Two-roller rolling machine manual roller replacing device and roller replacing method

A technology of roll changing device and two-roll rolling mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., and can solve the problems of high risk, high manufacturing cost, high maintenance and repair cost, low roll changing efficiency, etc. problems, to achieve the effect of high operational safety factor, low maintenance and repair costs, and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

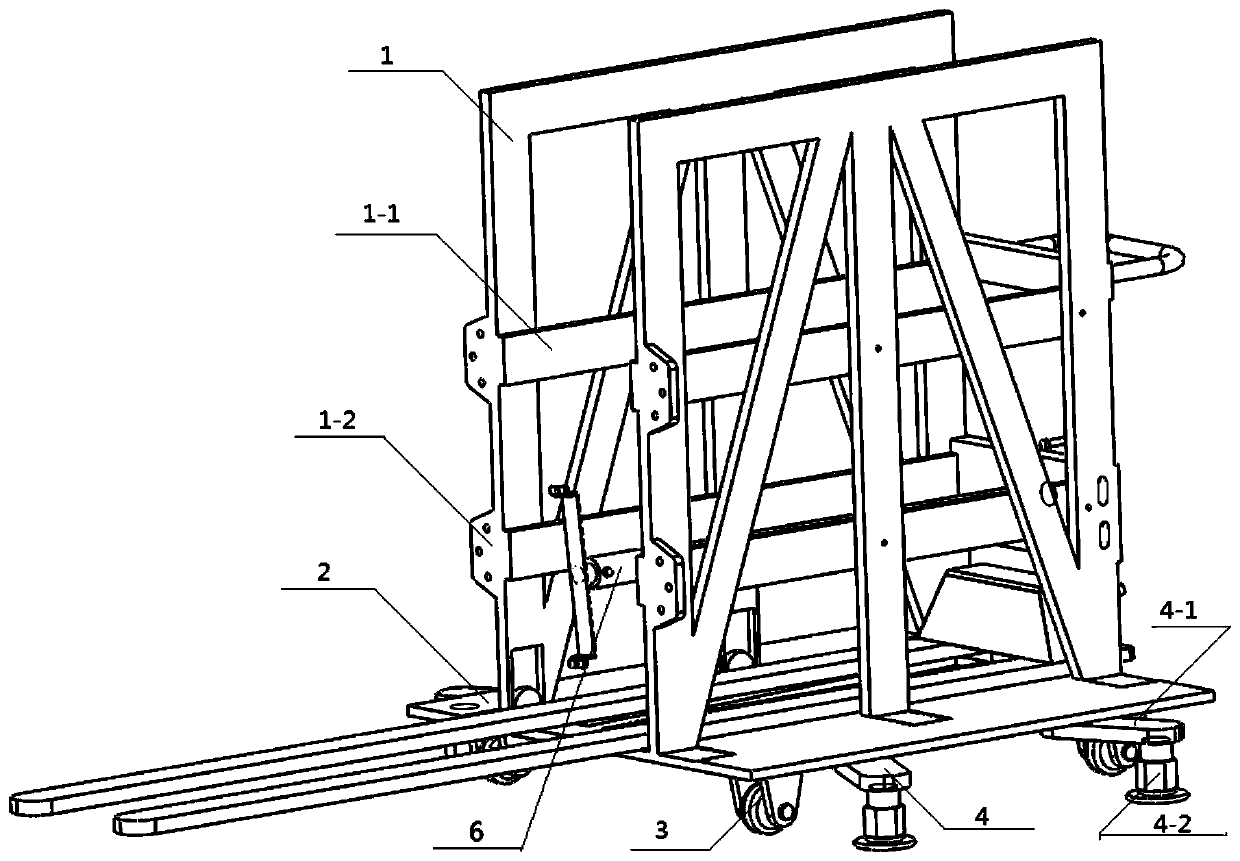

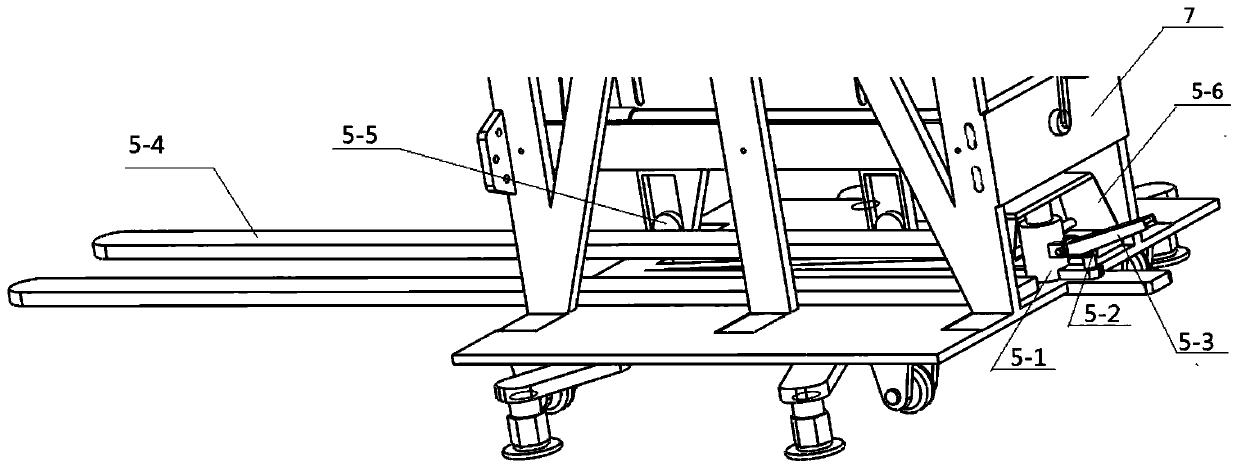

[0038] like Figure 1-Figure 4 As shown, a manual roll changing device for a two-roll rolling mill includes a roll changing frame, a lifting device, and a spiral