Water-free flying dust treatment device for constructional engineering

A construction engineering and processing device technology, applied in the directions of removing smoke and dust, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of difficult cleaning, dust adsorption on the inner wall of the shell, affecting the use effect, etc., to improve the processing effect and strengthen the filtration. effect, the effect of enhancing the brushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

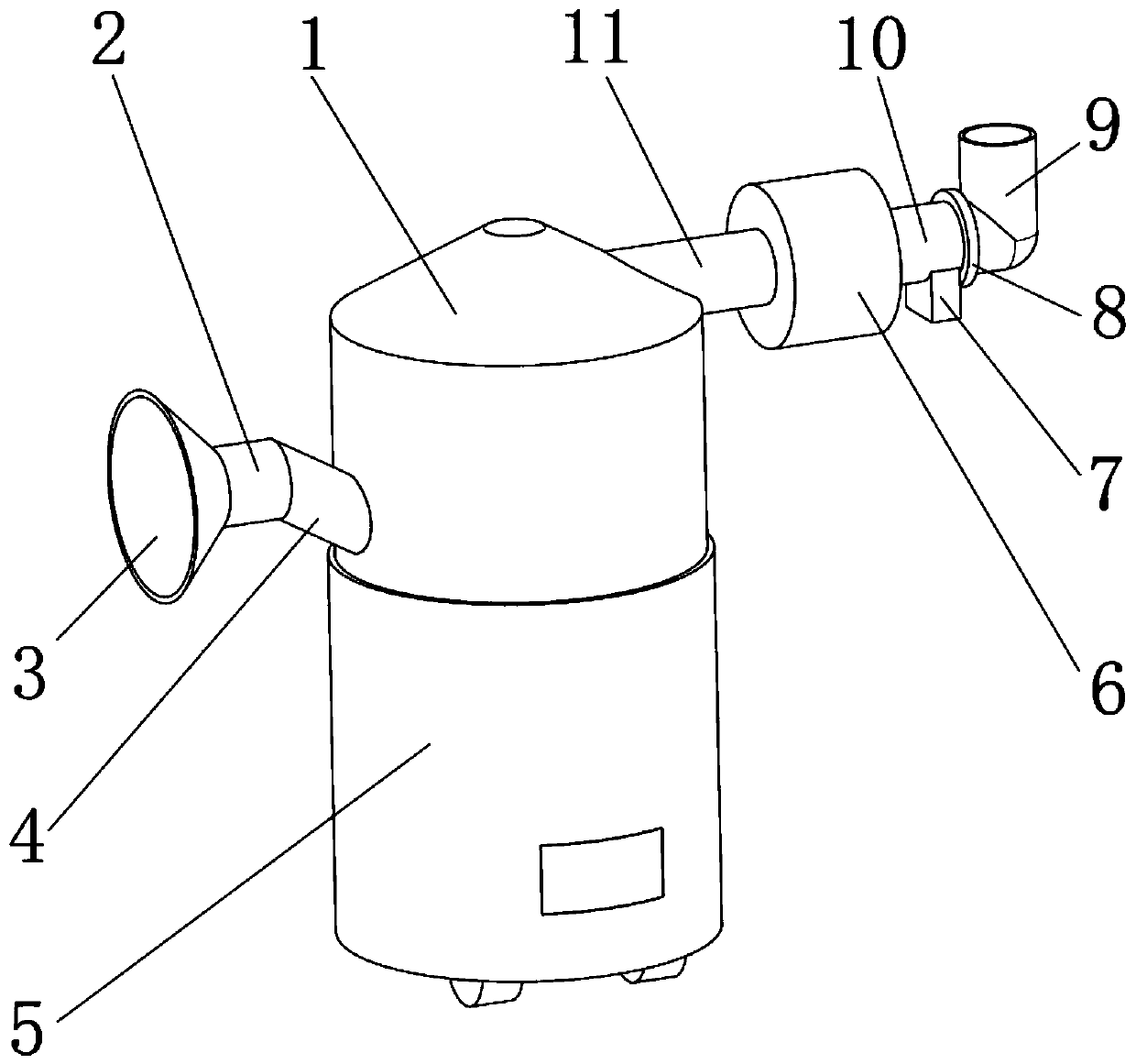

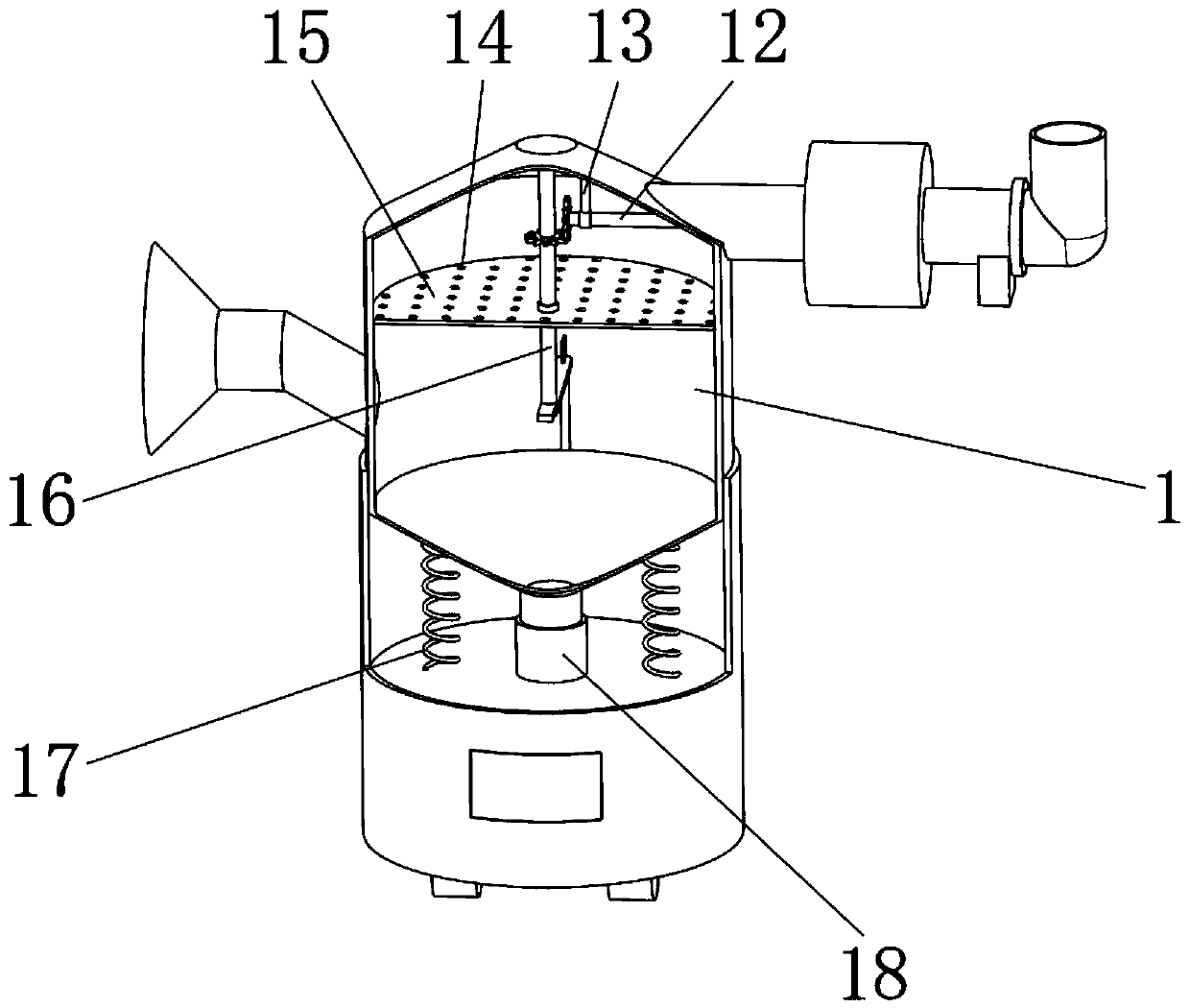

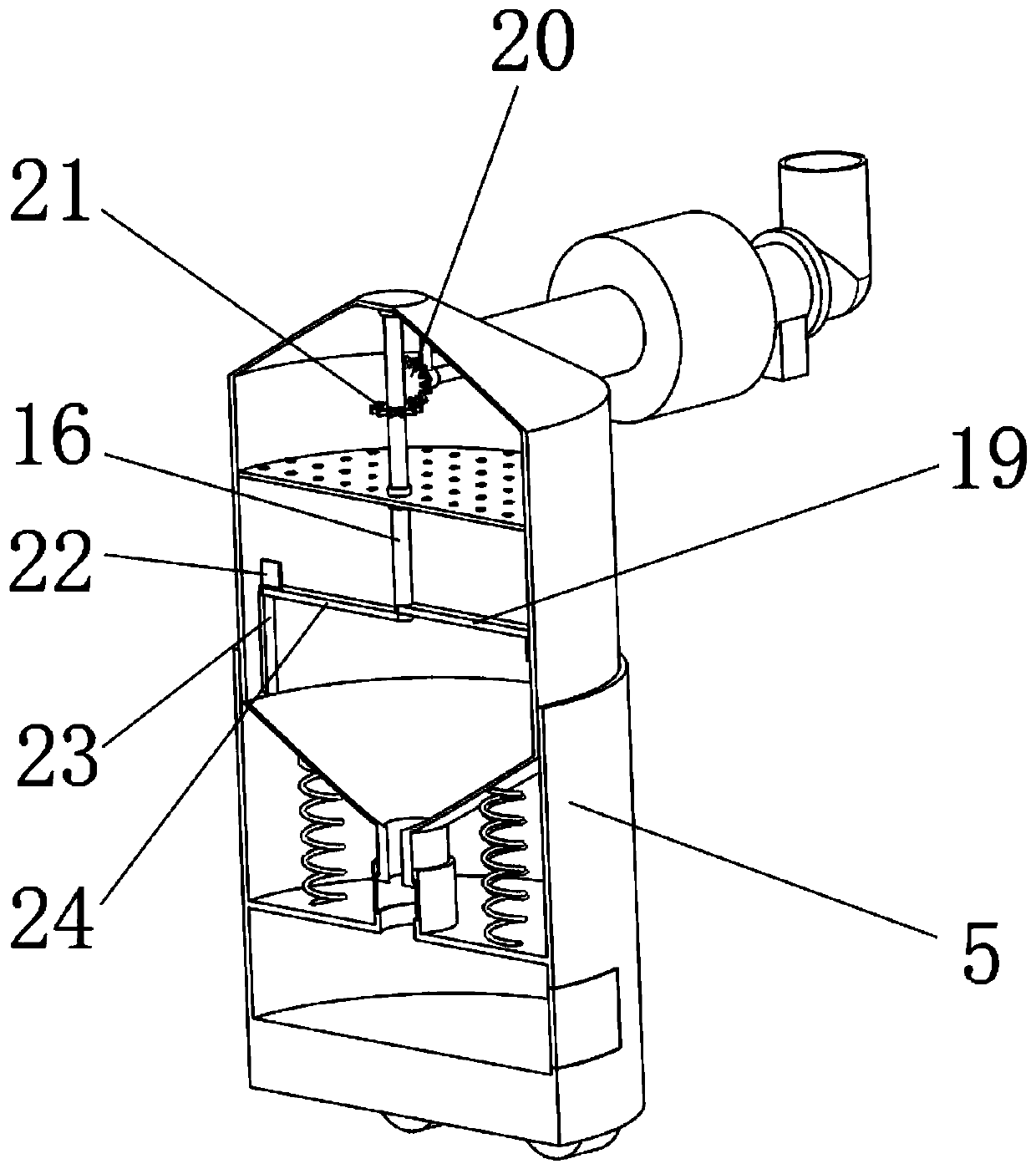

[0035] A water-free dust treatment device for construction engineering, such as Figure 1-4As shown, it includes a main body 1, the outer wall of one side of the main body 1 is welded with a first connecting pipe 11, and the outer wall of one side of the first connecting