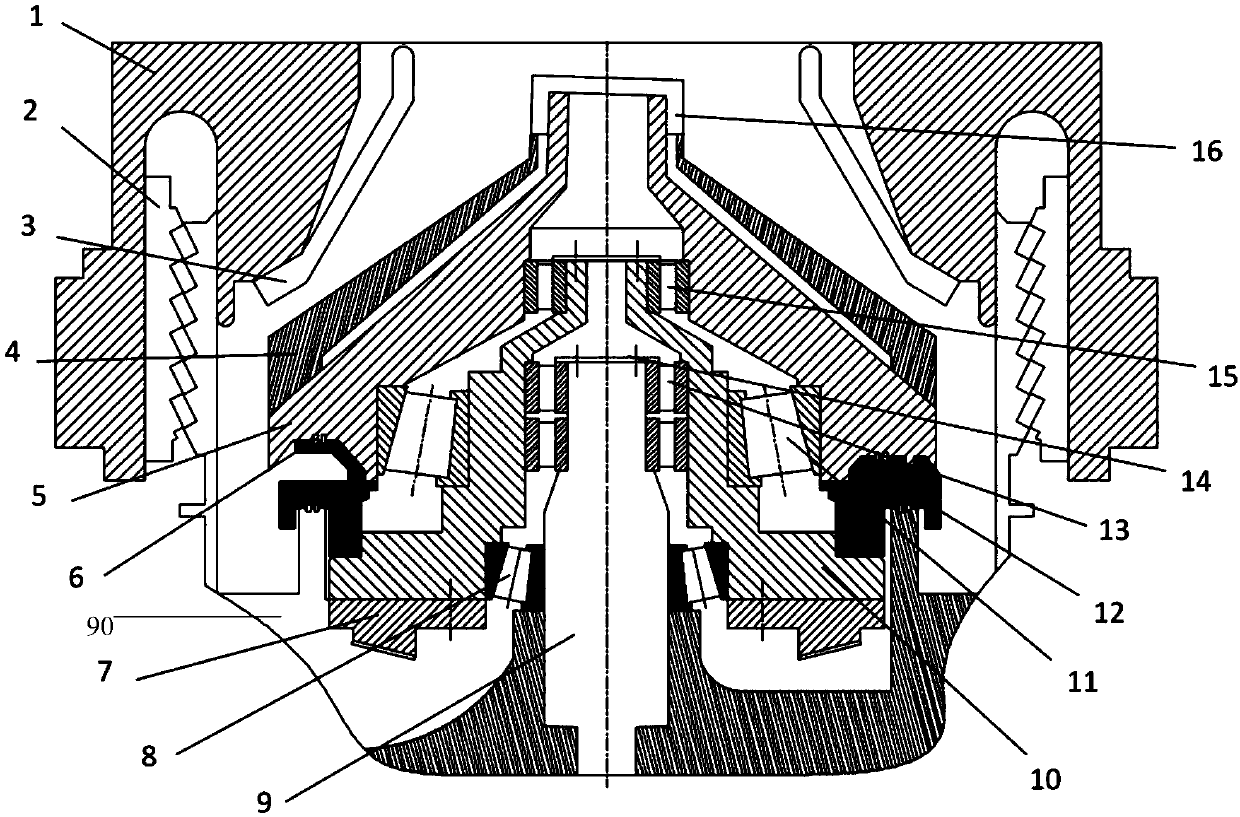

[0020] Please check figure 1 , a cone crusher in this embodiment, including a frame 90, a motor, a main shaft 9, an eccentric body 10, a moving cone assembly, a fixed cone assembly and a bearing assembly, a sealing assembly, and a height adjustment assembly;

[0021] Assembled as the main shaft 9 of the crusher, the main shaft 9 directly cooperates with the frame 90 of the crusher.

[0022] The eccentric body 10 and the moving cone assembly are sequentially sleeved on the main shaft 9 from bottom to top; the connection between the eccentric body 10 and the main shaft 9 is completed through a bearing, and an integrated structure design is adopted. The middle part of the cylindrical eccentric body is connected to the top of the eccentric body, the bottom of the eccentric body is provided with a large conical gear 7, and the motor drives the large conical gear 7 to drive the eccentric body to rotate;

[0023] The moving cone assembly includes a moving cone 5, a moving cone liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com