rotating push-pull device 6. The lifting device is installed on the roll changing frame, and the running track 5-4 of the lifting device A part stretches out the roll-changing vehicle frame, and the threaded rod 6-2 of the said helical rotation push-pull device 6 is connected with the roll-changing vehicle frame by thread.

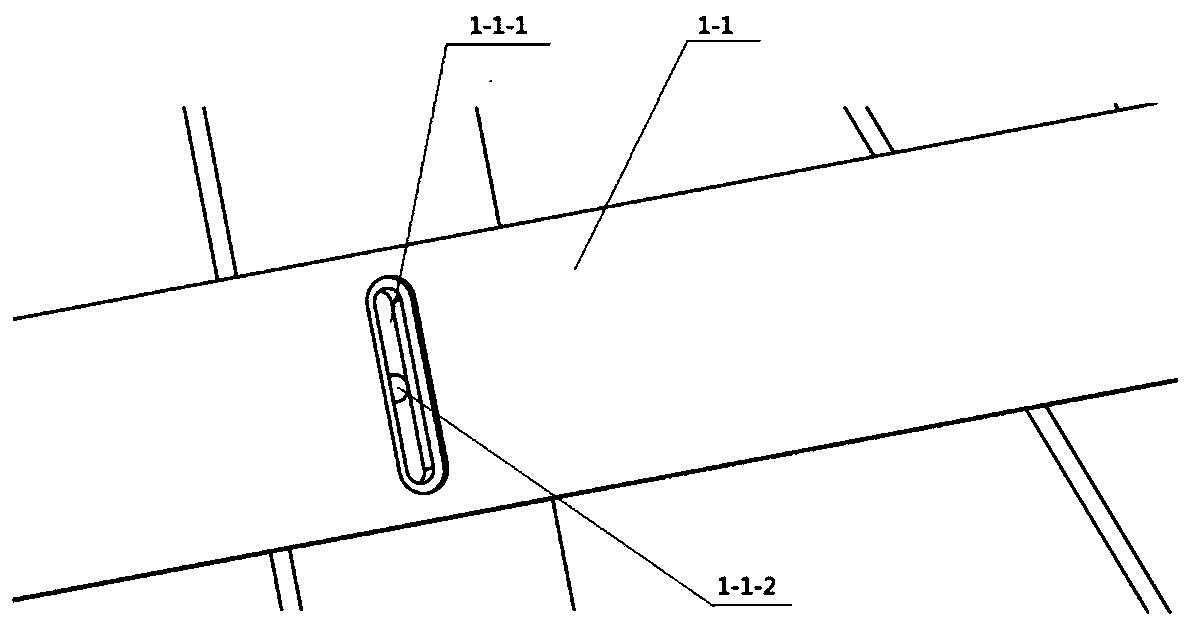

[0039] The roll changing frame includes a vertical support 1, a supporting chassis 2, a wheel 3, a supporting foot 4, and a mounting plate 7. The wheels 3 and the supporting feet 4 are installed on the bottom of the supporting chassis 2, and the vertical support 1 is symmetrical Installed on both sides of the upper end of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com