pipe 11 is fixed with an exhaust pump 6 by bolts; the inner wall of the top of the main body 1 is welded with a fixing frame 13. The inner wall of the fixed frame 13 is connected with the first rotating shaft 12 through bearings, the outer surface of one end of the first rotating shaft 12 is welded with evenly distributed fan blades 25 around the circumference, and the other end of the first rotating shaft 12 is fixed with the first rotating shaft 12 by screws. Gear 20, the outer wall of the top of the main body 1 is connected to the second rotating shaft 16 through the bearing seat, and the outer surface of the second rotating shaft 16 is fixed with a second gear 21 by screws, and the second gear 21 is meshed ...

Embodiment 2

[0046] A water-free dust treatment device for construction engineering, such as Figure 5 As shown, in order to increase the stability of the device; this embodiment makes the following improvements on the basis of Embodiment 1: the outer surface of the bottom of the collection pipe 28 is provided with a protrusion 29, the inner wall of the collection seat 18 is provided with a limiting groove 30, and the protrusion 29 Slidingly connected in the limiting groove 30; by setting the protrusion 29 and the limiting groove 30, it can limit the position of the main body 1 when the device vibrates, prevent the main body 1 from breaking away from the base 5, and increase the stability of the device.

[0047] When this embodiment is in use, when the device vibrates, the protrusion 29 can slide on the inner wall of the limiting groove 30, and at the same time, the limiting groove 30 plays a role of limiting the protrusion 29, thereby limiting the displacement of the main body 1 and preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com